ASTM B359/B359M-02(2006)

(Specification)Standard Specification for Copper and Copper-Alloy Seamless Condenser and Heat Exchanger Tubes With Integral Fins

Standard Specification for Copper and Copper-Alloy Seamless Condenser and Heat Exchanger Tubes With Integral Fins

ABSTRACT

This specification establishes the requirements for seamless copper and copper alloy tubing on which the external or internal surface, or both, has been modified by a coldforming process to produce an integral enhanced surface for improved heat transfer. The tubes are typically used in surface condensers, evaporators, and heat exchangers. The seamless copper and copper alloy tubing shall have the internal or external surface, or both, modified by a cold forming process to produce an integral enhanced surface for improved heat transfer. The tube, after enhancing, shall be supplied in the annealed (O61) or as-fabricated temper. The enhanced sections of tubes in the as-fabricated temper are in the cold-worked condition produced by the fabricating operation. The unenhanced sections of tubes in the asfabricated temper are in the temper of the tube prior to enhancing, annealed (O61), or light drawn (H55), and suitable for rolling-in operations. Samples of annealed-temper (O61) tubes selected for test shall be subjected to microscopical examination and shall show uniform and complete recrystallation. Grain size and mechanical properties such as tensile strength and yield strength of the alloys shall be determined. Expansion and flattening tests shall be done to the alloys for performance evaluation. Non-destructive tests such as eddy-current test, hydrostatic test, and pneumatic test shall be done as well.

SCOPE

1.1 This specification establishes the requirements for seamless copper and copper alloy tubing on which the external or internal surface, or both, has been modified by a cold-forming process to produce an integral enhanced surface for improved heat transfer.

1.2 Units—The values stated in either in-pound units or SI units are to be regarded separately as the standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems could result in nonconformance with the specification.

1.3 The tubes are typically used in surface condensers, evaporators, and heat exchangers.

1.4 The product shall be produced of the following coppers or copper alloys, as specified in the ordering information.Copper or Copper Alloy UNS No.Type of MetalC10100Oxygen-free electronicC10200Oxygen-free without residual deoxidantsC10300Oxygen-free, extra low phosphorusC10800Oxygen-free, low phosphorusC12000DLP Phosphorized, low residual phosphorus (See Note 1)C12200DHP, Phosphorized, high residual phosphorus (See Note 1)C14200DPA Phosphorized arsenical (See Note 1)C19200Phosphorized, 1 % ironC23000Red BrassC44300Admiralty Metal Types B,C44400C, andC44550DC60800Aluminum BronzeC68700Aluminum Brass Type BC7040095-5 Copper-NickelC7060090-10 Copper-NickelC7062090-10 Copper-Nickel (Modified for Welding)C7100080-20 Copper-Nickel Type AC7150070-30 Copper-NickelC7152070-30 Copper-Nickel (Modified for Welding)C72200Copper-Nickel

Note 1—Designations listed in Classification B 224.

1.5 The following safety hazard caveat pertains only to the test methods described in this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.6 Product produced in accordance with the Supplementary Requirements section for military applications shall be produced only to the inch-pound system of this specification.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

Designation: B359/B359M – 02 (Reapproved 2006)

Standard Specification for

Copper and Copper-Alloy Seamless Condenser and Heat

Exchanger Tubes With Integral Fins

This standard is issued under the fixed designation B359/B359M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

C70620 90-10 Copper-Nickel (Modified for Welding)

C71000 80-20 Copper-Nickel Type A

1.1 This specification establishes the requirements for

C71500 70-30 Copper-Nickel

seamless copper and copper alloy tubing on which the external

C71520 70-30 Copper-Nickel (Modified for Welding)

C72200 Copper-Nickel

or internal surface, or both, has been modified by a cold-

forming process to produce an integral enhanced surface for

NOTE 1—Designations listed in Classification B224.

improved heat transfer.

1.5 The following safety hazard caveat pertains only to the

1.2 Units—The values stated in either in-pound units or SI

testmethodsdescribedinthisspecification. This standard does

units are to be regarded separately as the standard. Within the

not purport to address all of the safety concerns, if any,

text, the SI units are shown in brackets. The values stated in

associated with its use. It is the responsibility of the user of this

each system are not exact equivalents; therefore, each system

standard to establish appropriate safety and health practices

shall be used independently of the other. Combining values

and determine the applicability of regulatory limitations prior

from the two systems could result in nonconformance with the

to use.

specification.

1.6 ProductproducedinaccordancewiththeSupplementary

1.3 The tubes are typically used in surface condensers,

Requirements section for military applications shall be pro-

evaporators, and heat exchangers.

duced only to the inch-pound system of this specification.

1.4 The product shall be produced of the following coppers

or copper alloys, as specified in the ordering information.

2. Referenced Documents

Copper or Copper Alloy Type of Metal

2.1 ASTM Standards:

UNS No.

B153 Test Method for Expansion (Pin Test) of Copper and

C10100 Oxygen-free electronic Copper-Alloy Pipe and Tubing

C10200 Oxygen-free without residual deoxidants

B154 Test Method for Mercurous Nitrate Test for Copper

C10300 Oxygen-free, extra low phosphorus

Alloys

C10800 Oxygen-free, low phosphorus

C12000 DLP Phosphorized, low residual phosphorus B170 Specification for Oxygen-Free Electrolytic Copper—

(See Note 1)

Refinery Shapes

C12200 DHP, Phosphorized, high residual phosphorus

B224 Classification of Coppers

(See Note 1)

C14200 DPA Phosphorized arsenical

B601 Classification for Temper Designations for Copper

(See Note 1)

and Copper Alloys—Wrought and Cast

C19200 Phosphorized, 1 % iron

B846 Terminology for Copper and Copper Alloys

C23000 Red Brass

C44300 Admiralty Metal Types B,

B858 Test Method for Ammonia Vapor Test for Determin-

C44400 C, and

ing Susceptibility to Stress Corrosion Cracking in Copper

C44550 D

Alloys

C60800 Aluminum Bronze

C68700 Aluminum Brass Type B

B900 Practice for Packaging of Copper and Copper Alloy

C70400 95-5 Copper-Nickel

Mill Products for U.S. Government Agencies

C70600 90-10 Copper-Nickel

D4727/D4727M Specification for Corrugated and Solid

Fiberboard Sheet Stock (Container Grade) and Cut Shapes

E3 Guide for Preparation of Metallographic Specimens

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe

and Tube.

