ASTM E430-97(2003)

(Test Method)Standard Test Methods for Measurement of Gloss of High-Gloss Surfaces by Goniophotometry

Standard Test Methods for Measurement of Gloss of High-Gloss Surfaces by Goniophotometry

SCOPE

1.1 These test methods cover the measurement of the reflection characteristics responsible for the glossy appearance of high-gloss surfaces. Two test methods, A and B, are provided for evaluating such surface characteristics at specular angles of 30 and 20, respectively. These test methods are not suitable for diffuse finish surfaces nor do they measure color, another appearance attribute.

1.2 As originally developed by Tingle and others (see Refs 1 and 2), the test methods were applied only to bright metals. Recently they have been applied to high-gloss automotive finishes and other nonmetallic surfaces.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E430–97(Reapproved2003)

Standard Test Methods for

Measurement of Gloss of High-Gloss Surfaces by

Goniophotometry

This standard is issued under the fixed designation E430; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1.1 reflectance, r,n—ratio of the reflected radiant or

luminous flux to the incident flux in the given conditions.

1.1 These test methods cover the measurement of the

(E284)

reflection characteristics responsible for the glossy appearance

(1) Discussion—The term reflectance is often used in a

of high-gloss surfaces. Two test methods, A and B, are

general sense or as an abbreviation for reflectance factor. Such

provided for evaluating such surface characteristics at specular

usage is not assumed in this method. The definition may

angles of 30° and 20°, respectively.These test methods are not

require that the term be modified by adjectives denoting the

suitable for diffuse finish surfaces nor do they measure color,

spectral and geometric conditions of measurement.

another appearance attribute.

3.1.1.2 reflectance factor, R, n—ratio of the flux reflected

1.2 As originally developed by Tingle and others (see Refs

2 from the specimen to the flux reflected from the perfect

1 and 2), the test methods were applied only to bright metals.

reflecting diffuser under the same spectral and geometric

Recently they have been applied to high-gloss automotive

conditions of measurement. (E284)

finishes and other nonmetallic surfaces.

3.1.1.3 gloss reflectance factor, R,n—ratio of the specu-

s

2. Referenced Documents larly reflected part of the (whole) flux reflected from the

specimen to the flux reflected from a specified gloss standard

2.1 ASTM Standards:

under the same geometric and spectral conditions of measure-

D523 Test Method for Specular Gloss

ment.

D2457 TestMethodforSpecularGlossofPlasticFilmsand

(1) Discussion—The gloss standard may be a black glass or

Solid Plastics

a mirror, and may be assigned one of a variety of scale values

E171 Specification for Standard Atmospheres for Condi-

G as specified. (E284)

tioning and Testing Flexible Barrier Materials s

3.1.2 Gloss and Types of Gloss:

E179 Guide for Selection of Geometric Conditions for

3.1.2.1 gloss, n—angular selectivity of reflected light, re-

Measurement of Reflectance and Transmission Properties

sponsibleforthedegreetowhichreflectedhighlightsorimages

of Materials

of objects may be seen as superimposed on a surface. (E284)

E284 Terminology of Appearance

(1) Discussion—Gloss is responsible for the object’s glossy

E308 Practice for Computing the Colors of Objects by

appearance,notforanobserver’sperceptionoftheappearance.

Using the CIE System

At least six types or characteristics of gloss may be observed

E1347 Test Method for Color and Color-Difference Mea-

depending upon the character of the surface and the spatial

surement by Tristimulus (Filler) Colormetry

distribution of the reflected light (3).

3. Terminology

3.1.2.2 specular gloss, n—ratio of flux reflected in specular

direction to incident flux for a specified angle of incidence and

3.1 Definitions:

source and receptor angular apertures. (E284)

3.1.1 Reflectance and Related Terms:

3.1.2.3 distinctness-of-image gloss, n—aspectofglosschar-

acterized by the sharpness of images of objects produced by

These test methods are under the jurisdiction of ASTM Committee E12 on

reflection at a surface. (E284)

Color andAppearance and are the direct responsibility of Subcommittee E12.03 on

3.1.2.4 sheen, n—the specular gloss at a large angle of

Geometry.

incidence for an otherwise matte specimen. (The usual angle

Current edition approved Jan. 10, 2003. Published March 2003. Originally

approved in 1971. Last previous edition approved in 1997 as E430–97. for measurement is 85°.) (E284)

The boldface numbers in parentheses refer to the list of references at the end of

3.1.3 Terms Relating to Surface Characteristics:

this method.

Annual Book of ASTM Standards, Vol 06.01.

Annual Book of ASTM Standards, Vol 08.02.

