ASTM D7853-13(2020)

(Test Method)Standard Test Method for Hydraulic Pullout Resistance of a Geomembrane with Locking Extensions Embedded in Concrete

Standard Test Method for Hydraulic Pullout Resistance of a Geomembrane with Locking Extensions Embedded in Concrete

SIGNIFICANCE AND USE

5.1 Due to hydraulic pressure that may be present on some applications, engineers need to understand the capability of these products to resist this pressure. This test allows engineers to compare products and verify pullout strength.

5.2 Hydraulic pullout resistance is a function of locking extension dimensions, locking extension geometry, locking extensions per area, locking extension polymer composition, and the properties of the concrete in which the locking extensions are embedded.

5.3 The data from this test method provides comparative information for rating hydraulic pullout resistance of different geomembranes with locking extensions embedded in concrete. Hydraulic pullout resistance, while partly dependent on locking extension dimensions, has no simple correlation to locking extension dimensions and geometry. Hence, hydraulic pullout resistance cannot be determined with a small sample without potentially producing misleading data to the actual hydraulic pullout resistance of the material. Therefore, the hydraulic pullout resistance is expressed in kPa (lb/ft2).

5.4 The apparatus can be circular or square in nature and must have a test area of 0.36 m2 (558 in.2).

5.5 Fig. 1 shows an example of a circular test apparatus that can be used in the performance of this test. The apparatus requires a pressure vessel rated to a minimum 690 kPa (14 410 lb/ft2). The vessel test diameter should be a minimum of 677.04 mm (26.655 in.) as shown in Fig. 1.

FIG. 1 Picture of Circular Test Apparatus

Note 1: Larger vessels may be used but it is up to user to establish correlation to the standard size vessel. The use of a smaller diameter vessel than denoted in this standard may contribute to higher pullout resistance due to thickness or stiffness of some products.

5.6 Test Pedestal—The base of the testing apparatus which holds the test specimen.

5.7 Upper Flange—Is the flange that is bolted down on top of specimen to create a seal.

5.8 Form—Is an alumi...

SCOPE

1.1 This test method covers the determination of the hydraulic pullout resistance of a geomembrane with locking extensions embedded in concrete by determining the pressure required for locking extensions of the embedded specimen to pullout of the concrete.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7853 − 13 (Reapproved 2020)

Standard Test Method for

Hydraulic Pullout Resistance of a Geomembrane with

Locking Extensions Embedded in Concrete

This standard is issued under the fixed designation D7853; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D4439 Terminology for Geosynthetics

D5947 Test Methods for Physical Dimensions of Solid

1.1 This test method covers the determination of the hy-

Plastics Specimens

draulic pullout resistance of a geomembrane with locking

extensions embedded in concrete by determining the pressure

3. Terminology

required for locking extensions of the embedded specimen to

pullout of the concrete.

3.1 Definitions of terms applying to this test method appear

in Terminology D4439.

1.2 The values stated in SI units are to be regarded as

standard. The values given in parentheses are provided for

4. Summary of Test Method

information only and are not considered standard.

1.3 This standard does not purport to address all of the

4.1 Ageomembrane with locking extensions on at least one

safety concerns, if any, associated with its use. It is the surface is embedded into concrete. The pullout resistance is

responsibility of the user of this standard to establish appro-

determined by measuring the maximum pressure required to

priate safety, health, and environmental practices and deter- initiate pullout of the locking extensions from the concrete.

mine the applicability of regulatory limitations prior to use.

Alternatively, the geomembrane with locking extensions is

1.4 This international standard was developed in accor- embeddedinconcreteandpressurizedtoaspecifiedpressureto

dance with internationally recognized principles on standard-

verify whether a minimum level of in-place strength has been

ization established in the Decision on Principles for the attained.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

5. Significance and Use

Barriers to Trade (TBT) Committee.

5.1 Due to hydraulic pressure that may be present on some

applications, engineers need to understand the capability of

2. Referenced Documents

these products to resist this pressure.This test allows engineers

2.1 ASTM Standards:

to compare products and verify pullout strength.

A1064/A1064M Specification for Carbon-Steel Wire and

5.2 Hydraulic pullout resistance is a function of locking

Welded Wire Reinforcement, Plain and Deformed, for

extension dimensions, locking extension geometry, locking

Concrete

extensions per area, locking extension polymer composition,

C31/C31M Practice for Making and Curing Concrete Test

and the properties of the concrete in which the locking

Specimens in the Field

extensions are embedded.

C39/C39M Test Method for Compressive Strength of Cylin-

drical Concrete Specimens

5.3 The data from this test method provides comparative

C94/C94M Specification for Ready-Mixed Concrete

information for rating hydraulic pullout resistance of different

D618 Practice for Conditioning Plastics for Testing

geomembranes with locking extensions embedded in concrete.

