ASTM D6081-98(2009)

(Practice)Standard Practice for Aquatic Toxicity Testing of Lubricants: Sample Preparation and Results Interpretation

Standard Practice for Aquatic Toxicity Testing of Lubricants: Sample Preparation and Results Interpretation

SIGNIFICANCE AND USE

This practice gives techniques to use in the preparation of lubricants or lubricant components for acute or chronic aquatic toxicity tests. Most lubricants and lubricant components are difficult to evaluate in toxicity tests because they are mixtures of chemical compounds with varying and usually poor solubility in water. Lubricants or lubricant component mixtures should not be added directly to aquatic systems for toxicity testing because the details of the addition procedure will have a large effect on the results of the toxicity test. Use of the techniques described in this practice will produce well-characterized test systems that will lead to tests with meaningful and reproducible results.

The toxicity of mixtures of poorly soluble components cannot be expressed in the usual terms of lethal concentration (or the similar terms of effect concentration or inhibition concentration) because the mixtures may not be completely soluble at treat levels that lead to toxic effects. The test material preparation techniques given in this practice lead to test results expressed in terms of loading rate, which is a practical and meaningful concept for expressing the toxicity of this type of material.

One of the recommended methods of material preparation for lubricants or their components is the mechanical dispersion technique. This particular technique generates turbulence, and thus, it should not be used for poorly swimming organisms.

SCOPE

1.1 This practice covers procedures to be used in the preparation of lubricants or their components for toxicity testing in aquatic systems and in the interpretation of the results of such tests.

1.2 This practice is suitable for use on fully-formulated lubricants or their components that are not completely soluble at the intended test treat rates. It is also suitable for use with additives, if the additive is tested after being blended into a carrier fluid at the approximate concentration as in the intended fully formulated lubricant. The carrier fluid shall meet the above solubility criterion, be known to be minimally toxic in the toxicity test in which the material will be tested, and be known to have a chemical composition similar to the rest of the intended fully formulated lubricant.

1.3 Samples prepared in accordance with this practice may be used in acute or chronic aquatic toxicity tests conducted in fresh water or salt water with fish, large invertebrates, or algae. This practice does not address preparation of samples for plant toxicity testing other than algae.

1.4 Standard acute and chronic aquatic toxicity procedures are more appropriate for lubricants with compositions that are completely soluble at the intended test treat rates (1, 2, 3, 4, 5).

1.5 This practice is intended for use with lubricants or lubricant components of any volatility.

1.6 This practice does not address any questions regarding the effects of any lubricant or lubricant component on human health.

1.7 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6081 − 98(Reapproved 2009)

Standard Practice for

Aquatic Toxicity Testing of Lubricants: Sample Preparation

and Results Interpretation

This standard is issued under the fixed designation D6081; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.8 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This practice covers procedures to be used in the

responsibility of the user of this standard to establish appro-

preparation of lubricants or their components for toxicity

priate safety and health practices and determine the applica-

testinginaquaticsystemsandintheinterpretationoftheresults

bility of regulatory limitations prior to use.

of such tests.

2. Referenced Documents

1.2 This practice is suitable for use on fully-formulated

lubricants or their components that are not completely soluble

2.1 ASTM Standards:

at the intended test treat rates. It is also suitable for use with

D1129 Terminology Relating to Water

additives, if the additive is tested after being blended into a

D1193 Specification for Reagent Water

carrierfluidattheapproximateconcentrationasintheintended

E729 Guide for Conducting Acute Toxicity Tests on Test

fully formulated lubricant. The carrier fluid shall meet the

Materials with Fishes, Macroinvertebrates, and Amphib-

above solubility criterion, be known to be minimally toxic in

ians

the toxicity test in which the material will be tested, and be

E943 Terminology Relating to Biological Effects and Envi-

knowntohaveachemicalcompositionsimilartotherestofthe

ronmental Fate

intended fully formulated lubricant.