Current edition approved Oct. 1, 2006. Published October 2006. Originally

approved in 1960. Last previous edition approved in 2002 as B359/B359M–02. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

DOI: 10.1520/B0359_B0359M-02R06. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

For ASME Boiler and Pressure Vessel Code applications see related Specifi- Standards volume information, refer to the standard’s Document Summary page on

cation SB-359 in Section II of that Code. the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

B359/B359M – 02 (2006)

E8 Test Methods for Tension Testing of Metallic Materials

E8M Test Methods for Tension Testing of Metallic Materi-

als [Metric]

E29 Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications

E53 TestMethodforDeterminationofCopperinUnalloyed

Copper by Gravimetry

E62 Test Methods for Chemical Analysis of Copper and

Copper Alloys (Photometric Methods)

E112 Test Methods for Determining Average Grain Size

E118 Test Methods for Chemical Analysis of Copper-

Chromium Alloys

E243 Practice for Electromagnetic (Eddy-Current) Exami-

nation of Copper and Copper-Alloy Tubes

E255 Practice for Sampling Copper and Copper Alloys for

the Determination of Chemical Composition

E478 TestMethodsforChemicalAnalysisofCopperAlloys

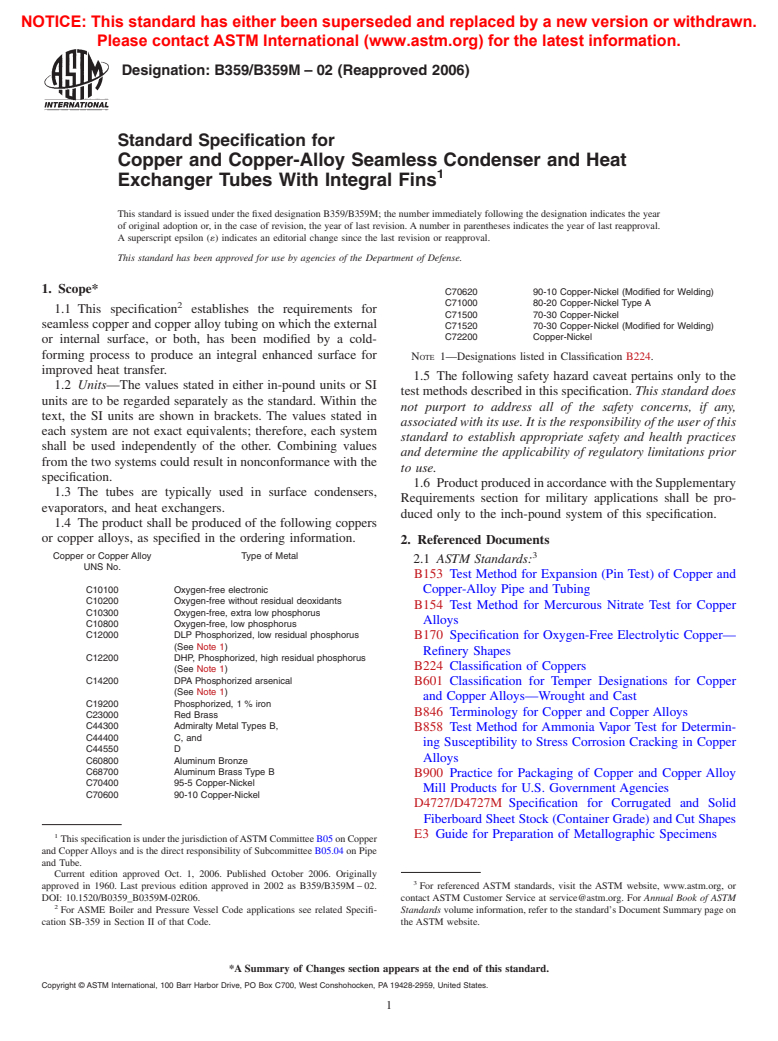

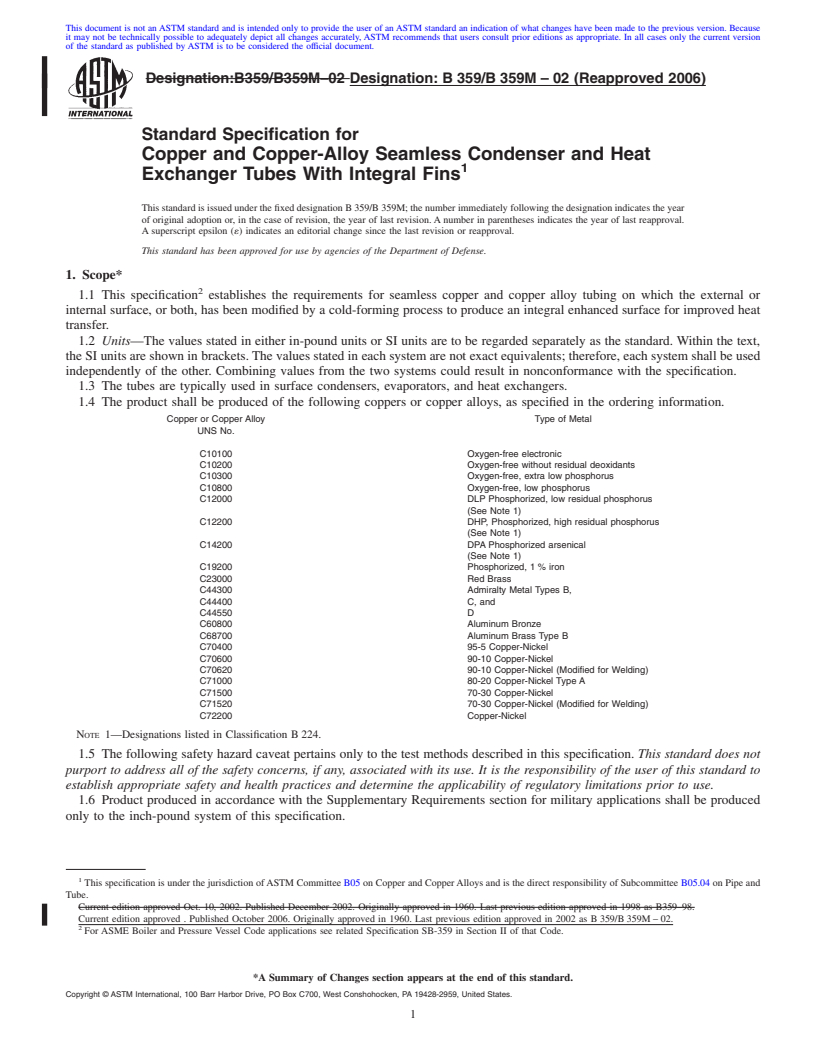

NOTE—The outside diameter over the enhanced section will not

normally exceed the outside diameter of the unenhanced section.

3. General Requirements

FIG. 1 Outside Diameter Enhanced Tube Nomenclature

3.1 Productdescribedbythisspecificationshalltypicallybe

5.1.5 Whether the product is to be subsequently welded for

furnished with unenhanced ends, but may be furnished with

UNS Alloy C72200, UNS Alloys C7062 and C71520 are

enhanced ends or stripped ends from which the O.D. enhance-

welding grades of C70600 and C71500,

ment has been removed by machining.

5.1.6 Quantity, and

3.1.1 The enhanced sections of the tube in the as-fabricated

5.1.7 If product is for the U.S. government.

temper are in the cold-worked condition produced by the

5.2 The following options are available and shall be speci-

enhancing operation.

fied at the time of placing the order, when required:

3.1.2 The unenhanced sections of the tube shall be in the

5.2.1 When heat identification or traceability is required,

annealed or light drawn temper, and shall be suitable for

5.2.2 When tubes are for Boiler and Pressure Vessel code

rolling-in operations.

application, which should then be ordered according toASME

SB 359,

4. Terminology

5.2.3 Flattening test (see 11.2),

4.1 Forthedefinitionsoftermsrelatedtocopperandcopper

5.2.4 Certification (see Section 22), when required,

alloys, refer to Terminology B846.

5.2.5 Mill test report (see Section 23), when required, and

4.2 Definitions:

5.2.6 Stress relief annealing (see 9.4), when required.

4.2.1 flattening, v—this term shall be interpreted as that

5.3 In addition, when material is purchased for agencies of

condition which allows a micrometer caliper, set at three times

the U.S. government, it shall conform to the requirements

the wall thickness, to pass over the tube freely throughout the

specified in the Supplementary Requirements section, when

flattenedpart,exceptatthepointswherethechangeinelement

specified in the contract or purchase order.

of flattening takes place.

