ASTM E831-05

(Test Method)Standard Test Method for Linear Thermal Expansion of Solid Materials by Thermomechanical Analysis

Standard Test Method for Linear Thermal Expansion of Solid Materials by Thermomechanical Analysis

SCOPE

1.1 This test method determines the apparent coefficient of linear thermal expansion of solid materials using thermomechanical analysis techniques. Related information can be found in Refs. (1-12)².

1.2 This test method is applicable to solid materials that exhibit sufficient rigidity over the test temperature range such that the sensing probe does not produce indentation of the specimen.

1.3 The recommended lower limit of coefficient of linear thermal expansion measured with this test method is 5 m/(mC). The test method may be used at lower (or negative) expansion levels with decreased accuracy and precision (see Section 11).

1.4 This test method is applicable to the temperature range from 120 to 900 C. The temperature range may be extended depending upon the instrumentation and calibration materials used.

1.5 Computer or electronic based instruments, techniques, or data treatment equivalent to this test method may also be used.

Note 1—Users of this test method are expressly advised that all such instruments or techniques may not be equivalent. It is the responsibility of the user to determine the necessary equivalency prior to use.

1.6 SI values are the standard.

1.7 This test method is related to ISO 11359-2 but is significantly different in technical detail.

1.8 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E831–05

Standard Test Method for

Linear Thermal Expansion of Solid Materials by

1

Thermomechanical Analysis

This standard is issued under the fixed designation E831; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

3

1.1 This test method determines the apparent coefficient of 2.1 ASTM Standards:

linear thermal expansion of solid materials using thermome- D696 Test Method for Coefficient of Linear Thermal Ex-

chanicalanalysistechniques.Relatedinformationcanbefound pansion of Plastics Between−30 and 30 °C

2

in Refs. (1-12) . D3386 Test Method for Coefficient of Linear Thermal

1.2 This test method is applicable to solid materials that Expansion of Electrical Insulating Materials

exhibit sufficient rigidity over the test temperature range such E228 Test Method for Linear Thermal Expansion of Solid

that the sensing probe does not produce indentation of the Materials with a Vitreous Silica Dilatometer

specimen. E473 Terminology Relating to Thermal Analysis

1.3 The recommended lower limit of coefficient of linear E1142 TerminologyRelatingtoThermophysicalProperties

thermal expansion measured with this test method is 5 µm/ E1363 Test Method for Temperature Calibration of Ther-

(m·°C). The test method may be used at lower (or negative) momechanical Analyzers

expansion levels with decreased accuracy and precision (see E2113 Test Method for Length Change Calibration of

Section 11). Thermomechanical Analyzers

4

1.4 This test method is applicable to the temperature range 2.2 ISO Standards:

from −120 to 900 °C. The temperature range may be extended ISO 11359-2 Plastics—Thermomechanical Analysis

depending upon the instrumentation and calibration materials (TMA)—Part 2: Determination of Coefficient of Linear

used. Thermal Expansion and Glass Transition Temperature

1.5 Computer or electronic based instruments, techniques,

3. Terminology

or data treatment equivalent to this test method may also be

used. 3.1 Definitions—Thermal analysis terms in Terminologies

E473 and E1142 shall apply to this test method.

NOTE 1—Users of this test method are expressly advised that all such

3.2 Definitions of Terms Specific to This Standard:

instrumentsortechniquesmaynotbeequivalent.Itistheresponsibilityof

3.2.1 apparent coeffıcient of linear thermal expansion,

the user to determine the necessary equivalency prior to use.

(a )—the change in length, relative to the specimen length at

m

1.6 SI values are the standard.

ambient temperature, accompanying a unit change in tempera-

1.7 This test method is related to ISO11359-2 but is

ture identified by the midpoint temperature of the temperature

significantly different in technical detail.

range of measurement

1.8 This standard does not purport to address all of the

safety problems, if any, associated with its use. It is the

4. Summary of Test Method

responsibility of the user of this standard to establish appro-

4.1 This test method uses a thermomechanical analyzer or

priate safety and health practices and determine the applica-

similar device to determine the linear thermal expansion of

bility of regulatory limitations prior to use.

solid materials when subjected to a constant heating rate.

