ASTM D6791-22

(Test Method)Standard Test Method for Determination of Grain Stability of Calcined Petroleum Coke

Standard Test Method for Determination of Grain Stability of Calcined Petroleum Coke

SIGNIFICANCE AND USE

5.1 The grain stability of calcined petroleum coke determines the resistance to breakdown of + 4 mm particles used in the manufacture of carbon anodes for use in the reduction process of aluminum.

5.2 Calcined petroleum cokes have to be relatively easy to grind for fines production but strong enough to withstand forming pressures and thermal stresses occurring when the anodes are used in the reduction process.

SCOPE

1.1 This test method covers a laboratory vibration mill method for the determination of the grain stability of calcined petroleum coke for the manufacture of carbon products used in the smelting of aluminum. Calcined petroleum coke with poor mechanical strength may become degraded during mixing. Poor grain stability will affect the grain size and may result in poor quality of baked blocks.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6791 − 22

Standard Test Method for

Determination of Grain Stability of Calcined Petroleum

1

Coke

This standard is issued under the fixed designation D6791; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D6970Practice for Collection of Calcined Petroleum Coke

Samples for Analysis

1.1 This test method covers a laboratory vibration mill

E11Specification forWovenWireTest Sieve Cloth andTest

method for the determination of the grain stability of calcined

Sieves

petroleumcokeforthemanufactureofcarbonproductsusedin

3

the smelting of aluminum. Calcined petroleum coke with poor 2.2 ISO Standard:

mechanical strength may become degraded during mixing. ISO 6375Carbonaceous Materials for the Production of

Poor grain stability will affect the grain size and may result in Aluminum—Coke for Electrodes—Sampling

poor quality of baked blocks.

3. Terminology

1.2 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

3.1 Definitions:

standard.

3.1.1 calcined petroleum coke, n—petroleum coke that has

been thermally treated to drive off the volatile matter and to

1.3 This standard does not purport to address all of the

develop crystalline structure.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.1.2 petroleum coke, n—solid, carbonaceous residue pro-

priate safety, health, and environmental practices and deter-

duced by thermal decomposition of heavy petroleum fractions,

mine the applicability of regulatory limitations prior to use.

or cracked stocks, or both.

1.4 This international standard was developed in accor-

dance with internationally recognized principles on standard-

4. Summary of Test Method

ization established in the Decision on Principles for the

4.1 A representative sample of calcined petroleum coke is

Development of International Standards, Guides and Recom-

dried and screened to a 4mm to 8mm fraction. The resultant

mendations issued by the World Trade Organization Technical

sample is weighed so that two separate portions of 100.0g 6

Barriers to Trade (TBT) Committee.

0.5g mass are obtained. The samples are place into the

2. Referenced Documents laboratorymillandgroundforaspecifiedperiodoftime.After

2 grinding the sample is screened and the mass of the + 4mm

2.1 ASTM Standards:

material is determined. The grain stability is the percent of the

D346Practice for Collection and Preparation of Coke

original material remaining on the + 4mm sieve.

Samples for Laboratory Analysis

D2013Practice for Preparing Coal Samples for Analysis

5. Significance and Use

D2234/D2234MPractice for Collection of a Gross Sample

of Coal

5.1 The grain stability of calcined petroleum coke deter-

D6969Practice for Preparation of Calcined Petroleum Coke

mines the resistance to breakdown of + 4mm particles used in

Samples for Analysis

the manufacture of carbon anodes for use in the reduction

process of aluminum.

1

5.2 Calcined petroleum cokes have to be relatively easy to

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

grind for fines production but strong enough to withstand

SubcommitteeD02.05onPropertiesofFuels,PetroleumCokeandCarbonMaterial.

forming pressures and thermal stresses occurring when the

Current edition approved May 1, 2022. Published May 2022. Originally

ɛ1 anodes are used in the reduction process.

approved in 2002. Last previous edition approved in 2017 as D6791–11 (2017) .