4.3 Definitions of Terms Specific to This Standard:

6. Materials and Manufacture

4.3.1 tube condenser, n—see tube, heat exchanger in Ter-

6.1 Materials:

minology B846.

6.1.1 The material of manufacture shall be of such quality

and purity that the finished product shall have the properties

5. Ordering Information

and characteristics prescribed in this specification for the

5.1 Include the following information when placing orders

applicable alloy and temper.

under this specification:

6.2 Manufacture:

5.1.1 ASTM designation and year of issue,

6.2.1 The seamless copper and copper alloy tubing shall

5.1.2 CopperorCopperAlloyUNSNo.designation(see1.4

have the internal or external surface, or both, modified by a

and Section 7),

cold forming process to produce an integral enhanced surface

5.1.3 Temper (see Section 8),

for improved heat transfer.

5.1.4 Dimensions: diameter, wall thickness, length and lo-

6.2.2 The cut ends of the tubes shall be deburred.

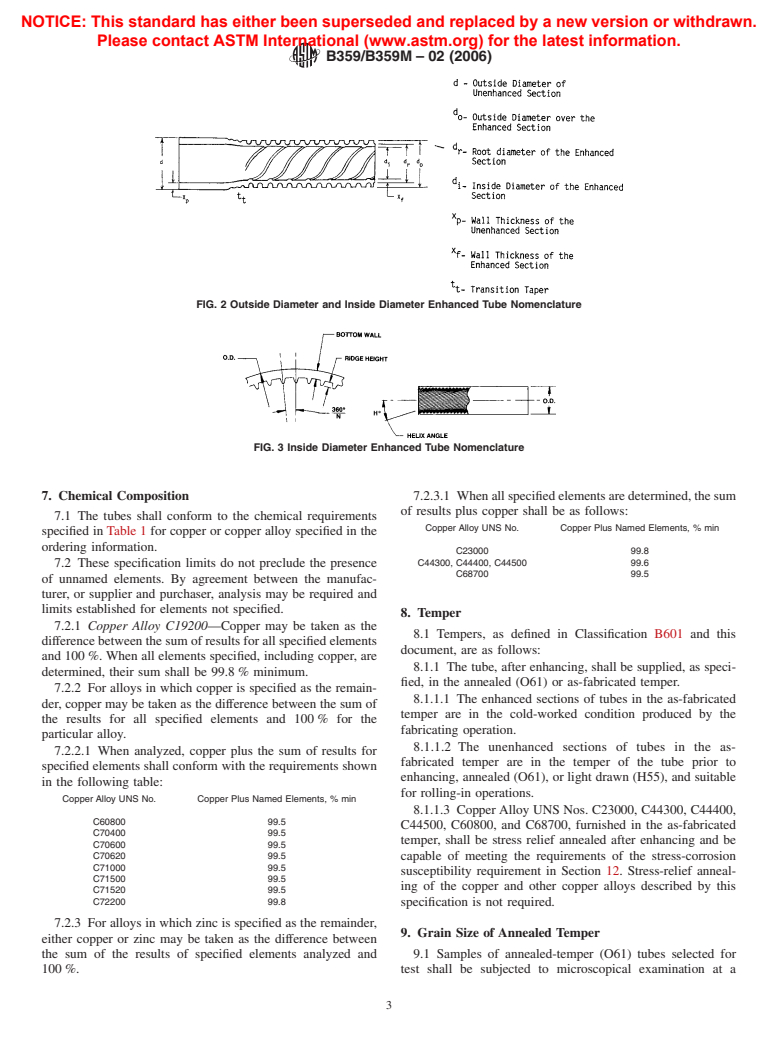

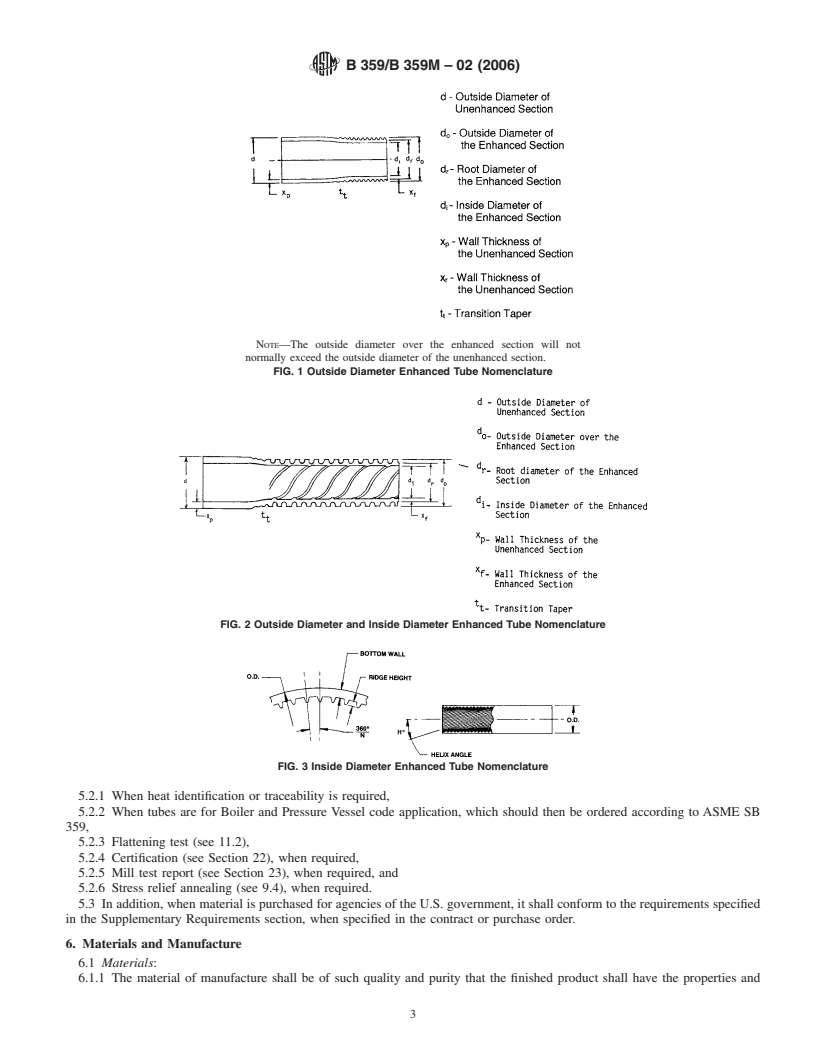

cation of unenhanced surfaces and total tube length. Configu-

6.2.3 Due to the discontinuous nature of the processing of

ration of enhanced surfaces shall be as agreed upon between

castings into wrought products, it is not practical to identify

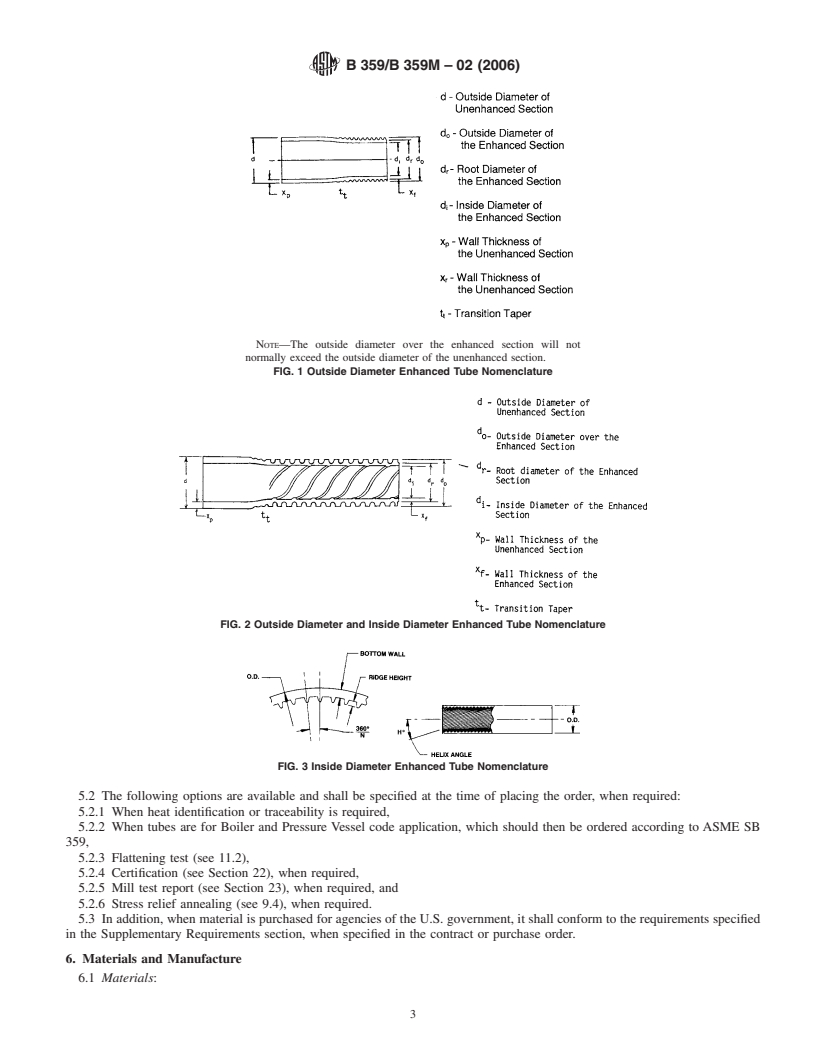

the manufacturer and the purchaser. (See Figs. 1-3).

specific casting analysis with a specific quantity of finished

material.

6.2.4 When heat identification is required, the purchaser

shall specify the details desired in the purchase order or

Withdrawn. The last approved version of this historical standard is referenced

on www.astm.org. contract.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

B359/B359M – 02 (2006)

FIG. 2 Outside Diameter and Inside Diameter Enhanced Tube Nomenclature

FIG. 3 Inside Diameter Enhanced Tube Nomenclature

7. Chemical Composition 7.2.3.1 Whenallspecifiedelementsaredetermined,thesum

of results plus copper shall be as follows:

7.1 The tubes shall conform to the chemical requirements

Copper Alloy UNS No. Copper Plus Named Elements, % min

specified in Table 1 for copper or copper alloy specified in the

ordering information.

C23000 99.8

C44300, C44400, C44500 99.6

7.2 These specification limits do not preclude the presence

C68700 99.5

of unnamed elements. By agreement between the manufac-

turer, or supplier and purchaser, analysis may be required and

limits established for elements not specified.

8. Temper

7.2.1 Copper Alloy C19200—Copper may be taken as the

8.1 Tempers, as defined in Classification B601 and this

differencebetweenthesumofresultsforallspecifiedelements

document, are as follows:

and 100%. When all elements specified, including copper, are

8.1.1 The tube, after enhancing, shall be supplied, as speci-

determined, their sum shall be 99.8% minimum.

fied, in the annealed (O61) or as-fabricated temper.

7.2.2 For alloys in which copper is specified as the remain-

8.1.1.1 The enhanced sections of tubes in the as-fabricated

der, copper may be taken as the difference between the sum of