3. Terminology

1.3 Samples prepared in accordance with this practice may

3.1 Definitions:

be used in acute or chronic aquatic toxicity tests conducted in

3.1.1 acute toxicity test, n—a comparative toxicity test in

fresh water or salt water with fish, large invertebrates, or algae.

which a representative subpopulation of organisms is exposed

This practice does not address preparation of samples for plant

to different treat rates of a test material and is observed for a

toxicity testing other than algae.

short period, usually not constituting a substantial portion of

1.4 Standard acute and chronic aquatic toxicity procedures

their life span.

are more appropriate for lubricants with compositions that are

3.1.2 chronic toxicity test, n—a comparative toxicity test in

completelysolubleattheintendedtesttreatrates (1, 2, 3, 4, 5).

which a representative subpopulation of organisms is exposed

1.5 This practice is intended for use with lubricants or

to different treat rates of a test material and is observed for a

lubricant components of any volatility.

periodoftimethatconstitutesamajorportionoftheirlifespan.

1.6 This practice does not address any questions regarding

3.1.3 ecotoxicity, n—propensityofatestmaterialtoproduce

the effects of any lubricant or lubricant component on human

adverse behavioral, biochemical, or physiological effects in

health.

non-human organisms or populations.

1.7 The values stated in SI units are to be regarded as 3.1.4 effect load XX (ELXX), n—astatisticallyorgraphically

estimated loading rate of test material that is expected to cause

standard. No other units of measurement are included in this

standard. one or more specified effects in XX % of a representative

subpopulation of organisms under specified conditions.

3.1.4.1 Discussion—This terminology should be used in-

stead of the standard ECXX when the test material is not

This practice is under the jurisdiction ofASTM Committee D02 on Petroleum

completely soluble at the test treat rates.

Products and Lubricants and is the direct responsibility of Subcommittee D02.12 on

Environmental Standards for Lubricants.

Current edition approved Oct. 1, 2009. Published November 2009. Originally

approved in 1998. Last previous edition approved in 2004 as D6081–98(2004). For referenced ASTM standards, visit the ASTM website, www.astm.org, or

DOI: 10.1520/D6081-98R09. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

The boldface numbers in parentheses refer to the list of references at the end of Standards volume information, refer to the standard’s Document Summary page on

this standard. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6081 − 98 (2009)

3.1.5 inhibition load XX (ILXX), n—a statistically or graphi- 4. Summary of Practice

cally estimated loading rate of test material that is expected to

4.1 Thispracticediscussesvarioustechniquesfortheprepa-

cause a XX % inhibition of a biological process (such as

ration of test material for toxicity testing of poorly water-

growth or reproduction) that has an analog as opposed to a

soluble lubricants or their components under acute or chronic

digital measure.

exposure conditions with fish, large invertebrates, or algae.

3.1.5.1 Discussion—An example of a digital measure would

bealive/dead.Thisterminology(ILXX)shouldbeusedinstead

5. Significance and Use

of the standard ICXX when the test material is not completely

5.1 This practice gives techniques to use in the preparation

soluble at the test treat rates.

of lubricants or lubricant components for acute or chronic

3.1.6 lethal load XX (LLXX), n—a statistically or graphi-

aquatic toxicity tests. Most lubricants and lubricant compo-

cally estimated loading rate of test material that is expected to

nents are difficult to evaluate in toxicity tests because they are

be lethal to XX % of a representative subpopulation of organ-

mixtures of chemical compounds with varying and usually

isms under specified conditions.

poor solubility in water. Lubricants or lubricant component

3.1.6.1 Discussion—This terminology should be used in-

mixtures should not be added directly to aquatic systems for

stead of the standard LCXX when the material is not com-

toxicity testing because the details of the addition procedure

pletely soluble at the test treat rates.

will have a large effect on the results of the toxicity test. Use

3.1.7 loading rate, n—the ratio of test material to aqueous

of the techniques described in this practice will produce

medium used in the preparation of WAF, WSF, or mechanical

well-characterized test systems that will lead to tests with

dispersion and in the interpretation of the results of a toxicity

meaningful and reproducible results.

study with a poorly water-soluble lubricant or lubricant com-

5.2 The toxicity of mixtures of poorly soluble components

ponent.

cannot be expressed in the usual terms of lethal concentration

3.1.8 mechanical dispersion, n—a low energy aqueous me-

(or the similar terms of effect concentration or inhibition

dium produced by continuous stirring of the test solution and

concentration) because the mixtures may not be completely

containing both dissolved and undissolved components of the

solubleattreatlevelsthatleadtotoxiceffects.Thetestmaterial

test material.

preparation techniques given in this practice lead to test results

3.1.9 toxicity, n—thepropensityofatestmaterialtoproduce expressed in terms of loading rate, which is a practical and

adverse behavioral, biochemical, or physiological effects in a

meaningful concept for expressing the toxicity of this type of

living organism. material.

