ASTM D3606-10

(Test Method)Standard Test Method for Determination of Benzene and Toluene in Finished Motor and Aviation Gasoline by Gas Chromatography

Standard Test Method for Determination of Benzene and Toluene in Finished Motor and Aviation Gasoline by Gas Chromatography

SIGNIFICANCE AND USE

Benzene is classed as a toxic material. A knowledge of the concentration of this compound can be an aid in evaluating the possible health hazard to persons handling and using the gasoline. This test method is not intended to evaluate such hazards.

SCOPE

1.1 This test method covers the determination of benzene and toluene in finished motor and aviation gasolines by gas chromatography.

1.2 Benzene can be determined between the levels of 0.1 and 5 volume % and toluene can be determined between the levels of 2 and 20 volume %.

1.3 The precision for this test method was determined using conventional gasoline as well as gasolines containing oxygenates (ethers such as methyl tert-butyl ether, ethyl tert-butyl ether and tert-amyl methyl ether).

1.4 Methanol may cause interference. Appendix X1 provides an option for modifying the test method for analyzing samples containing ethanol.

1.5 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3606 − 10

StandardTest Method for

Determination of Benzene and Toluene in Finished Motor

1

and Aviation Gasoline by Gas Chromatography

This standard is issued under the fixed designation D3606; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* E1293Specification for Glass Measuring Pipets

1.1 This test method covers the determination of benzene

3. Summary of Test Method

and toluene in finished motor and aviation gasolines by gas

3.1 An internal standard, methyl ethyl ketone (MEK), is

chromatography.

added to the sample which is then introduced into a gas

1.2 Benzene can be determined between the levels of 0.1

chromatograph equipped with two columns connected in

and 5 volume% and toluene can be determined between the

series.Thesamplepassesfirstthroughacolumnpackedwitha

levels of 2 and 20 volume%.

nonpolar phase such as dimethylpolysiloxane (8.1.1) which

1.3 Theprecisionforthistestmethodwasdeterminedusing

separates the components according to boiling point. After

conventional gasoline as well as gasolines containing oxygen-

octane has eluted, the flow through the nonpolar column is

ates (ethers such as methyl tert-butyl ether, ethyl tert-butyl

reversed,flushingoutthecomponentsheavierthanoctane.The

ether and tert-amyl methyl ether).

octane and lighter components then pass through a column

packed with a highly polar phase such as 1, 2, 3-tris(2-

1.4 Methanol may cause interference. Appendix X1 pro-

cyanoethoxy)propane(8.1.2)whichseparatesthearomaticand

vides an option for modifying the test method for analyzing

nonaromatic compounds. The eluted components are detected

samples containing ethanol.

by a thermal conductivity detector. The detector response is

1.5 The values stated in SI units are to be regarded as

recorded,thepeakareasaremeasured,andtheconcentrationof

standard. The values given in parentheses are for information

each component is calculated with reference to the internal

only.

standard.

1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 4. Significance and Use

responsibility of the user of this standard to establish appro-

4.1 Benzene is classed as a toxic material.Aknowledge of

priate safety and health practices and determine the applica-

theconcentrationofthiscompoundcanbeanaidinevaluating

bility of regulatory limitations prior to use.

the possible health hazard to persons handling and using the

gasoline. This test method is not intended to evaluate such

2. Referenced Documents

hazards.