temper are in the cold-worked condition produced by the

the results for all specified elements and 100% for the

fabricating operation.

particular alloy.

8.1.1.2 The unenhanced sections of tubes in the as-

7.2.2.1 When analyzed, copper plus the sum of results for

fabricated temper are in the temper of the tube prior to

specified elements shall conform with the requirements shown

enhancing, annealed (O61), or light drawn (H55), and suitable

in the following table:

for rolling-in operations.

Copper Alloy UNS No. Copper Plus Named Elements, % min

8.1.1.3 CopperAlloy UNS Nos. C23000, C44300, C44400,

C60800 99.5

C44500, C60800, and C68700, furnished in the as-fabricated

C70400 99.5

temper, shall be stress relief annealed after enhancing and be

C70600 99.5

C70620 99.5 capable of meeting the requirements of the stress-corrosion

C71000 99.5

susceptibility requirement in Section 12. Stress-relief anneal-

C71500 99.5

ing of the copper and other copper alloys described by this

C71520 99.5

C72200 99.8 specification is not required.

7.2.3 For alloys in which zinc is specified as the remainder,

9. Grain Size of Annealed Temper

either copper or zinc may be taken as the difference between

the sum of the results of specified elements analyzed and 9.1 Samples of annealed-temper (O61) tubes selected for

100%. test shall be subjected to microscopical examination at a

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

B359/B359M – 02 (2006)

TABLE 1 Chemical Requirements

Composition, %

Copper

or

Other

Copper

Alumi- Nickel, incl Lead, Named

Copper Tin Iron Zinc Manganese Arsenic Antimony Phosphorus Chromium

Alloy

num Cobalt max Ele-

UNS No.

ments

A,B

C10100 99.99 min 0.0002 max . . . 0.0010 max 0.0005 0.0010 max 0.0001 max 0.00005 max 0.0005 max 0.0004 max 0.0003 max . . . Te 0.0002

C,D,E

C10200 99.95 min . . . . . . . . . . . .

C,F

C10300 99.95 min . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.001–0.005 . . . . . .

C,F

C10800 99.95 min . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.005–0.012 . . . . . .

C

C12000 99.90 min . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.004–0.012 . . . . . .

C

C12200 99.9 min . . . . . . . . . . . . . . . . . . . . . . . . 0.015–0.040 . . .

C

C14200 99.4 min . . . . . . . . . . . . . . . . . . . . . 0.15–0.50 . . . 0.015–0.040 . . . . . .

G

C19200 98.5 min . . . . . . . . . . . . 0.8–1.2 0.20 max . . . . . . . . . 0.01–0.04 . . . . . .

G

C23000 84.0–86.0 . . . . . . . . . 0.05 0.05 max remainder . . . . . . . . . . . . . . . . . .

H

C44300 70.0–73.0 0.9–1.2 . . . . . . 0.07 0.06 max remainder . . . 0.02–0.06 . . . . . . . . . . . .

H

C44400 70.0–73.0 0.9–1.2 . . . . . . 0.07 0.06 max remainder . . . . . . 0.02–0.10 . . . . . . . . .

H

C44500 70.0–73.0 0.9–1.2 . . . . . . 0.07 0.06 max remainder . . . . . . . . . 0.02–0.10 . . . . . .

C,I

C60800 remainder . . . 5.0–6.5 . . . 0.10 0.10 max . . . . . . 0.02–0.35 . . . . . . . . . . . .

C,I

C68700 76.0–79.0 . . . 1.8–2.5 . . . 0.07 0.06 max remainder . . . 0.02–0.06 . . . . . . . . . . . .

