ASTM D1142-95(2006)

(Test Method)Standard Test Method for Water Vapor Content of Gaseous Fuels by Measurement of Dew-Point Temperature

Standard Test Method for Water Vapor Content of Gaseous Fuels by Measurement of Dew-Point Temperature

SIGNIFICANCE AND USE

Generally, contracts governing the pipeline transmission of natural gas contain specifications limiting the maximum concentration of water vapor allowed. Excess water vapor can cause corrosive conditions, degrading pipelines and equipment. It can also condense and freeze or form methane hydrates causing blockages. Water–vapor content also affects the heating value of natural gas, thus influencing the quality of the gas. This test method permits the determination of water content of natural gas.

SCOPE

1.1 This test method covers the determination of the water vapor content of gaseous fuels by measurement of the dew-point temperature and the calculation therefrom of the water vapor content. Note 1Some gaseous fuels contain vapors of hydrocarbons or other components that easily condense into liquid and sometimes interfere with or mask the water dew point. When this occurs, it is sometimes very helpful to supplement the apparatus in with an optical attachment that uniformly illuminates the dew-point mirror and also magnifies the condensate on the mirror. With this attachment it is possible, in some cases, to observe separate condensation points of water vapor, hydrocarbons, and glycolamines as well as ice points. However, if the dew point of the condensable hydrocarbons is higher than the water vapor dew point, when such hydrocarbons are present in large amounts, they may flood the mirror and obscure or wash off the water dew point. Best results in distinguishing multiple component dew points are obtained when they are not too closely spaced.

Note 2

Condensation of water vapor on the dew-point mirror may appear as liquid water at temperatures as low as 0 to 10F (18 to 23C). At lower temperatures an ice point rather than a water dew point likely will be observed. The minimum dew point of any vapor that can be observed is limited by the mechanical parts of the equipment. Mirror temperatures as low as 150F (100C) have been measured, using liquid nitrogen as the coolant with a thermocouple attached to the mirror, instead of a thermometer well.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1142 − 95(Reapproved 2006)

Standard Test Method for

Water Vapor Content of Gaseous Fuels by

Measurement of Dew-Point Temperature

This standard is issued under the fixed designation D1142; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope saturated with the gas mixture. When a gas containing water

vapor is at the water dew-point temperature, it is said to be

1.1 This test method covers the determination of the water

saturated at the existing pressure.

vapor content of gaseous fuels by measurement of the dew-

point temperature and the calculation therefrom of the water 2.1.2 specific volume—of a gaseous fuel, the volume of the

gas in cubic feet per pound.

vapor content.

2.1.3 water dew-point temperature— of a gaseous fuel, the

NOTE 1—Some gaseous fuels contain vapors of hydrocarbons or other

temperature at which the gas is saturated with water vapor at

components that easily condense into liquid and sometimes interfere with

or mask the water dew point. When this occurs, it is sometimes very

the existing pressure.

helpful to supplement the apparatus in Fig. 1 with an optical attachment

that uniformly illuminates the dew–point mirror and also magnifies the

3. Significance and Use

condensate on the mirror. With this attachment it is possible, in some

cases, to observe separate condensation points of water vapor,

3.1 Generally,contractsgoverningthepipelinetransmission

hydrocarbons,andglycolaminesaswellasicepoints.However,ifthedew

of natural gas contain specifications limiting the maximum

point of the condensable hydrocarbons is higher than the water vapor dew

concentration of water vapor allowed. Excess water vapor can

point, when such hydrocarbons are present in large amounts, they may

flood the mirror and obscure or wash off the water dew point. Best results causecorrosiveconditions,degradingpipelinesandequipment.

in distinguishing multiple component dew points are obtained when they

It can also condense and freeze or form methane hydrates

are not too closely spaced.

causing blockages. Water–vapor content also affects the heat-

NOTE 2—Condensation of water vapor on the dew-point mirror may

ingvalueofnaturalgas,thusinfluencingthequalityofthegas.

appear as liquid water at temperatures as low as 0 to−10°F (−18

This test method permits the determination of water content of

to−23°C). At lower temperatures an ice point rather than a water dew

point likely will be observed. The minimum dew point of any vapor that natural gas.

can be observed is limited by the mechanical parts of the equipment.

