ASTM D6378-10(2016)

(Test Method)Standard Test Method for Determination of Vapor Pressure (VPX) of Petroleum Products, Hydrocarbons, and Hydrocarbon-Oxygenate Mixtures (Triple Expansion Method)

Standard Test Method for Determination of Vapor Pressure (VP<inf>X</inf>) of Petroleum Products, Hydrocarbons, and Hydrocarbon-Oxygenate Mixtures (Triple Expansion Method)

SIGNIFICANCE AND USE

5.1 Vapor pressure is a very important physical property of volatile liquids for shipping and storage.

5.2 The vapor pressure of gasoline and gasoline-oxygenate blends is regulated by various government agencies.

5.3 Specifications for volatile petroleum products generally include vapor pressure limits to ensure products of suitable volatility performance.

5.4 In this test method, an air saturation procedure prior to the measurement is not required, thus eliminating losses of high volatile compounds during this step. This test method is faster and minimizes potential errors from improper air saturation. This test method permits VPX determinations in the field.

5.5 This test method can be applied in online applications in which an air saturation procedure prior to the measurement cannot be performed.

SCOPE

1.1 This test method covers the use of automated vapor pressure instruments to determine the vapor pressure exerted in vacuum by volatile, liquid petroleum products, hydrocarbons, and hydrocarbon-oxygenate mixtures. This test method is suitable for testing samples with boiling points above 0 °C (32 °F) that exert a vapor pressure between 7 kPa and 150 kPa (1.0 psi and 21 psi) at 37.8 °C (100 °F) at a vapor-to-liquid ratio of 4:1. The liquid sample volume size required for analysis is dependent upon the vapor-to-liquid ratio chosen (see Note 1) and the measuring chamber volume capacity of the instrument (see 6.1.1 and Note 3).

Note 1: The test method is suitable for the determination of the vapor pressure of volatile, liquid petroleum products at temperatures from 0 °C to 100 °C at vapor to liquid ratios of 4:1 to 1:1 (X = 4 to 1) and pressures up to 500 kPa (70 psi), but the precision statement (see Section 16) may not be applicable.

1.2 This test method also covers the use of automated vapor pressure instruments to determine the vapor pressure exerted in vacuum by aviation turbine fuels. This test method is suitable for testing aviation turbine fuel samples with boiling points above 0 °C (32 °F) that exert a vapor pressure between 0 kPa and 110 kPa (0 psi and 15.5 psi) at a vapor-to-liquid ratio of 4:1, in the temperature range from 25 °C to 100 °C (77 °F to 212 °F).

1.3 The vapor pressure (VPX) determined by this test method at a vapor-liquid ratio of 4:1 (X = 4) of gasoline and gasoline-oxygenate blends at 37.8 °C can be correlated to the dry vapor pressure equivalent (DVPE) value determined by Test Method D5191 (see 16.3). This condition does not apply when the sample is aviation turbine fuel.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see 7.2 – 7.8.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6378 − 10 (Reapproved 2016)

Standard Test Method for

Determination of Vapor Pressure (VP ) of Petroleum

X

Products, Hydrocarbons, and Hydrocarbon-Oxygenate

Mixtures (Triple Expansion Method)

This standard is issued under the fixed designation D6378; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method covers the use of automated vapor

responsibility of the user of this standard to establish appro-

pressureinstrumentstodeterminethevaporpressureexertedin

priate safety and health practices and determine the applica-

vacuum by volatile, liquid petroleum products, hydrocarbons,

bility of regulatory limitations prior to use. For specific

and hydrocarbon-oxygenate mixtures. This test method is

warning statements, see 7.2 – 7.8.

suitable for testing samples with boiling points above 0°C

(32°F) that exert a vapor pressure between 7kPa and 150kPa

2. Referenced Documents

(1.0psi and 21psi) at 37.8°C (100°F) at a vapor-to-liquid

2.1 ASTM Standards:

ratio of 4:1. The liquid sample volume size required for

D323TestMethodforVaporPressureofPetroleumProducts

analysis is dependent upon the vapor-to-liquid ratio chosen

(Reid Method)

(see Note 1) and the measuring chamber volume capacity of

D2892Test Method for Distillation of Crude Petroleum

the instrument (see 6.1.1 and Note 3).

(15-Theoretical Plate Column)

NOTE 1—The test method is suitable for the determination of the vapor

D4057Practice for Manual Sampling of Petroleum and

pressure of volatile, liquid petroleum products at temperatures from 0°C

Petroleum Products

to 100°C at vapor to liquid ratios of 4:1 to 1:1 (X=4to1)and pressures

D4177Practice for Automatic Sampling of Petroleum and

up to 500kPa (70psi), but the precision statement (see Section 16) may

Petroleum Products

not be applicable.

