ASTM F1608-21

(Test Method)Standard Test Method for Microbial Ranking of Porous Packaging Materials (Exposure Chamber Method)

Standard Test Method for Microbial Ranking of Porous Packaging Materials (Exposure Chamber Method)

SIGNIFICANCE AND USE

5.1 The exposure-chamber method is a quantitative procedure for determining the microbial-barrier properties of porous materials under the conditions specified by the test. Data obtained from this test is useful in assessing the relative potential of a particular porous material in contributing to the loss of sterility to the contents of the package versus another porous material. This test method is not intended to predict the performance of a given material in a specific sterile-packaging application. The maintenance of sterility in a particular packaging application will depend on a number of factors, including, but not limited to the following:

5.1.1 The bacterial challenge (number and kinds of microorganisms) that the package will encounter in its distribution and use. This may be influenced by factors such as shipping methods, expected shelf life, geographic location, and storage conditions.

5.1.2 The package design, including factors such as adhesion between materials, the presence or absence of secondary and tertiary packaging, and the nature of the device within the package.

5.1.3 The rate and volume exchange of air that the porous package encounters during its distribution and shelf life. This can be influenced by factors including the free-air volume within the package and pressure changes occurring as a result of transportation, manipulation, weather, or mechanical influences (such as room door closures and HVAC systems).

5.1.4 The microstructure of a porous material which influences the relative ability to adsorb or entrap microorganisms, or both, under different air-flow conditions.

SCOPE

1.1 This test method is used to determine the passage of airborne bacteria through porous materials intended for use in packaging sterile medical devices. This test method is designed to test materials under conditions that result in the detectable passage of bacterial spores through the test material.

1.1.1 A round-robin study was conducted with eleven laboratories participating. Each laboratory tested duplicate samples of six commercially available porous materials to determine the Log Reduction Value (LRV) (see calculation in Section 12). Materials tested under the standard conditions described in this test method returned average values that range from LRV 1.7 to 4.3.

1.1.2 Results of this round-robin study indicate that caution should be used when comparing test data and ranking materials, especially when a small number of sample replicates are used. In addition, further collaborative work (such as described in Practice E691) should be conducted before this test method would be considered adequate for purposes of setting performance standards.

1.2 This test method requires manipulation of microorganisms and should be performed only by trained personnel. The U.S. Department of Health and Human Services publication Biosafety in Microbiological and Biomedical Laboratories (CDC/NIH-HHS Publication No. 84-8395) should be consulted for guidance.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

- Status

- Published

- Publication Date

- 30-Sep-2021

- Technical Committee

- F02 - Primary Barrier Packaging

- Drafting Committee

- F02.15 - Chemical/Safety Properties

- Current Stage

Relations

- Effective Date

- 01-May-2013

- Effective Date

- 01-Nov-2011

- Effective Date

- 01-Oct-2008

- Effective Date

- 01-Nov-2005

- Effective Date

- 10-May-1999

ASTM F1608-21 - Standard Test Method for Microbial Ranking of Porous Packaging Materials (Exposure Chamber Method)

REDLINE ASTM F1608-21 - Standard Test Method for Microbial Ranking of Porous Packaging Materials (Exposure Chamber Method)

Frequently Asked Questions

ASTM F1608-21 is a standard published by ASTM International. Its full title is "Standard Test Method for Microbial Ranking of Porous Packaging Materials (Exposure Chamber Method)". This standard covers: SIGNIFICANCE AND USE 5.1 The exposure-chamber method is a quantitative procedure for determining the microbial-barrier properties of porous materials under the conditions specified by the test. Data obtained from this test is useful in assessing the relative potential of a particular porous material in contributing to the loss of sterility to the contents of the package versus another porous material. This test method is not intended to predict the performance of a given material in a specific sterile-packaging application. The maintenance of sterility in a particular packaging application will depend on a number of factors, including, but not limited to the following: 5.1.1 The bacterial challenge (number and kinds of microorganisms) that the package will encounter in its distribution and use. This may be influenced by factors such as shipping methods, expected shelf life, geographic location, and storage conditions. 5.1.2 The package design, including factors such as adhesion between materials, the presence or absence of secondary and tertiary packaging, and the nature of the device within the package. 5.1.3 The rate and volume exchange of air that the porous package encounters during its distribution and shelf life. This can be influenced by factors including the free-air volume within the package and pressure changes occurring as a result of transportation, manipulation, weather, or mechanical influences (such as room door closures and HVAC systems). 5.1.4 The microstructure of a porous material which influences the relative ability to adsorb or entrap microorganisms, or both, under different air-flow conditions. SCOPE 1.1 This test method is used to determine the passage of airborne bacteria through porous materials intended for use in packaging sterile medical devices. This test method is designed to test materials under conditions that result in the detectable passage of bacterial spores through the test material. 1.1.1 A round-robin study was conducted with eleven laboratories participating. Each laboratory tested duplicate samples of six commercially available porous materials to determine the Log Reduction Value (LRV) (see calculation in Section 12). Materials tested under the standard conditions described in this test method returned average values that range from LRV 1.7 to 4.3. 1.1.2 Results of this round-robin study indicate that caution should be used when comparing test data and ranking materials, especially when a small number of sample replicates are used. In addition, further collaborative work (such as described in Practice E691) should be conducted before this test method would be considered adequate for purposes of setting performance standards. 1.2 This test method requires manipulation of microorganisms and should be performed only by trained personnel. The U.S. Department of Health and Human Services publication Biosafety in Microbiological and Biomedical Laboratories (CDC/NIH-HHS Publication No. 84-8395) should be consulted for guidance. 1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard. 1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. 1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