C,I

C70400 remainder . . . . . . 4.8–6.2 0.05 1.3–1.7 1.0 max 0.30–0.8 . . . . . . . . . . . . . . .

C,I

C70600 remainder . . . . . . 9.0–11.0 0.05 1.0–1.8 1.0 max 1.0 max . . . . . . . . . . . . . . .

C,I

C70620 86.5 min . . . . . . 9.0–11.0 0.02 1.0–1.8 0.5 max 1.0 max . . . . . . 0.02 max . . . 0.05 C max

0.02 S max

C,I,J

C71000 remainder . . . . . . 19.0–23.0 0.05 1.0 max 1.0 max 1.0 max . . . . . . . . . . . .

C,I

C71500 remainder . . . . . . 29.0–33.0 0.05 0.40–1.0 1.0 max 1.0 max . . . . . . . . . . . . . . .

C71520 65.0 min . . . . . . 29.0–33.0 0.02 0.40–1.0 0.50 max 1.0 max . . . . . . 0.02 max . . . 0.05 C max

0.02 S max

C,G,J

C72200 remainder . . . . . . 15.0–18.0 0.05 0.50–1.0 1.0 max 1.0 max . . . . . . . . . 0.30–0.70 0.03 Si

0.03 Ti

A

This value is exclusive of silver and shall be determined by difference of “impurity total” from 100 %. “Impurity total” is defined as the sum of sulfur, silver, lead, tin,

bismuth, arsenic, antimony, iron

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B359/B359M–02 Designation: B 359/B 359M – 02 (Reapproved 2006)

Standard Specification for

Copper and Copper-Alloy Seamless Condenser and Heat

Exchanger Tubes With Integral Fins

ThisstandardisissuedunderthefixeddesignationB359/B359M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This specification establishes the requirements for seamless copper and copper alloy tubing on which the external or

internal surface, or both, has been modified by a cold-forming process to produce an integral enhanced surface for improved heat

transfer.

1.2 Units—The values stated in either in-pound units or SI units are to be regarded separately as the standard. Within the text,

theSIunitsareshowninbrackets.Thevaluesstatedineachsystemarenotexactequivalents;therefore,eachsystemshallbeused

independently of the other. Combining values from the two systems could result in nonconformance with the specification.

1.3 The tubes are typically used in surface condensers, evaporators, and heat exchangers.

1.4 The product shall be produced of the following coppers or copper alloys, as specified in the ordering information.

Copper or Copper Alloy Type of Metal

UNS No.

C10100 Oxygen-free electronic

C10200 Oxygen-free without residual deoxidants

C10300 Oxygen-free, extra low phosphorus

C10800 Oxygen-free, low phosphorus

C12000 DLP Phosphorized, low residual phosphorus

(See Note 1)

C12200 DHP, Phosphorized, high residual phosphorus

(See Note 1)

C14200 DPA Phosphorized arsenical

(See Note 1)

C19200 Phosphorized, 1 % iron

C23000 Red Brass

C44300 Admiralty Metal Types B,

C44400 C, and

C44550 D

C60800 Aluminum Bronze

C68700 Aluminum Brass Type B

C70400 95-5 Copper-Nickel

C70600 90-10 Copper-Nickel

C70620 90-10 Copper-Nickel (Modified for Welding)

C71000 80-20 Copper-Nickel Type A

C71500 70-30 Copper-Nickel

C71520 70-30 Copper-Nickel (Modified for Welding)

C72200 Copper-Nickel

NOTE 1—Designations listed in Classification B224.

1.5 The following safety hazard caveat pertains only to the test methods described in this specification. This standard does not

purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to

establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.6 Product produced in accordance with the Supplementary Requirements section for military applications shall be produced

only to the inch-pound system of this specification.

This specification is under the jurisdiction ofASTM Committee B05 on Copper and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe and

Tube.

Current edition approved Oct. 10, 2002. Published December 2002. Originally approved in 1960. Last previous edition approved in 1998 as B359–98.

Current edition approved . Published October 2006. Originally approved in 1960. Last previous edition approved in 2002 as B359/B359M–02.

For ASME Boiler and Pressure Vessel Code applications see related Specification SB-359 in Section II of that Code.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 359/B 359M – 02 (2006)

2. Referenced Documents

2.1 ASTM Standards:

B153 Test Method for Expansion (Pin Test) of Copper and Copper-Alloy Pipe and Tubing

B154 Test Method for Mercurous Nitrate Test for Copper and Copper Alloys

B170 Specification for Oxygen-Free Electrolytic Copper—Refinery Shapes

B224 Classification of Coppers

B601 Classification for Temper Designations for Copper and Copper Alloys—Wrought and Cast

B846 Terminology for Copper and Copper Alloys

B858TestMethodforDeterminationofSusceptibilitytoStressCorrosionCrackinginCopperAlloysUsingtheAmmoniaVapor

Test Test Method for Ammonia Vapor Test for Determining Susceptibility to Stress Corrosion Cracking in Copper Alloys

B900Practice for Packaging of Copper and Copper-Alloy Mill-Products for U. S. Government Agencies Practice for

Packaging of Copper and Copper Alloy Mill Products for U.S. Government Agencies

D4727/D4727M Specification for Corrugated and Solid Fiberboard Sheet Stock (Container Grade) and Cut Shapes

E3Test Methods of Preparation of Metallographic Specimens Guide for Preparation of Metallographic Specimens

E8 Test Methods for Tension Testing of Metallic Materials

E8M Test Methods for Tension Testing of Metallic Materials (Metric) [Metric]

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E53 Test Method for Determination of Copper in Unalloyed Copper by Gravimetry

E62 Test Methods for Chemical Analysis of Copper and Copper Alloys (Photometric Methods)

E112 Test Methods for Determining Average Grain Size

E118 Test Methods for Chemical Analysis of Copper-Chromium Alloys

E243 Practice for Electromagnetic (Eddy-Current) Examination of Copper and Copper-Alloy Tubes

E255 Practice for Sampling Copper and Copper Alloys for the Determination of Chemical Composition

E478 Test Methods for Chemical Analysis of Copper Alloys

3. General Requirements

3.1 Product described by this specification shall typically be furnished with unenhanced ends, but may be furnished with

enhanced ends or stripped ends from which the O.D. enhancement has been removed by machining.

3.1.1 Theenhancedsectionsofthetubeintheas-fabricatedtemperareinthecold-workedconditionproducedbytheenhancing

operation.

3.1.2 The unenhanced sections of the tube shall be in the annealed or light drawn temper, and shall be suitable for rolling-in

operations.

4. Terminology

4.1 For the definitions of terms related to copper and copper alloys, refer to Terminology B846.

4.2 Definitions:

4.2.1 flattening, v—thistermshallbeinterpretedasthatconditionwhichallowsamicrometercaliper,setatthreetimesthewall

thickness, to pass over the tube freely throughout the flattened part, except at the points where the change in element of flattening

takes place.

4.3 Definitions of Terms Specific to This Standard:

4.3.1 tube condenser, n—see tube, heat exchanger in Terminology B846.

5. Ordering Information

5.1 Include the following information when placing orders under this specification:

5.1.1 ASTM designation and year of issue,

5.1.2 Copper or Copper Alloy UNS No. designation (see 1.4 and Section 7),

5.1.3 Temper (see Section 8),

5.1.4 Dimensions: diameter, wall thickness, length and location of unenhanced surfaces and total tube length. Configuration of

enhanced surfaces shall be as agreed upon between the manufacturer and the purchaser. (See Figs. 1-3).