D4953Test Method for Vapor Pressure of Gasoline and

1.2 Thistestmethodalsocoverstheuseofautomatedvapor

Gasoline-Oxygenate Blends (Dry Method)

pressureinstrumentstodeterminethevaporpressureexertedin

D5191Test Method for Vapor Pressure of Petroleum Prod-

vacuum by aviation turbine fuels. This test method is suitable

ucts (Mini Method)

for testing aviation turbine fuel samples with boiling points

D5842Practice for Sampling and Handling of Fuels for

above 0°C (32°F) that exert a vapor pressure between 0kPa

Volatility Measurement

and 110kPa (0psi and 15.5psi) at a vapor-to-liquid ratio of

D5854Practice for Mixing and Handling of Liquid Samples

4:1, in the temperature range from 25°C to 100°C (77°F to

of Petroleum and Petroleum Products

212°F).

D6299Practice for Applying Statistical Quality Assurance

1.3 The vapor pressure (VP ) determined by this test

X

and Control Charting Techniques to Evaluate Analytical

method at a vapor-liquid ratio of 4:1 (X = 4) of gasoline and

Measurement System Performance

gasoline-oxygenate blends at 37.8°C can be correlated to the

D6300Practice for Determination of Precision and Bias

dry vapor pressure equivalent (DVPE) value determined by

Data for Use in Test Methods for Petroleum Products and

Test Method D5191 (see 16.3). This condition does not apply

Lubricants

when the sample is aviation turbine fuel.

D6708Practice for StatisticalAssessment and Improvement

of Expected Agreement Between Two Test Methods that

1.4 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information Purport to Measure the Same Property of a Material

only.

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.08 on Volatility. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2016. Published November 2016. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1999. Last previous edition approved in 2010 as D6378–10 DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D6378-10R16. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6378 − 10 (2016)

3.1.1 dry vapor pressure equivalent (DVPE)—a value cal- associated equipment to control the chamber temperature

culated by a correlation equation from the total pressure (Test within the range from 0°C to 100°C.The measuring chamber

Method D5191), which is equivalent to the value obtained on

shall contain a movable piston with a maximum dead volume

the sample by Test Method D4953, Procedure A.

of less than 1% of the total volume at the lowest position to

allow sample introduction into the measuring chamber and

3.1.2 partial pressure from dissolved air (PPA), n—the

expansion to the desired vapor-liquid ratio. A static pressure

pressure exerted in vacuum from dissolved air that escapes

transducer shall be incorporated in the piston. The measuring

from the liquid phase into the vapor phase.

chamber shall contain an inlet/outlet valve combination for

3.1.3 Reid vapor pressure equivalent (RVPE)—a value cal-

sample introduction and expulsion. The piston and the valve

culated by a correlation equation from the TP , which is

X

combinationshallbeatthesametemperatureasthemeasuring

equivalenttothevalueobtainedonthesamplebyTestMethod

chamber to avoid any condensation or excessive evaporation.

D323.

6.1.1 The measuring chamber shall be designed to contain

3.1.4 total pressure (TP ), n—the pressure exerted in

X

between5mLand15mLofliquidandvaporandbecapableof

vacuum by air- and gas-containing petroleum products, com-

maintaining a vapor-liquid ratio of 4:1 to 1:1. The accuracy of

ponents and feedstocks, and other liquids, in the absence of

the adjusted vapor-liquid ratio shall be within 0.05.

undissolved water at a vapor-liquid ratio of X:1.

3.1.5 vapor pressure (VP ), n—the total pressure minus the

X

NOTE 3—The measuring chamber employed by the instruments used in

PPA in the liquid at a vapor-liquid ratio of X:1.

generating the precision and bias statements were constructed of nickel

plated aluminum and stainless steel with a total volume of 5mL.

VP 5TP 2PPA (1)

X X

Measuring chambers exceeding a 5mL capacity can be used, but the

precision and bias statements (see Section 16) are not known to apply.