3.1.10 water accommodated fraction (WAF), n—the pre-

5.3 One of the recommended methods of material prepara-

dominantly aqueous portion of a mixture of water and a

tion for lubricants or their components is the mechanical

material poorly soluble in water, which separates in a specified

dispersion technique. This particular technique generates

period of time after the mixture has undergone a specified

turbulence, and thus, it should not be used for poorly swim-

degree of mixing and which includes water, dissolved

ming organisms.

components, and dispersed droplets of the poorly soluble

material.

6. Preparation of Exposure Matrix

3.1.10.1 Discussion—The composition of the WAF depends

6.1 Experimental design considerations for fish and inver-

on the ratio of poorly soluble material to water in the original

tebrateswilldeterminethetestspecies,numberofloadingrates

mixture as well as on the details of the mixing procedure.

tested, and number of organisms per treatment. Experimental

3.1.11 water soluble fraction (WSF), n—the filtrate or cen-

design considerations for algae will determine the test species,

trifugate of the water accommodated fraction, which includes

number of loading rates tested, and appropriate initial biomass

allpartsoftheWAF,exceptthedisperseddropletsofthepoorly

per treatment.

soluble material.

6.2 An acute or chronic test intended to allow calculation of

3.2 Definitions of Terms Specific to This Standard:

an LLXX, ILXX, or ELXX will typically consist of a dilution

3.2.1 dilution water, n—the water used in the aquatic test

water or test medium control and a series of at least five

under consideration, which may contain organic or inorganic

loading rates of test material.

components depending on the test requirements.

6.3 Test material should be added directly to the dilution

3.2.2 exposure matrix, n—the WAF, WSF, or mechanical

water to prepare the exposure matrix. Use of a solvent or

dispersion to which test organisms are exposed for toxicity

chemical dispersant is not recommended because these may

testing.

alter the nature of the exposure to the test material and lead to

3.2.3 test systems, n—the test organisms plus the exposure

non-representative ecotoxicity relationships.

matrix and the test chambers themselves.

6.4 Preparation of Water-Accommodated Fraction (WAF):

3.2.4 water, n—a reagent that is defined by Type II of

6.4.1 Components dissolved in the water phase or entrained

Specification D1193.

as stable droplets in the water phase are evaluated in a WAF

3.3 Definitions of additional terms used in this practice can study (6). Individual WAFs must be generated for each test

be found in Terminologies D1129 and E943. exposure loading. Serial dilutions of a single WAF are not

D6081 − 98 (2009)