5.1.5 Whether the product is to be subsequently welded for UNSAlloy C72200, UNSAlloys C 70620 and C71520 are welding

grades of C70600 and C71500,

5.1.6 Quantity, and

5.1.7 If product is for the U.S. government.

5.2 The following options are available and shall be specified at the time of placing the order, when required:

Annual Book of ASTM Standards, Vol 02.01.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

B 359/B 359M – 02 (2006)

NOTE—The outside diameter over the enhanced section will not

normally exceed the outside diameter of the unenhanced section.

FIG. 1 Outside Diameter Enhanced Tube Nomenclature

FIG. 2 Outside Diameter and Inside Diameter Enhanced Tube Nomenclature

FIG. 3 Inside Diameter Enhanced Tube Nomenclature

5.2.1 When heat identification or traceability is required,

5.2.2 When tubes are for Boiler and Pressure Vessel code application, which should then be ordered according to ASME SB

359,

5.2.3 Flattening test (see 11.2),

5.2.4 Certification (see Section 22), when required,

5.2.5 Mill test report (see Section 23), when required, and

5.2.6 Stress relief annealing (see 9.4), when required.

5.3 In addition, when material is purchased for agencies of the U.S. government, it shall conform to the requirements specified

in the Supplementary Requirements section, when specified in the contract or purchase order.

6. Materials and Manufacture

6.1 Materials:

6.1.1 The material of manufacture shall be of such quality and purity that the finished product shall have the properties and

B 359/B 359M – 02 (2006)

characteristics prescribed in this specification for the applicable alloy and temper.

6.2 Manufacture:

6.2.1 The seamless copper and copper alloy tubing shall have the internal or external surface, or both, modified by a cold

forming process to produce an integral enhanced surface for improved heat transfer.

6.2.2 The cut ends of the tubes shall be deburred.

6.2.3 Due to the discontinuous nature of the processing of castings into wrought products, it is not practical to identify specific

casting analysis with a specific quantity of finished material.

6.2.4 When heat identification is required, the purchaser shall specify the details desired in the purchase order or contract.

7. Chemical Composition

7.1 The tubes shall conform to the chemical requirements specified in Table 1 for copper or copper alloy specified in the

ordering information.

7.2 These specification limits do not preclude the presence of unnamed elements. By agreement between the manufacturer, or

supplier and purchaser, analysis may be required and limits established for elements not specified.

7.2.1 Copper Alloy C19200—Copper may be taken as the difference between the sum of results for all specified elements and

100%. When all elements specified, including copper, are determined, their sum shall be 99.8% minimum.

7.2.2 For alloys in which copper is specified as the remainder, copper may be taken as the difference between the sum of the

results for all specified elements and 100% for the particular alloy.

7.2.2.1 When analyzed, copper plus the sum of results for specified elements shall conform with the requirements shown in the

following table:

TABLE 1 Chemical Requirements

Composition, %

Copper

or

Other

Copper

Alumi- Nickel, incl Lead, Named

Copper Tin Iron Zinc Manganese Arsenic Antimony Phosphorus Chromium

Alloy

num Cobalt max Ele-

UNS No.

ments

A,B

C10100 99.99 min 0.0002 max . . . 0.0010 max 0.0005 0.0010 max 0.0001 max 0.00005 max 0.0005 max 0.0004 max 0.0003 max . . . Te 0.0002

C,D,E

C10200 99.95 min . . . . . . . . . . . .

C,F

C10300 99.95 min . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.001–0.005 . . . . . .

C,F

C10800 99.95 min . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.005–0.012 . . . . . .

C

C12000 99.90 min . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.004–0.012 . . . . . .

C

C12200 99.9 min . . . . . . . . . . . . . . . . . . . . . . . . 0.015–0.040 . . .

C

C14200 99.4 min . . . . . . . . . . . . . . . . . . . . . 0.15–0.50 . . . 0.015–0.040 . . . . . .

G

C19200 98.5 min . . . . . . . . . . . . 0.8–1.2 0.20 max . . . . . . . . . 0.01–0.04 . . . . . .

G

C23000 84.0–86.0 . . . . . . . . . 0.05 0.05 max remainder . . . . . . . . . . . . . . . . . .

H

C44300 70.0–73.0 0.9–1.2 . . . . . . 0.07 0.06 max remainder . . . 0.02–0.06 . . . . . . . . . . . .

H

C44400 70.0–73.0 0.9–1.2 . . . . . . 0.07 0.06 max remainder . . . . . . 0.02–0.10 . . . . . . . . .

H

C44500 70.0–73.0 0.9–1.2 . . . . . . 0.07 0.06 max remainder . . . . . . . . . 0.02–0.10 . . . . . .

C,I

C60800 remainder . . . 5.0–6.5 . . . 0.10 0.10 max . . . . . . 0.02–0.35 . . . . . . . . . . . .

C,I

C68700 76.0–79.0 . . . 1.8–2.5 . . . 0.07 0.06 max remainder . . . 0.02–0.06 . . . . . . . . . . . .

C,I

C70400 remainder . . . . . . 4.8–6.2 0.05 1.3–1.7 1.0 max 0.30–0.8 . . . . . . . . . . . . . . .

C,I

C70600 remainder . . . . . . 9.0–11.0 0.05 1.0–1.8 1.0 max 1.0 max . . . . . . . . . . . . . . .

C,I

C70620 86.5 min . . . . . . 9.0–11.0 0.02 1.0–1.8 0.5 max 1.0 max . . . . . . 0.02 max . . . 0.05 C max

0.02 S max

C,I,J

C71000 remainder . . . . . . 19.0–23.0 0.05 1.0 max 1.0 max 1.0 max . . . . . . . . . . . .

C,I

C71500 remainder . . . . . . 29.0–33.0 0.05 0.40–1.0 1.0 max 1.0 max . . . . . . . . . . . . . . .

C71520 65.0 min . . . . . . 29.0–33.0 0.02 0.40–1.0 0.50 max 1.0 max . . . . . . 0.02 max . . . 0.05 C max

0.02 S max

C,G,J

C72200 remainder . . . . . . 15.0–18.0 0.05 0.50–1.0 1.0 max 1.0 max . . . . . . . . . 0.30–0.70 0.03 Si

0.03 Ti

A

This value is exclusive of silver and shall be determined by difference of “impurity total” from 100 %. “Impurity total” is defined as the sum of sulfur, silver, lead, tin,

bismuth, arsenic, antimony, iron, nickel, zinc, phosphorus, selenium, tellurium, manganese, cadmium, and oxygen present in the sample.

B

Other impurity maximums for C10100 shall be: bismuth and cadmium 0.0001 each, oxygen 0.0005, selenium 0.0003, silver 0.0025, and sulfur 0.0015.

C

Copper (including silver).

D

Oxygen in C10200 shall be 0.0010 max.

E

Cu is determined by the difference in the impurity total and 100 %.

F

Copper plus sum of named elements shall be 99.95 % min.

G

Cu + Sum of Named Elements, 99.8 % min.

H

Cu + Sum of Named Elements, 99.6 % min.

I

Cu + Sum of Named Elements, 99.5 % min.

J

When the product is for subsequent welding applications, and so specified in the contract or purchase order, zinc shall be 0.50 % max, lead 0.02 % max, phosphorus

0.02 % max, sulfur 0.02 % max, and carbon 0.05 % max.