SIGNIFICANCE AND USE 5.1 The exposure-chamber method is a quantitative procedure for determining the microbial-barrier properties of porous materials under the conditions specified by the test. Data obtained from this test is useful in assessing the relative potential of a particular porous material in contributing to the loss of sterility to the contents of the package versus another porous material. This test method is not intended to predict the performance of a given material in a specific sterile-packaging application. The maintenance of sterility in a particular packaging application will depend on a number of factors, including, but not limited to the following: 5.1.1 The bacterial challenge (number and kinds of microorganisms) that the package will encounter in its distribution and use. This may be influenced by factors such as shipping methods, expected shelf life, geographic location, and storage conditions. 5.1.2 The package design, including factors such as adhesion between materials, the presence or absence of secondary and tertiary packaging, and the nature of the device within the package. 5.1.3 The rate and volume exchange of air that the porous package encounters during its distribution and shelf life. This can be influenced by factors including the free-air volume within the package and pressure changes occurring as a result of transportation, manipulation, weather, or mechanical influences (such as room door closures and HVAC systems). 5.1.4 The microstructure of a porous material which influences the relative ability to adsorb or entrap microorganisms, or both, under different air-flow conditions. SCOPE 1.1 This test method is used to determine the passage of airborne bacteria through porous materials intended for use in packaging sterile medical devices. This test method is designed to test materials under conditions that result in the detectable passage of bacterial spores through the test material. 1.1.1 A round-robin study was conducted with eleven laboratories participating. Each laboratory tested duplicate samples of six commercially available porous materials to determine the Log Reduction Value (LRV) (see calculation in Section 12). Materials tested under the standard conditions described in this test method returned average values that range from LRV 1.7 to 4.3. 1.1.2 Results of this round-robin study indicate that caution should be used when comparing test data and ranking materials, especially when a small number of sample replicates are used. In addition, further collaborative work (such as described in Practice E691) should be conducted before this test method would be considered adequate for purposes of setting performance standards. 1.2 This test method requires manipulation of microorganisms and should be performed only by trained personnel. The U.S. Department of Health and Human Services publication Biosafety in Microbiological and Biomedical Laboratories (CDC/NIH-HHS Publication No. 84-8395) should be consulted for guidance. 1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard. 1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. 1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

ASTM F1608-21 is classified under the following ICS (International Classification for Standards) categories: 07.100.01 - Microbiology in general; 55.040 - Packaging materials and accessories. The ICS classification helps identify the subject area and facilitates finding related standards.

ASTM F1608-21 has the following relationships with other standards: It is inter standard links to ASTM E691-13, ASTM E691-11, ASTM E691-08, ASTM E691-05, ASTM E691-99. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ASTM F1608-21 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F1608 − 21

Standard Test Method for

Microbial Ranking of Porous Packaging Materials (Exposure

Chamber Method)

This standard is issued under the fixed designation F1608; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.5 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 This test method is used to determine the passage of

ization established in the Decision on Principles for the

airborne bacteria through porous materials intended for use in

Development of International Standards, Guides and Recom-

packagingsterilemedicaldevices.Thistestmethodisdesigned

mendations issued by the World Trade Organization Technical

to test materials under conditions that result in the detectable

Barriers to Trade (TBT) Committee.

passage of bacterial spores through the test material.

1.1.1 Around-robin study was conducted with eleven labo-

2. Referenced Documents

ratories participating. Each laboratory tested duplicate samples

2.1 ASTM Standards:

of six commercially available porous materials to determine

E691Practice for Conducting an Interlaboratory Study to

theLogReductionValue(LRV)(seecalculationinSection12).

Determine the Precision of a Test Method

Materialstestedunderthestandardconditionsdescribedinthis

testmethodreturnedaveragevaluesthatrangefromLRV1.7to

3. Terminology

4.3.

3.1 Definitions:

1.1.2 Results of this round-robin study indicate that caution

3.1.1 porous packaging material, n—a material used in

should be used when comparing test data and ranking

medical packaging which is intended to provide an environ-

materials,especiallywhenasmallnumberofsamplereplicates

mentalandbiologicalbarrier,whileallowingsufficientairflow

are used. In addition, further collaborative work (such as

to be used in gaseous sterilization methods (for example,

described in Practice E691) should be conducted before this

ethylene oxide, steam, gas plasma).

test method would be considered adequate for purposes of

setting performance standards.

4. Summary of Test Method

1.2 This test method requires manipulation of microorgan-

4.1 Samples of porous materials are subjected to an aerosol

isms and should be performed only by trained personnel. The

of Bacillus atrophaeus spores within an exposure chamber.