Mirror temperatures as low as−150°F (−100°C) have been measured,

4. Apparatus

using liquid nitrogen as the coolant with a thermocouple attached to the

mirror, instead of a thermometer well.

4.1 Any properly constructed dew-point apparatus may be

1.2 This standard does not purport to address all of the used that satisfies the basic requirements that means must be

provided:

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 4.1.1 To permit a controlled flow of gas to enter and leave

priate safety and health practices and determine the applica- the apparatus while the apparatus is at a temperature at least

bility of regulatory limitations prior to use. 3°F above the dew point of the gas.

4.1.2 To cool and control the cooling rate of a portion

2. Terminology

(preferably a small portion) of the apparatus, with which the

flowing gas comes in contact, to a temperature low enough to

2.1 Definitions of Terms Specific to This Standard:

cause vapor to condense from the gas.

2.1.1 saturated water vapor or equilibrium water–vapor

4.1.3 To observe the deposition of dew on the cold portion

content—the water vapor concentration in a gas mixture that is

of the apparatus.

in equilibrium with a liquid phase of pure water that is

4.1.4 To measure the temperature of the cold portion on the

apparatus on which the dew is deposited, and

4.1.5 To measure the pressure of the gas within the appara-

ThistestmethodisunderthejurisdictionofASTMCommitteeD03onGaseous

Fuels and is the direct responsibility of Subcommittee D03.05 on Determination of

tus or the deviation from the known existing barometric

Special Constituents of Gaseous Fuels.

pressure.

Current edition approved June 1, 2006. Published June 2006. Originally

4.1.6 The apparatus should be constructed so that the “cold

approved in 1950. Last previous edition approved in 2000 as D1142–95(2000).

DOI: 10.1520/D1142-95R06. spot,” that is, the cold portion of the apparatus on which dew

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1142 − 95 (2006)

