ASTM B106-96

(Test Method)Standard Test Methods for Flexivity of Thermostat Metals

Standard Test Methods for Flexivity of Thermostat Metals

SCOPE

1.1 These test methods cover the determination of flexivity (a measure of thermal deflection rate or deflection temperature characteristics) of thermostat metals.

1.1.1 Test Method A—Tested in the form of flat strip 0.012 in. (0.30 mm) or over in thickness.

1.1.2 Test Method B—Tested in the form of spiral coils less than 0.012 in. in thickness.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for information purposes only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

Designation: B 106 – 96 An American National Standard

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Methods for

1

Flexivity of Thermostat Metals

This standard is issued under the fixed designation B 106; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope and T , it is necessary to measure the curvature 1/R and 1/R

2 1 2

at temperature T and T , respectively. To find the curvature at

1 2

1.1 These test methods cover the determination of flexivity

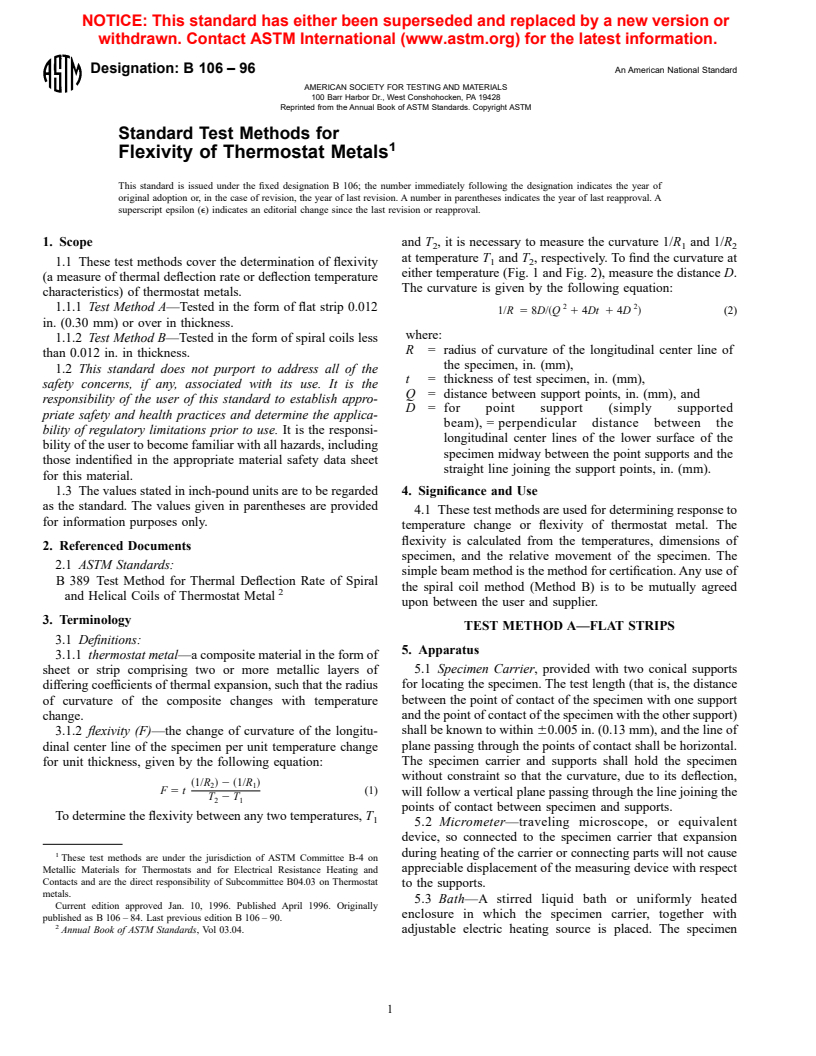

either temperature (Fig. 1 and Fig. 2), measure the distance D.

(a measure of thermal deflection rate or deflection temperature

The curvature is given by the following equation:

characteristics) of thermostat metals.

2 2

1.1.1 Test Method A—Tested in the form of flat strip 0.012

1/R 5 8D/~Q 1 4Dt 1 4D ! (2)

in. (0.30 mm) or over in thickness.

where:

1.1.2 Test Method B—Tested in the form of spiral coils less

R = radius of curvature of the longitudinal center line of

than 0.012 in. in thickness.

the specimen, in. (mm),

1.2 This standard does not purport to address all of the

t = thickness of test specimen, in. (mm),

safety concerns, if any, associated with its use. It is the

Q = distance between support points, in. (mm), and

responsibility of the user of this standard to establish appro-

D = for point support (simply supported

priate safety and health practices and determine the applica-

beam), = perpendicular distance between the

bility of regulatory limitations prior to use. It is the responsi-

longitudinal center lines of the lower surface of the

bility of the user to become familiar with all hazards, including

specimen midway between the point supports and the

those indentified in the appropriate material safety data sheet

straight line joining the support points, in. (mm).

for this material.