U.S. Department of Health and Human Services publication

Spores which pass through the porous sample are collected on

Biosafety in Microbiological and Biomedical Laboratories

membrane filters and enumerated. The LRV is calculated by

(CDC/NIH-HHS Publication No. 84-8395) should be con-

comparing the logarithm of the number of spores passing

sulted for guidance.

throughtheporousmaterialwiththelogarithmofthemicrobial

1.3 The values stated in SI units are to be regarded as

challenge.

standard. No other units of measurement are included in this

4.2 Standard Set of Conditions—This test method specifies

standard.

a standard set of conditions for conducting the exposure

1.4 This standard does not purport to address all of the

chambertestmethod.Astandardsetofconditionsisrequiredto

safety concerns, if any, associated with its use. It is the

enable evaluation of materials between laboratories. The con-

responsibility of the user of this standard to establish appro-

ditions stated in this test method were chosen for several

priate safety, health, and environmental practices and deter-

reasons. First, it is difficult to maintain an aerosol of spores

mine the applicability of regulatory limitations prior to use.

over long periods of time. (Also, if the spore challenge time is

long, the cost of the test increases). Second, to determine the

differences between materials, it is necessary to test the

ThistestmethodisunderthejurisdictionofASTMCommitteeF02onPrimary

Barrier Packaging and is the direct responsibility of Subcommittee F02.15 on

Chemical/Safety Properties. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2021. Published November 2021. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1995. Last previous edition approved in 2016 as F1608–16. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F1608-21. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1608 − 21

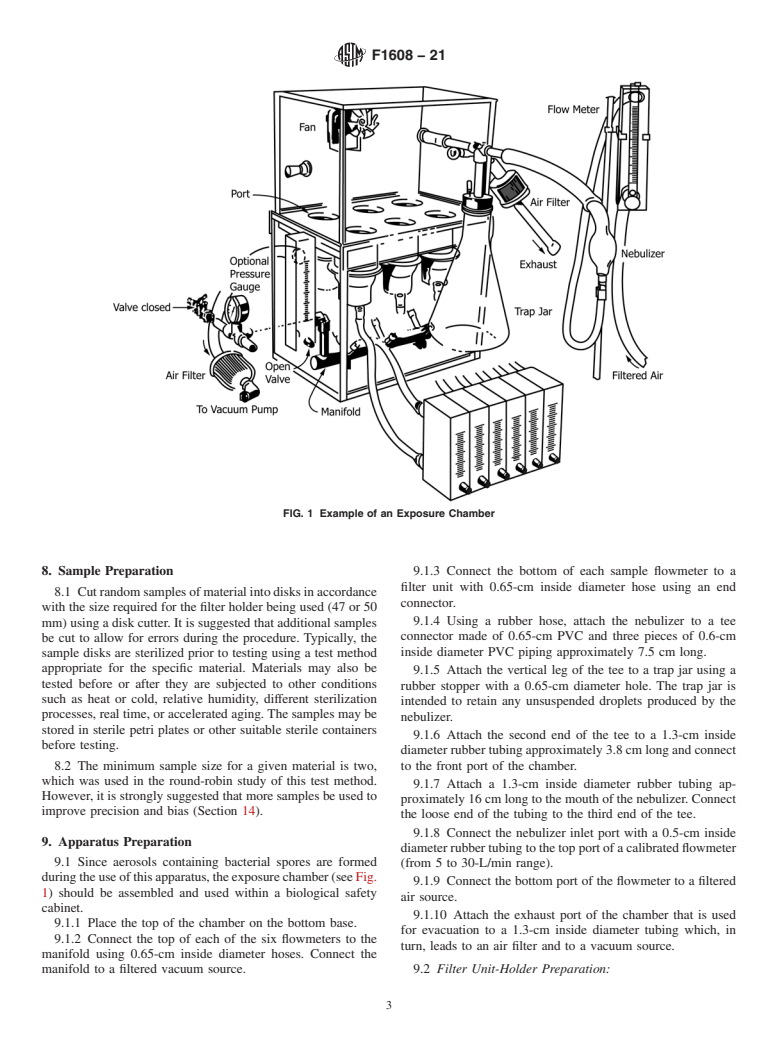

materials under conditions which allow passage of bacterial 6.2 Exposure Chamber, constructed primarily from acrylic

spores. If a material does not allow any passage of spores, all sheeting and consists of two major sections, as illustrated in

that can be stated is that it has better resistance to penetration Fig. 1. The bottom section contains a six-place manifold

than the severity of the challenge conditions. Third, it is connected to six flowmeters, one per port, containing hoses

necessary to have a large spore challenge level to be able to attached to six filtering units. The port to the manifold is

detect the passage of spores through the entire range of attached to a vacuum source. A vacuum gauge is mounted

commercially available porous packaging materials. The stan- between the manifold and the vacuum source. The upper

dard conditions stated in this test method are based upon these chamber contains a fan for dispersion of the bacterial aerosol,

factors. (Additional information may be found in the Refer- aportforattachmentofthenebulizer,aportforexhaustingthe

ences section). However, since many factors influence the chamber, and a plate for attachment of disposable or steriliz-

determination of an appropriate porous material (outlined in ablefilterunits.Thechambermayusedisposablefilterunitsor

5.1.1 – 5.1.4), each user may modify these conditions (that is, reusable filter units, or both.

bacterial challenge, time, flow rate) after first conducting

studiesatthespecifiedstandardconditions.Thestandardsetof 7. Materials

targetparametersforconductingthetestmethodareasfollows:

7.1 Bacillus atrophaeus (ATCC9372), aqueous spore sus-

4.2.1 Flow Rate Through Sample—2.8 L/min.

pension in water.

4.2.2 Exposure Time— 15 min.

7.2 Soybean Casein Digest Agar/ Tryptic Soy Agar—Bottles

4.2.3 Target Microbial Challenge —1×10 colony forming

for pour plates and pre-poured plates (;25 mL in 100 by

units (CFU)/sample port.

15-mm plates) prepared commercially or in accordance with

standard techniques.

