ASTM F2964-12(2020)

(Test Method)Standard Test Method for Determining the Uniformity of the Luminance of an Electroluminescent Lamp or Other Diffuse Lighting Device (Withdrawn 2023)

Standard Test Method for Determining the Uniformity of the Luminance of an Electroluminescent Lamp or Other Diffuse Lighting Device (Withdrawn 2023)

SIGNIFICANCE AND USE

4.1 Application of an EL lamp (or other diffuse lighting source) to illuminate a device has a functional purpose and must meet specifications to satisfy the functional requirements of the device.

4.2 Illumination of the device or application can be affected by variations in the quality, efficiency, and design of the lamp and any attendant mounting or shading fixtures.

4.3 This test method addresses only the optical and visual appearance of the lamp and not its electrical function.

4.4 This test method is non-destructive.

4.5 This test method is described for application to the illumination layer in which case the results apply to that layer only. However, it may be desirable and practical to apply the test to a further assembly or to a fully assembled device with built in illumination. In such a case, the results refer specifically to the subassembly or the entire device respectively.

SCOPE

1.1 This test method covers procedures for determining the uniformity of the luminance of an electroluminescent (EL) lamp. While written specifically for the purpose of evaluating EL devices, which are intrinsically very uniform, it can be applied (judiciously) to the measurement of any diffuse, essentially planar, light source. For specific purposes, it can be applied to partially assembled devices into which the illumination is installed (such as a membrane switch) as a diagnostic for the performance of the entire device. In such a case it must be understood that the results pertain only to the partial assembly and will be modified as the further assembly proceeds.

1.2 The method is to take a 2-dimensional set of measurements, sampling the surface of the unit under test with appropriate density. The method is restricted to measuring luminance only, since variations in color will also show as luminance non-uniformity especially in any photoptically calibrated measuring device.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

WITHDRAWN RATIONALE

This test method covers procedures for determining the uniformity of the luminance of an electroluminescent (EL) lamp. While written specifically for the purpose of evaluating EL devices, which are intrinsically very uniform, it can be applied (judiciously) to the measurement of any diffuse, essentially planar, light source. For specific purposes, it can be applied to partially assembled devices into which the illumination is installed (such as a membrane switch) as a diagnostic for the performance of the entire device. In such a case it must be understood that the results pertain only to the partial assembly and will be modified as the further assembly proceeds.

Formerly under the jurisdiction of Committee F01 on Electronics, this test method was withdrawn in November 2023. This standard is being withdrawn without replacement because Committee F01 was disbanded.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2964 − 12 (Reapproved 2020)

Standard Test Method for

Determining the Uniformity of the Luminance of an

Electroluminescent Lamp or Other Diffuse Lighting Device

This standard is issued under the fixed designation F2964; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This test method covers procedures for determining the

F2360 Test Method for Determining Luminance of a Mem-

uniformity of the luminance of an electroluminescent (EL)

brane Switch Backlit with Diffuse Light Source

lamp. While written specifically for the purpose of evaluating

F2771 Test Method for Determining the Luminance Curve

EL devices, which are intrinsically very uniform, it can be

of an Electroluminescent Lamp at Ambient Conditions

applied (judiciously) to the measurement of any diffuse,

essentially planar, light source. For specific purposes, it can be

3. Terminology

applied to partially assembled devices into which the illumi-

3.1 Definitions:

nation is installed (such as a membrane switch) as a diagnostic

3.1.1 luminance, n—measure of the brightness or luminous

for the performance of the entire device. In such a case it must

intensity of light, usually expressed in units of candelas per

be understood that the results pertain only to the partial

2 2

square metre (cd/m ) or foot lamberts. 1 fL = 3.426 cd/m .

assembly and will be modified as the further assembly pro-

3.1.2 luminance curve, n—a graphical representation of the

ceeds.

variation of luminance with time (implicitly under unvarying

1.2 The method is to take a 2-dimensional set of

operating conditions).

measurements, sampling the surface of the unit under test with

3.1.3 electroluminescent lamp (EL lamp), n—essentially a

appropriate density. The method is restricted to measuring

capacitor structure with phosphor and a dielectric sandwiched

luminance only, since variations in color will also show as

between electrodes, one of which is transparent to allow light

luminance non-uniformity especially in any photoptically cali-

to escape. Application of an ac voltage across the electrodes

brated measuring device.

