ASTM D1210-05(2010)

(Test Method)Standard Test Method for Fineness of Dispersion of Pigment-Vehicle Systems by Hegman-Type Gage

Standard Test Method for Fineness of Dispersion of Pigment-Vehicle Systems by Hegman-Type Gage

SIGNIFICANCE AND USE

In making pigmented products, the pigment is usually dispersed in a portion of the vehicle in some sort of mill. At this stage, it is necessary to be able to judge if the pigment agglomerates have been sufficiently broken up so as not to interfere with the smoothness of the finished coating film. This test method describes a way of making this judgment.

SCOPE

1.1 This test method covers measurement of the degree of dispersion (commonly referred to as “fineness of grind”) of the pigment in a pigment-vehicle system such as liquid coatings and their intermediates. It may also be used to assess the inclusion of particulates by a cleanliness (or texture) rating.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1210 − 05 (Reapproved2010)

Standard Test Method for

Fineness of Dispersion of Pigment-Vehicle Systems by

Hegman-Type Gage

This standard is issued under the fixed designation D1210; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

2 2

1. Scope this gage, each of 6.5 cm (1 in. ) area, and of two different

depths. A count is made of the particles deposited in the two

1.1 This test method covers measurement of the degree of

delimited areas, and cleanliness (texture) reading is deter-

dispersion (commonly referred to as “fineness of grind”) of the

mined.

pigment in a pigment-vehicle system such as liquid coatings

and their intermediates. It may also be used to assess the

4. Significance and Use

inclusion of particulates by a cleanliness (or texture) rating.

4.1 In making pigmented products, the pigment is usually

1.2 The values stated in SI units are to be regarded as the

dispersedinaportionofthevehicleinsomesortofmill.Atthis

standard. The values given in parentheses are for information

stage, it is necessary to be able to judge if the pigment

only.

agglomerates have been sufficiently broken up so as not to

1.3 This standard does not purport to address all of the

interfere with the smoothness of the finished coating film. This

safety concerns, if any, associated with its use. It is the

test method describes a way of making this judgment.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5. Apparatus

bility of regulatory limitations prior to use.

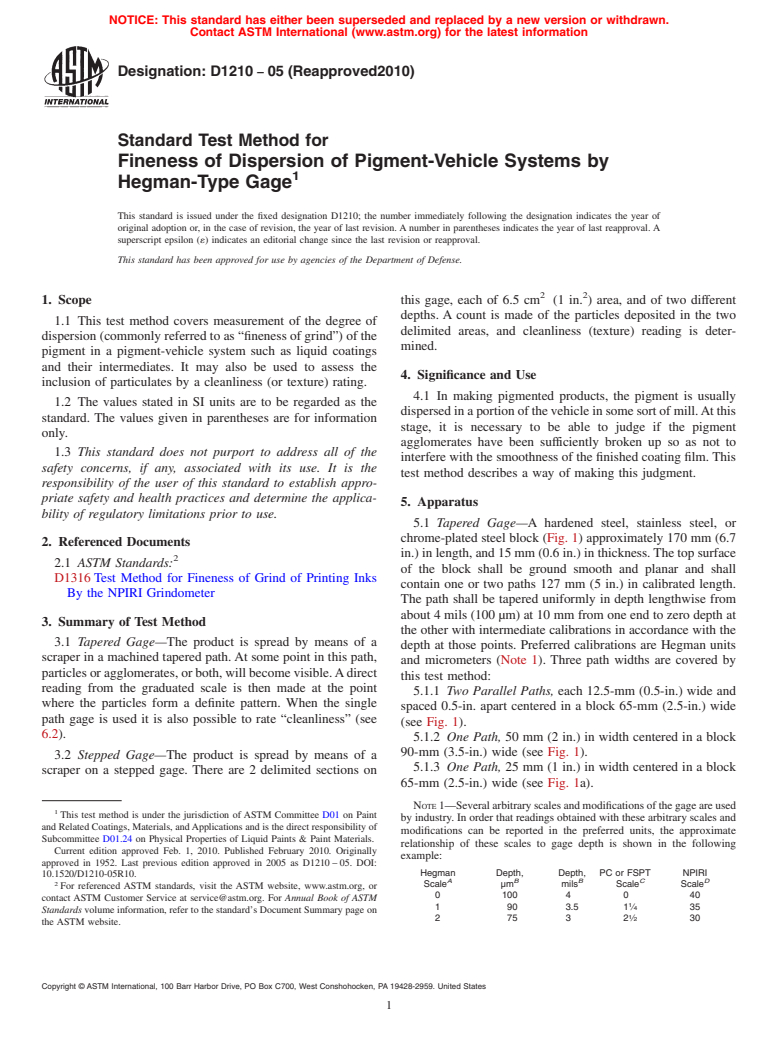

5.1 Tapered Gage—A hardened steel, stainless steel, or

chrome-plated steel block (Fig. 1) approximately 170 mm (6.7

2. Referenced Documents

in.) in length, and 15 mm (0.6 in.) in thickness.The top surface

2.1 ASTM Standards:

of the block shall be ground smooth and planar and shall

D1316 Test Method for Fineness of Grind of Printing Inks

contain one or two paths 127 mm (5 in.) in calibrated length.