5. Significance and Use

7.3 Sterile Cellulose Nitrate Filters, 47 or 50-mm diameter,

5.1 The exposure-chamber method is a quantitative proce-

depending upon filter unit specification, 0.45-µm pore size.

dure for determining the microbial-barrier properties of porous

materials under the conditions specified by the test. Data 7.4 Sterile Bottle-Top Filter Units, (Falcon-type 7104 or

obtained from this test is useful in assessing the relative

filter holders with funnel 310-4000 or equivalent).

potential of a particular porous material in contributing to the

7.5 Glass Nebulizer.

loss of sterility to the contents of the package versus another

7.6 Sterile Forceps.

porous material.This test method is not intended to predict the

performance of a given material in a specific sterile-packaging

7.7 Incubator, 30 to 35°C.

application. The maintenance of sterility in a particular pack-

7.8 Disk Cutter, 47 or 50-mm diameter, depending upon

aging application will depend on a number of factors,

filter unit specification.

including, but not limited to the following:

7.9 Sterile Gloves.

5.1.1 The bacterial challenge (number and kinds of micro-

organisms) that the package will encounter in its distribution

7.10 Sterile Syringe, 3-cm with needle or micropipette.

and use. This may be influenced by factors such as shipping

7.11 Sterile Pipettes, to deliver 0.1, 1, 10, and 25 mL.

methods, expected shelf life, geographic location, and storage

7.12 Blender, with sterile ⁄2-pt jar(s).

conditions.

5.1.2 The package design, including factors such as adhe-

7.13 Vortex Mixer.

sion between materials, the presence or absence of secondary

7.14 Vacuum Pump, with air filter.

and tertiary packaging, and the nature of the device within the

7.15 NIST Traceable Calibrated Timer.

package.

5.1.3 The rate and volume exchange of air that the porous

7.16 NIST Traceable Calibrated Flowmeters—Onepressure

package encounters during its distribution and shelf life. This

flowmeter with a range from 5 to 30 L/min; six vacuum

can be influenced by factors including the free-air volume

flowmeters each with a range from 1.0 to 5.0 L/min.

within the package and pressure changes occurring as a result

7.17 Sterile Petri Plates.

of transportation, manipulation, weather, or mechanical influ-

7.18 Sterile Water, 100 and 9.9-mLaliquots, or other appro-

ences (such as room door closures and HVAC systems).

priate volumes for membrane grinding and dilutions.

5.1.4 The microstructure of a porous material which influ-

ences the relative ability to adsorb or entrap microorganisms,

7.19 Hoses and Piping— See Section 9 for lengths and

or both, under different air-flow conditions.

diameters.

7.20 Rubber Stoppers with Holes—See Section 9 for sizes.

6. Apparatus

7.21 Trap Jar.

6.1 This procedure should be conducted in a microbiologi-

7.22 NIST Traceable Calibrated Vacuum Gauge.

cal laboratory by trained personnel. As a result, it is assumed

thatbasicmicrobiologicalequipmentandsuppliesforconduct-

7.23 Compressed Air Source, with air filter.

ing routine microbiological manipulations (that is, standard

7.24 Biocontainment Hood.

plate counts, sterilization with an autoclave, and so forth) will

be available. 7.25 Chlorine Bleach, or suitable sporocide.

F1608 − 21

FIG. 1 Example of an Exposure Chamber

8. Sample Preparation 9.1.3 Connect the bottom of each sample flowmeter to a

filter unit with 0.65-cm inside diameter hose using an end

8.1 Cutrandomsamplesofmaterialintodisksinaccordance

connector.

with the size required for the filter holder being used (47 or 50

9.1.4 Using a rubber hose, attach the nebulizer to a tee

mm) using a disk cutter. It is suggested that additional samples

connector made of 0.65-cm PVC and three pieces of 0.6-cm

be cut to allow for errors during the procedure. Typically, the

inside diameter PVC piping approximately 7.5 cm long.

sample disks are sterilized prior to testing using a test method

appropriate for the specific material. Materials may also be

9.1.5 Attach the vertical leg of the tee to a trap jar using a

tested before or after they are subjected to other conditions

rubber stopper with a 0.65-cm diameter hole. The trap jar is

such as heat or cold, relative humidity, different sterilization

intended to retain any unsuspended droplets produced by the

processes, real time, or accelerated aging.The samples may be

nebulizer.

stored in sterile petri plates or other suitable sterile containers

9.1.6 Attach the second end of the tee to a 1.3-cm inside

before testing.

diameterrubbertubingapproximately3.8cmlongandconnect

8.2 The minimum sample size for a given material is two, to the front port of the chamber.

which was used in the round-robin study of this test method.

9.1.7 Attach a 1.3-cm inside diameter rubber tubing ap-

However,itisstronglysuggestedthatmoresamplesbeusedto

proximately16cmlongtothemouthofthenebulizer.Connect

improve precision and bias (Section 14).

the loose end of the tubing to the third end of the tee.

9.1.8 Connect the nebulizer inlet port with a 0.5-cm inside

9. Apparatus Preparation

diameterrubbertubingtothetopportofacalibratedflowmeter

9.1 Since aerosols containing bacterial spores are formed

(from 5 to 30-L/min range).

duringtheuseofthisapparatus,theexposurechamber(seeFig.

9.1.9 Connect the bottom port of the flowmeter to a filtered

1) should be assembled and used within a biological safety

air source.

cabinet.