generates a charging field within the phosphor, which causes it

1.3 The values stated in SI units are to be regarded as to emit light.

standard. No other units of measurement are included in this

3.1.4 time to half luminance (THL), n—the elapsed operat-

standard.

ing time over which the luminance of a lamp maintained under

constant power will be reduced to half of its initial value.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3.1.5 UUT, n—unit under test.

responsibility of the user of this standard to establish appro-

4. Significance and Use

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

4.1 Application of an EL lamp (or other diffuse lighting

source) to illuminate a device has a functional purpose and

1.5 This international standard was developed in accor-

must meet specifications to satisfy the functional requirements

dance with internationally recognized principles on standard-

of the device.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

4.2 Illumination of the device or application can be affected

mendations issued by the World Trade Organization Technical

by variations in the quality, efficiency, and design of the lamp

Barriers to Trade (TBT) Committee.

and any attendant mounting or shading fixtures.

4.3 This test method addresses only the optical and visual

appearance of the lamp and not its electrical function.

This test method is under the jurisdiction of ASTM Committee F01 on

Electronics and is the direct responsibility of Subcommittee F01.18 on Printed

Electronics. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Sept. 1, 2020. Published August 2012. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2012. Last previous edition approved in 2012 as F2964-12. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F2964-12R20 the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2964 − 12 (2020)

4.4 This test method is non-destructive.

4.5 This test method is described for application to the

illumination layer in which case the results apply to that layer

only. However, it may be desirable and practical to apply the

test to a further assembly or to a fully assembled device with

built in illumination. In such a case, the results refer specifi-

cally to the subassembly or the entire device respectively.

5. Interferences

5.1 State of Assembly—Tests on incomplete assemblies give

results appropriate to that state of assembly. Specifically, later

application of mounting hardware, baffling, or fixtures may

alter the results.

5.2 Filling of Aperture—Failure to fill the sampling aperture

of the photometer will bias the results in a way which is not

necessarily predictable.