Annual Book of ASTM Standards, Vol 15.09.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E430–97 (2003)

3.1.3.1 directionality, n—perceived, the degree to which the 5. Significance and Use

appearance of a surface changes as the surface is rotated in its

5.1 Theglossofmetallicfinishesisimportantcommercially

ownplane,underfixedconditionsofilluminationandviewing.

on metals for automotive, architectural, and other uses where

(E284)

thesemetalsundergospecialfinishingprocessestoproducethe

3.1.3.2 texture, n—the visible surface structure depending

appearancesdesired.Itisimportantfortheend-productswhich

on the size and organization of small constituent parts of a

use such finished metals that parts placed together have the

material; typically, the surface structure of a woven fabric.

same glossy appearance.

(E284)

5.2 It is also important that automotive finishes and other

3.1.4 Other Terms:

high-gloss nonmetallic surfaces possess the desired finished

3.1.4.1 aperture angle, 2 ,n—anglesubtendedatapointon appearance. The present method identifies by measurements

k

a specimen by the maximum dimension of the illuminator or important aspects of finishes. Those having identical sets of

receiver, within which the flux in a directional beam is numbers normally have the same gloss characteristics. It

contained. usually requires more than one measurement to identify

properlytheglossyappearanceofanyfinish(seeRefs 3and 4).

(1) Discussion—In optics, the symbol k is used for the half

angle; hence the recommended symbol here is 2.(E284)

k

6. Apparatus

3.1.4.2 goniophotometer, n—instrument that measures flux

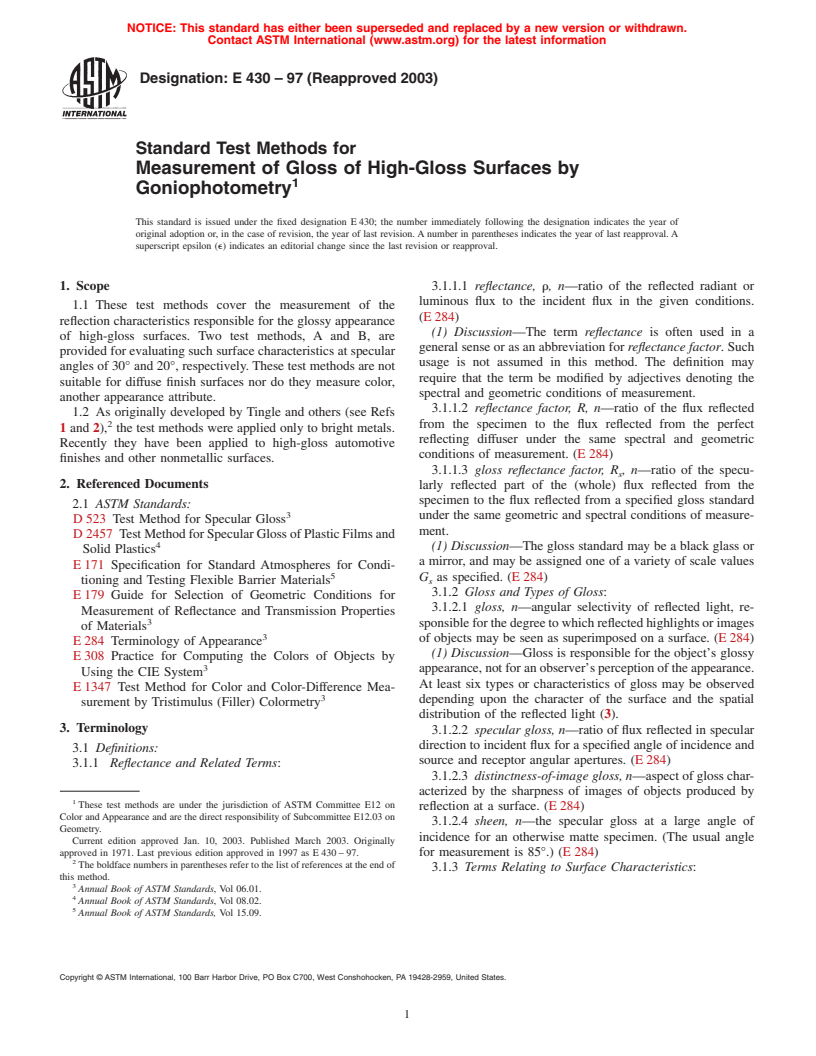

6.1 The apparatus shall be either an abridged goniophotom-

as a function of angles of illumination or observation. (E284)

eter (see Fig. 1 and Fig. 2) or a full goniophotometer (see Fig.