B 359/B 359M – 02 (2006)

Copper Alloy UNS No. Copper Plus Named Elements, % min

C60800 99.5

C70400 99.5

C70600 99.5

C70620 99.5

C71000 99.5

C71500 99.5

C71520 99.5

C72200 99.8

7.2.3 For alloys in which zinc is specified as the remainder, either copper or zinc may be taken as the difference between the

sum of the results of specified elements analyzed and 100%.

7.2.3.1 When all specified elements are determined, the sum of results plus copper shall be as follows:

Copper Alloy UNS No. Copper Plus Named Elements, % min

C23000 99.8

C44300, C44400, C44500 99.6

C68700 99.5

8. Temper

8.1 Tempers, as defined in Classification B601 and this document, are as follows:

8.1.1 The tube, after enhanci

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B359/B359M–02 Designation: B 359/B 359M – 02 (Reapproved 2006)

Standard Specification for

Copper and Copper-Alloy Seamless Condenser and Heat

Exchanger Tubes With Integral Fins

ThisstandardisissuedunderthefixeddesignationB359/B359M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This specification establishes the requirements for seamless copper and copper alloy tubing on which the external or

internal surface, or both, has been modified by a cold-forming process to produce an integral enhanced surface for improved heat

transfer.

1.2 Units—The values stated in either in-pound units or SI units are to be regarded separately as the standard. Within the text,

theSIunitsareshowninbrackets.Thevaluesstatedineachsystemarenotexactequivalents;therefore,eachsystemshallbeused

independently of the other. Combining values from the two systems could result in nonconformance with the specification.

1.3 The tubes are typically used in surface condensers, evaporators, and heat exchangers.

1.4 The product shall be produced of the following coppers or copper alloys, as specified in the ordering information.

Copper or Copper Alloy Type of Metal

UNS No.

C10100 Oxygen-free electronic

C10200 Oxygen-free without residual deoxidants

C10300 Oxygen-free, extra low phosphorus

C10800 Oxygen-free, low phosphorus

C12000 DLP Phosphorized, low residual phosphorus

(See Note 1)

C12200 DHP, Phosphorized, high residual phosphorus

(See Note 1)

C14200 DPA Phosphorized arsenical

(See Note 1)

C19200 Phosphorized, 1 % iron

C23000 Red Brass

C44300 Admiralty Metal Types B,

C44400 C, and

C44550 D

C60800 Aluminum Bronze

C68700 Aluminum Brass Type B

C70400 95-5 Copper-Nickel

C70600 90-10 Copper-Nickel

C70620 90-10 Copper-Nickel (Modified for Welding)

C71000 80-20 Copper-Nickel Type A

C71500 70-30 Copper-Nickel

C71520 70-30 Copper-Nickel (Modified for Welding)

C72200 Copper-Nickel

NOTE 1—Designations listed in Classification B224.

1.5 The following safety hazard caveat pertains only to the test methods described in this specification. This standard does not

purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to

establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.6 Product produced in accordance with the Supplementary Requirements section for military applications shall be produced

only to the inch-pound system of this specification.

This specification is under the jurisdiction ofASTM Committee B05 on Copper and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe and

Tube.

Current edition approved Oct. 10, 2002. Published December 2002. Originally approved in 1960. Last previous edition approved in 1998 as B359–98.

Current edition approved . Published October 2006. Originally approved in 1960. Last previous edition approved in 2002 as B359/B359M–02.

For ASME Boiler and Pressure Vessel Code applications see related Specification SB-359 in Section II of that Code.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 359/B 359M – 02 (2006)

2. Referenced Documents

2.1 ASTM Standards:

B153 Test Method for Expansion (Pin Test) of Copper and Copper-Alloy Pipe and Tubing

B154 Test Method for Mercurous Nitrate Test for Copper and Copper Alloys

B170 Specification for Oxygen-Free Electrolytic Copper—Refinery Shapes

B224 Classification of Coppers

B601 Classification for Temper Designations for Copper and Copper Alloys—Wrought and Cast

B846 Terminology for Copper and Copper Alloys

B858 Test Method for Determination of Susceptibility to Stress Corrosion Cracking in Copper Alloys Using the Ammonia

Vapor Test Test Method for Ammonia Vapor Test for Determining Susceptibility to Stress Corrosion Cracking in Copper

Alloys

B900 Practice for Packaging of Copper and Copper-Alloy Mill-Products for U. S. Government Agencies Practice for

Packaging of Copper and Copper Alloy Mill Products for U.S. Government Agencies

D4727/D4727M Specification for Corrugated and Solid Fiberboard Sheet Stock (Container Grade) and Cut Shapes

E3 Test Methods of Preparation of Metallographic Specimens Guide for Preparation of Metallographic Specimens

E8 Test Methods for Tension Testing of Metallic Materials

E8M Test Methods for Tension Testing of Metallic Materials (Metric) [Metric]

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E53 Test Method for Determination of Copper in Unalloyed Copper by Gravimetry

E62 Test Methods for Chemical Analysis of Copper and Copper Alloys (Photometric Methods)

E112 Test Methods for Determining Average Grain Size

E118 Test Methods for Chemical Analysis of Copper-Chromium Alloys

E243 Practice for Electromagnetic (Eddy-Current) Examination of Copper and Copper-Alloy Tubes

E255 Practice for Sampling Copper and Copper Alloys for the Determination of Chemical Composition

E478 Test Methods for Chemical Analysis of Copper Alloys

3. General Requirements

3.1 Product described by this specification shall typically be furnished with unenhanced ends, but may be furnished with

enhanced ends or stripped ends from which the O.D. enhancement has been removed by machining.

3.1.1 Theenhancedsectionsofthetubeintheas-fabricatedtemperareinthecold-workedconditionproducedbytheenhancing

operation.

3.1.2 The unenhanced sections of the tube shall be in the annealed or light drawn temper, and shall be suitable for rolling-in

operations.

4. Terminology

4.1 For the definitions of terms related to copper and copper alloys, refer to Terminology B846.

4.2 Definitions:

4.2.1 flattening, v—thistermshallbeinterpretedasthatconditionwhichallowsamicrometercaliper,setatthreetimesthewall

thickness, to pass over the tube freely throughout the flattened part, except at the points where the change in element of flattening

takes place.

4.3 Definitions of Terms Specific to This Standard:

4.3.1 tube condenser, n—see tube, heat exchanger in Terminology B846.

5. Ordering Information

5.1 Include the following information when placing orders under this specification:

5.1.1 ASTM designation and year of issue,

5.1.2 Copper or Copper Alloy UNS No. designation (see 1.4 and Section 7),

5.1.3 Temper (see Section 8),

5.1.4 Dimensions: diameter, wall thickness, length and location of unenhanced surfaces and total tube length. Configuration of

enhanced surfaces shall be as agreed upon between the manufacturer and the purchaser. (See Figs. 1-3).

5.1.5 Whether the product is to be subsequently welded for UNSAlloy C72200, UNSAlloys C 70620 and C71520 are welding

grades of C70600 and C71500,

5.1.6 Quantity, and

5.1.7 If product is for the U.S. government.

Annual Book of ASTM Standards, Vol 02.01.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

B 359/B 359M – 02 (2006)

NOTE—The outside diameter over the enhanced section will not

normally exceed the outside diameter of the unenhanced section.

