ASTM D483-00

(Test Method)Standard Test Method for Unsulfonated Residue of Petroleum Plant Spray Oils

Standard Test Method for Unsulfonated Residue of Petroleum Plant Spray Oils

SCOPE

1.1 This test method covers the determination of unsulfonated residue in plant spray oils of petroleum origin and applies only to the petroleum oil content. It provides a measure of the degree of refinement of plant spray oils by determining the extent to which the oil is attacked by 98.61% sulfuric acid under closely standardized conditions. Since the relationship between unsulfonated residue and the actual composition of the oil is not known, this test method should be applied only for measuring the degree of refinement and not for the determination of aromatics or olefins, or both.

1.2 The values stated in inch-pound units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D483–00

Standard Test Method for

Unsulfonated Residue of Petroleum Plant Spray Oils

This standard is issued under the fixed designation D 483; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers the determination of unsul- 3.1 Definition:

fonated residue in plant spray oils of petroleum origin and 3.1.1 unsulfonated residue, n— in oils, that portion of an oil

applies only to the petroleum oil content. It provides a measure remaining unsulfonated after treatment with concentrated sul-

of the degree of refinement of plant spray oils by determining furic acid.

the extent to which the oil is attacked by 98.61 % sulfuric acid

4. Summary of Test Method

under closely standardized conditions. Since the relationship

betweenunsulfonatedresidueandtheactualcompositionofthe 4.1 A measured volume of sample is shaken with 98.61 %

sulfuric acid at 100°C in a Babcock bottle, shaking mechani-

oil is not known, this test method should be applied only for

measuring the degree of refinement and not for the determina- cally for 10 s at 10-min intervals. The volume not absorbed by

the acid is a measure of the unsulfonated residue in the sample.

tion of aromatics or olefins, or both.

1.2 The values stated in SI units are to be regarded as the

5. Significance and Use

standard.

5.1 This test method is useful for distinguishing between

1.3 This standard does not purport to address all of the

oils that are adaptable to various types of spraying application,

safety concerns, if any, associated with its use. It is the

with a higher unsulfonated oil being required for leaf spraying

responsibility of the user of this standard to establish appro-

as compared to dormant vegetation application.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

6. Apparatus

2. Referenced Documents

6.1 Sulfonation Flask—The flask is shown in Fig.A1.1 and

described in Annex A1.

2.1 ASTM Standards:

6.2 Meniscus Viewing Lens, focusing type, consisting of

D 1193 Specification for Reagent Water

eyepiece and objective to facilitate reading the meniscus with

D 1250 Guide for Petroleum Measurement Tables

a minimum of parallax, is recommended.

D 1298 Test Method for Density, Relative Density (Specific

6.3 Water Baths— Two water baths maintained at 25 6

Gravity), or API Gravity of Crude Petroleum and Liquid

0.5°C and 99.5 to 100°C, and conforming to the requirements

Petroleum Products by Hydrometer Method

prescribed in Annex A1.

D 4052 Test Method for Density and Relative Density of

6.4 Shaking Machine— The exact design described in the

Liquids by Digital Density Meter

appendix is required for uniform control of shaking and

D 4057 Practice for Manual Sampling of Petroleum and

precision results. Hand shaking is permissible if technique is

Petroleum Products

developed to correlate results by machine shaking.

D 4177 Practice for Automatic Sampling of Petroleum and

6.5 Centrifuge—A centrifuge as described in Annex A1 is

Petroleum Products

recommended.

7. Reagents

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricantsand is the direct responsibility of Subcommittee

7.1 Purity of Reagents—Reagent grade chemicals shall be

D02.06on Analysis of Lubricants.

used in all tests. Unless otherwise indicated, it is intended that

Current edition approved Dec. 10, 2000. Published January 2001. Originally

published as D 483 – 61 T. Last previous edition D 483 – 97.

all reagents shall conform to the specifications of the Commit-

Annual Book of ASTM Standards, Vol 11.01.

tee onAnalytical Reagents of theAmerican Chemical Society,

Annual Book of ASTM Standards, Vol 05.01.