1.3 The values stated in inch-pound units are to be regarded 4. Significance and Use

as the standard. The values given in parentheses are provided

4.1 These test methods are used for determining response to

for information purposes only.

temperature change or flexivity of thermostat metal. The

flexivity is calculated from the temperatures, dimensions of

2. Referenced Documents

specimen, and the relative movement of the specimen. The

2.1 ASTM Standards:

simple beam method is the method for certification. Any use of

B 389 Test Method for Thermal Deflection Rate of Spiral

the spiral coil method (Method B) is to be mutually agreed

2

and Helical Coils of Thermostat Metal

upon between the user and supplier.

3. Terminology

TEST METHOD A—FLAT STRIPS

3.1 Definitions:

5. Apparatus

3.1.1 thermostat metal—a composite material in the form of

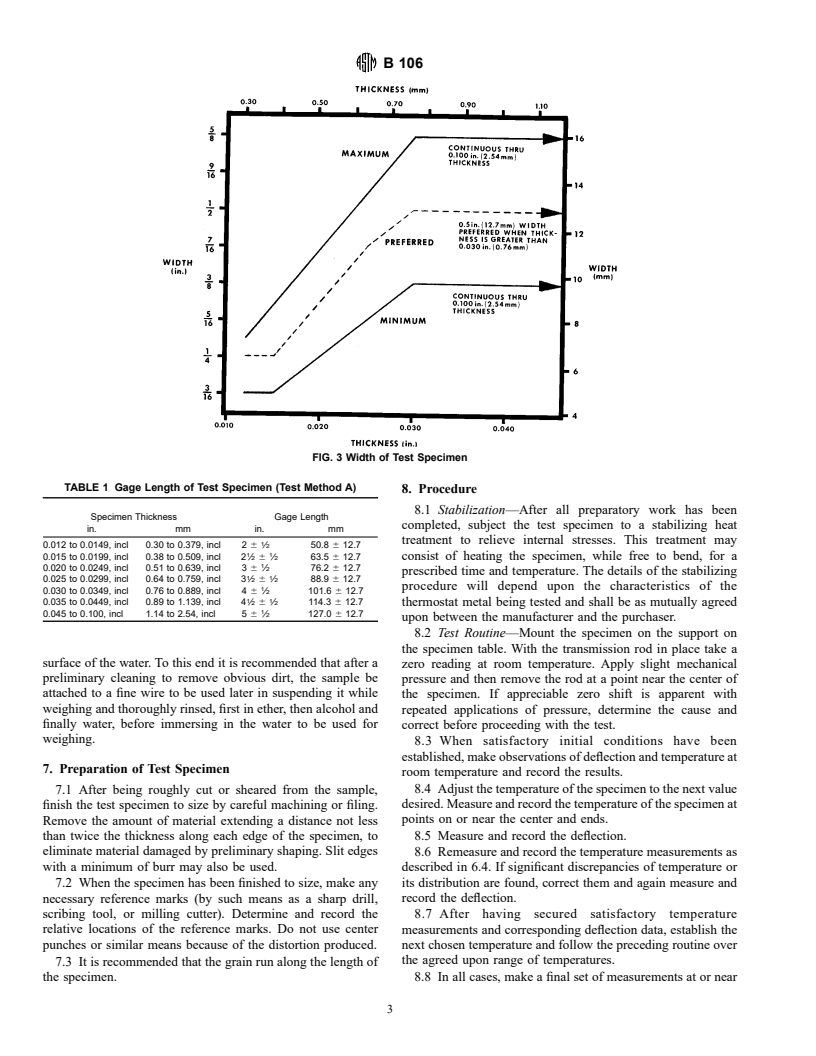

5.1 Specimen Carrier, provided with two conical supports

sheet or strip comprising two or more metallic layers of

for locating the specimen. The test length (that is, the distance

differing coefficients of thermal expansion, such that the radius

between the point of contact of the specimen with one support

of curvature of the composite changes with temperature

and the point of contact of the specimen with the other support)

change.

shall be known to within 60.005 in. (0.13 mm), and the line of

3.1.2 flexivity (F)—the change of curvature of the longitu-

plane passing through the points of contact shall be horizontal.

dinal center line of the specimen per unit temperature change

The specimen carrier and supports shall hold the specimen

for unit thickness, given by the following equation:

without constraint so that the curvature, due to its deflection,

~1/R ! 2 ~1/R !

2 1

F 5 t (1)

will follow a vertical plane passing through the line joining the

T 2 T

2 1

points of contact between specimen and supports.

To determine the flexivity between any two temperatures, T

1

5.2 Micrometer—traveling microscope, or equivalent

device, so connected to the specimen carrier that expansion

1 during heating of the carrier or connecting parts will not cause

These test methods are under the jurisdiction of ASTM Committee B-4 on

Metallic Materials for Thermostats and for Electrical Resistance Heating and appreciable displacement of the measuring device with respect

Contacts and are the direct responsibility of Subcommittee B04.03 on Thermostat

to the supports.

metals.

5.3 Bath—A stirred liquid bath or uniformly heated

Current edition approved Jan. 10, 1996. Published April 1996. Originally

enclosure in which the specimen carrier, together with

published as B 106 – 84. Last previous edition B 106 – 90.

2

Annual Book of ASTM Standards, Vol 03.04. adju

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.