9.1.10 Attach the exhaust port of the chamber that is used

9.1.1 Place the top of the chamber on the bottom base.

for evacuation to a 1.3-cm inside diameter tubing which, in

9.1.2 Connect the top of each of the six flowmeters to the

turn, leads to an air filter and to a vacuum source.

manifold using 0.65-cm inside diameter hoses. Connect the

manifold to a filtered vacuum source. 9.2 Filter Unit-Holder Preparation:

F1608 − 21

9.2.1 Wrap the non-sterile sterilizable filter unit in a steril- of 3.0 mLat a concentration of 5×10 spores/mLis necessary

izable wrap. toachieveachallengeof1×10 CFU(60.5log)perportin15

9.2.2 Sterilize the filter units as specified by the manufac- min.

turer. Presterilized filter units do not need to be resterilized. 10.1.5 Turn on the chamber fan.

10.1.6 Adjust port flowmeters to 2.8 L/min. It is important

10. Apparatus Validation that all ports be set to the same flow and monitored during the

exposure period. Before adjusting each flowmeter, open each

10.1 The test apparatus (see Fig. 1) must be validated for

valve completely, then slowly open the vacuum and fine adjust

bacterialchallengetoeachport.Thisstepshouldbeperformed

until the desired flow is achieved.

upon first use of the chamber and a minimum of three runs

10.1.7 Adjust the nebulizer flow rate as recommended by

should be conducted. The following description outlines the

6 the nebulizer manufacturer to produce droplets that are within

validation of the test procedure for a challenge of 1×10

the appropriate particle size range. When using the DeVilbiss

colonyformingunits(CFU)perportin15minataflowrateof

#40 nebulizer, a flow rate of 8.5 L/min is used.

2.8L/min.Iftestingistobeconductedusingotherparameters,

10.1.8 Immediately start the 15-min timer. At regular

a validation should be conducted using those parameters.

intervals, observe and adjust (if necessary) all flowmeters to

10.1.1 Place the sterile filtering apparatus in a biological

maintain the appropriate flow rate settings during the 15-min

safety cabinet.

test period.

10.1.2 Asepticallypreparesixfilterunitsbyplacingasterile

10.1.9 After exposure, turn off the vacuum, the fan, and the

0.45-µm membrane filter on the base of each filter unit using

air flow to the nebulizer. Open the filtered exhaust port at the

sterile forceps and gloves (Fig. 2B).

back of the chamber.

10.1.3 Attach the top of each filter unit to the bottom of the

10.1.10 Evacuate the chamber for 15 min by connecting the

exposure chamber.Then attach each filter unit to its respective

vacuum source to the front of the chamber through a microbial

flowmeter.

filter assembly.

10.1.4 Dispense 3.0 mL of the spore suspension into the

10.1.11 Disconnect the hoses from each of the filter units

nebulizer. When using the DeVilbiss #40 nebulizer, a volume

and remove the units from the bottom plate of the exposure

chamber.

10.1.12 Disinfect the outside of each filtering unit with a

suitable sporicide being careful not to compromise the test

material.

FIG. 2 Sample and Control Material Setup FIG. 3 Example of Possible Dilution Scheme

F1608 − 21

10.1.13 Remove the filter membranes aseptically, one at a 11.2 Aseptically place a sterile 0.45-µm membrane filter on

time,andenumeratetheorganismsoneachmembrane(Fig.3). the base of each unit, using sterile forceps and gloves (Fig.

2A).

Since more than 100 CFU are anticipated, the spores must be

elutedfromthemembranebygrindingthemembranefor1min

11.3 Place an appropriate diameter disk of test material on

in a suitable blender that has been validated containing 100.0

top of the membrane (Fig. 2A).

mL of sterile water. Samples are then serially diluted prior to

11.3.1 If the materials to be tested are known to produce

performing standard plate counts to accurately determine the

high LRV values, it may be advisable to include a sample of a

number of spores. A dilution and plating scheme, which was

known material which allows substantial passage of spores in

used in the round-robin study, includes plating 10.0, 1.0, and

each run. A known material will also provide a frame of

0.1-mL aliquots of the blended membrane in duplicate. An

reference. In this case, refer to the sample as the positive

additional 1 to 100 dilution is prepared by placing 0.1 mL in

control.

9.9 mLof sterile water and plating 1.0 and 0.1-mLaliquots of

11.4 Prepare one of the six units with the challenge control

this dilution in duplicate. This scheme produces dilution

membrane (N ) on top of the sterile 0.45-µm membrane filter

−1 −2 −3 −4 −5 0

factors of 10 ,10 ,10 ,10 , and 10 . Other validated

(Fig. 2B).

extraction and enumeration protocols may be used. Plates

11.4.1 This bottom 0.45-µm membrane filter serves as the

having between 25 and 250 CFU should be used for enumera-

negative control.

tion. If alternative test conditions are used, then the previously

11.5 Attach the top of each filter unit to the bottom of the

describeddilutionschememaynotbeappropri

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F1608 − 16 F1608 − 21

Standard Test Method for

Microbial Ranking of Porous Packaging Materials (Exposure

Chamber Method)

This standard is issued under the fixed designation F1608; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method is used to determine the passage of airborne bacteria through porous materials intended for use in packaging

sterile medical devices. This test method is designed to test materials under conditions that result in the detectable passage of

bacterial spores through the test material.

1.1.1 A round-robin study was conducted with eleven laboratories participating. Each laboratory tested duplicate samples of six

commercially available porous materials to determine the Log Reduction Value (LRV) (see calculation in Section 12). Materials

tested under the standard conditions described in this test method returned average values that range from LRV 1.7 to 4.3.