3.2 Terms Specific to This Test Method:

3) that can be set to the specified specular, off-specular, and

3.2.1 Terms Relating to Reflection Haze:

aperture angles given in Table 1 and Table 2. The abridged

3.2.1.1 reflection haze, H, n—for a specified specular angle,

goniophotometer may have a fixed angle of incidence (forTest

ratio of flux reflected at a specified angle (or angles) from the

Method A, 30°; for Test Method B, 20°) and specific fixed

specular direction to the flux similarly reflected at the specular

directions of view at which the flux from the specimen is

angle by a specified gloss standard.

measured (see Table 1 and Table 2).

(1) Discussion—Modifiersmaybeusedtospecifytheangles

6.1.1 Geometric Conditions for Test Method A—The direc-

at which the haze is measured (for example, 2° or 5°); whether

tion of incidence shall be 30°. The directions of view shall be

H or a logarithmic form is to be stated; or whether H is to be

opposite the direction of incidence at 30° for specular reflec-

compensated for the luminance of the specimen by multipli-

tance, 29.7 or 30.3° for distinctness of image comparisons, 28

cation by Y /Y , where n denotes the reference white; or

specimen n

or 32° for narrow-angle haze comparisons, and 25 or 35° for

any combination of these.

wide-angle haze comparisons. The angular dimensions of the

3.2.2 Terms Relating to Metallic Reflection:

mirror reflected image of the source slit in the plane of

3.2.2.1 metallic brightness, n—freedom of a metal surface

measurement and the angular dimensions of the receiver

from diffuse haze or texture.

windows in this plane of measurement shall be as shown in

3.2.3 Terms Relating to Specimen Directionality: Table 1.

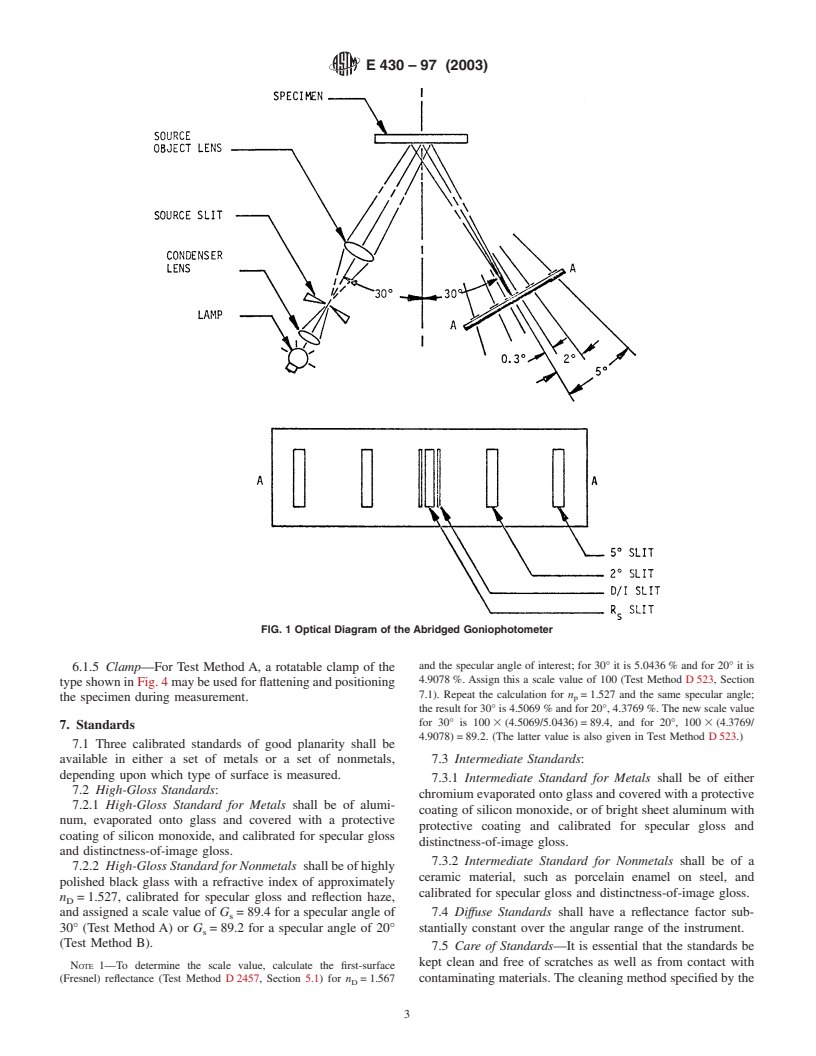

3.2.3.1 ‘with-machine’direction, n—the axis of a specimen 6.1.2 Geometric Conditions for Test Method B—The direc-

tion of incidence shall be 20 6 0.1°. The directions of view

that is parallel to the direction of mill rolling or extrusion, or

other surface-finish texture. shall be opposite the direction of incidence, at 20° for specular

gloss measurement and at 18.1 and 21.9° for narrow-angle

3.2.3.2 ‘across-machine’ direction, n—the perpendicular to

reflection haze measurement. The angular dimensions of the

‘with-machine’ direction.

specularly reflected image of the source slit in the plane of

3.3 Other appearance terms and definitions in Terminology

measurement and the angular dimensions of the receiver

E284 are applicable to this test method.

windows in this plane of measurement shall be as shown in

Table 2.