5.3 Age of Device—Since every system of illumination

changescharacteristicsasitages,itmustberecognizedthatthe

results apply to a particular interval in the lifetime of the

system. Characterization of the aging properties may be

addressed in a separate test method. (See for example Test

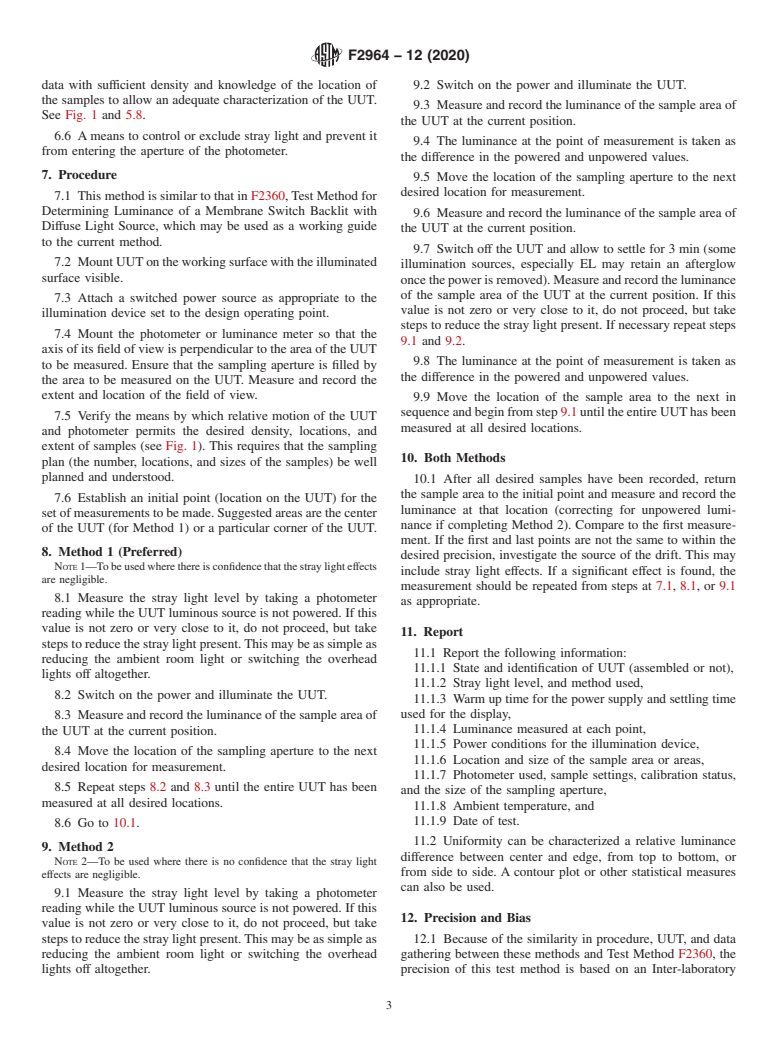

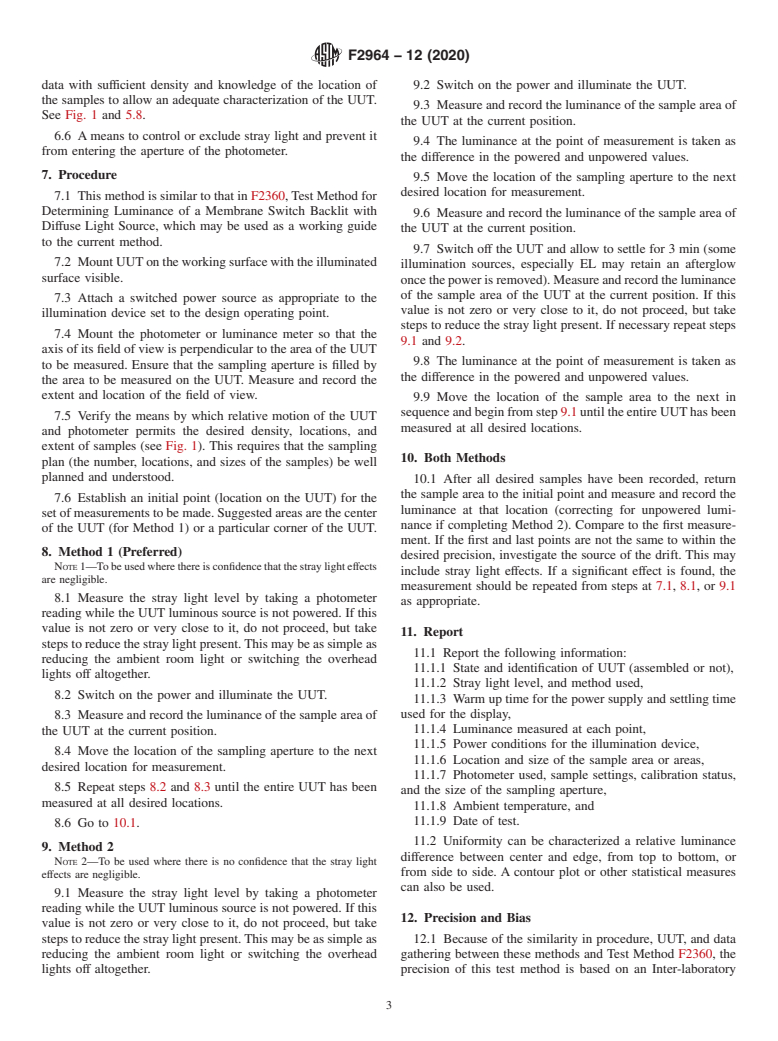

NOTE 1—A sequence of nine, non-overlapping measurements which

Method F2771.)

willrevealside-to-side,centertoedge,andtoptobottomnon-uniformities

ofluminance.Theorderofsamplingissuggestedbythenumbers.See5.8.

5.4 Perpendicularity—Since the angular distribution of

NOTE 2—Size for the sampling area (shown here as small rectangles)

emitted light can be altered by any material through which it

can be chosen to maximize significance by taking it to be large enough to

passes, it is important that the photometer be held perpendicu-

average over any intrinsic granularity of the lamp (such as phosphor

lar to the area to be sampled.

crystalsize)andsmallenoughtoavoidoverlapwithitsneighbor(andthus

remain independent).

5.5 Temperature—Since the performance of many light

FIG. 1 Suggested Organization of Sampling Points for Uniformity

sources can vary with temperature, it is important to allow the

Measurement

UUT to stabilize thermally, if necessary, and then record the

ambient temperature at which the measurements are made.