4. Summary of Test Method

4.1 Employing a measuring chamber with a built-in piston, 6.1.2 The pressure transducer shall have a minimum opera-

a sample of known volume is drawn into the temperature

tional range from 0kPa to 200kPa (0psi to 29psi) with a

controlled chamber at 20°C or higher. After sealing the minimum resolution of 0.1kPa (0.01psi) and a minimum

chamber, the temperature of the chamber is increased to a

accuracy of 60.2kPa (60.03psi). The pressure measurement

specified value simultaneously with the first expansion. Two

systemshallincludeassociatedelectronicsandreadoutdevices

further expansions are performed to a final volume of (X+1)

to display the resulting pressure reading.

times that of the test specimen.After each expansion, the TP

X

6.1.3 Electronic temperature control shall be used to main-

isdetermined.ThePPAandthesolubilityofairinthespecimen

tain the measuring chamber at the prescribed temperature

are calculated from the three resulting pressures. The (VP )is

X

within 60.1°Cforthedurationofthevaporpressuremeasure-

calculated by subtracting the PPA in the liquid from TP .

X

ment.

NOTE 2—For liquids containing very low levels of high vapor pressure

6.1.4 A platinum resistance thermometer shall be used for

contaminants, which behave like a gas, this test method of determination

of the PPAand gases may lead to wrong results since the partial pressure measuring the temperature of the measuring chamber. The

ofthecontaminantswillbeincludedinthePPA.Thiseffectisshownwhen

minimum temperature range of the measuring device shall be

the value of the PPA and gases exceeds the average maximum limit of

from 0°C to 100°C with a resolution of 0.1°C and an

7kPa (1psi).

accuracy of 60.1°C.

5. Significance and Use

6.1.5 Thevaporpressureapparatusshallhaveprovisionsfor

5.1 Vapor pressure is a very important physical property of

rinsing the measuring chamber with a solvent of low vapor

volatile liquids for shipping and storage.

pressure or with the next sample to be tested.

5.2 The vapor pressure of gasoline and gasoline-oxygenate

6.2 Vacuum Pump for Calibration, capable of reducing the

blends is regulated by various government agencies.

pressure in the measuring chamber to less than 0.01kPa

5.3 Specifications for volatile petroleum products generally

(0.001psi) absolute.

include vapor pressure limits to ensure products of suitable

6.3 McLeod Vacuum Gauge or Calibrated Electronic

volatility performance.

Vacuum Measuring Device for Calibration,tocoveratleastthe

5.4 In this test method, an air saturation procedure prior to

range from 0.01kPa to 0.67kPa (0.1mm to 5mm Hg). The

the measurement is not required, thus eliminating losses of

calibration of the electronic vacuum measuring device shall be

high volatile compounds during this step. This test method is

regularly verified in accordance with Annex A6.3 on Vacuum

faster and minimizes potential errors from improper air satu-

Sensors in Test Method D2892.

ration. This test method permits VP determinations in the

X

6.4 Pressure Measuring Device for Calibration, capable of

field.

measuring local station pressure with an accuracy and a

5.5 Thistestmethodcanbeappliedinonlineapplicationsin

resolution of 0.1kPa (1mm Hg), or better, at the same

which an air saturation procedure prior to the measurement

elevationrelativetosealevelastheapparatusinthelaboratory.

cannot be performed.

NOTE 4—This test method does not give full details of instruments

6. Apparatus

suitableforcarryingoutthistest.Detailsontheinstallation,operation,and

6.1 The apparatus suitable for this test method employs a

maintenance of each instrument may be found in the manufacturer’s

small volume, cylindrically shaped measuring chamber with manual.

D6378 − 10 (2016)