Hydraulic pullout resistance, while partly dependent on lock-

ing extension dimensions, has no simple correlation to locking

This test method is under the jurisdiction of ASTM Committee D35 on

extension dimensions and geometry. Hence, hydraulic pullout

Geosynthetics and is the direct responsibility of Subcommittee D35.01 on Mechani-

cal Properties. resistance cannot be determined with a small sample without

Current edition approved June 1, 2020. Published June 2020. Originally

potentially producing misleading data to the actual hydraulic

approved in 2013. Last previous edition approved in 2013 as D7853 – 13. DOI:

pullout resistance of the material. Therefore, the hydraulic

10.1520/D7853-13R20.

pullout resistance is expressed in kPa (lb/ft ).

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.4 The apparatus can be circular or square in nature and

Standards volume information, refer to the standard’s Document Summary page on

2 2

the ASTM website. must have a test area of 0.36 m (558 in. ).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7853 − 13 (2020)

project-specific applications with the approval of the owner or engineer.

5.5 Fig. 1 shows an example of a circular test apparatus that

can be used in the performance of this test. The apparatus

5.12 All tests shall be conducted at standard laboratory

requires a pressure vessel rated to a minimum 690 kPa (14 410

temperatures of 23 6 2 °C (73.4 6 3.6 °F).

lb/ft ). The vessel test diameter should be a minimum of

677.04 mm (26.655 in.) as shown in Fig. 1.

6. Test Specimens

NOTE 1—Larger vessels may be used but it is up to user to establish 6.1 Cut the test specimens large enough to ensure a good

correlationtothestandardsizevessel.Theuseofasmallerdiametervessel

seal while maintaining a 677.04 mm (26.655 in.) diameter

than denoted in this standard may contribute to higher pullout resistance

testable specimen.

due to thickness or stiffness of some products.

6.2 Do not use test specimens with defects or any other

5.6 Test Pedestal—The base of the testing apparatus which

abnormalities, unless this is the item of interest.

holds the test specimen.

6.3 Test three replicate specimens on each sample unless

5.7 Upper Flange—Is the flange that is bolted down on top

otherwise noted.

of specimen to create a seal.

NOTE 3—This test may be used to test the seamed areas of different

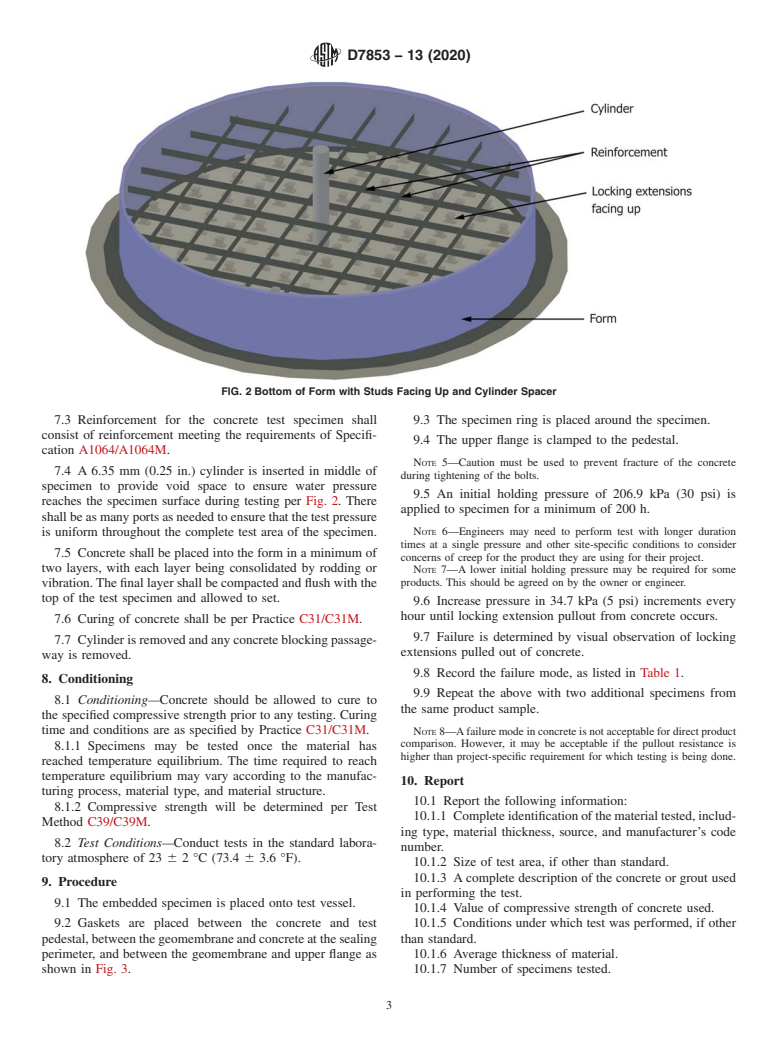

5.8 Form—Is an aluminum ring used to form test specimen

products.

as shown in Fig. 2.

5.9 SpecimenRing—Thesolidringthatisplacedaroundtest 7. Preparation of Embedded Specimen

specimen to contain leakage through the concrete.

7.1 Geomembrane is placed in bottom of form with locking

5.10 The vessel will have a system to measure pressur

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.