2

2.1 ASTM Standards:

D4057Practice for Manual Sampling of Petroleum and

5. Apparatus

Petroleum Products

5.1 Chromatograph—Any chromatographic instrument that

E694Specification for Laboratory Glass Volumetric Appa-

has a backflush system and thermal conductivity detector, and

ratus

that can be operated at the conditions given in Table 1, can be

E969Specification for Glass Volumetric (Transfer) Pipets

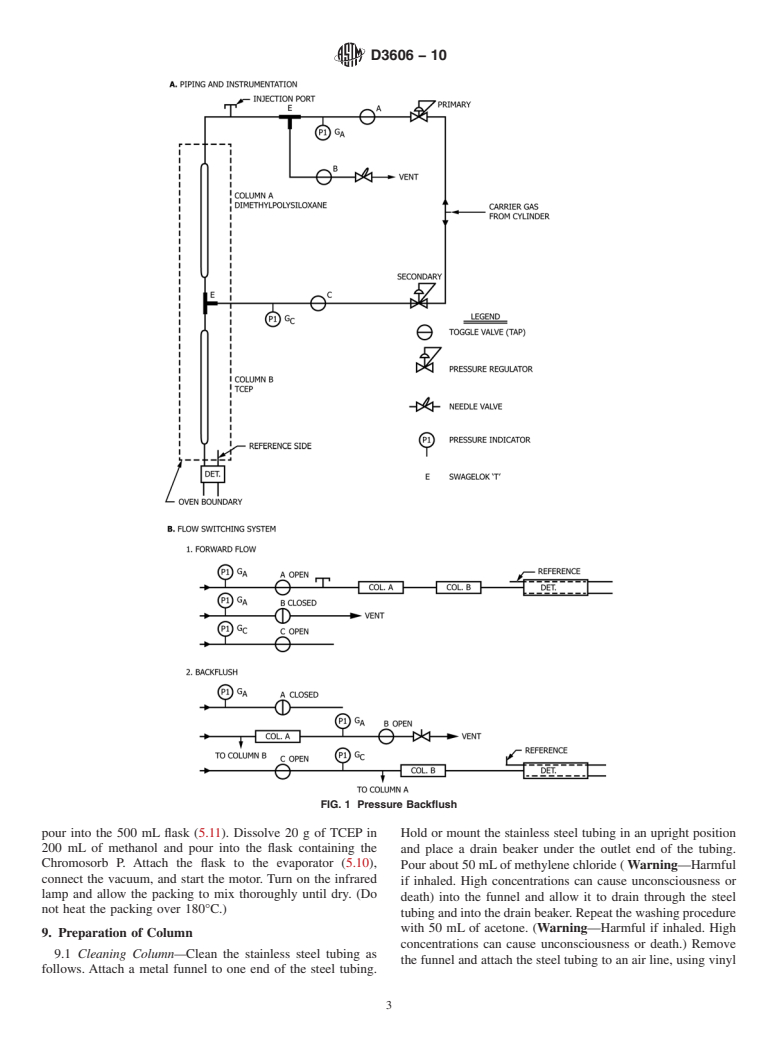

employed. Two backflush systems are shown. Fig. 1 is a

E1044Specification for Glass Serological Pipets (General

pressure system and Fig. 2 is a switching valve system. Either

Purpose and Kahn)

one can be used.

1

This test method is under the jurisdiction of ASTM Committee D02 on

5.2 Columns:

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

1

5.2.1 Column A—One 0.8 m (2.5 ft) by 3.2 mm ( ⁄8 in.)

Subcommittee D02.04.0L on Gas Chromatography Methods.

outsidediameterstainlesssteelcolumnpackedwith10mass%

Current edition approved Oct. 1, 2010. Published November 2010. Originally

dimethylpolysiloxane (for example, OV-101) on Chromosorb

approved in 1977. Last previous edition approved in 2007 as D3606–07. DOI:

10.1520/D3606-10.

W, 60 to 80 mesh.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.2.2 Column B—One 4.6 m (15 ft) by 3.2 mm outside

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

diameter stainless steel column packed with 20 mass % TCEP

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. on Chromosorb P, 80 to 100 mesh.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3606 − 10

TABLE 1 Instrument Parameters

6. Materials

Detector thermal conductivity

6.1 Carrier Gas—Helium, 99.99 % pure. (Warning—

Columns: two, stainless steel

Compressed gas under high pressure.)

Length, m (A) 0.8; (B) 4.6

Outside diameter, mm 3.

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D3606–07 Designation: D3606 – 10

Standard Test Method for

Determination of Benzene and Toluene in Finished Motor

1

and Aviation Gasoline by Gas Chromatography

This standard is issued under the fixed designation D3606; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the determination of benzene and toluene in finished motor and aviation gasolines by gas

chromatography.

1.2 Benzene can be determined between the levels of 0.1 and 5 volume % and toluene can be determined between the levels

of 2 and 20 volume %.

1.3 The precision for this test method was determined using conventional gasoline as well as gasolines containing oxygenates

(ethers such as methyl tert-butyl ether, ethyl tert-butyl ether and tert-amyl methyl ether).

1.4 Methanol may cause interference. Appendix X1 provides an option for modifying the test method for analyzing samples

containing ethanol.

1.5 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

E694 Specification for Laboratory Glass Volumetric Apparatus

E969 Specification for Glass Volumetric (Transfer) Pipets

E1044 Specification for Glass Serological Pipets (General Purpose and Kahn)

E1293 Specification for Glass Measuring Pipets

3. Summary of Test Method

3.1 An internal standard, methyl ethyl ketone (MEK), is added to the sample which is then introduced into a gas chromatograph

equipped with two columns connected in series. The sample passes first through a column packed with a nonpolar phase such as

dimethylpolysiloxane (8.1.1) which separates the components according to boiling point.After octane has eluted, the flow through

the nonpolar column is reversed, flushing out the components heavier than octane. The octane and lighter components then pass

through a column packed with a highly polar phase such as 1, 2, 3-tris(2-cyanoethoxy) propane (8.1.2) which separates the

aromatic and nonaromatic compounds. The eluted components are detected by a thermal conductivity detector. The detector

response is recorded, the peak areas are measured, and the concentration of each component is calculated with reference to the

internal standard.