Annual Book of ASTM Standards, Vol 05.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

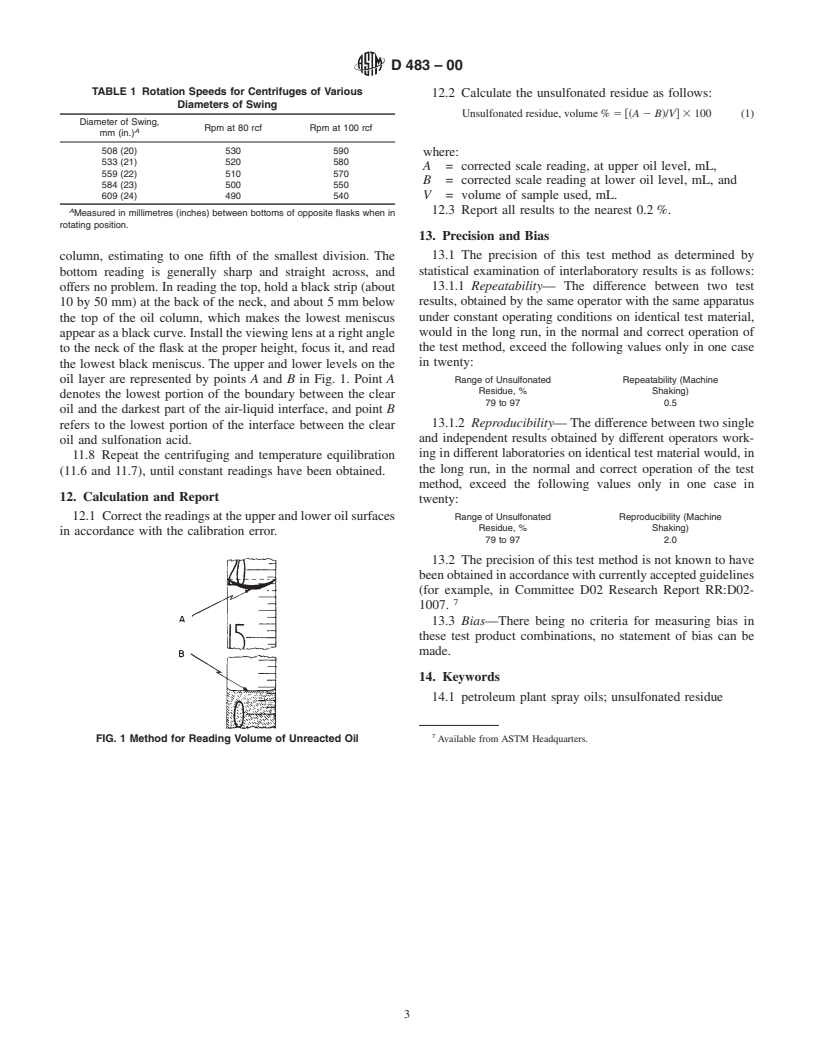

D483–00

where such specifications are available. Other grades may be test. Adjust the shaker rate and check it before and after each

used, provided it is first ascertained that the reagent is of test to make sure that the rate does not deviate more than 610

sufficiently high purity to permit its use without lessening the cycles/min from the rate established by calibration.

accuracy of the determination. (Warning—When hand shaking, protect the face with a safety

7.2 Fuming Sulfuric Acid (approximately 15 % free mask and point the Babcock bottle away from other personnel.

SO ).Warning—See Notes 1 and 2. Protect hands by wearing suitable safety gloves.)

7.3 Sulfuric Acid (98.61 %)—Prepare (Warning—

NOTE 1—If hand shaking is used, shake the sulfonation flask by

Corrosive. Health hazard. Oxidizer.) (Warning—While pre-

grasping the neck between the thumb and index finger and swinging the

paring the reagent, protect the face with a safety mask and

flask through an arc of approximately 20° so that the bottom of the flask

placetheflaskinatray.)byblendingreagent-gradefumingand passes through a distance of 64 to 89 mm (2.5 to 3.5 in.). Shake at the rate

established by calibration within a tolerance of 610 cycles/min.

concentratedsulfuricacidstoaconcentrationof98.61 60.1 %

H SO as determined by titration.