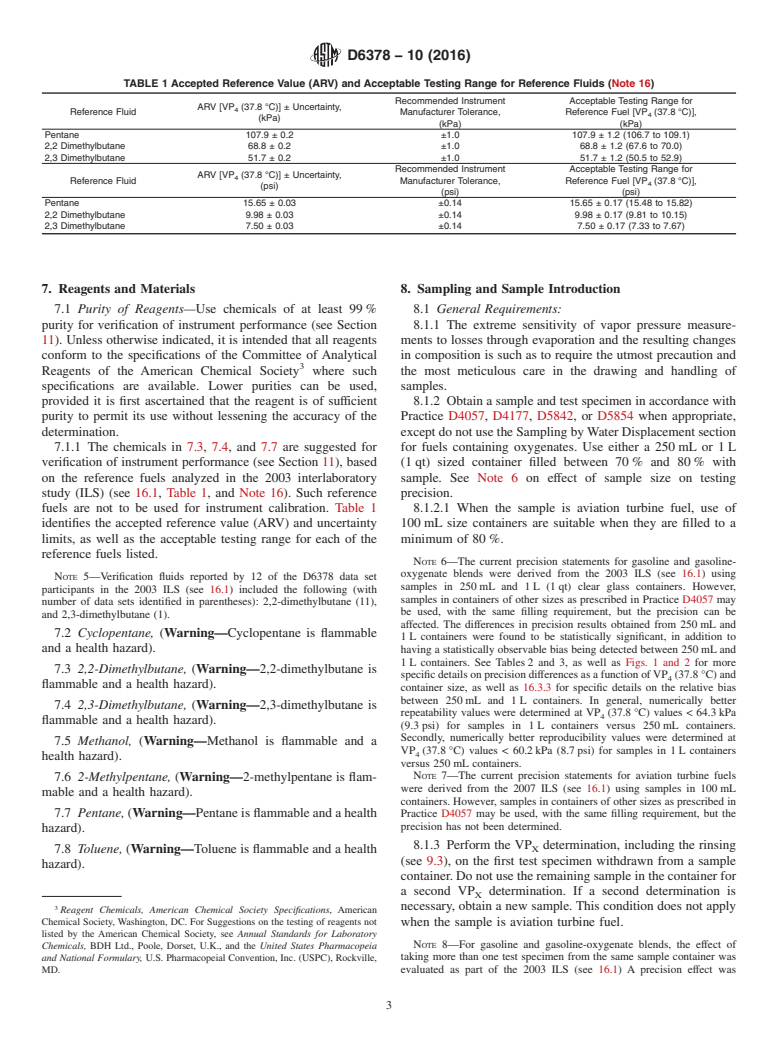

TABLE 1 Accepted Reference Value (ARV) and Acceptable Testing Range for Reference Fluids (Note 16)

Recommended Instrument Acceptable Testing Range for

ARV [VP (37.8 °C)] ± Uncertainty,

Reference Fluid Manufacturer Tolerance, Reference Fuel [VP (37.8 °C)],

(kPa)

(kPa) (kPa)

Pentane 107.9 ± 0.2 ±1.0 107.9 ± 1.2 (106.7 to 109.1)

2,2 Dimethylbutane 68.8 ± 0.2 ±1.0 68.8 ± 1.2 (67.6 to 70.0)

2,3 Dimethylbutane 51.7 ± 0.2 ±1.0 51.7 ± 1.2 (50.5 to 52.9)

Recommended Instrument Acceptable Testing Range for

ARV [VP (37.8 °C)] ± Uncertainty,

(37.8 °C)],

Reference Fluid Manufacturer Tolerance, Reference Fuel [VP

(psi)

(psi) (psi)

Pentane 15.65 ± 0.03 ±0.14 15.65 ± 0.17 (15.48 to 15.82)

2,2 Dimethylbutane 9.98 ± 0.03 ±0.14 9.98 ± 0.17 (9.81 to 10.15)

2,3 Dimethylbutane 7.50 ± 0.03 ±0.14 7.50 ± 0.17 (7.33 to 7.67)

7. Reagents and Materials 8. Sampling and Sample Introduction

7.1 Purity of Reagents—Use chemicals of at least 99% 8.1 General Requirements:

purity for verification of instrument performance (see Section 8.1.1 The extreme sensitivity of vapor pressure measure-

11). Unless otherwise indicated, it is intended that all reagents ments to losses through evaporation and the resulting changes

conform to the specifications of the Committee of Analytical in composition is such as to require the utmost precaution and

Reagents of the American Chemical Society where such the most meticulous care in the drawing and handling of

specifications are available. Lower purities can be used, samples.

provided it is first ascertained that the reagent is of sufficient 8.1.2 Obtainasampleandtestspecimeninaccordancewith

purity to permit its use without lessening the accuracy of the Practice D4057, D4177, D5842,or D5854 when appropriate,

determination. exceptdonotusetheSamplingbyWaterDisplacementsection

7.1.1 The chemicals in 7.3, 7.4, and 7.7 are suggested for for fuels containing oxygenates. Use either a 250mL or 1L

verification of instrument performance (see Section 11), based (1qt) sized container filled between 70% and 80% with

on the reference fuels analyzed in the 2003 interlaboratory sample. See Note 6 on effect of sample size on testing

study (ILS) (see 16.1, Table 1, and Note 16). Such reference precision.

fuels are not to be used for instrument calibration. Table 1 8.1.2.1 When the sample is aviation turbine fuel, use of

identifies the accepted reference value (ARV) and uncertainty 100mL size containers are suitable when they are filled to a

limits, as well as the acceptable testing range for each of the minimum of 80%.

reference fuels listed.

