ASTM B1003-16(2023)

(Specification)Standard Specification for Seamless Copper Tube for Linesets

Standard Specification for Seamless Copper Tube for Linesets

ABSTRACT

This specification applies to seamless copper tube for linesets intended for use in air conditioning units. The pressure rating established is 700 psi at 250 °F and incorporates fully annealed and brazed copper tubing.

SCOPE

1.1 This specification establishes the requirements for seamless copper tube for linesets intended for use in air conditioning units. The pressure rating established is 700 psi at 250 °F and incorporates fully annealed and brazed copper tubing.

1.2 The tube shall be produced from the following copper alloy:

Copper UNS No.

Previously Used

Designation

Description

C12200

DHP

Phosphorus deoxidized,

high residual phosphorus

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 The following safety hazard caveat pertains only to the test methods described in this specification:

1.4.1 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B1003 − 16 (Reapproved 2023)

Standard Specification for

Seamless Copper Tube for Linesets

This standard is issued under the fixed designation B1003; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope B577 Test Methods for Detection of Cuprous Oxide (Hydro-

gen Embrittlement Susceptibility) in Copper

1.1 This specification establishes the requirements for seam-

B601 Classification for Temper Designations for Copper and

less copper tube for linesets intended for use in air conditioning

Copper Alloys—Wrought and Cast

units. The pressure rating established is 700 psi at 250 °F and

B846 Terminology for Copper and Copper Alloys

incorporates fully annealed and brazed copper tubing.

B900 Practice for Packaging of Copper and Copper Alloy

1.2 The tube shall be produced from the following copper

Mill Products for U.S. Government Agencies

alloy:

E3 Guide for Preparation of Metallographic Specimens

Previously Used

E8/E8M Test Methods for Tension Testing of Metallic Ma-

Copper UNS No. Description

Designation

terials

E29 Practice for Using Significant Digits in Test Data to

Phosphorus deoxidized,

C12200 DHP

high residual phosphorus

Determine Conformance with Specifications

1.3 The values stated in inch-pound units are to be regarded E53 Test Method for Determination of Copper in Unalloyed

Copper by Gravimetry (Withdrawn 2022)

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only E62 Test Methods for Chemical Analysis of Copper and

Copper Alloys (Photometric Methods) (Withdrawn 2010)

and are not considered standard.

E112 Test Methods for Determining Average Grain Size

1.4 The following safety hazard caveat pertains only to the

E243 Practice for Electromagnetic (Eddy Current) Examina-

test methods described in this specification:

tion of Copper and Copper-Alloy Tubes

1.4.1 This standard does not purport to address all of the

E255 Practice for Sampling Copper and Copper Alloys for

safety concerns, if any, associated with its use. It is the

the Determination of Chemical Composition

responsibility of the user of this standard to establish appro-

2.2 ASME Standard:

priate safety and health practices and determine the applica-

B16.22 Wrought Copper and Copper Alloy Solder-Joint

bility of regulatory limitations prior to use.

Pressure Fittings

1.5 This international standard was developed in accor-

3. Terminology

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

3.1 For definitions of terms related to copper and copper

Development of International Standards, Guides and Recom-

alloys, refer to Terminology B846.

mendations issued by the World Trade Organization Technical

3.2 Definitions of Terms Specific to This Standard:

Barriers to Trade (TBT) Committee.

3.2.1 insulating material, n—any material used to impart

insulating properties to the copper coil provided the material

2. Referenced Documents

does not cause corrosion of the copper.

2.1 ASTM Standards:

3.2.2 lineset, n—a set of two (2) coils consisting of a suction

B153 Test Method for Expansion (Pin Test) of Copper and

line and a liquid line.

Copper-Alloy Pipe and Tubing

3.2.2.1 liquid line, n—a specified length of coiled tube with

or without a sleeved insulating material.

This specification is under the jurisdiction of ASTM Committee B05 on Copper

and Copper Alloys and is the direct responsibility of Subcommittee B05.04 on Pipe 3.2.2.2 suction line, n—a specified length of coiled tube

and Tube.

with a sleeved insulating material.