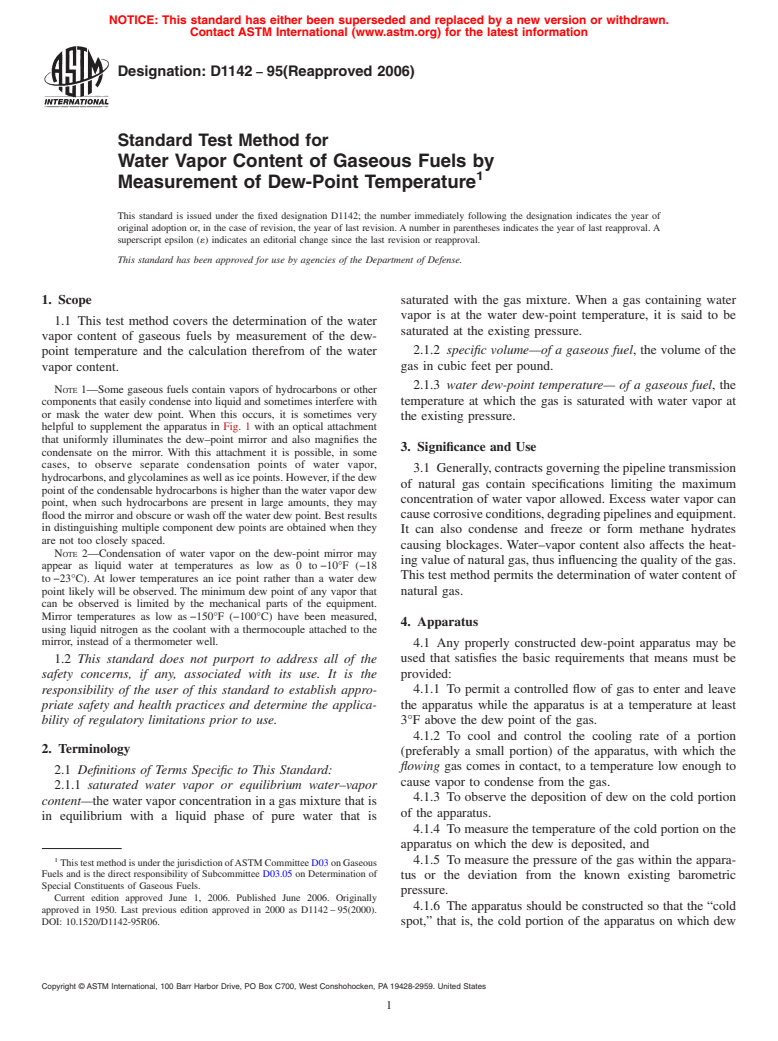

FIG. 1 Bureau of Mines Dew-Point Apparatus

is deposited, is protected from all gases other than the gas either end. The lower header is connected with the upper

under test. The apparatus may or may not be designed for use

header by numerous small holes drilled in the copper body

under pressure. through which the vaporized refrigerant passes. The chiller is

attached to the cooling rod, F, by means of a taper joint. The

4.2 The Bureau of Mines type of dew-point apparatus

temperature of the target mirror, C, is indicated by a calibrated

shown in Fig. 1 fulfills the requirements specified in 4.1.

mercury-in-glass thermometer, K, whose bulb fits snugly into

Within the range of conditions in Section 1, this apparatus is

the thermometer well. Observation of the dew deposit is made

satisfactory for determining the dew point of gaseous fuels.

through the pressure-resisting transparent window, E.

Briefly, this apparatus consists of a metal chamber into and out

4.2.1 Note that only the central portion of the stainless steel

ofwhichthetestgasispermittedtoflowthroughcontrolvalves

A and D. Gas entering the apparatus through valve A is target mirror, C, is thermally bonded to the fitting, I, through

deflectedbynozzleBtowardsthecoldportionoftheapparatus, which C is cooled. Since stainless steel is a relatively poor

C. The gas flows across the face of C and out of the apparatus thermal conductor, the central portion of the mirror is thus

through valve D. Part C is a highly polished stainless steel maintained at a slightly lower temperature than the outer

“target mirror,” cooled by means of a copper cooling rod, F. portion, with the result that the dew first appears on the central

The mirror, C, is silver-soldered to a nib on the copper portionofthemirroranditsdetectionisaidedmateriallybythe

thermometer well fitting, I, which is soft-soldered to the

contrast afforded.The arrangement for measuring the tempera-

cooling rod, F. The thermometer well is integral with the ture of the target mirror, C, also should be noted. The

fitting, I. Cooling of rod F is accomplished by vaporizing a

temperature is read with a thermometer or RTD, K, inserted in

refrigerant such as liquid butane, propane, carbon dioxide, or the cooling rod, F, so that the bulb of the temperature

some other liquefied gas in the chiller, G. The refrigerant is

measuring device is entirely within the thermometer well in

throttled into the chiller through valve H and passes out at J.

fitting, I. The stud to which the stainless steel mirror is

The chiller body is made of copper and has brass headers on

silver-soldered is a part of the base of the thermometer well,

and as there is no metallic contact between the thermometer

well and the cooling tube, other than through its base, the

Deaton, W. M., and Frost, E. M., Jr., “Bureau of Mines Apparatus for

thermometer or RTD indicates the temperature of the mirror

Determining the Dew Point of Gases Under Pressure,” Bureau of Mines Report of

Investigation 3399, May 1938. rather than some compromise temperature influenced by the

D1142 − 95 (2006)

temperature gradient along the cooling tube as would be the 0.2°F (0.1°C) allow equilibrium conditions to be approached

case if this type of construction were not used. The RTD will closely and favor an accurate determination. When dew has

include suitable electronics and display. been deposited, allow the target mirror to warm up at a rate

4.2.2 Tests with the Bureau of Mines type of dew-point comparable to the recommended rate of cooling. The normal

apparatus are reported to permit a determination with a warming rate usually will be faster than desired. To reduce the

precision (reproducibility) of 60.2°F (60.1°C) and with an rate, “crack” valve H momentarily at intervals to supply

accuracy of 60.2°F (60.1°C) when the dew-point tempera- coolingtothecoolingtube, F.Repeatthecoolingandwarming

tures range from room temperature to a temperature of 32°F cycles several times. The arithmetic average of the tempera-

(0°C). It is estimated that water dew points may be determined tures at which dew is observed to appear and disappear is

with an accuracy of 60.5°F (0.3°C) when they are below 32°F considered to be the observed dew point.