NOTE 6—The current precision statements for gasoline and gasoline-

oxygenate blends were derived from the 2003 ILS (see 16.1) using

NOTE 5—Verification fluids reported by 12 of the D6378 data set

samples in 250mL and 1L (1qt) clear glass containers. However,

participants in the 2003 ILS (see 16.1) included the following (with

samples in containers of other sizes as prescribed in Practice D4057 may

number of data sets identified in parentheses): 2,2-dimethylbutane (11),

be used, with the same filling requirement, but the precision can be

and 2,3-dimethylbutane (1).

affected. The differences in precision results obtained from 250mL and

7.2 Cyclopentane, (Warning—Cyclopentane is flammable

1L containers were found to be statistically significant, in addition to

and a health hazard).

having a statistically observable bias being detected between 250mLand

1L containers. See Tables2 and 3, as well as Figs. 1 and 2 for more

7.3 2,2-Dimethylbutane, (Warning—2,2-dimethylbutane is

specificdetailsonprecisiondifferencesasafunctionofVP (37.8°C)and

flammable and a health hazard).

container size, as well as 16.3.3 for specific details on the relative bias

between 250mL and 1L containers. In general, numerically better

7.4 2,3-Dimethylbutane, (Warning—2,3-dimethylbutane is

repeatability values were determined at VP (37.8°C) values < 64.3kPa

flammable and a health hazard).

(9.3psi) for samples in 1L containers versus 250mL containers.

Secondly, numerically better reproducibility values were determined at

7.5 Methanol, (Warning—Methanol is flammable and a

VP (37.8°C) values < 60.2kPa (8.7psi) for samples in 1L containers

health hazard).

versus 250mL containers.

NOTE 7—The curren

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6378 − 10 D6378 − 10 (Reapproved 2016)

Standard Test Method for

Determination of Vapor Pressure (VP ) of Petroleum

X

Products, Hydrocarbons, and Hydrocarbon-Oxygenate

Mixtures (Triple Expansion Method)

This standard is issued under the fixed designation D6378; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*Scope

1.1 This test method covers the use of automated vapor pressure instruments to determine the vapor pressure exerted in vacuum

by volatile, liquid petroleum products, hydrocarbons, and hydrocarbon-oxygenate mixtures. This test method is suitable for testing

samples with boiling points above 0°C (32°F)0 °C (32 °F) that exert a vapor pressure between 7 and 150 kPa (1.0 and 21 psi) at

37.8°C (100°F)7 kPa and 150 kPa (1.0 psi and 21 psi) at 37.8 °C (100 °F) at a vapor-to-liquid ratio of 4:1. The liquid sample

volume size required for analysis is dependent upon the vapor-to-liquid ratio chosen (see Note 1) and the measuring chamber

volume capacity of the instrument (see 6.1.1 and Note 3).

NOTE 1—The test method is suitable for the determination of the vapor pressure of volatile, liquid petroleum products at temperatures from 00 °C to

100°C100 °C at vapor to liquid ratios of 4:1 to 1:1 (X = 4 to 1) and pressures up to 500 kPa (70 psi), 500 kPa (70 psi), but the precision statement (see

Section 16) may not be applicable.

1.2 This test method also covers the use of automated vapor pressure instruments to determine the vapor pressure exerted in

vacuum by aviation turbine fuels. This test method is suitable for testing aviation turbine fuel samples with boiling points above

0°C (32°F)0 °C (32 °F) that exert a vapor pressure between 0 and 110 kPa (0 and 15.5 psi) 0 kPa and 110 kPa (0 psi and 15.5 psi)

at a vapor-to-liquid ratio of 4:1, in the temperature range from 2525 °C to 100°C (77100 °C (77 °F to 212°F).212 °F).

1.3 The vapor pressure (VP ) determined by this test method at a vapor-liquid ratio of 4:1 (X = 4) of gasoline and

X

gasoline-oxygenate blends at 37.8°C37.8 °C can be correlated to the dry vapor pressure equivalent (DVPE) value determined by

Test Method D5191 (see 16.3). This condition does not apply when the sample is aviation turbine fuel.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific warning statements, see 7.2 – 7.8.