4. Significance and Use

4.1 Benzene is classed as a toxic material.Aknowledge of the concentration of this compound can be an aid in evaluating the

possible health hazard to persons handling and using the gasoline. This test method is not intended to evaluate such hazards.

1

This test method is under the jurisdiction ofASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.04.0L

on Gas Chromatography Methods.

´1

Current edition approved Nov. 1, 2007. Published January 2008. Originally approved in 1977. Last previous edition approved in 2006 as D3606–06 . DOI:

10.1520/D3606-07.

Current edition approved Oct. 1, 2010. Published November 2010. Originally approved in 1977. Last previous edition approved in 2007 as D3606–07. DOI:

10.1520/D3606-10.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3606 – 10

5. Apparatus

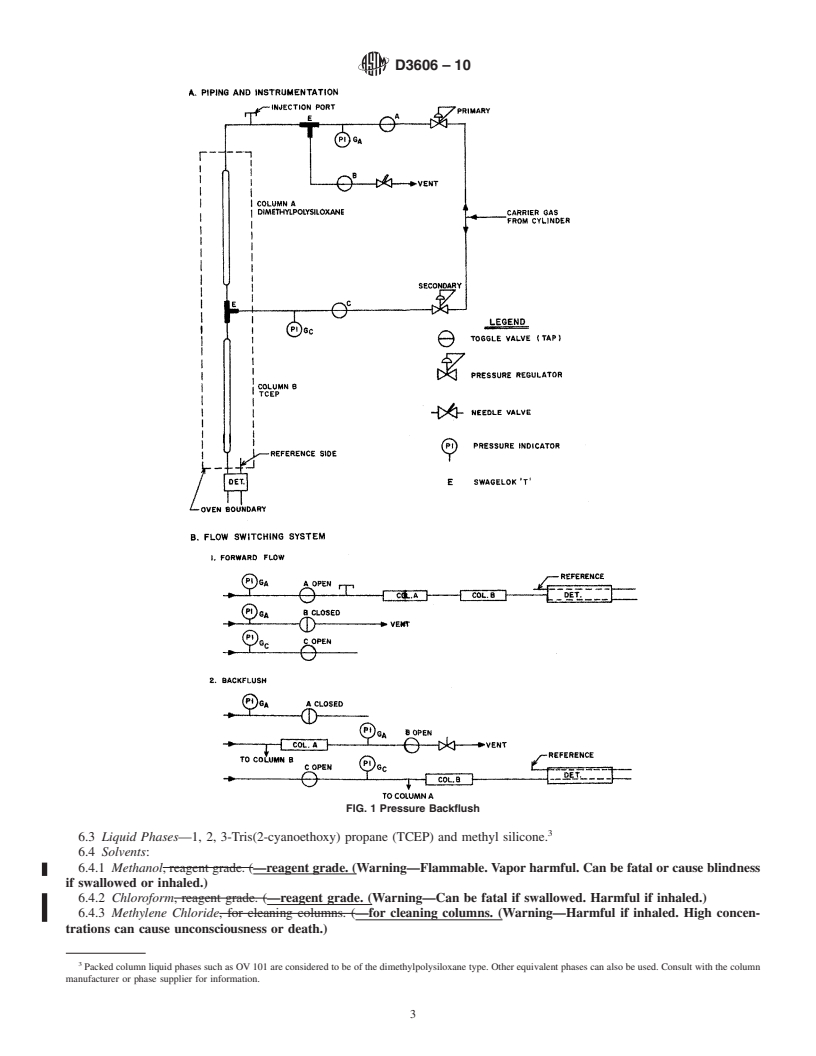

5.1 Chromatograph—Any chromatographic instrument that has a backflush system and thermal conductivity detector, and that

can be operated at the conditions given inTable 1, can be employed.Two backflush systems are shown. Fig. 1 is a pressure system

and Fig. 2 is a switching valve system. Either one can be used.

5.2 Columns:

1

5.2.1 Column A—One 0.8-m (2.5-ft) 0.8 m (2.5 ft) by 3.2-mm 3.2

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.