ASTM F1137-00(2006)

(Specification)Standard Specification for Phosphate/Oil and Phosphate/Organic Corrosion Protective Coatings for Fasteners

Standard Specification for Phosphate/Oil and Phosphate/Organic Corrosion Protective Coatings for Fasteners

ABSTRACT

This specification covers the basic physical requirements and test methods for phosphate/oil and phosphate/organic corrosion protective coatings for fasteners such as nuts, clips, washers, and other ferrous threaded and non-threaded fasteners that require corrosion protection. The zinc phosphate treatment and subsequent protective coatings are classified into seven grades according to the following requirements: Grade 0A consists of a zinc phosphate coating with no additional sealer (dry); Grade 0B consists of a zinc phosphate coating with a dry organic sealer; Grades 0C, 0D, and I consist of a zinc phosphate coating with supplemental protective oil type compound; and Grades II and III consist of a zinc phosphate with a supplemental zinc-rich epoxy resin coating (with the addition of a clear organic topcoat for Grade II). These coatings may or may not have a decorative finish. The coatings shall meet the requirements specified for appearance, adhesion, corrosion resistance, coating flexibility, thread fit, and dry-to-touch characteristics. In addition, they shall also undergo humidity and coating thickness tests.

SCOPE

1.1 This specification covers the basic requirements for seven grades of corrosion protection for fasteners. Grade 0A consists of a zinc phosphate coating with no additional sealer (dry), Grade 0B consists of a zinc phosphate coating with a dry organic sealer, Grade 0C, Grade 0D, and Grade I consist of a zinc phosphate coating with supplemental protective oil type compound, and Grades II and III consist of a zinc phosphate with a supplemental zinc-rich epoxy resin coating (Grade II includes a clear organic topcoat).

1.2 This specification is intended primarily for fasteners such as nuts, clips, washers, and other ferrous threaded and non-threaded fasteners that require corrosion protection.

1.3 These coatings may or may not have a decorative finish.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1137 – 00 (Reapproved 2006)

Standard Specification for

Phosphate/Oil and Phosphate/Organic Corrosion Protective

Coatings for Fasteners

This standard is issued under the fixed designation F1137; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