1.1.2 Results of this round-robin study indicate that caution should be used when comparing test data and ranking materials,

especially when a small number of sample replicates are used. In addition, further collaborative work (such as described in Practice

E691) should be conducted before this test method would be considered adequate for purposes of setting performance standards.

1.2 This test method requires manipulation of microorganisms and should be performed only by trained personnel. The U.S.

Department of Health and Human Services publication Biosafety in Microbiological and Biomedical Laboratories (CDC/NIH-

HHS Publication No. 84-8395) should be consulted for guidance.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

This test method is under the jurisdiction of ASTM Committee F02 on FlexiblePrimary Barrier Packaging and is the direct responsibility of Subcommittee F02.15 on

Chemical/Safety Properties.

Current edition approved May 1, 2016Oct. 1, 2021. Published June 2016November 2021. Originally approved in 1995. Last previous edition approved in 20092016 as

F1608 – 00 (2009).F1608 – 16. DOI: 10.1520/F1608-16.10.1520/F1608-21.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1608 − 21

3. Terminology

3.1 Definitions:

3.1.1 porous packaging material, n—a material used in medical packaging which is intended to provide an environmental and

biological barrier, while allowing sufficient air flow to be used in gaseous sterilization methods (for example, ethylene oxide,

steam, gas plasma).

4. Summary of Test Method

4.1 Samples of porous materials are subjected to an aerosol of Bacillus atrophaeus spores within an exposure chamber. Spores

which pass through the porous sample are collected on membrane filters and enumerated. The LRV is calculated by comparing the

logarithm of the number of spores passing through the porous material with the logarithm of the microbial challenge.

4.2 Standard Set of Conditions—This test method specifies a standard set of conditions for conducting the exposure chamber test

method. A standard set of conditions is required to enable evaluation of materials between laboratories. The conditions stated in

this test method were chosen for several reasons. First, it is difficult to maintain an aerosol of spores over long periods of time.

(Also, if the spore challenge time is long, the cost of the test increases). Second, to determine the differences between materials,

it is necessary to test the materials under conditions which allow passage of bacterial spores. If a material does not allow any

passage of spores, all that can be stated is that it has better resistance to penetration than the severity of the challenge conditions.

Third, it is necessary to have a large spore challenge level to be able to detect the passage of spores through the entire range of

commercially available porous packaging materials. The standard conditions stated in this test method are based upon these factors.

(Additional information may be found in the References section). However, since many factors influence the determination of an

appropriate porous material (outlined in 5.1.1 – 5.1.4), each user may modify these conditions (that is, bacterial challenge, time,

flow rate) after first conducting studies at the specified standard conditions. The standard set of target parameters for conducting

the test method are as follows:

4.2.1 Flow Rate Through Sample—2.8 L/min.

4.2.2 Exposure Time— 15 min.

4.2.3 Target Microbial Challenge —1 × 10 colony forming units (CFU)/sample port.

5. Significance and Use

5.1 The exposure-chamber method is a quantitative procedure for determining the microbial-barrier properties of porous materials

under the conditions specified by the test. Data obtained from this test is useful in assessing the relative potential of a particular

porous material in contributing to the loss of sterility to the contents of the package versus another porous material. This test

method is not intended to predict the performance of a given material in a specific sterile-packaging application. The maintenance

of sterility in a particular packaging application will depend on a number of factors, including, but not limited to the following:

5.1.1 The bacterial challenge (number and kinds of microorganisms) that the package will encounter in its distribution and use.

This may be influenced by factors such as shipping methods, expected shelf life, geographic location, and storage conditions.

5.1.2 The package design, including factors such as adhesion between materials, the presence or absence of secondary and tertiary

packaging, and the nature of the device within the package.

5.1.3 The rate and volume exchange of air that the porous package encounters during its distribution and shelf life. This can be

influenced by factors including the free-air volume within the package and pressure changes occurring as a result of transportation,

manipulation, weather, or mechanical influences (such as room door closures and HVAC systems).

5.1.4 The microstructure of a porous material which influences the relative ability to adsorb or entrap microorganisms, or both,

under different air-flow conditions.

6. Apparatus

6.1 This procedure should be conducted in a microbiological laboratory by trained personnel. As a result, it is assumed that basic

microbiological equipment and supplies for conducting routine microbiological manipulations (that is, standard plate counts,

sterilization with an autoclave, and so forth) will be available.