2 4 11.2 Using Test Methods D 1298 or D 4052, determine the

7.4 Sulfuric Acid (sp gr 1.84, approximately 95 %)—

density at 25°C in grams per millilitre by means of data

Concentrated sulfuric acid (H SO ). (Warning—Corrosive.

2 4 obtained from Vol VIII and Vol XI/XII of the Petroleum

Health hazard. Oxidizer.).

Measurement Tables. (See Guide D 1250.)

11.3 Weigh into a clean, dry sulfonation flask the equivalent

8. Reference Spray Oil

of 4.9 to 5.1 mL of the sample at 25°C, weighed to the nearest

8.1 Test results for unsulfonated residue are highly depen-

0.005 g, adding the oil to the flask by pipet, and taking care to

dent upon rate of shaking. A reference spray oil has been

deposit as little oil as possible on the neck of the flask. From

calibrated for unsulfonated residue by a group of cooperating

the weight of the sample, calculate its volume at 25°C.

laboratories using both machine and hand shaking. Instructions

11.4 Slowly introduce 20 6 0.5 mL of H SO (98.61 %)

2 4

are given in Section 8 for using this reference oil as a guide to

into the flask in such a way that oil adhering to the neck of the

ensure that the rate of shaking is correct.

flask will be washed down.Transfer the flask to the carrier, and

suspend the carrier in the boiling water bath, with the flask

9. Calibration

immersed to a point between the 0 and 10 marks, noting the

9.1 Machine Shaking Rate—A rate of 425 cycles/min was

time when this is done. Close the cover of the bath, and direct

used in the cooperative work to establish the unsulfonated

a gentle stream of air across the top of the flask to blow away

residue of the reference spray oil. There are small variations in

any steam arising from the opening.

severity of shaking between individual machines, even when

11.5 After the flask has been in the bath for 10 6 1 min,

they are newly built and of the same make; and these

remove the carrier and install it, with minimum delay, on the

differences can increase with use. Consequently, each labora-

shaker. While wearing a face shield, shake for 10 61satthe

tory shall run occasional tests on the reference spray oil. If an

rate established in the calibration with the reference spray oil.

unsulfonated residue is found which differs by more than

(Warning—Certain samples of low unsulfonated residue can

60.4 % from the established value, the rate of shaking shall be

foam excessively when shaken. Stop the shaker when the foam

adjusted accordingly. A faster rate tends to give a lower

rises in the neck of the flask, and shake intermittently but at the

unsulfonated residue, and vice versa.

specified rate. Substitute the counter for the timer and shake a

9.2 Hand Shaking Rate—Each operator shall standardize

total number of cycles equal to one-sixth of the number

his technique of shaking so as to obtain the established value

representing the established rate in cycles per minute, even

(within 6 0.4 %) on the reference spray oil. A rate of 300

though it requires more than 10 s for example, if the rate is 425

cycles/min was used in the manual shaking tests in the

cycles/min, shake 71 cycles.) After shaking, return the carrier

cooperative program on the reference oil; however, an indi-

to the bath as quickly as possible. Repeat the shaking at 10 6

vidual operator’s calibrated rate can differ appreciably from

1 min intervals for a total of six shaking periods, so that an

300 cycles/min.

hour has elapsed between the time of placing the flask in the

bath, and the removal for the final shaking.

10. Sampling

11.6 After the final shaking, cool to approximately room

10.1 Obtain a sample for this test method using Practices D

temperature, and add sufficient H SO (95 %) to raise the oil

2 4

4057 or D 4177.

into the neck of the flask nearly to the top graduation. Place the

flask in the centrifuge, balancing as necessary, and centrifuge

11. Procedure

for 10 min at a speed calculated by

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.