Current edition approved Oct. 15, 2023. Published October 2023. Originally

approved in 2016. Last previous edition approved in 2016 as B1003 – 16. DOI:

10.1520/B1003-16R23. The last approved version of this historical standard is referenced on

For referenced ASTM standards, visit the ASTM website, www.astm.org, or www.astm.org.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from American Society of Mechanical Engineers (ASME), ASME

Standards volume information, refer to the standard’s Document Summary page on International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

the ASTM website. www.asme.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B1003 − 16 (2023)

3.2.3 R-value, n—the quantity determined by the tempera- and manufacturer. The insulating material shall be chemically

ture difference, at steady state, between two defined surfaces of compatible with copper and shall not cause corrosion of the

a material or construction that induces a unit heat flow rate copper.

through a unit area.

5.2 Manufacture:

5.2.1 The tube shall be manufactured by such hot- or

4. Ordering Information

cold-working processes as to produce a uniform wrought

4.1 Include the following specified choices when placing

structure in the finished product.

orders for product under this specification, as applicable:

5.2.2 The tube shall be cold drawn to the finished diameter

4.1.1 ASTM designation and year of issue (for example,

and wall thickness and subsequently bright annealed. The tube

B1003 – 16),

can be in the form of a level-wound coil, bunch coil, straight

4.1.2 Copper UNS No. (or other internationally recognized

length, or other form depending upon the manufacturer’s

copper alloy designation) – not necessary unless a specific

processing capabilities.

copper is desired,

5.2.3 After annealing, the insulating material shall be ap-

4.1.3 Dimensions; diameter,

plied to the suction line and the liquid line as specified.

4.1.4 Standard Size (Table 1),

Re-coiling of the insulated tube may be performed upon the

4.1.5 Length,

specified lengths, as required.

4.1.6 Quantity (total pieces of each size and type),

5.2.4 Bends, fittings, and refrigerant charges may be applied

4.1.7 Insulation Type (Section 5),

to the material after application of the insulating material.

4.1.8 Insulation Thickness or R-Value, or both (Section 5),

4.1.9 End Bend/Fittings/Refrigerant Charge (Section 5), and

6. Chemical Composition

4.1.10 If product is purchased for agencies of the U.S.

6.1 The material shall conform to the chemical composition

Government (Section 11).

requirements in Table 2.

4.2 The following options are available but may not be 6.1.1 These composition limits do not preclude the presence

included unless specified at the time of order placement:

of other elements. By agreement between the supplier and

4.2.1 Expansion test (10.1), purchaser, limits may be established and analysis required for

4.2.2 Cleanness test (Sections 10.2 and 17.2.5),

unnamed elements.

4.2.3 Microscopical Examination for Hydrogen Embrittle-

7. Temper

ment, Procedure B (10.3.2),

4.2.4 Certification (Section 21),

7.1 Tubes produced under this specification shall be fur-

4.2.5 Test report (Section 22),

nished in O60 (soft annealed) as defined in Classification

4.2.6 Tensile test (9.1),

B601.

4.2.7 If the specification number must be shown in the

package marking (23.1.1), and 8. Grain Size

4.2.8 Tubing with pressure ratings other than 700 psi.

8.1 Tubes shall have a recrystallized grain size of 0.030 mm

minimum and 0.070 mm maximum when determined in accor-

5. Materials and Manufacture

dance with Test Methods E112.

