ASTM D5306-92(1997)

(Test Method)Standard Test Method for Linear Flame Propagation Rate of Lubricating Oils and Hydraulic Fluids

Standard Test Method for Linear Flame Propagation Rate of Lubricating Oils and Hydraulic Fluids

SCOPE

1.1 This test method covers the determination of the linear flame propagation rates of lubricating oils and hydraulic fluids supported on the surfaces of and impregnated into ceramic fiber media. Data thus generated are to be used for the comparison of relative flammability.

1.2 This test method should be used to measure and describe the properties of materials, products, or assemblies in response to heat and flame under controlled laboratory conditions and should not be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under actual fire conditions. However, results of this test method may be used as elements of fire risk which takes into account all of the factors that are pertinent to an assessment of the fire hazard of a particular end use.

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in the note.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact

ASTM International (www.astm.org) for the latest information.

Designation: D 5306 – 92 (Reapproved 1997)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Linear Flame Propagation Rate of Lubricating Oils and

Hydraulic Fluids

This standard is issued under the fixed designation D 5306; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 linear flame propagation rate, n—the average quotient

of the distance of flame travel and the time required for the

1.1 This test method covers the determination of the linear

flame front to travel that distance.

flame propagation rates of lubricating oils and hydraulic fluids

supported on the surfaces of and impregnated into ceramic

4. Summary of Test Method

fiber media. Data thus generated are to be used for the

4.1 A section of a ceramic fiber support medium (string) is

comparison of relative flammability.

impregnated with the sample under specific conditions. The

1.2 This test method should be used to measure and describe

impregnated fiber is placed on a standard support. The sample

the properties of materials, products, or assemblies in response

is ignited and the time required for the flame front to propagate

to heat and flame under controlled laboratory conditions and

should not be used to describe or appraise the fire hazard or fire across a measured distance is determined by use of a thermo-

electric system. The average propagation rate is then calculated

risk of materials, products, or assemblies under actual fire

conditions. However, results of this test method may be used as from the measured distance of flame travel and the time

required for the flame front to propagate over that distance.

elements of fire risk which takes into account all of the factors

that are pertinent to an assessment of the fire hazard of a

5. Significance and Use

particular end use.

1.3 The values stated in SI units are to be regarded as the

5.1 The linear flame propagation rate of a sample is a

standard.

property that is relevant to the overall assessment of the

1.4 This standard does not purport to address all of the

flammability or relative ignitability of fire resistance lubricants

safety concerns, if any, associated with its use. It is the

and hydraulic fluids. It is intended to be used as a bench-scale

responsibility of the user of this standard to establish appro-

test for distinguishing between the relative resistance to igni-

priate safety and health practices and determine the applica-

tion of such materials. It is not intended to be used for the

bility of regulatory limitations prior to use. Specific precau-

evaluation of the relative flammability of flammable, extremely

tionary statements are given in the note.

flammable, or volatile fuels, solvents, or chemicals.

2. Referenced Documents

6. Apparatus

2.1 ASTM Standards:

6.1 Apparatus for measurement of linear flame propagation

E 691 Practice for Conducting an Interlaboratory Test Pro-

rates:

gram to Determine the Precision of Test Methods

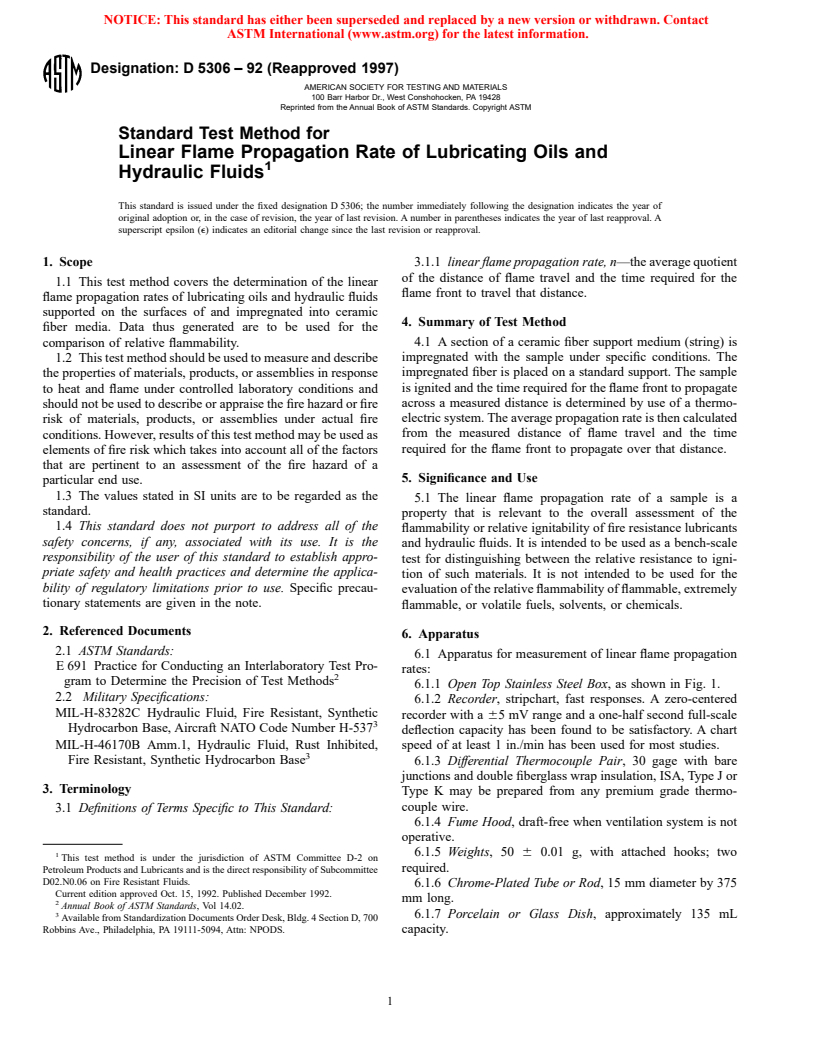

6.1.1 Open Top Stainless Steel Box, as shown in Fig. 1.

2.2 Military Specifications:

6.1.2 Recorder, stripchart, fast responses. A zero-centered

MIL-H-83282C Hydraulic Fluid, Fire Resistant, Synthetic

recorder with a 65 mV range and a one-half second full-scale

Hydrocarbon Base, Aircraft NATO Code Number H-537

deflection capacity has been found to be satisfactory. A chart

MIL-H-46170B Amm.1, Hydraulic Fluid, Rust Inhibited,

speed of at least 1 in./min has been used for most studies.

Fire Resistant, Synthetic Hydrocarbon Base 6.1.3 Differential Thermocouple Pair, 30 gage with bare

junctions and double fiberglass wrap insulation, ISA, Type J or

3. Terminology

Type K may be prepared from any premium grade thermo-

couple wire.

3.1 Definitions of Terms Specific to This Standard:

6.1.4 Fume Hood, draft-free when ventilation system is not

operative.

1 6.1.5 Weights,50 6 0.01 g, with attached hooks; two

This test method is under the jurisdiction of ASTM Committee D-2 on

required.

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.N0.06 on Fire Resistant Fluids.

6.1.6 Chrome-Plated Tube or Rod, 15 mm diameter by 375

Current edition approved Oct. 15, 1992. Published December 1992.

mm long.

Annual Book of ASTM Standards, Vol 14.02.

6.1.7 Porcelain or Glass Dish, approximately 135 mL

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS. capacity.

NOTICE:¬This¬standard¬has¬either¬been¬superceded¬and¬replaced¬by¬a¬new¬version¬or¬discontinued.¬

Contact¬ASTM¬International¬(www.astm.org)¬for¬the¬latest¬information.¬

D 5306

8.5 Place the string support and thermocouple holder in a

draft-free hood with the ventilation turned off. Level the

apparatus with a spirit level. Place the prepared string on the

string supports. The attached weights should be left in place to

provide tension in the string. Adjust the differential thermo-

couple junctions so that they are exactly 2 mm directly above

the string. Connect the differential thermocouple pair to the

fast-response, zero-centered strip chart recorder.

8.6 Start the recorder chart after an appropriate warm-up

period. With an ignition source, ignite the sample on the string

near its support at one end of the apparatus. Permit the flame to

advance along the string past each thermocouple until it

extinguishes itself upon reaching the opposite string support.

FIG. 1 Apparatus for Determination of Linear Flame Propagation

Rates Stop the recorder and start the hood ventilator to exhaust the

combustion products of the sample.

7. Materials NOTE 1—Warning: Take extreme care to avoid inhalation of the

combustion products as extremely toxic substances are formed during the

7.1 Absorbent Paper Wipers, 375 by 213 mm.

combustion of some synthetic materials, especially halogenated and

7.2 Ceramic Fiber, twisted yarn type 390/312, 4/5, 2.72 or

phosphorus-based compounds.

type 390/312, 3/4, 2.72. Ceramic fiber size used shall be agreed

upon by supplier and consumer and shall be specified in test 8.7 Measure the horizontal distance between the thermo-

report. couples and interval between the first thermal effects as shown

7.3 Ignition Source, any paper book matches or wooden

in Fig. 2. From the measured interval, the chart speed of the

kitchen matches can be used.

recorder and the known horizontal distance between thermo-

couples in the test apparatus, calculate and report the horizontal

8. Procedure

linear flame propagation rate in millimetres per second. If the

8.1 Tie small loops in each end of a 500 mm section of

flame does not advance during the experimental run, or if it

ceramic fiber support (string). Place a few millilitres of the

extinguishes itself before passing both thermocouples, record

sample to be studied in an evaporating dish. Immerse the

that fact. Replicate runs shall be made as required.

ceramic fiber support (string) in the liquid sample for 60 s.

Avoid immersion of the loops at the end of the string.

9. Calculation and Report

8.2 While the ceramic fiber support (string) is immersed in

9.1 Calculate the linear flame propagation rate as follows:

the sample, carefully wrap an absorbent paper wiper around the

15 mm diameter chrome plated rod. Leave one end of the rod

dv

linear flame propagation rate 5 (1)

uncovered by the wiper.

p

8.3 Remove the ceramic fiber support (string) section from

where:

the liquid sample and attach a 50 g weight to the loop at each

d 5 distance between thermocouples, mm (see Fig. 1),

end. Fix the chrome-plated rod with its absorbent paper

v 5 chart speed in mm/s, and

wrapping in a horizontal position and hang the soaked string

p 5 distance measured peak to peak between thermal

section with attached weights over the unwrapped section of

effects, mm (see Fig. 2).

the rod. Press down gently on the uppermost weight to cause

the soaked string to pass over the bare rod, flexing gently as it

moves. When the lower weight has been drawn up to the rod,

reverse the process until the first weight has again been drawn

up the rod. Repeat the cycle four times to work the sample

thoroughly into the string.

8.4 Transfer the strin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.