2. Referenced Documents

2.1 ASTM Standards:

D323 Test Method for Vapor Pressure of Petroleum Products (Reid Method)

D2892 Test Method for Distillation of Crude Petroleum (15-Theoretical Plate Column)

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4177 Practice for Automatic Sampling of Petroleum and Petroleum Products

D4953 Test Method for Vapor Pressure of Gasoline and Gasoline-Oxygenate Blends (Dry Method)

D5191 Test Method for Vapor Pressure of Petroleum Products (Mini Method)

D5842 Practice for Sampling and Handling of Fuels for Volatility Measurement

D5854 Practice for Mixing and Handling of Liquid Samples of Petroleum and Petroleum Products

D6299 Practice for Applying Statistical Quality Assurance and Control Charting Techniques to Evaluate Analytical Measure-

ment System Performance

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.08 on Volatility.

Current edition approved Oct. 1, 2010Oct. 1, 2016. Published November 2010November 2016. Originally approved in 1999. Last previous edition approved in 20082010

as D6378D6378 – 10–08. DOI: 10.1520/D6378-10.10.1520/D6378-10R16.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6378 − 10 (2016)

D6300 Practice for Determination of Precision and Bias Data for Use in Test Methods for Petroleum Products and Lubricants

D6708 Practice for Statistical Assessment and Improvement of Expected Agreement Between Two Test Methods that Purport

to Measure the Same Property of a Material

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 dry vapor pressure equivalent (DVPE)—a value calculated by a correlation equation from the total pressure (Test Method

D5191), which is equivalent to the value obtained on the sample by Test Method D4953, Procedure A.

3.1.2 partial pressure from dissolved air (PPA), n—the pressure exerted in vacuum from dissolved air that escapes from the

liquid phase into the vapor phase.

3.1.3 Reid vapor pressure equivalent (RVPE)—a value calculated by a correlation equation from the TP , which is equivalent

X

to the value obtained on the sample by Test Method D323.

3.1.4 total pressure (TP ),n—the pressure exerted in vacuum by air- and gas-containing petroleum products, components and

X

feedstocks, and other liquids, in the absence of undissolved water at a vapor-liquid ratio of X:1.

3.1.5 vapor pressure (VP ),n—the total pressure minus the PPA in the liquid at a vapor-liquid ratio of X:1.

X

VP 5 TP 2 PPA (1)

X X

4. Summary of Test Method

4.1 Employing a measuring chamber with a built-in piston, a sample of known volume is drawn into the temperature controlled

chamber at 20°C20 °C or higher. After sealing the chamber, the temperature of the chamber is increased to a specified value

simultaneously with the first expansion. Two further expansions are performed to a final volume of (X+1) times that of the test

specimen. After each expansion, the TP is determined. The PPA and the solubility of air in the specimen are calculated from the

X

three resulting pressures. The (VP ) is calculated by subtracting the PPA in the liquid from TP .

X X

NOTE 2—For liquids containing very low levels of high vapor pressure contaminants, which behave like a gas, this test method of determination of

the PPA and gases may lead to wrong results since the partial pressure of the contaminants will be included in the PPA. This effect is shown when the

value of the PPA and gases exceeds the average maximum limit of 7 kPa (1 psi).(1 psi).

5. Significance and Use

5.1 Vapor pressure is a very important physical property of volatile liquids for shipping and storage.

5.2 The vapor pressure of gasoline and gasoline-oxygenate blends is regulated by various government agencies.

5.3 Specifications for volatile petroleum products generally include vapor pressure limits to ensure products of suitable

volatility performance.

5.4 In this test method, an air saturation procedure prior to the measurement is not required, thus eliminating losses of high

volatile compounds during this step. This test method is faster and minimizes potential errors from improper air saturation. This

test method permits VP determinations in the field.

X

5.5 This test method can be applied in online applications in which an air saturation procedure prior to the measurement cannot

be performed.

6. Apparatus

6.1 The apparatus suitable for this test method employs a small volume, cylindrically shaped measuring chamber with

associated equipment to control the chamber temperature within the range from 00 °C to 100°C.100 °C. The measuring chamber

shall contain a movable piston with a maximum dead volume of less than 1 % of the total volume at the lowest position to allow

sample introduction into the measuring chamber and expansion to the desired vapor-liquid ratio. A static pressure transducer shall

be incorporated in the piston. The measuring chamber shall contain an inlet/outlet valve combination for sample introduction and

expulsion. The piston and the valve combination shall be at the same temperature as the measuring chamber to avoid any

condensation or excessive evaporation.

6.1.1 The measuring chamber shall be designed to contain between 55 mL and 15 mL 15 mL of liquid and vapor and be capable

of maintaining a vapor-liquid ratio of 4:1 to 1:1. The accuracy of the adjusted vapor-liquid ratio shall be within 0.05.