F1608 − 21

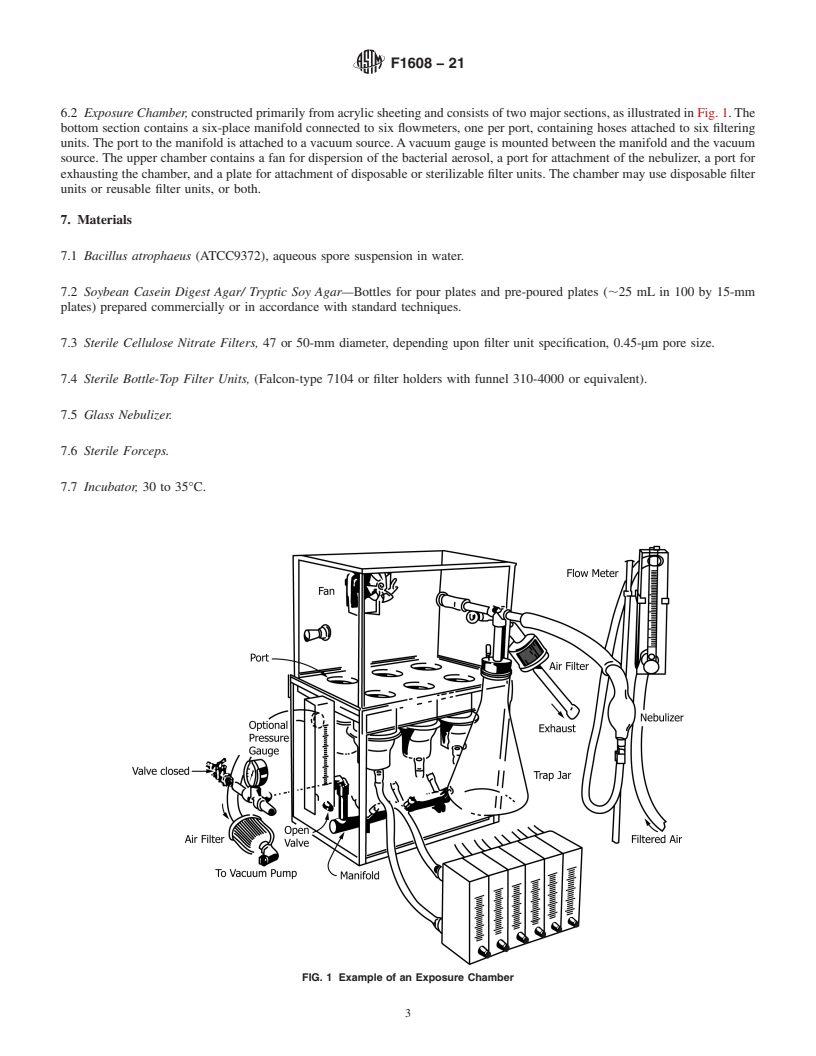

6.2 Exposure Chamber, constructed primarily from acrylic sheeting and consists of two major sections, as illustrated in Fig. 1. The

bottom section contains a six-place manifold connected to six flowmeters, one per port, containing hoses attached to six filtering

units. The port to the manifold is attached to a vacuum source. A vacuum gauge is mounted between the manifold and the vacuum

source. The upper chamber contains a fan for dispersion of the bacterial aerosol, a port for attachment of the nebulizer, a port for

exhausting the chamber, and a plate for attachment of disposable or sterilizable filter units. The chamber may use disposable filter

units or reusable filter units, or both.

7. Materials

7.1 Bacillus atrophaeus (ATCC9372), aqueous spore suspension in water.

7.2 Soybean Casein Digest Agar/ Tryptic Soy Agar—Bottles for pour plates and pre-poured plates (;25 mL in 100 by 15-mm

plates) prepared commercially or in accordance with standard techniques.

7.3 Sterile Cellulose Nitrate Filters, 47 or 50-mm diameter, depending upon filter unit specification, 0.45-μm pore size.

7.4 Sterile Bottle-Top Filter Units, (Falcon-type 7104 or filter holders with funnel 310-4000 or equivalent).

7.5 Glass Nebulizer.

7.6 Sterile Forceps.

7.7 Incubator, 30 to 35°C.

FIG. 1 Example of an Exposure Chamber

F1608 − 21

7.8 Disk Cutter, 47 or 50-mm diameter, depending upon filter unit specification.

7.9 Sterile Gloves.

7.10 Sterile Syringe, 3-cm with needle or micropipette.

7.11 Sterile Pipettes, to deliver 0.1, 1, 10, and 25 mL.

7.12 Blender, with sterile ⁄2-pt jar(s).

7.13 Vortex Mixer.

7.14 Vacuum Pump, with air filter.

7.15 NIST Traceable Calibrated Timer.

7.16 NIST Traceable Calibrated Flowmeters—One pressure flowmeter with a range from 5 to 30 L/min; six vacuum flowmeters

each with a range from 1.0 to 5.0 L/min.

7.17 Sterile Petri Plates.

7.18 Sterile Water, 100 and 9.9-mL aliquots, or other appropriate volumes for membrane grinding and dilutions.

7.19 Hoses and Piping— See Section 9 for lengths and diameters.

7.20 Rubber Stoppers with Holes—See Section 9 for sizes.

7.21 Trap Jar.

7.22 NIST Traceable Calibrated Vacuum Gauge.

7.23 Compressed Air Source, with air filter.

7.24 Biocontainment Hood.

7.25 Chlorine Bleach, or suitable sporocide.

8. Sample Preparation

8.1 Cut random samples of material into disks in accordance with the size required for the filter holder being used (47 or 50 mm)

using a disk cutter. It is suggested that additional samples be cut to allow for errors during the procedure. Typically, the sample

disks are sterilized prior to testing using a test method appropriate for the specific material. Materials may also be tested before

or after they are subjected to other conditions such as heat or cold, relative humidity, different sterilization processes, real time,

or accelerated aging. The samples may be stored in sterile petri plates or other suitable sterile containers before testing.

8.2 The minimum sample size for a given material is two, which was used in the round-robin study of this test method. However,

it is strongly suggested that more samples be used to improve precision and bias (Section 14).

F1608 − 21

9. Apparatus Preparation

9.1 Since aerosols containing bacterial spores are formed during the use of this apparatus, the exposure chamber (see Fig. 1)

should be assembled and used within a biological safety cabinet.

9.1.1 Place the top of the chamber on the bottom base.

9.1.2 Connect the top of each of the six flowmeters to the manifold using 0.65-cm inside diameter hoses. Connect the manifold

to a filtered vacuum source.

9.1.3 Connect the bottom of each sample flowmeter to a filter unit with 0.65-cm inside diameter hose using an end connector.