By the NPIRI Grindometer

The path shall be tapered uniformly in depth lengthwise from

about 4 mils (100 µm) at 10 mm from one end to zero depth at

3. Summary of Test Method

the other with intermediate calibrations in accordance with the

3.1 Tapered Gage—The product is spread by means of a

depth at those points. Preferred calibrations are Hegman units

scraper in a machined tapered path.At some point in this path,

and micrometers (Note 1). Three path widths are covered by

particlesoragglomerates,orboth,willbecomevisible.Adirect

this test method:

reading from the graduated scale is then made at the point

5.1.1 Two Parallel Paths, each 12.5-mm (0.5-in.) wide and

where the particles form a definite pattern. When the single

spaced 0.5-in. apart centered in a block 65-mm (2.5-in.) wide

path gage is used it is also possible to rate “cleanliness” (see

(see Fig. 1).

6.2).

5.1.2 One Path, 50 mm (2 in.) in width centered in a block

90-mm (3.5-in.) wide (see Fig. 1).

3.2 Stepped Gage—The product is spread by means of a

5.1.3 One Path, 25 mm (1 in.) in width centered in a block

scraper on a stepped gage. There are 2 delimited sections on

65-mm (2.5-in.) wide (see Fig. 1a).

NOTE1—Severalarbitraryscalesandmodificationsofthegageareused

This test method is under the jurisdiction of ASTM Committee D01 on Paint

by industry. In order that readings obtained with these arbitrary scales and

and Related Coatings, Materials, andApplications and is the direct responsibility of

modifications can be reported in the preferred units, the approximate

Subcommittee D01.24 on Physical Properties of Liquid Paints & Paint Materials.

relationship of these scales to gage depth is shown in the following

Current edition approved Feb. 1, 2010. Published February 2010. Originally

example:

approved in 1952. Last previous edition approved in 2005 as D1210 – 05. DOI:

Hegman Depth, Depth, PC or FSPT NPIRI

10.1520/D1210-05R10.

A B B C D

2 Scale µm mils Scale Scale

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

0 100 4 0 40

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1 90 3.5 1 ⁄4 35

Standards volume information, refer to the standard’s Document Summary page on

275 3 2 ⁄2 30

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1210 − 05 (2010)

FIG. 1 Fineness Gages

5.4 Illumination—The gage shall be illuminated for viewing

3 65 2.5 3 ⁄4 25

450 2 5 20

with a fluorescent tube, mounted approximately 250 mm (10

5 40 1.5 6 ⁄4 15

in.) above the gage with the length of the tube parallel to the

625 1 7 ⁄2 10

7 15 0.5 8 ⁄4 5 length of the gage. The tube will be mounted so that the angle

80 0 10 0

between the plane of the gage, and the tube is 75 to 80°. A

A

Sometimes referred to in error as the North Standard scale.

viewing box is not mandatory for illumination, but if one is

B

Rounded to nearest 5 µm or 0.5 mil.

desired, a proposed design for a viewing box is contained in

C

Federation of Societies for Paint Technology scale.

D

Appendix X1.

National Printing Ink Research Institute scale, 0 to 10 on the NPIRI Production

Grindometer, but extended on many gages to 20 or 30 (see Test Method D1316).

5.2 Stepped Gage—A hardened steel, stainless steel, or 6. Care of Gage

chrome-plated steel block (Fig. 1a), approximately 170 mm

6.1 Clean the gage immediately after each use. Use a

(6.7 in.) in length, and 15 mm (0.6 in.) in thickness. A path

solvent and a soft cloth. Keep the gage covered or encased at

25-mm (1-in.) wide shall be cut the length of, and centered in

all times when not in use. Protect gages that lie idle for

a block 65-mm (2.5-in.) wide. The path will be cut to two

extended periods of time from rust with an oil coating or oil

different depths, each for half of its length.The two depths will

soaked wrap.

be 3 mils, and 1 mil, or as agreed upon between the buyer and

6.2 Do not allow any hard materials to come in contact with

the seller. There shall be two tick marks, above and below the

the gage surface or scraper in any manner that might result in

“step,” and spaced 25 mm (1 in.) from it.