1

ThistestmethodisunderthejurisdictionofASTMCommitteeE37onThermal

3

Measurements and is the direct responsibility of Subcommittee E37.01 on Test For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Methods and Recommended Practices. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved May 1, 2005. Published June 2005. Originally Standards volume information, refer to the standard’s Document Summary page on

approved in 1981. Last previous edition approved in 2003 as E831–03. the ASTM website.

2 4

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof AvailablefromtheAmericanNationalStandardsInstitute,11W.42ndSt.,13th

this standard. Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E831–05

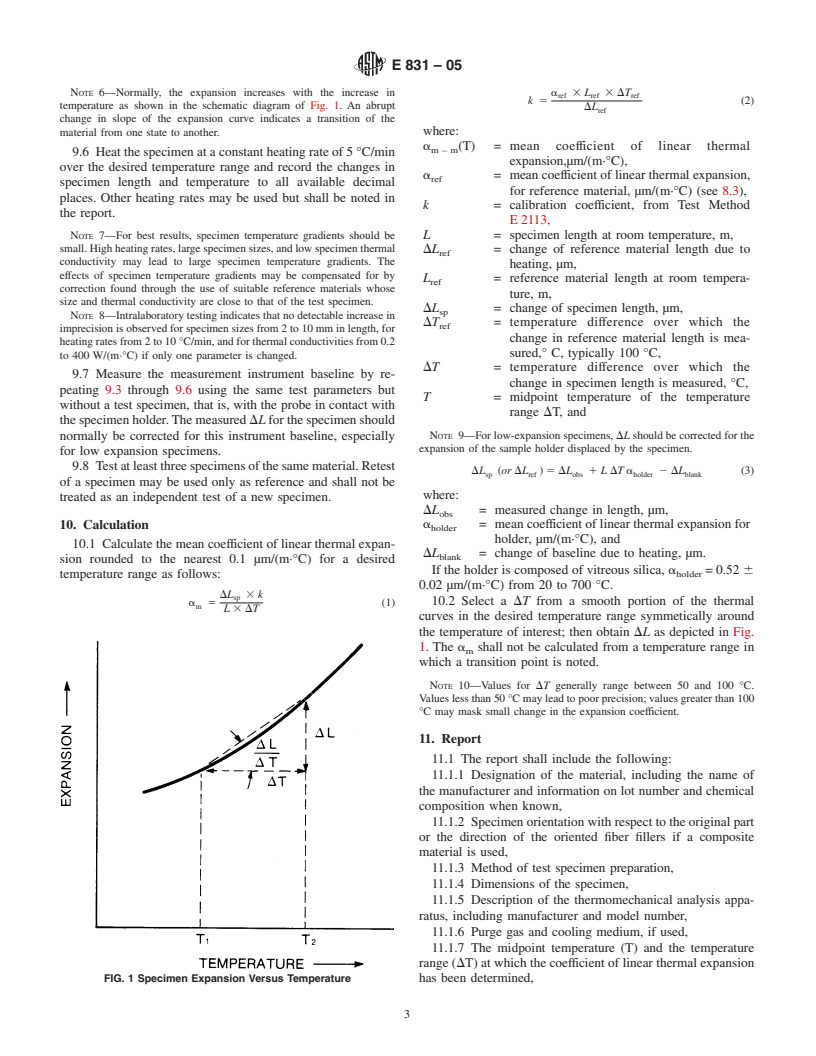

4.2 The change of the specimen length is electronically 6.2 Cooling Capability, to sustain a subambient specimen

recorded as a function of temperature.The coefficient of linear temperature(ifsubambientmeasurementsaretobemade)orto

thermal expansion can be calculated from these recorded data. hasten cool down of the specimen from elevated temperatures.

6.3 Micrometer, or other length-measuring device with a

range of up to 10 mm to determine specimen dimensio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.