9.1.4 Using a rubber hose, attach the nebulizer to a tee connector made of 0.65-cm PVC and three pieces of 0.6-cm inside diameter

PVC piping approximately 7.5 cm long.

9.1.5 Attach the vertical leg of the tee to a trap jar using a rubber stopper with a 0.65-cm diameter hole. The trap jar is intended

to retain any unsuspended droplets produced by the nebulizer.

9.1.6 Attach the second end of the tee to a 1.3-cm inside diameter rubber tubing approximately 3.8 cm long and connect to the

front port of the chamber.

9.1.7 Attach a 1.3-cm inside diameter rubber tubing approximately 16 cm long to the mouth of the nebulizer. Connect the loose

end of the tubing to the third end of the tee.

9.1.8 Connect the nebulizer inlet port with a 0.5-cm inside diameter rubber tubing to the top port of a calibrated flowmeter (from

5 to 30-L/min range).

9.1.9 Connect the bottom port of the flowmeter to a filtered air source.

9.1.10 Attach the exhaust port of the chamber that is used for evacuation to a 1.3-cm inside diameter tubing which, in turn, leads

to an air filter and to a vacuum source.

9.2 Filter Unit-Holder Preparation:

9.2.1 Wrap the non-sterile sterilizable filter unit in a sterilizable wrap.

9.2.2 Sterilize the filter units as specified by the manufacturer. Presterilized filter units do not need to be resterilized.

10. Apparatus Validation

10.1 The test apparatus (see Fig. 1) must be validated for bacterial challenge to each port. This step should be performed upon

first use of the chamber and a minimum of three runs should be conducted. The following description outlines the validation of

the test procedure for a challenge of 1 × 10 colony forming units (CFU) per port in 15 min at a flow rate of 2.8 L/min. If testing

is to be conducted using other parameters, a validation should be conducted using those parameters.

10.1.1 Place the sterile filtering apparatus in a biological safety cabinet.

10.1.2 Aseptically prepare six filter units by placing a sterile 0.45-μm membrane filter on the base of each filter unit using sterile

forceps and gloves (Fig. 2B).

10.1.3 Attach the top of each filter unit to the bottom of the exposure chamber. Then attach each filter unit to its respective

flowmeter.

10.1.4 Dispense 3.0 mL of the spore suspension into the nebulizer. When using the DeVilbiss #40 nebulizer, a volume of 3.0 mL

7 6

at a concentration of 5 × 10 spores/mL is necessary to achieve a challenge of 1 × 10 CFU (60.5 log) per port in 15 min.

10.1.5 Turn on the chamber fan.

F1608 − 21

FIG. 2 Sample and Control Material Setup

10.1.6 Adjust port flowmeters to 2.8 L/min. It is important that all ports be set to the same flow and monitored during the exposure

period. Before adjusting each flowmeter, open each valve completely, then slowly open the vacuum and fine adjust until the desired

flow is achieved.

10.1.7 Adjust the nebulizer flow rate as recommended by the nebulizer manufacturer to produce droplets that are within the

appropriate particle size range. When using the DeVilbiss #40 nebulizer, a flow rate of 8.5 L/min is used.

10.1.8 Immediately start the 15-min timer. At regular intervals, observe and adjust (if necessary) all flowmeters to maintain the

appropriate flow rate settings during the 15-min test period.

10.1.9 After exposure, turn off the vacuum, the fan, and the air flow to the nebulizer. Open the filtered exhaust port at the back

of the chamber.

10.1.10 Evacuate the chamber for 15 min by connecting the vacuum source to the front of the chamber through a microbial filter

assembly.

10.1.11 Disconnect the hoses from each of the filter units and remove the units from the bottom plate of the exposure chamber.

10.1.12 Disinfect the outside of each filtering unit with a suitable sporicide being careful not to compromise the test material.

10.1.13 Remove the filter membranes aseptically, one at a time, and enumerate the organisms on each membrane (Fig. 3). Since

more than 100 CFU are anticipated, the spores must be eluted from the membrane by grinding the membrane for 1 min in a suitable

blender that has been validated containing 100.0 mL of sterile water. Samples are then serially diluted prior to performing standard

plate counts to accurately determine the number of spores. A dilution and plating scheme, which was used in the round-robin study,

includes plating 10.0, 1.0, and 0.1-mL aliquots of the blended membrane in duplicate. An additional 1 to 100 dilution is prepared

F1608 − 21

FIG. 3 Example of Possible Dilution Scheme

by placing 0.1 mL in 9.9 mL of sterile water and plating 1.0 and 0.1-mL aliquots of this dilution in duplicate. This scheme produces

−1 −2 −3 −4 −5

dilution factors of 10 , 10 , 10 , 10 , and 10 . Other validated extraction and enumeration protocols may be used. Plates

having between 25 and 250 CFU should be used for enumeration. If alternative test conditions are used, then the previously

described dilution scheme may not be appropriate. In instances where colony counts are less than 30 CFU, the limit of detection

is dependent upon the volume of the undiluted aliquot plated from the blender jar. Duplicate 10-mL samples will result in a limit

of detection of 5 CFU/membrane. If a lower limit is desired, plate an appropriately larger volume. However, there is increased

statistical variation with these low numbers. If the membrane grinding and plating procedure consistently results in counts less than

25 CFU from all dilutions, enumeration can be accomplished by placing the membrane directly onto the surface of a SCDA plate

with the challenge side up.

10.1.14 Enumeration cultures are incubated for a minim

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...