NOTE 3—The measuring chamber employed by the instruments used in generating the precision and bias statements were constructed of nickel plated

aluminum and stainless steel with a total volume of 5 mL. 5 mL. Measuring chambers exceeding a 5-mL5 mL capacity can be used, but the precision

and bias statements (see Section 16) are not known to apply.

6.1.2 The pressure transducer shall have a minimum operational range from 0 to 200 kPa (0 to 29 psi) 0 kPa to 200 kPa (0 psi

to 29 psi) with a minimum resolution of 0.1 kPa (0.01 psi) 0.1 kPa (0.01 psi) and a minimum accuracy of 60.2 kPa (60.03 psi).

60.2 kPa (60.03 psi). The pressure measurement system shall include associated electronics and readout devices to display the

resulting pressure reading.

D6378 − 10 (2016)

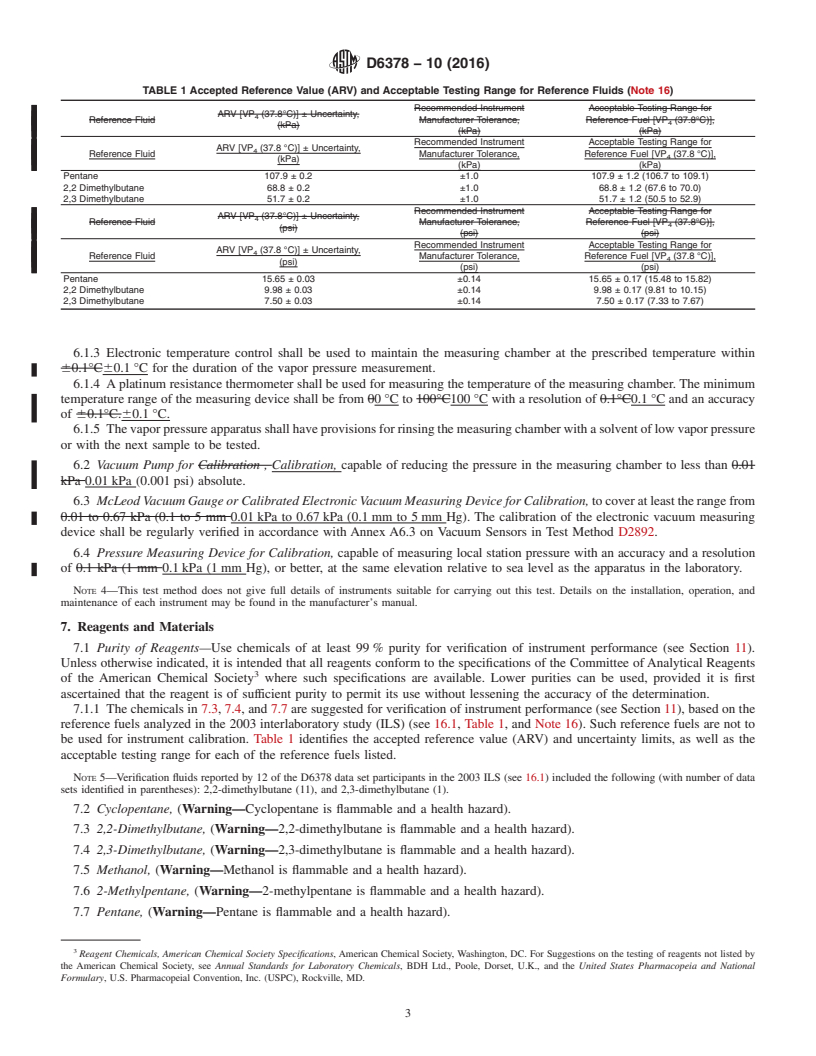

TABLE 1 Accepted Reference Value (ARV) and Acceptable Testing Range for Reference Fluids (Note 16)

Recommended Instrument Acceptable Testing Range for

ARV [VP (37.8°C)] ± Uncertainty,

Reference Fluid Manufacturer Tolerance, Reference Fuel [VP (37.8°C)],

(kPa)

(kPa) (kPa)

Recommended Instrument Acceptable Testing Range for

ARV [VP (37.8 °C)] ± Uncertainty,

Reference Fluid Manufacturer Tolerance, Reference Fuel [VP (37.8 °C)],

(kPa)

(kPa) (kPa)

Pentane 107.9 ± 0.2 ±1.0 107.9 ± 1.2 (106.7 to 109.1)

2,2 Dimethylbutane 68.8 ± 0.2 ±1.0 68.8 ± 1.2 (67.6 to 70.0)