5.1 Materials:

5.1.1 The material of manufacture shall be billets, bars, or

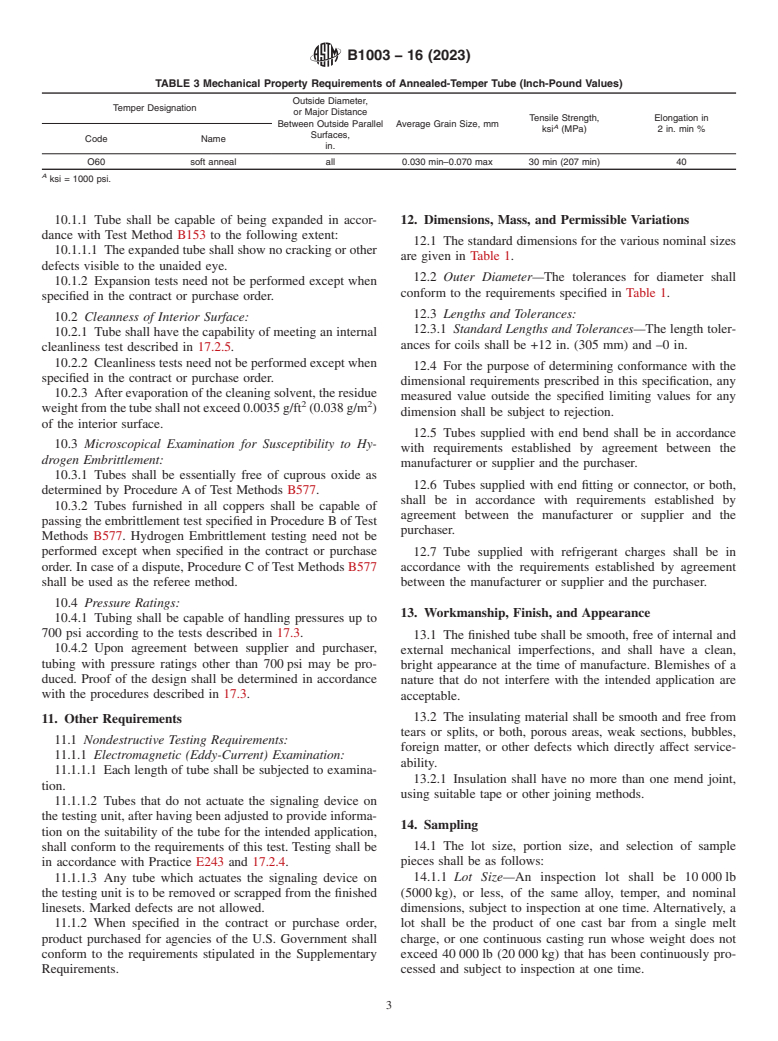

9. Mechanical Property Requirements

tube and shall be of such soundness as to be suitable for

9.1 Tensile Requirements—The tube shall conform to the

processing into the tubular products described.

tensile requirements prescribed in Table 3.

5.1.2 The material of insulation shall be agreed upon

9.1.1 Tensile requirements shall be made prior to re-coiling.

between the purchaser and manufacturer. The thickness or

9.1.2 Tensile tests need not be performed except when

R-Values, or both, shall also be agreed upon by the purchaser

specified in the contract or purchase order.

9.1.3 Acceptance or rejection based upon mechanical prop-

TABLE 1 Standard Dimensions and Tolerances in Diameter

erties shall depend only on tensile strength.

for Coils

9.2 Straightening—It shall not be prohibited to use light

Tolerances

straightening for tube.

Outside Diameter, A

Average, Outside

Standard Size, in.

in. (mm)

Diameter, Plus and

Minus, in. (mm)

10. Performance Requirements

⁄4 0.250 (6.35) 0.002 (0.051)

10.1 Expansion Test:

⁄16 0.312 (7.92) 0.002 (0.051)

⁄8 0.375 (9.53) 0.002 (0.051)

⁄2 0.500 (12.7) 0.002 (0.051)

⁄8 0.625 (15.9) 0.002 (0.051)

TABLE 2 Chemical Composition—Weight %

⁄4 0.750 (19.1) 0.0025 (0.064)

Element Copper UNS No. C12200

⁄8 0.875 (22.2) 0.003 (0.076)

A

1 ⁄8 1.125 (28.6) 0.0035 (0.089) Copper, min 99.9

Phosphorus 0.015–0.040

A

The average outside diameter of a tube is the average of the maximum and

A

minimum outside diameters as determined at any one cross section of the tube. Copper + silver.

B1003 − 16 (2023)

TABLE 3 Mechanical Property Requirements of Annealed-Temper Tube (Inch-Pound Values)

Outside Diameter,

Temper Designation

or Major Distance

Tensile Strength, Elongation in

Between Outside Parallel Average Grain Size, mm

A

ksi (MPa) 2 in. min %

Surfaces,

Code Name

in.

O60 soft anneal all 0.030 min–0.070 max 30 min (207 min) 40

A

ksi = 1000 psi.

10.1.1 Tube shall be capable of being expanded in accor- 12. Dimensions, Mass, and Permissible Variations

dance with Test Method B153 to the following extent:

12.1 The standard dimensions for the various nominal sizes

10.1.1.1 The expanded tube shall show no cracking or other

are given in Table 1.

defects visible to the unaided eye.