scarring or nicking. Avoid tapping or scratching with other

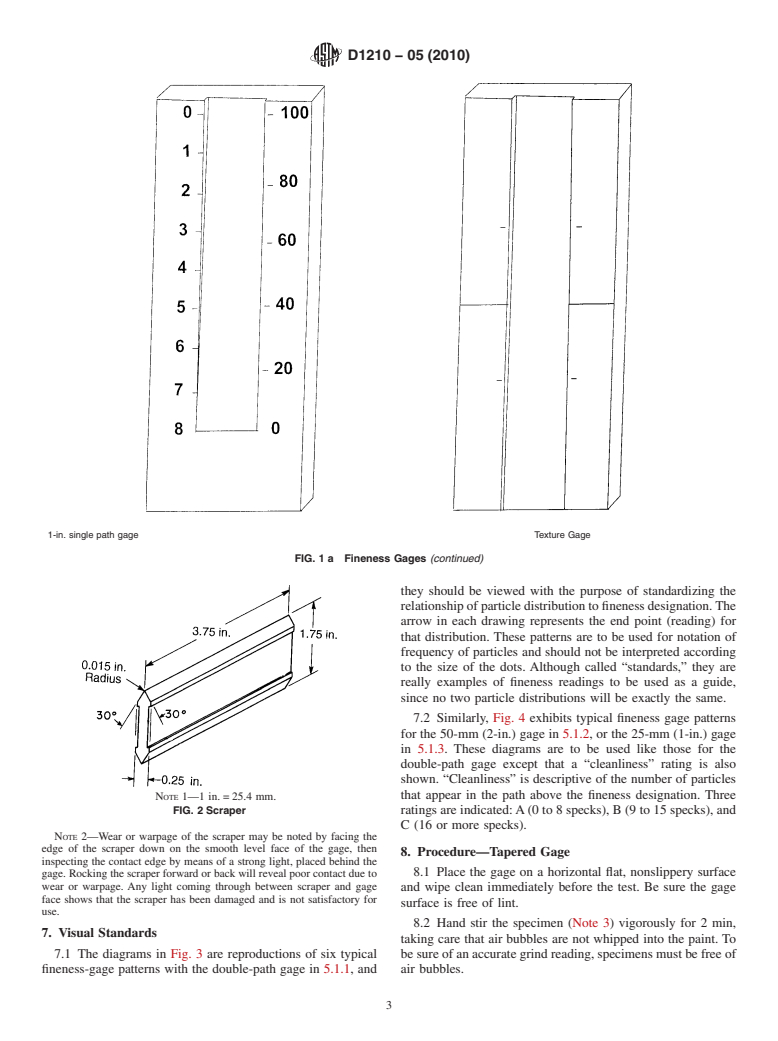

5.3 Scraper—Adouble-edgedhardenedsteel,stainlesssteel,

metal.

or chrome-plated steel blade (Fig. 2) 95-mm (3.75-in.) long,

40-mm (1.5-in.) wide, and 6.4-mm (0.25-in.) thick. The two 6.3 The scraper may be rendered unsatisfactory for use by

edges on the 3.75-in. sides shall be rounded to a radius of 0.38 wear or nicks of the contact edge or warpage (Note 2). Replace

mm (0.015 in.). or recondition unsatisfactory blades.

D1210 − 05 (2010)

1-in. single path gage Texture Gage

FIG. 1 a Fineness Gages (continued)

they should be viewed with the purpose of standardizing the

relationshipofparticledistributiontofinenessdesignation.The

arrow in each drawing represents the end point (reading) for

that distribution. These patterns are to be used for notation of

frequency of particles and should not be interpreted according

to the size of the dots. Although called “standards,” they are

really examples of fineness readings to be used as a guide,

since no two particle distributions will be exactly the same.

7.2 Similarly, Fig. 4 exhibits typical fineness gage patterns

for the 50-mm (2-in.) gage in 5.1.2, or the 25-mm (1-in.) gage

in 5.1.3. These diagrams are to be used like those for the

double-path gage except that a “cleanliness” rating is also

shown. “Cleanliness” is descriptive of the number of particles

that appear in the path above the fineness designation. Three

NOTE 1—1 in. = 25.4 mm.

FIG. 2 Scraper ratings are indicated:A(0 to 8 specks), B (9 to 15 specks), and

C (16 or more specks).

NOTE 2—Wear or warpage of the scraper may be noted by facing the

edge of the scraper down on the smooth level face of the gage, then

8. Procedure—Tapered Gage

inspecting the contact edge by means of a strong light, placed behind the

8.1 Place the gage on a horizontal flat, nonslippery surface

gage. Rocking the scraper forward or back will reveal poor contact due to

wear or warpage. Any light coming through between scraper and gage

and wipe clean immediately before the test. Be sure the gage

face shows that the scraper has been damaged and is not satisfactory for

surface is free of lint.

use.

8.2 Hand stir the specimen (Note 3) vigorously for 2 min,

7. Visual Standards

taking care that air bubbles are not whipped into the paint. To

7.1 The diagrams in Fig. 3 are reproductions of six typical be sure of an accurate grind reading, specimens must be free of

fineness-gage patterns with the double-path gage in 5.1.1, and air bubbles.

D1210 − 05 (2010)

FIG. 3 a Typical Fineness Gage Patterns

NOTE3—Forthistestmethodtofunctionproperly,thepigmentparticles

8.4.1 View the gage from the si

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.