2,3 Dimethylbutane 51.7 ± 0.2 ±1.0 51.7 ± 1.2 (50.5 to 52.9)

Recommended Instrument Acceptable Testing Range for

ARV [VP (37.8°C)] ± Uncertainty,

Reference Fluid Manufacturer Tolerance, Reference Fuel [VP (37.8°C)],

(psi)

(psi) (psi)

Recommended Instrument Acceptable Testing Range for

ARV [VP (37.8 °C)] ± Uncertainty,

Reference Fluid Manufacturer Tolerance, Reference Fuel [VP (37.8 °C)],

(psi)

(psi) (psi)

Pentane 15.65 ± 0.03 ±0.14 15.65 ± 0.17 (15.48 to 15.82)

2,2 Dimethylbutane 9.98 ± 0.03 ±0.14 9.98 ± 0.17 (9.81 to 10.15)

2,3 Dimethylbutane 7.50 ± 0.03 ±0.14 7.50 ± 0.17 (7.33 to 7.67)

6.1.3 Electronic temperature control shall be used to maintain the measuring chamber at the prescribed temperature within

60.1°C60.1 °C for the duration of the vapor pressure measurement.

6.1.4 A platinum resistance thermometer shall be used for measuring the temperature of the measuring chamber. The minimum

temperature range of the measuring device shall be from 00 °C to 100°C100 °C with a resolution of 0.1°C0.1 °C and an accuracy

of 60.1°C.60.1 °C.

6.1.5 The vapor pressure apparatus shall have provisions for rinsing the measuring chamber with a solvent of low vapor pressure

or with the next sample to be tested.

6.2 Vacuum Pump for Calibration , Calibration, capable of reducing the pressure in the measuring chamber to less than 0.01

kPa 0.01 kPa (0.001 psi) absolute.

6.3 McLeod Vacuum Gauge or Calibrated Electronic Vacuum Measuring Device for Calibration, to cover at least the range from

0.01 to 0.67 kPa (0.1 to 5 mm 0.01 kPa to 0.67 kPa (0.1 mm to 5 mm Hg). The calibration of the electronic vacuum measuring

device shall be regularly verified in accordance with Annex A6.3 on Vacuum Sensors in Test Method D2892.

6.4 Pressure Measuring Device for Calibration, capable of measuring local station pressure with an accuracy and a resolution

of 0.1 kPa (1 mm 0.1 kPa (1 mm Hg), or better, at the same elevation relative to sea level as the apparatus in the laboratory.

NOTE 4—This test method does not give full details of instruments suitable for carrying out this test. Details on the installation, operation, and

maintenance of each instrument may be found in the manufacturer’s manual.

7. Reagents and Materials

7.1 Purity of Reagents—Use chemicals of at least 99 % purity for verification of instrument performance (see Section 11).

Unless otherwise indicated, it is intended that all reagents conform to the specifications of the Committee of Analytical Reagents

of the American Chemical Society where such specifications are available. Lower purities can be used, provided it is first

ascertained that the reagent is of sufficient purity to permit its use without lessening the accuracy of the determination.

7.1.1 The chemicals in 7.3, 7.4, and 7.7 are suggested for verification of instrument performance (see Section 11), based on the

reference fuels analyzed in the 2003 interlaboratory study (ILS) (see 16.1, Table 1, and Note 16). Such reference fuels are not to

be used for instrument calibration. Table 1 identifies the accepted reference value (ARV) and uncertainty limits, as well as the

acceptable testing range for each of the reference fuels listed.

NOTE 5—Verification fluids reported by 12 of the D6378 data set participants in the 2003 ILS (see 16.1) included the following (with number of data

sets identified in parentheses): 2,2-dimethylbutane (11), and 2,3-dimethylbutane (1).

7.2 Cyclopentane, (Warning—Cyclopentane is flammable and a health hazard).

7.3 2,2-Dimethylbutane, (Warning—2,2-dimethylbutane is flammable and a health hazard).

7.4 2,3-Dimethylbutane, (Warning—2,3-dimethylbutane is flammable and a health hazard).

7.5 Methanol, (Warning—Methanol is flammable and a health hazard).

7.6 2-Methylpentane, (Warning—2-methylpentane is flammable and a health hazard).

7.7 Pentane, (Warning—Pentane is flammable and a health hazard).

Reagent Chemicals, American Chemical Society Specifications, American Chemical Society, Washington, DC. For Suggestions on the testing of reagents not listed by

the American Chemical Society, see Annual Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia and National

Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, MD.

D6378

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.