ASTM F3592-23

(Guide)Standard Guide for Additive Manufacturing of Metals – Powder Bed Fusion – Guidelines for Feedstock Re-use and Sampling Strategies

Standard Guide for Additive Manufacturing of Metals – Powder Bed Fusion – Guidelines for Feedstock Re-use and Sampling Strategies

SIGNIFICANCE AND USE

4.1 The overall aim of this guide is to support AM users with the selection of the optimum re-use strategy for their AM process and end-use application, and provide guidance on how to implement re-use strategies in their organization.

4.2 This guide suggests possible control measures that AM users can use to maintain powder quality, and factors to consider when validating selected re-use strategies, including guidance on sampling techniques.

4.3 This guide is intended for metal powders used in Powder Bed Fusion processes.

SCOPE

1.1 This guide:

1.1.1 Defines key powder re-use variables and factors affecting powder re-use strategies.

1.1.2 Outlines implications associated with implementation of powder re-use strategies based on selection of powder re-use variables and factors.

1.1.3 Provides guidance to AM users in selection of factors in powder re-use variables depending on considered material type, AM process type and end-use application.

1.1.4 Provides guidance on key process variables affecting powder properties, and considerations to mitigate their effects.

1.1.5 Identifies key powder properties that may be affected by powder re-use and provides AM users guidance on control measures that can be exploited to ensure quality of re-used powder.

1.1.6 Provides recommendations and guidance on factors to consider when implementing powder re-use strategies.

1.1.7 Provides information on how to design a powder re-use study to validate the selected re-use variables.

1.1.8 Summarizes sampling techniques and provides recommendations to AM users on sampling technique selection, and suitability of sampling techniques for powder re-use strategies.

1.1.9 Provides factors to consider when designing a powder sampling study to validate the selected sampling technique.

1.2 Units—The values stated in SI units are to be regarded as the standard units. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F3592 − 23

Standard Guide for

Additive Manufacturing of Metals – Powder Bed Fusion –

1

Guidelines for Feedstock Re-use and Sampling Strategies

This standard is issued under the fixed designation F3592; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

1.1 This guide:

Barriers to Trade (TBT) Committee.

1.1.1 Defines key powder re-use variables and factors af-

fecting powder re-use strategies.

2. Referenced Documents

1.1.2 Outlines implications associated with implementation

2

2.1 ASTM Standards:

of powder re-use strategies based on selection of powder re-use

B215 Practices for Sampling Metal Powders

variables and factors.

B243 Terminology of Powder Metallurgy

1.1.3 Provides guidance to AM users in selection of factors

F2924 Specification for Additive Manufacturing Titanium-6

in powder re-use variables depending on considered material

Aluminum-4 Vanadium with Powder Bed Fusion

type, AM process type and end-use application.

F3001 Specification for Additive Manufacturing Titanium-6

1.1.4 Provides guidance on key process variables affecting

Aluminum-4 Vanadium ELI (Extra Low Interstitial) with

powder properties, and considerations to mitigate their effects.

Powder Bed Fusion

1.1.5 Identifies key powder properties that may be affected

F3055 Specification for Additive Manufacturing Nickel Al-

by powder re-use and provides AM users guidance on control

loy (UNS N07718) with Powder Bed Fusion

measures that can be exploited to ensure quality of re-used

F3184 Specification for Additive Manufacturing Stainless

powder.

Steel Alloy (UNS S31603) with Powder Bed Fusion

1.1.6 Provides recommendations and guidance on factors to

F3318 for Additive Manufacturing – Finished Part Proper-

consider when implementing powder re-use strategies.

ties – Specification for AlSi10Mg with Powder Bed

1.1.7 Provides information on how to design a powder

Fusion – Laser Beam

re-use study to validate the selected re-use variables.

F3456 Guide for Powder Reuse Schema in Powder Bed

1.1.8 Summarizes sampling techniques and provides recom-

Fusion Processes for Medical Applications for Additive

mendations to AM users on sampling technique selection, and

Manufacturing Feedstock Materials

suitability of sampling techniques for powder re-use strategies.