DOI: 10.1520/D6791-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

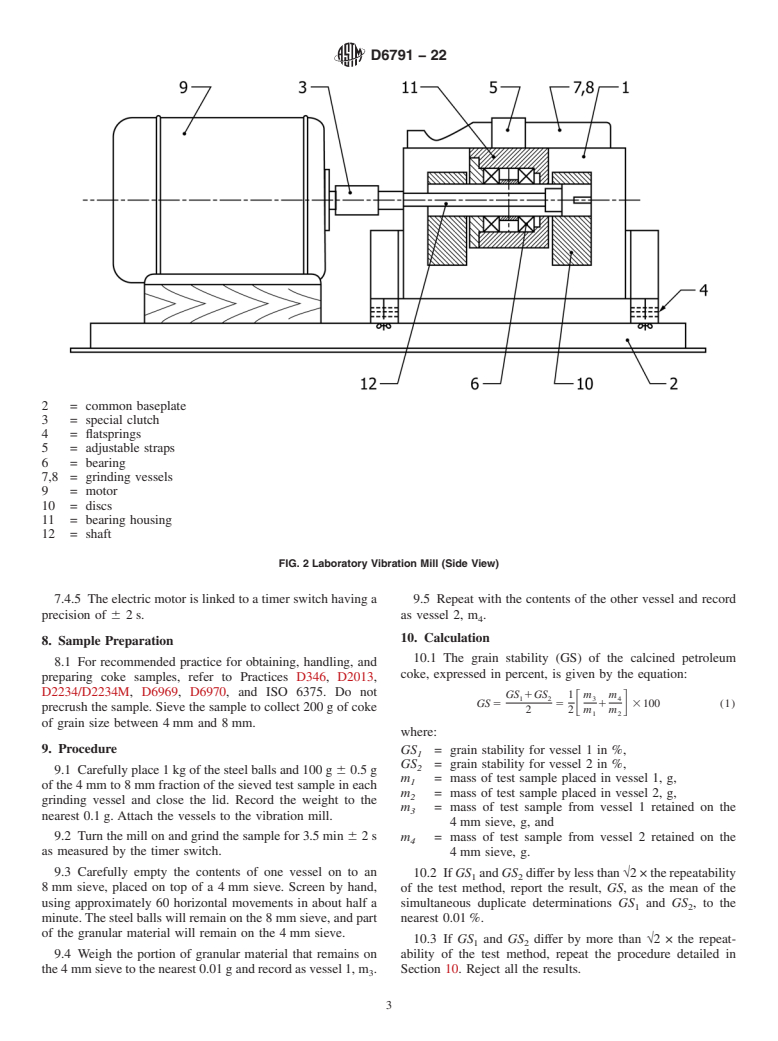

D6791 − 22

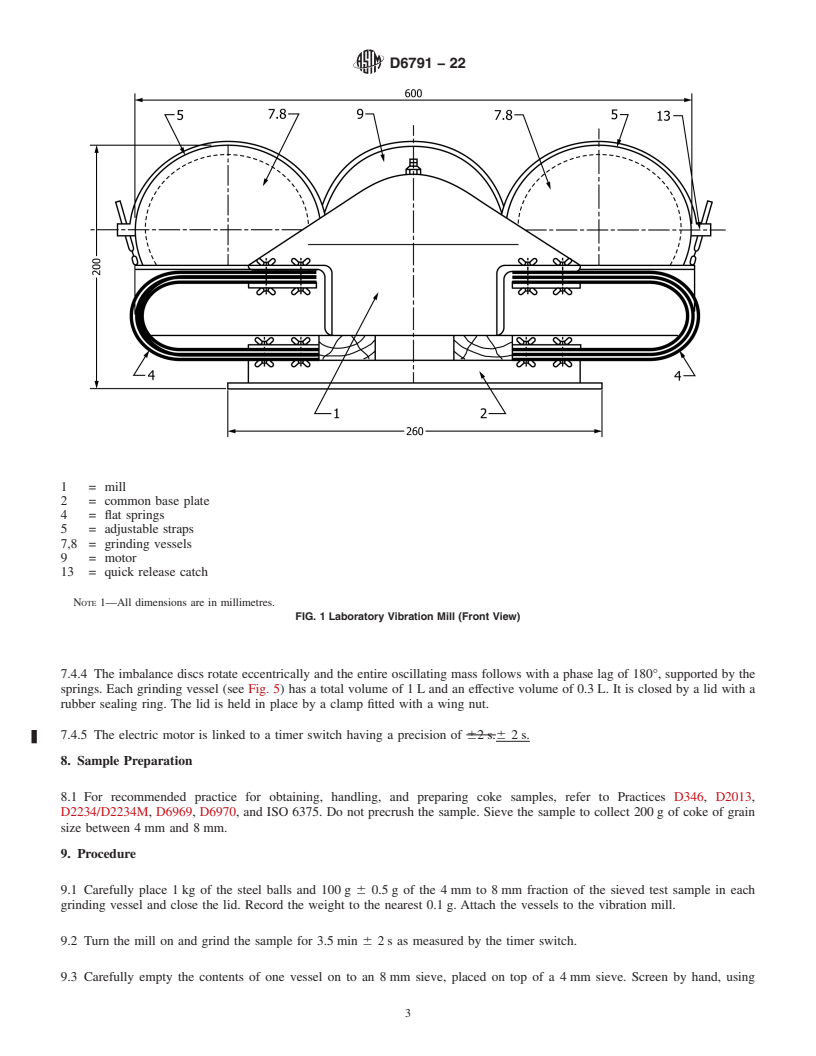

1 = mill

2 = common base plate

4 = flat springs

5 = adjustable straps

7,8 = grinding vessels

9 = motor

13 = quick release catch

NOTE 1—All dimensions are in millimetres.

FIG. 1 Laboratory Vibration Mill (Fron

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D6791 − 11 (Reapproved 2017) D6791 − 22

Standard Test Method for

Determination of Grain Stability of Calcined Petroleum

1

Coke

This standard is issued under the fixed designation D6791; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Units formatting was corrected editorially in February 2017.

1. Scope Scope*

1.1 This test method covers a laboratory vibration mill method for the determination of the grain stability of calcined petroleum

coke for the manufacture of carbon products used in the smelting of aluminum. Calcined petroleum coke with poor mechanical

strength may become degraded during mixing. Poor grain stability will affect the grain size and may result in poor quality of baked

blocks.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D346 Practice for Collection and Preparation of Coke Samples for Laboratory Analysis

D2013 Practice for Preparing Coal Samples for Analysis

D2234/D2234M Practice for Collection of a Gross Sample of Coal

D6969 Practice for Preparation of Calcined Petroleum Coke Samples for Analysis

D6970 Practice for Collection of Calcined Petroleum Coke Samples for Analysis

E11 Specification for Woven Wire Test Sieve Cloth and Test Sieves

3

2.2 ISO Standard:

ISO 6375 Carbonaceous Materials for the Production of Aluminum—Coke for Electrodes—Sampling

3. Terminology

3.1 Definitions:

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.05 on Properties of Fuels, Petroleum Coke and Carbon Material.

Current edition approved Jan. 1, 2017May 1, 2022. Published February 2017May 2022. Originally approved in 2002. Last previous edition approved in 20112017 as

ɛ1

D6791 – 11.D6791 – 11 (2017) . DOI: 10.1520/D6791-11R17E01.10.1520/D6791-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6791 − 22

3.1.1 calcined petroleum coke, n—petroleum coke that has been thermally treated to drive off the volatile matter and to develop

crystalline structure.

3.1.2 petroleum coke, n—solid, carbonaceous residue produced by thermal decomposition of heavy petroleum fractions, or

cracked stocks, or both.

4. Summary of Test Method

4.1 A representative sample of calcined petroleum coke is dried and screened to a 4 mm to 8 mm fraction. The resultant sample

is weighed so that two separate portions of 100.0 g 6 0.5 g mass are obtained. The samples are place into the laboratory mill and

ground for a specified period of time. After grinding the sample is screened and the mass of the +4 mm + 4 mm material is

determined. The grain stability is the percent of the original material remaining on the +4 mm + 4 mm sieve.

5. Significance and Use

5.1 The grain stability of calcined petroleum coke determines the resistance to breakdown of +4 mm + 4 mm particles used in the

manufacture of carbon anodes for use in the reduction process of aluminum.

5.2 Calcined petroleum cokes have to be relatively easy to g

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.