ASTM E1735-95(2000)e1

(Test Method)Standard Test Method for Determining Relative Image Quality of Industrial Radiographic Film Exposed to X-Radiation from 4 to 25 MV

Standard Test Method for Determining Relative Image Quality of Industrial Radiographic Film Exposed to X-Radiation from 4 to 25 MV

SCOPE

1.1 This test method covers determination of the relative image quality response of industrial radiographic film when exposed to X-radiation sources having photon energies from 4 to 25 MV. Evaluation of the film is based on the visibility of holes in a special image quality indicator (IQI). Since results for a given film type may vary, depending on the particular processing system used, it is essential to state the exposure parameters, processing chemistry, and processing cycle. For the purposes of this test method, it is assumed that all components of the X-ray system are operating properly and are capable of producing a given image quality. This test method is not intended to be used for films exposed with Cobalt 60 sources or X-ray sources below 4 MV.

1.2 The values stated in either SI or inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation:E1735–95 (Reapproved 2000)

Standard Test Method for

Determining Relative Image Quality of Industrial

Radiographic Film Exposed to X-Radiation from 4 to 25 MV

This standard is issued under the fixed designation E 1735; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Paragraph 8.5 was corrected editorially in May 2000.

1. Scope 4. Significance and Use

1.1 This test method covers determination of the relative 4.1 This test method provides a test for determining the

image quality response of industrial radiographic film when relative image quality response of radiographic film when

exposed to X-radiation sources having photon energies from 4 exposed to 4 to 25 MV X rays as any single component of the

to 25 MV. Evaluation of the film is based on the visibility of total X-ray system (for example, screens) is varied. By holding

holes in a special image quality indicator (IQI). Since results the technique parameters (except exposure time) and process-

for a given film type may vary, depending on the particular ing parameters constant, the image quality response of radio-

processing system used, it is essential to state the exposure graphic film may be evaluated on a relative basis.

parameters, processing chemistry, and processing cycle. For 4.2 Alternately, this test method provides a test for measur-

the purposes of this test method, it is assumed that all ing the image quality of the X-ray system or any component of

components of the X-ray system are operating properly and are the system.

capableofproducingagivenimagequality.Thistestmethodis

5. Test Specimen

not intended to be used for films exposed with Cobalt 60

sources or X-ray sources below 4 MV. 5.1 The test specimen will consist of a 15-cm (6-in.) steel

absorber with a special IQI placed on the radiation (source)

1.2 The values stated in either SI or inch-pound units are to

be regarded as the standard. The values given in parentheses side of the absorber.

5.1.1 Absorber—Theabsorbershallbemadeofcarbonsteel

are for information only.

1.3 This standard does not purport to address all of the or Type 300 stainless steel. The thickness of 15 cm (6 in.) can

be achieved by stacking thinner plates whose length and width

safety concerns, if any, associated with its use. It is the

shall be at least 20 by 25 cm (8 by 10 in.). The surface finish

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- of the top and bottom of the absorber shall be a maximum of

6.3-µm (250-µin.) R ground finish.

bility of regulatory limitations prior to use.

a

5.1.2 Image Quality Indicator—The IQI shall be fabricated

2. Referenced Documents

of carbon steel orType 300 stainless steel and shall conform to

2.1 ASTM Standards: Fig. 1. The IQI steps, identified as Plaques A-D, may be

E 999 Guide for Controlling the Quality of Industrial Ra- fabricated separately and then taped together, as shown in Fig.

diographic Film Processing 1,usingsuitabletapetoformthearrayasshown.Thetapeshall

E 1025 Practice for Hole Type Image Quality Indicators not cover any of the holes in the IQI. The surface finish of the

Used for Radiography IQI top and bottom surfaces shall be a maximum of 6.3-µm

E 1079 Practice for the Calibration of Transmission Densi- (250-µin.) R ground finish.

a

tometers

6. Radiation Source

E 1316 Terminology for Nondestructive Examinations

6.1 The source of radiation shall be an X-ray generator

3. Terminology

capable of operating in any part (or all) of the range from 4 to

3.1 Definitions—Definitionsoftermsrelatingtogammaand 25 MV.

X-radiology are found in Terminology E 1316.