(0°C) and not lower than 0°F (−17.8°C), provided ice crystals

NOTE 3—If the water–vapor content is to be calculated as described in

do not form during the determination.

6.2,thegasspecimenshouldbethrottledattheinletvalve, A,toapressure

within the apparatus approximately equal to atmospheric pressure. The

5. Procedure

outlet valve may be left wide open or restricted, as desired. The pressure

existing within the apparatus must, however, be known to the required

5.1 General Considerations—Take the specimen so as to be

accuracy.

representative of the gas at the source. Do not take at a point

where isolation would permit condensate to collect or would

6. Calculation

otherwise allow a vapor content to exist that is not in

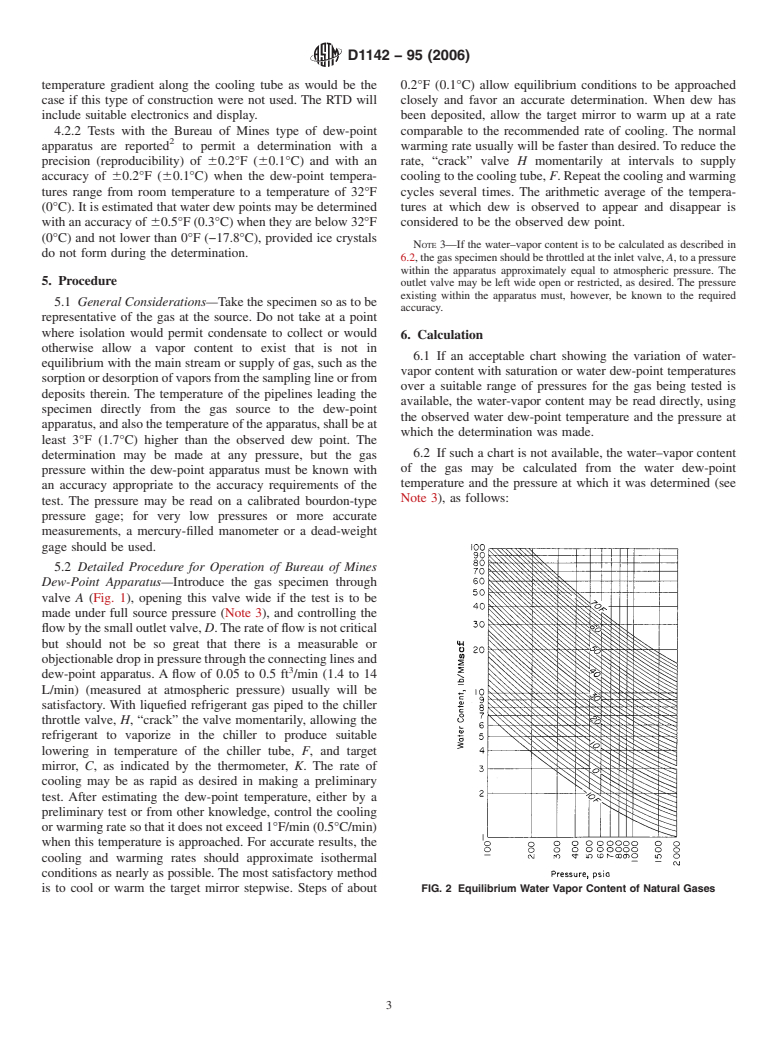

6.1 If an acceptable chart showing the variation of water-

equilibrium with the main stream or supply of gas, such as the

vapor content with saturation or water dew-point temperatures

sorptionordesorptionofvaporsfromthesamplinglineorfrom

over a suitable range of pressures for the gas being tested is

deposits therein. The temperature of the pipelines leading the

available, the water-vapor content may be read directly, using

specimen directly from the gas source to the dew-point

the observed water dew-point temperature and the pressure at

apparatus,andalsothetemperatureoftheapparatus,shallbeat

which the determination was made.

least 3°F (1.7°C) higher than the observed dew point. The

6.2 If such a chart is not available, the water–vapor content

determination may be made at any pressure, but the gas

of the gas may be calculated from the water dew-point

pressure within the dew-point apparatus must be known with

temperature and the pressure at which it was determined (see

an accuracy appropriate to the accuracy requirements of the

Note 3), as follows:

test. The pressure may be read on a calibrated bourdon-type

pressure gage; for very low pressures or more accurate

measurements, a mercury-filled manometer or a dead-weight

gage should be used.