6. Apparatus

5.6 Power—Since the performance of many power sources

6.1 A working or mounting surface to hold and support the

can vary with temperature, it is important to allow the power

UUTandanysupportingfixtures,providingelectricalaccessto

supply for the UUT to stabilize thermally, if necessary, and

the termination region from which the ELlamp illumination is

then record the warm-up time at which the measurements are

tobepoweredandvisibleaccesstoallregionsofinterestonthe

made.

lamp at which the luminance is to be measured.

5.7 Ambient Light—Stray light sources will be detected by

6.2 A power supply providing appropriate, stable and ad-

the photometer and will affect the UUT luminance measure-

equate power to drive the illumination device(s) with appro-

ment. It is important to measure the ambient light before

priate connector(s). This should be specified as dc or ac, with

illuminating the UUT. This ambient light reading should be

voltage and power level given, and ideally should be switched.

zero or as close to zero as possible.

6.3 A calibrated device to measure surface luminance (or

5.8 Sampling Aperture—The sampling aperture (area of the

radiance). This is typically a spot photometer, with a fairly

UUTsampleandoverwhichluminancevaluesareaveragedby

compact sampling aperture (<1-cm diameter at the minimum

the measuring instrument) should be large enough to average

working distance). Output should be in foot lamberts (candela

overanyintrinsicgranularityoftheUUT.Thisareashouldalso

per meter squared).Alternatively, a radiometer may be used, or

be small enough compared with the overall size of the UUT to

even a video photometer, but cognizance must be maintained

allow multiple measurements to be made without the sampling

of the output units and calibration. Hereinafter we refer to this

apertures of adjacent measurements overlapping (at least nine

as the photometer.

measurements are recommended). If areas overlap, the indi-

6.4 A means to support the photometer at a fixed distance

vidual samples may no longer be considered as independent

and orientation to the emitting surface of the UUT.

samples. The decision to allow individual samples to overlap

or to remain physically distinct is one the ex

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2964 − 12 (Reapproved 2020)

Standard Test Method for

Determining the Uniformity of the Luminance of an

Electroluminescent Lamp or Other Diffuse Lighting Device

This standard is issued under the fixed designation F2964; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This test method covers procedures for determining the

F2360 Test Method for Determining Luminance of a Mem-

uniformity of the luminance of an electroluminescent (EL)

brane Switch Backlit with Diffuse Light Source

lamp. While written specifically for the purpose of evaluating

F2771 Test Method for Determining the Luminance Curve

EL devices, which are intrinsically very uniform, it can be

of an Electroluminescent Lamp at Ambient Conditions

applied (judiciously) to the measurement of any diffuse,

essentially planar, light source. For specific purposes, it can be

3. Terminology

applied to partially assembled devices into which the illumi-

3.1 Definitions:

nation is installed (such as a membrane switch) as a diagnostic

3.1.1 luminance, n—measure of the brightness or luminous

for the performance of the entire device. In such a case it must

intensity of light, usually expressed in units of candelas per

be understood that the results pertain only to the partial

2 2

square metre (cd/m ) or foot lamberts. 1 fL = 3.426 cd/m .

assembly and will be modified as the further assembly pro-

3.1.2 luminance curve, n—a graphical representation of the

ceeds.

variation of luminance with time (implicitly under unvarying

1.2 The method is to take a 2-dimensional set of

operating conditions).

measurements, sampling the surface of the unit under test with

3.1.3 electroluminescent lamp (EL lamp), n—essentially a

appropriate density. The method is restricted to measuring

capacitor structure with phosphor and a dielectric sandwiched

luminance only, since variations in color will also show as

between electrodes, one of which is transparent to allow light

luminance non-uniformity especially in any photoptically cali-

to escape. Application of an ac voltage across the electrodes

brated measuring device.

generates a charging field within the phosphor, which causes it

1.3 The values stated in SI units are to be regarded as

to emit light.

standard. No other units of measurement are included in this

3.1.4 time to half luminance (THL), n—the elapsed operat-

standard.

ing time over which the luminance of a lamp maintained under

constant power will be reduced to half of its initial value.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 3.1.5 UUT, n—unit under test.

responsibility of the user of this standard to establish appro-

4. Significance and Use

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use. 4.1 Application of an EL lamp (or other diffuse lighting

source) to illuminate a device has a functional purpose and

1.5 This international standard was developed in accor-

must meet specifications to satisfy the functional requirements

dance with internationally recognized principles on standard-

of the device.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

4.2 Illumination of the device or application can be affected

mendations issued by the World Trade Organization Technical

by variations in the quality, efficiency, and design of the lamp

Barriers to Trade (TBT) Committee.

and any attendant mounting or shading fixtures.