FIG. 1 Outside Diameter Enhanced Tube Nomenclature

FIG. 2 Outside Diameter and Inside Diameter Enhanced Tube Nomenclature

FIG. 3 Inside Diameter Enhanced Tube Nomenclature

5.2 The following options are available and shall be specified at the time of placing the order, when required:

5.2.1 When heat identification or traceability is required,

5.2.2 When tubes are for Boiler and Pressure Vessel code application, which should then be ordered according to ASME SB

359,

5.2.3 Flattening test (see 11.2),

5.2.4 Certification (see Section 22), when required,

5.2.5 Mill test report (see Section 23), when required, and

5.2.6 Stress relief annealing (see 9.4), when required.

5.3 In addition, when material is purchased for agencies of the U.S. government, it shall conform to the requirements specified

in the Supplementary Requirements section, when specified in the contract or purchase order.

6. Materials and Manufacture

6.1 Materials:

B 359/B 359M – 02 (2006)

6.1.1 The material of manufacture shall be of such quality and purity that the finished product shall have the properties and

characteristics prescribed in this specification for the applicable alloy and temper.

6.2 Manufacture:

6.2.1 The seamless copper and copper alloy tubing shall have the internal or external surface, or both, modified by a cold

forming process to produce an integral enhanced surface for improved heat transfer.

6.2.2 The cut ends of the tubes shall be deburred.

6.2.3 Due to the discontinuous nature of the processing of castings into wrought products, it is not practical to identify specific

casting analysis with a specific quantity of finished material.

6.2.4 When heat identification is required, the purchaser shall specify the details desired in the purchase order or contract.

7. Chemical Composition

7.1 The tubes shall conform to the chemical requirements specified in Table 1 for copper or copper alloy specified in the

ordering information.

7.2 These specification limits do not preclude the presence of unnamed elements. By agreement between the manufacturer, or

supplier and purchaser, analysis may be required and limits established for elements not specified.

7.2.1 Copper Alloy C19200—Copper may be taken as the difference between the sum of results for all specified elements and

100%. When all elements specified, including copper, are determined, their sum shall be 99.8% minimum.

7.2.2 For alloys in which copper is specified as the remainder, copper may be taken as the difference between the sum of the

results for all specified elements and 100% for the particular alloy.

7.2.2.1 When analyzed, copper plus the sum of results for specified elements shall conform with the requirements shown in the

following table:

TABLE 1 Chemical Requirements

Composition, %

Copper

or

Other

Copper

Alumi- Nickel, incl Lead, Named

Copper Tin Iron Zinc Manganese Arsenic Antimony Phosphorus Chromium

Alloy

num Cobalt max Ele-

UNS No.

ments

A,B

C10100 99.99 min 0.0002 max . . . 0.0010 max 0.0005 0.0010 max 0.0001 max 0.00005 max 0.0005 max 0.0004 max 0.0003 max . . . Te 0.0002

C,D,E

C10200 99.95 min . . . . . . . . . . . .

C,F

C10300 99.95 min . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.001–0.005 . . . . . .

C,F

C10800 99.95 min . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.005–0.012 . . . . . .

C

C12000 99.90 min . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.004–0.012 . . . . . .

C

C12200 99.9 min . . . . . . . . . . . . . . . . . . . . . . . . 0.015–0.040 . . .

C

C14200 99.4 min . . . . . . . . . . . . . . . . . . . . . 0.15–0.50 . . . 0.015–0.040 . . . . . .

G

C19200 98.5 min . . . . . . . . . . . . 0.8–1.2 0.20 max . . . . . . . . . 0.01–0.04 . . . . . .

G

C23000 84.0–86.0 . . . . . . . . . 0.05 0.05 max remainder . . . . . . . . . . . . . . . . . .

H

C44300 70.0–73.0 0.9–1.2 . . . . . . 0.07 0.06 max remainder . . . 0.02–0.06 . . . . . . . . . . . .

H

C44400 70.0–73.0 0.9–1.2 . . . . . . 0.07 0.06 max remainder . . . . . . 0.02–0.10 . . . . . . . . .

H

C44500 70.0–73.0 0.9–1.2 . . . . . . 0.07 0.06 max remainder . . . . . . . . . 0.02–0.10 . . . . . .

C,I

C60800 remainder . . . 5.0–6.5 . . . 0.10 0.10 max . . . . . . 0.02–0.35 . . . . . . . . . . . .

C,I

C68700 76.0–79.0 . . . 1.8–2.5 . . . 0.07 0.06 max remainder . . . 0.02–0.06 . . . . . . . . . . . .

C,I

C70400 remainder . . . . . . 4.8–6.2 0.05 1.3–1.7 1.0 max 0.30–0.8 . . . . . . . . . . . . . . .

C,I

C70600 remainder . . . . . . 9.0–11.0 0.05 1.0–1.8 1.0 max 1.0 max . . . . . . . . . . . . . . .

C,I

C70620 86.5 min . . . . . . 9.0–11.0 0.02 1.0–1.8 0.5 max 1.0 max . . . . . . 0.02 max . . . 0.05 C max

0.02 S max

C,I,J

C71000 remainder . . . . . . 19.0–23.0 0.05 1.0 max 1.0 max 1.0 max . . . . . . . . . . . .

C,I

C71500 remainder . . . . . . 29.0–33.0 0.05 0.40–1.0 1.0 max 1.0 max . . . . . . . . . . . . . . .

C71520 65.0 min . . . . . . 29.0–33.0 0.02 0.40–1.0 0.50 max 1.0 max . . . . . . 0.02 max . . . 0.05 C max

0.02 S max

C,G,J

C72200 remainder . . . . . . 15.0–18.0 0.05 0.50–1.0 1.0 max 1.0 max . . . . . . . . . 0.30–0.70 0.03 Si

0.03 Ti

A

This value is exclusive of silver and shall be determined by difference of “impurity total” from 100 %. “Impurity total” is defined as the sum of sulfur, silver, lead, tin,

bismuth, arsenic, antimony, iron, nickel, zinc, phosphorus, selenium, tellurium, manganese, cadmium, and oxygen present in the sample.

B

Other impurity maximums for C10100 shall be: bismuth and cadmium 0.0001 each, oxygen 0.0005, selenium 0.0003, silver 0.0025, and sulfur 0.0015.

C

Copper (including silver).

D

Oxygen in C10200 shall be 0.0010 max.

E

Cu is determined by the difference in the impurity total and 100 %.

F

Copper plus sum of named elements shall be 99.95 % min.

G

Cu + Sum of Named Elements, 99.8 % min.

H

Cu + Sum of Named Elements, 99.6 % min.

I

Cu + Sum of Named Elements, 99.5 % min.

J

When the product is for subsequent welding applications, and so specified in the contract or purchase order, zinc shall be 0.50 % max, lead 0.02 % max, phosphorus

0.02 % max, sulfur 0.02 % max, and carbon 0.05 % max.

B 359/B 359M – 02 (2006)

Copper Alloy UNS No. Copper Plus Named Elements, % min

C60800 99.5

C70400 99.5

C70600 99.5

C70620 99.5

C71000 99.5

C71500 99.5

C71520 99.5

C72200 99.8

7.2.3 For alloys in which zinc is specified as the remainder, either copper or zinc may be taken as the difference between the

sum of the results of specified elements analyzed and 100%.

7.2.3.1 When all specified elements are determined, the sum of results plus copper shall be as follows:

Copper Alloy UNS No. Copper Plus Named Elements, % min

C23000 99.8

C44300, C44400, C44500 99.6

C68700 99.5

8. Temper

8.1 Tempers, as defined in Classification B601 and this document, are as follows:

8.1.1 The

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.