12.2 Outer Diameter—The tolerances for diameter shall

10.1.2 Expansion tests need not be performed except when

conform to the requirements specified in Table 1.

specified in the contract or purchase order.

12.3 Lengths and Tolerances:

10.2 Cleanness of Interior Surface:

12.3.1 Standard Lengths and Tolerances—The length toler-

10.2.1 Tube shall have the capability of meeting an internal

ances for coils shall be +12 in. (305 mm) and –0 in.

cleanliness test described in 17.2.5.

10.2.2 Cleanliness tests need not be performed except when

12.4 For the purpose of determining conformance with the

specified in the contract or purchase order.

dimensional requirements prescribed in this specification, any

10.2.3 After evaporation of the cleaning solvent, the residue

measured value outside the specified limiting values for any

2 2

weight from the tube shall not exceed 0.0035 g/ft (0.038 g/m )

dimension shall be subject to rejection.

of the interior surface.

12.5 Tubes supplied with end bend shall be in accordance

10.3 Microscopical Examination for Susceptibility to Hy-

with requirements established by agreement between the

drogen Embrittlement:

manufacturer or supplier and the purchaser.

10.3.1 Tubes shall be essentially free of cuprous oxide as

12.6 Tubes supplied with end fitting or connector, or both,

determined by Procedure A of Test Methods B577.

shall be in accordance with requirements established by

10.3.2 Tubes furnished in all coppers shall be capable of

agreement between the manufacturer or supplier and the

passing the embrittlement test specified in Procedure B of Test

purchaser.

Methods B577. Hydrogen Embrittlement testing need not be

performed except when specified in the contract or purchase 12.7 Tube supplied with refrigerant charges shall be in

order. In case of a dispute, Procedure C of Test Methods B577 accordance with the requirements established by agreement

shall be used as the referee method. between the manufacturer or supplier and the purchaser.

10.4 Pressure Ratings:

13. Workmanship, Finish, and Appearance

10.4.1 Tubing shall be capable of handling pressures up to

700 psi according to the tests described in 17.3.

13.1 The finished tube shall be smooth, free of internal and

10.4.2 Upon agreement between supplier and purchaser,

external mechanical imperfections, and shall have a clean,

tubing with pressure ratings other than 700 psi may be pro-

bright appearance at the time of manufacture. Blemishes of a

duced. Proof of the design shall be determined in accordance

nature that do not interfere with the intended application are

with the procedures described in 17.3.

acceptable.

13.2 The insulating material shall be smooth and free from

11. Other Requirements

tears or splits, or both, porous areas, weak sections, bubbles,

11.1 Nondestructive Testing Requirements:

foreign matter, or other defects which directly affect service-

11.1.1 Electromagnetic (Eddy-Current) Examination:

ability.

11.1.1.1 Each length of tube shall be subjected to examina-

13.2.1 Insulation shall have no more than one mend joint,

tion.

using suitable tape or other joining methods.

11.1.1.2 Tubes that do not actuate the signaling device on

the testing unit, after having been adjusted to provide informa-

14. Sampling

tion on the suitability of the tube for the intended application,

shall conform to the requirements of this test. Testing shall be 14.1 The lot size, portion size, and selection of sample

pieces shall be as follows:

in accordance with Practice E243 and 17.2.4.

11.1.1.3 Any tube which actuates the signaling device on 14.1.1 Lot Size—An inspection lot shall be 10 000 lb

the testing unit is to be removed or scrapped from the finished (5000 kg), or less, of the same alloy, temper, and nominal

linesets. Marked defects are not allowed. dimensions, subject to inspection at one time. Alternatively, a

11.1.2 When specified in the contract or purchase order, lot shall be the product of one cast bar from a single melt

product purchased for agencies of the U.S. Government shall charge, or one continuous casting run whose weight does not

conform to the requirements stipulated in the Supplementary exceed 40 000 lb (20 000 kg) that has been continuously pro-

Requirements. cessed and subject to inspection at one time.

B1003 − 16 (2023)

14.1.2 Portion Size—Sample pieces shall be selected to be 16.2.2 The surface of the specimen shall approximate a

representative of the lot as shown in Table 4. radial longitudinal section of the tube.

14.2 Chemical Composition: 16.3 Tensile—Tensile test specimens shall be of the full

14.2.1 The sample shall be taken in approximately equal section of the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.