4.3 This test method addresses only the optical and visual

appearance of the lamp and not its electrical function.

This test method is under the jurisdiction of ASTM Committee F01 on

Electronics and is the direct responsibility of Subcommittee F01.18 on Printed

Electronics. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Sept. 1, 2020. Published August 2012. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2012. Last previous edition approved in 2012 as F2964-12. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F2964-12R20 the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2964 − 12 (2020)

4.4 This test method is non-destructive.

4.5 This test method is described for application to the

illumination layer in which case the results apply to that layer

only. However, it may be desirable and practical to apply the

test to a further assembly or to a fully assembled device with

built in illumination. In such a case, the results refer specifi-

cally to the subassembly or the entire device respectively.

5. Interferences

5.1 State of Assembly—Tests on incomplete assemblies give

results appropriate to that state of assembly. Specifically, later

application of mounting hardware, baffling, or fixtures may

alter the results.

5.2 Filling of Aperture—Failure to fill the sampling aperture

of the photometer will bias the results in a way which is not

necessarily predictable.

5.3 Age of Device—Since every system of illumination

changes characteristics as it ages, it must be recognized that the

results apply to a particular interval in the lifetime of the

system. Characterization of the aging properties may be

addressed in a separate test method. (See for example Test

NOTE 1—A sequence of nine, non-overlapping measurements which

Method F2771.)

will reveal side-to-side, center to edge, and top to bottom non-uniformities

of luminance. The order of sampling is suggested by the numbers. See 5.8.

5.4 Perpendicularity—Since the angular distribution of

NOTE 2—Size for the sampling area (shown here as small rectangles)

emitted light can be altered by any material through which it

can be chosen to maximize significance by taking it to be large enough to

passes, it is important that the photometer be held perpendicu-

average over any intrinsic granularity of the lamp (such as phosphor

lar to the area to be sampled.

crystal size) and small enough to avoid overlap with its neighbor (and thus

remain independent).

5.5 Temperature—Since the performance of many light

FIG. 1 Suggested Organization of Sampling Points for Uniformity

sources can vary with temperature, it is important to allow the

Measurement

UUT to stabilize thermally, if necessary, and then record the

ambient temperature at which the measurements are made.

6. Apparatus

5.6 Power—Since the performance of many power sources

6.1 A working or mounting surface to hold and support the

can vary with temperature, it is important to allow the power

UUT and any supporting fixtures, providing electrical access to

supply for the UUT to stabilize thermally, if necessary, and

the termination region from which the EL lamp illumination is

then record the warm-up time at which the measurements are

to be powered and visible access to all regions of interest on the

made.

lamp at which the luminance is to be measured.

5.7 Ambient Light—Stray light sources will be detected by

6.2 A power supply providing appropriate, stable and ad-

the photometer and will affect the UUT luminance measure-

equate power to drive the illumination device(s) with appro-

ment. It is important to measure the ambient light before

priate connector(s). This should be specified as dc or ac, with

illuminating the UUT. This ambient light reading should be

voltage and power level given, and ideally should be switched.

zero or as close to zero as possible.

6.3 A calibrated device to measure surface luminance (or

5.8 Sampling Aperture—The sampling aperture (area of the

radiance). This is typically a spot photometer, with a fairly

UUT sample and over which luminance values are averaged by

compact sampling aperture (<1-cm diameter at the minimum

the measuring instrument) should be large enough to average

working distance). Output should be in foot lamberts (candela

over any intrinsic granularity of the UUT. This area should also

per meter squared). Alternatively, a radiometer may be used, or

be small enough compared with the overall size of the UUT to

even a video photometer, but cognizance must be maintained

allow multiple measurements to be made without the sampling

of the output units and calibration. Hereinafter we refer to this

apertures of adjacent measurements overlapping (at least nine

as the photometer.

measurements are recommended). If areas overlap, the indi-

6.4 A means to support the photometer at a fixed distance

vidual samples may no longer be considered as independent

and orientation to the emitting surface of the UUT.

samples. The decision to allow individual samples to overlap

or to remain physically distinct is one the experimenter must 6.5 A means to move the lamp and photometer relative t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.