7. Film Holder and Screens

7.1 Film Holder—The film holder shall be a medical-type,

This test method is under the jurisdiction of ASTM Committee E-7 on

hard-backed cassette or a flexible film holder with a vacuum or

Nondestructive Testing and is the direct responsibility of Subcommittee E07.01 on

mechanical means for providing good film-screen contact.

Radiology (X and Gamma) Method.

Current edition approved Sept. 10, 1995. Published November 1995.

Annual Book of ASTM Standards, Vol 03.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

E1735–95 (2000)

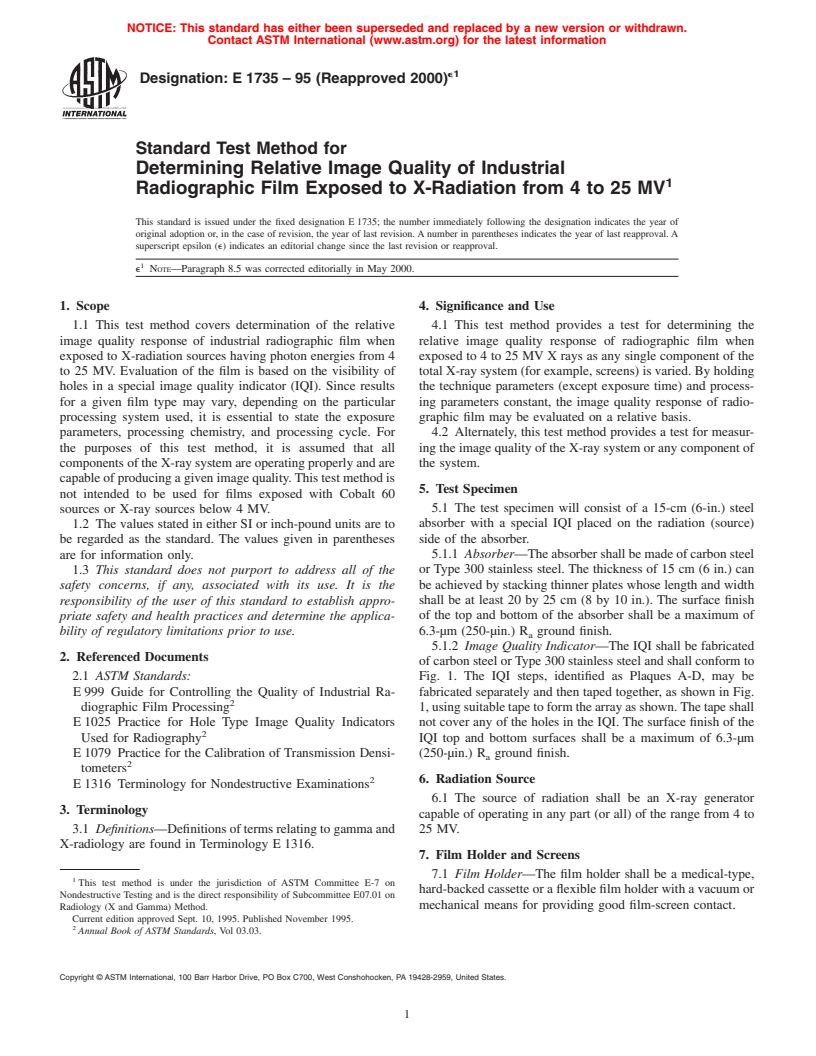

NOTE 1—All plaques identical except hole size and plaque thickness hole: row spacing tolerance 6 0.1 mm (6 0.004 in.), nonaccumulative Dimension

A=10 6 0.1 mm (0.395 6 0.004 in.) and Dimension B = 12.5 6 0.1 mm (0.492 6 0.004 in.); other dimensions in accordance with standard engineering

practice.

Plaque Letter Plaque Thickness Hole Set Hole Diameter

mm (in.) mm (in.)