2

2.2 ISO/ASTM Standards:

1.1.9 Provides factors to consider when designing a powder

sampling study to validate the selected sampling technique. ISO/ASTM FDIS 52900 Additive manufacturing — General

principles — Fundamentals and vocabulary

1.2 Units—The values stated in SI units are to be regarded

ISO/ASTM PWI 52928 Additive manufacturing of metals

as the standard units. No other units of measurement are

— Feedstock materials — Powder life cycle management

included in this standard.

ISO/ASTM 52907 Additive manufacturing — Feedstock

1.3 This standard does not purport to address all of the

materials — Methods to characterize metal powders

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3. Terminology

priate safety, health, and environmental practices and deter-

3.1 Powder metallurgy terms can be found in Terminology

mine the applicability of regulatory limitations prior to use.

B243 and AM processes and terms can be found in ISO/ASTM

1.4 This international standard was developed in accor-

52900. Terms used frequently in this document are given

dance with internationally recognized principles on standard-

below.

ization established in the Decision on Principles for the

3.2 Definitions:

1

This guide is under the jurisdiction of ASTM Committee F42 on Additive

2

Manufacturing Technologies and is the direct responsibility of Subcommittee For referenced ASTM standards, visit the ASTM website, www.astm.org, or

F42.05 on Materials and Processes. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved July 15, 2023. Published September 2023. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F3592-23. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F3592 − 23

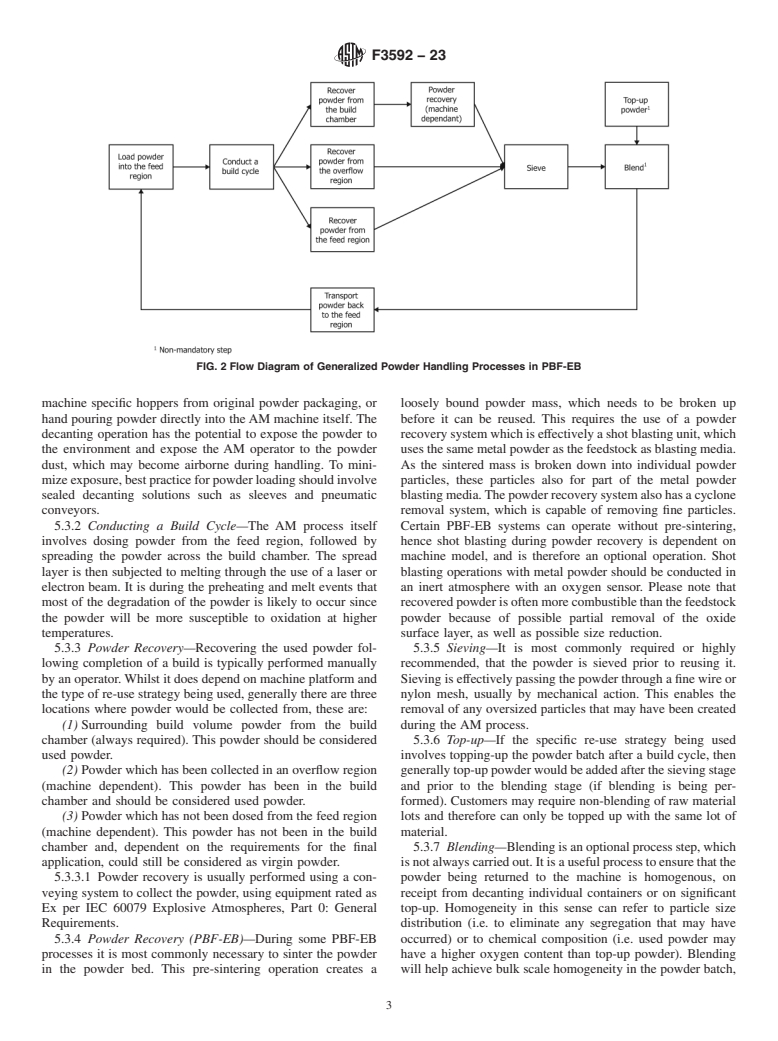

FIG. 1 Flow Diagram of Generalized Powder Handling Processes in PB

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.