5.2 Detailed Procedure for Operation of Bureau of Mines

Dew-Point Apparatus—Introduce the gas specimen through

valve A (Fig. 1), opening this valve wide if the test is to be

made under full source pressure (Note 3), and controlling the

flowbythesmalloutletvalve, D.Therateofflowisnotcritical

but should not be so great that there is a measurable or

objectionabledropinpressurethroughtheconnectinglinesand

dew-point apparatus. A flow of 0.05 to 0.5 ft /min (1.4 to 14

L/min) (measured at atmospheric pressure) usually will be

satisfactory. With liquefied refrigerant gas piped to the chiller

throttle valve, H, “crack” the valve momentarily, allowing the

refrigerant to vaporize in the chiller to produce suitable

lowering in temperature of the chiller tube, F, and target

mirror, C, as indicated by the thermometer, K. The rate of

cooling may be as rapid as desired in making a preliminary

test. After estimating the dew-point temperature, either by a

preliminary test or from other knowledge, control the cooling

orwarmingratesothatitdoesnotexceed1°F/min(0.5°C/min)

when this temperature is approached. For accurate results, the

cooling and warming rates should approximate isothermal

conditions as nearly as possible. The most satisfactory method

is to cool or warm the target mirror stepwise. Steps of about FIG. 2 Equilibrium Water Vapor Content of Natural Gases

D1142 − 95 (2006)

W 5 w 310 3 P /P 3 T/T (1) 6.3 A correlation of the available data on the equilibrium

~ ~ !!

b b

water content of natural gases has been reported by Bukacek.

where:

This correlation is believed to be accurate enough for the

W = lb of water/million ft of gaseous mixture at pressure

requirements of the gaseous fuels industry, except for unusual

P and temperature T ;

b b situations where the dew point is measured at conditions close

w = weight of saturated water vapor, lb/ft , at the water

to the critical temperature of the gas. The correlation is a

dew-point temperature, that is, the reciprocal of the

modified form of Raoult’s law having the following form:

specific volume of saturated vapor (see Table 1);

W 5 A/P 1B (2)

~ !

P = pressure-base of gas measurement, psia;

b

P = pressure at which the water dew point of gas was

where:

determined, psia;

W = water–vapor content, lb/million ft ;

t = observed water dew-point temperature, °F;

P = total pressure, psia;

T = Rankine (absolute Fahrenheit scale) water dew point, t

A = a constant proportional to the vapor pressure of water;

+460, at pressure P; and

and

T = base temperature of gas measurement, t +460.

b b

B = a constant depending on temperature and gas

NOTE 4—Example 1:

composition.

Given: Water dew point=37°F at 15.0-psia pressure.

NOTE 5—Values of B were computed from available data on methane,

What is the water–vapor content million ft of gas (gas measurement

methane-ethane mixtures, and natural gases.

base of 60°F and 14.7-psia pressure)?

6.3.1 Table2listsvaluesoftheconstantsAandBfornatural

From Table 1 the specific volume of saturated water at 37°F is 2731.9

gases in the temperature range from−40 to 460°F (−40 to

ft /lb, from which:

w =(1/2731.9)=0.0003660 lb/ft

238°C).

and

6.3.2 Tables 3-5 list values of water–vapor content

W =0.0003660×10 ×(14.7/15.0)×[(460+37)/(460+60)]

from−40to250°F(−40°to121°C)andfrom14.7to5000psia

=342.8 lb/million ft

(101 to 34475 kPa), covering the range of most natural gas

Example 2:

processing applications.

Given: Wat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.