A1.6 6 0.025 (0.06256 0.001) 1 3.0 6 0.025 (0.118 6 0.001)

B1.3 6 0.025 (0.050 6 0.001) 2 1.8 6 0.025 (0.072 6 0.001)

C 0.97 6 0.025 (0.038 6 0.001) 3 1.8 6 0.025 (0.072 6 0.001)

D 0.64 6 0.025 (0.025 6 0.001) 4 1.5 6 0.025 (0.060 6 0.001)

51.5 6 0.025 (0.060 6 0.001)

6 1.22 6 0.025 (0.048 6 0.001)

7 1.42 6 0.025 (0.056 6 0.001)

8 1.17 6 0.025 (0.046 6 0.001)

9 0.94 6 0.025 (0.037 6 0.001)

FIG. 1 Image Quality Indicator

7.2 Screens—Lead foil screens with a front thickness of used at the user’s discretion, provided that the actual thickness

0.010 to 0.050 in. (0.25 mm to 1.27 mm) and back thickness of used is documented on the data sheet (Fig. 2) and agreed upon

0.010 in., minimum, shall be used. Thicker screens may be by all parties concerned.

e1

E1735–95 (2000)

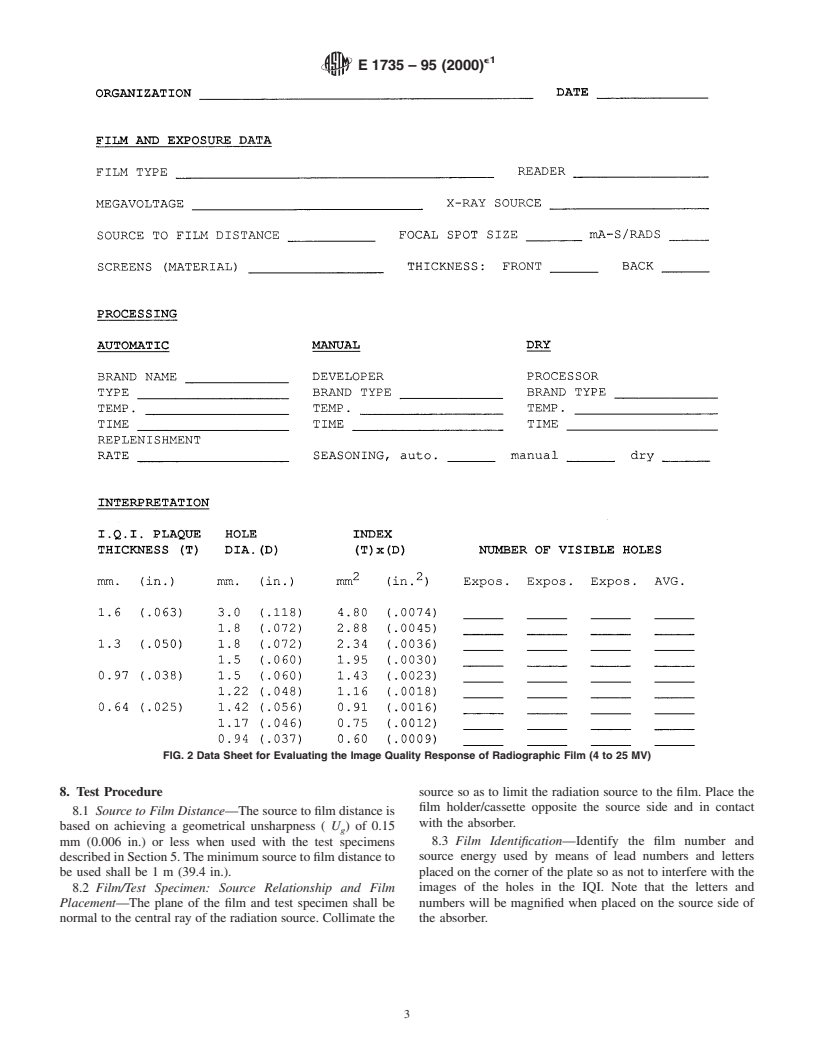

FIG. 2 Data Sheet for Evaluating the Image Quality Response of Radiographic Film (4 to 25 MV)

8. Test Procedure source so as to limit the radiation source to the film. Place the

film holder/cassette opposite the source side and in contact

8.1 Source to Film Distance—The source to film distance is

with the absorber.

based on achieving a geometrical unsharpness ( U ) of 0.15

g

8.3 Film Identification—Identify the film number and

mm (0.006 in.) or less when used with the test specimens

describedinSection5.Theminimumsourcetofilmdistanceto source energy used by means of lead numbers and letters

placed on the corner of the plate so as not to interfere with the

be used shall be 1 m (39.4 in.).

8.2 Film/Test Specimen: Source Relationship and Film images of the holes in the IQI. Note that the letters and

Placement—The plane of the film and test specimen shall be numbers will be magnified when placed on the source side of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.