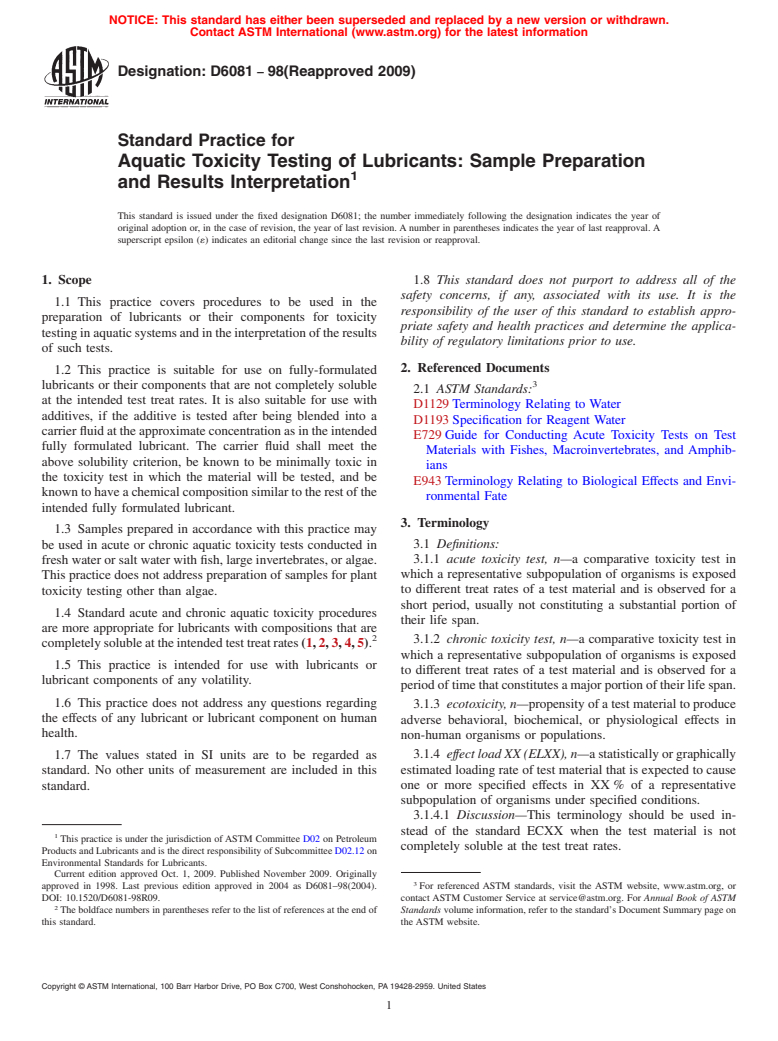

appropriate due to differential solubility of constituents at low these dense fluids, a propeller-driven system that stirs the test

exposure loads (6, 7). A schematic of the WAF setup is solution from the top of the vessel may be preferable to a stir

provided in Fig. 1.

plate that stirs the test solution from the bottom of the vessel.

6.4.2 Vessels for WAF preparation should be of suitable

In all cases, care should be taken to ensure that non-dispersed

shape and size for the experimental design. The vessels should

test material is not collected with the WAF.

be of sufficient size to maintain the vortex intensity and

6.4.3 Vessels for WAF preparation should be filled with the

optimize surface area contact between the test material and the

appropriate volume of dilution water, and be prepared for

water. Height to diameter ratio for the WAF preparation at

stirring as described in 6.4.2. Test material should be slowly

initiation should be between 1:1 and 2:1, and solutions should

added to the top of each vessel after dilution water addition.

notexceed20Lperindividualpreparation.Iflargervolumesof

The vessel should be capped with foil or a non-reactive

test solution are required for experimental design, separate

covering and stirred at the test temperature. For test tempera-

WAF preparations of the same test load may be combined.

tures different than room temperature, the WAF preparation

Aspiratorbottlesorothervesselswithoutletportsatthebottom

vessels may need to be housed in water baths or incubators to

are preferable for WAF collection, if the test material is less

maintainthedesiredtemperature.Ifphotodecompositionofthe

dense than water. If a glass siphon is used to remove the WAF,

test material is likely, the stirring phase should be conducted in

it should be in place prior to the introduction of the test

the dark. Preparation vessels should be inspected occasionally

material. WAF solutions from test materials that are denser

than water should be decanted from the top of the vessel. For to ensure an appropriate vortex is maintained.

FIG. 1 Water Accommodated Fraction (WAF) Schematic

D6081 − 98 (2009)

6.4.4 The amount of test material added to each vessel

should be determined by the desired nominal exposure load.

Nominal exposure loads may be based on direct weight of

material added per volume solution (wt/vol) or calculated on

the basis of test material density and added on a vol/vol basis.

6.4.5 The stir plates should be run at a sufficient speed to

ensure a vortex depth of 10 to 35 % of the test solution height

in the WAF preparation vessel. The vortex in all WAF

preparationvesselsforanyoneexperimentshouldbethesame.

Exercise care to ensure that test material is not pulled down to

the bottom of the vessel, and that the rate of stirring is not so

vigorous as to promote emulsification.