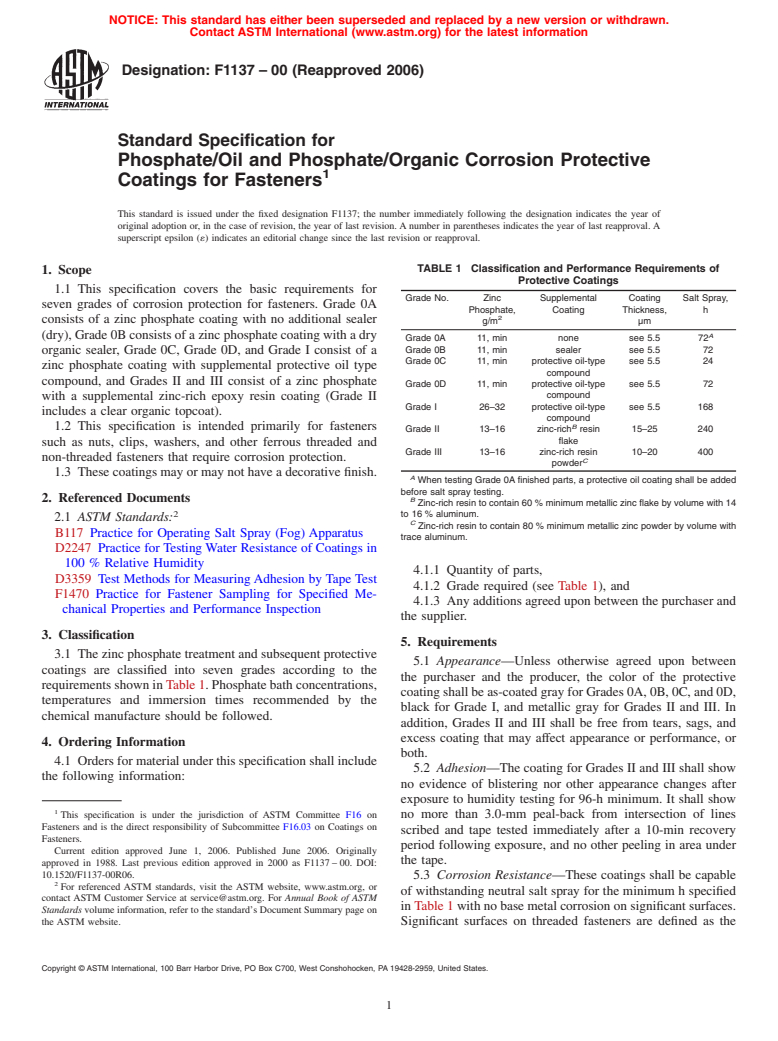

TABLE 1 Classification and Performance Requirements of

1. Scope

Protective Coatings

1.1 This specification covers the basic requirements for

Grade No. Zinc Supplemental Coating Salt Spray,

seven grades of corrosion protection for fasteners. Grade 0A

Phosphate, Coating Thickness, h

consists of a zinc phosphate coating with no additional sealer

g/m µm

A

(dry), Grade 0B consists of a zinc phosphate coating with a dry

Grade 0A 11, min none see 5.5 72

organic sealer, Grade 0C, Grade 0D, and Grade I consist of a Grade 0B 11, min sealer see 5.5 72

Grade 0C 11, min protective oil-type see 5.5 24

zinc phosphate coating with supplemental protective oil type

compound

compound, and Grades II and III consist of a zinc phosphate

Grade 0D 11, min protective oil-type see 5.5 72

compound

with a supplemental zinc-rich epoxy resin coating (Grade II

Grade I 26–32 protective oil-type see 5.5 168

includes a clear organic topcoat).

compound

B

1.2 This specification is intended primarily for fasteners

Grade II 13–16 zinc-rich resin 15–25 240

flake

such as nuts, clips, washers, and other ferrous threaded and

Grade III 13–16 zinc-rich resin 10–20 400

non-threaded fasteners that require corrosion protection.

C

powder

1.3 These coatings may or may not have a decorative finish.

A

When testing Grade 0A finished parts, a protective oil coating shall be added

before salt spray testing.

2. Referenced Documents B

Zinc-rich resin to contain 60 % minimum metallic zinc flake by volume with 14

to 16 % aluminum.

2.1 ASTM Standards:

C

Zinc-rich resin to contain 80 % minimum metallic zinc powder by volume with

B117 Practice for Operating Salt Spray (Fog) Apparatus

trace aluminum.

D2247 Practice for Testing Water Resistance of Coatings in

100 % Relative Humidity

4.1.1 Quantity of parts,

D3359 Test Methods for Measuring Adhesion by Tape Test

4.1.2 Grade required (see Table 1), and

F1470 Practice for Fastener Sampling for Specified Me-

4.1.3 Any additions agreed upon between the purchaser and

chanical Properties and Performance Inspection

the supplier.

3. Classification

5. Requirements

3.1 The zinc phosphate treatment and subsequent protective

5.1 Appearance—Unless otherwise agreed upon between

coatings are classified into seven grades according to the

the purchaser and the producer, the color of the protective

requirements shown inTable 1. Phosphate bath concentrations,

coating shall be as-coated gray for Grades 0A, 0B, 0C, and 0D,

temperatures and immersion times recommended by the

black for Grade I, and metallic gray for Grades II and III. In

chemical manufacture should be followed.

addition, Grades II and III shall be free from tears, sags, and

excess coating that may affect appearance or performance, or

4. Ordering Information

both.

4.1 Orders for material under this specification shall include

5.2 Adhesion—The coating for Grades II and III shall show

the following information:

no evidence of blistering nor other appearance changes after

exposure to humidity testing for 96-h minimum. It shall show

This specification is under the jurisdiction of ASTM Committee F16 on

no more than 3.0-mm peal-back from intersection of lines

Fasteners and is the direct responsibility of Subcommittee F16.03 on Coatings on

scribed and tape tested immediately after a 10-min recovery

Fasteners.

period following exposure, and no other peeling in area under

Current edition approved June 1, 2006. Published June 2006. Originally

the tape.

approved in 1988. Last previous edition approved in 2000 as F1137 – 00. DOI:

10.1520/F1137-00R06.

5.3 Corrosion Resistance—These coatings shall be capable

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

of withstanding neutral salt spray for the minimum h specified

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

inTable 1 with no base metal corrosion on significant surfaces.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Significant surfaces on threaded fasteners are defined as the

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.