6.4.6 The duration of WAF preparation may depend on the

results of an optional equilibrium/stability study (see 6.7). In

the absence of this study, a standard 20 to 24-h mixing and 1

to 4-h settling period should be used (6, 8).

6.4.7 Upon completion of the WAF mixing and settling

period, the aqueous solution should be drained or decanted

from below the surface of each preparation vessel. The first 5

to 10 mL of solution decanted from the vessel should be

discarded. The remaining solution should be used undiluted in

the exposure vessels.

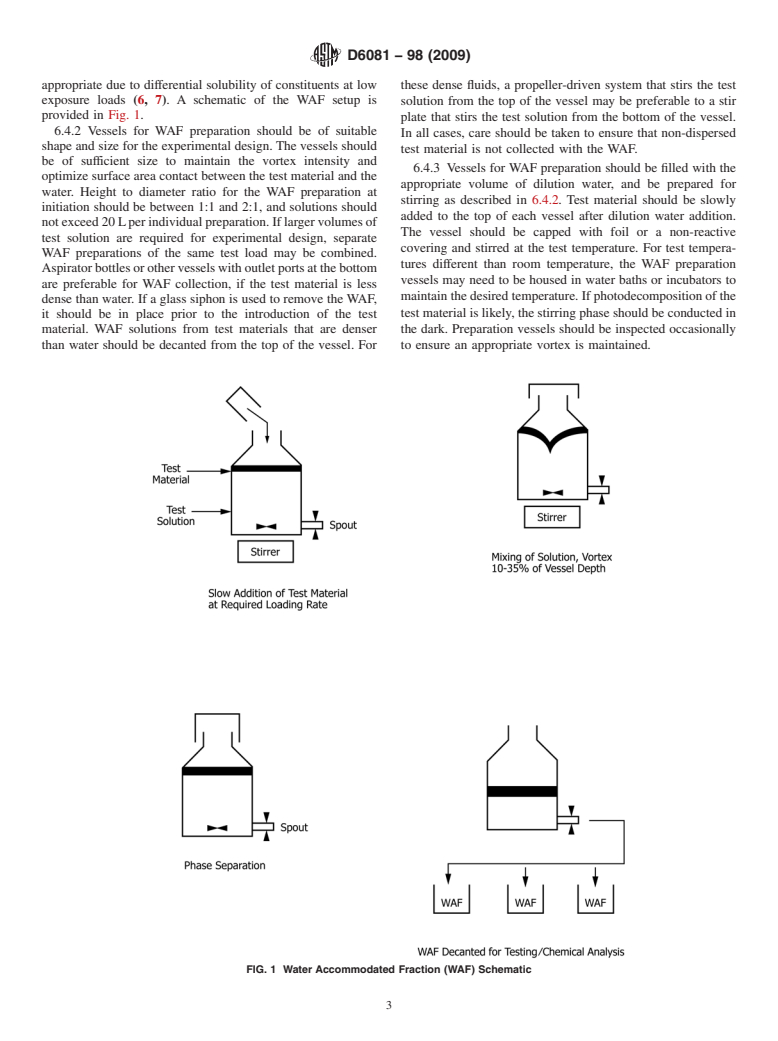

6.5 Preparation of Water-Soluble Fraction (WSF):

6.5.1 Only components dissolved in the water phase are

evaluated in a WSF study (6) . WSFs are prepared by filtration

of WAFs through a 0.45-µm nominal cellulose-acetate filter or

by centrifugation to remove undissolved material. Preliminary

testing may be necessary to ensure that the filter disc will not

removetestmaterialconstituentsthataredissolvedinthewater

FIG. 2 Water Soluble Fraction (WSF) Schematic

phase. Individual WSFs must be generated for each test

exposure load. Serial dilutions of a single WSF are not

appropriate due to differential solubility of constituents at low

exposure loads. A schematic of the WSF setup is provided in

Fig. 2.

6.5.2 The procedures described in 6.4.3 – 6.4.7 for theWAF

preparation are the initial steps of the WSF procedure.

6.5.3 Upon completion of the WAF mixing and settling

period, the aqueous solution should be decanted from below

the surface of each preparation ves

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.