4. Summary of Test Method

6.1.3 Spectral Conditions—Themeasurementshallbemade

4.1 Several geometrically different measures of light re-

with visible light to give results in accordance with the CIE

flected by a surface are proposed for use in describing its gloss

spectral luminous efficiency function V (l identical with y¯) in

appearance. In Test Method A, gloss reflectance factor is

the CIE 1931 standard observer and CIE standard illuminant C

measured at 30° to the specimen normal using narrow illumi-

(see Practice E308 and Test Method E1347). If another

nator and receiver aperture angles (0.5° wide maximum).

illuminant A, is used, this shall be specified in the report.

Distinctness-of-image gloss is measured at 29.7 or 30.3° or

6.1.4 Polarization—The incident flux shall be unpolarized

both. Narrow-angle (2°) reflection haze is measured at 28 or

and the receiver shall be insensitive to the state of polarization

32° or both, and wide-angle (5°) reflection haze at 25 or 35° or

of the reflected luminous flux.

both. The ratio of reflectance factors for 28 or 32° or both,

perpendicular and parallel to the machine direction of the

specimen, is computed as a measure of directionality. In

The sole source of supply of the apparatus known to the committee at this time

for Method A is Hunter Associates Laboratory, Reston, VA, and for Method B is

Method B, specular gloss is measured at 20° according to Test

BVK-Gardner USA, Columbia, MD. If you are aware of alternative suppliers,

MethodD523,andnarrow-anglereflectionhazeismeasuredat

please provide this information to ASTM International Headquarters. Your com-

18.1 and 21.9°. For additional information on the selection of

ments will receive careful consideration at a meeting of the responsible technical

geometric conditions, see Guide E179. committee, which you may attend.

E430–97 (2003)

FIG. 1 Optical Diagram of the Abridged Goniophotometer

and the specular angle of interest; for 30° it is 5.0436% and for 20° it is

6.1.5 Clamp—For Test Method A, a rotatable clamp of the

4.9078%. Assign this a scale value of 100 (Test Method D523, Section

typeshowninFig.4maybeusedforflatteningandpositioning

7.1). Repeat the calculation for n =1.527 and the same specular angle;

the specimen during measurement. p

the result for 30° is 4.5069% and for 20°, 4.3769%.The new scale value

for 30° is 100 3(4.5069/5.0436)=89.4, and for 20°, 100 3(4.3769/

7. Standards

4.9078)=89.2. (The latter value is also given in Test Method D523.)

7.1 Three calibrated standards of good planarity shall be

available in either a set of metals or a set of nonmetals, 7.3 Intermediate Standards:

depending upon which type of surface is measured.

7.3.1 Intermediate Standard for Metals shall be of either

7.2 High-Gloss Standards:

chromium evaporated onto glass and covered with a protective

7.2.1 High-Gloss Standard for Metals shall be of alumi-

coating of silicon monoxide, or of bright sheet aluminum with

num, evaporated onto glass and covered with a protective

protective coating and calibrated for specular gloss and

coating of silicon monoxide, and calibrated for specular gloss

distinctness-of-image gloss.

and distinctness-of-image gloss.

7.3.2 Intermediate Standard for Nonmetals shall be of a

7.2.2 High-Gloss Standard for Nonmetals shallbeofhighly

ceramic material, such as porcelain enamel on steel, and

polished black glass with a refractive index of approximately

calibrated for specular gloss and distinctness-of-image gloss.

n =1.527, calibrated for specular gloss and reflection haze,

D

7.4 Diffuse Standards shall have a reflectance factor sub-

and assigned a scale value of G =89.4 for a specular angle of

s

30° (Test Method A) or G =89.2 for a specular angle of 20° stantially constant over the angular range of the instrument.

s

(Test Method B).

7.5 Care of Standards—It is essential that the standards be

kept clean and free of scratches as well as from contact with

NOTE 1—To determine the scale value, calculate the first-surface

(Fresnel) reflectance (Test Method D2457, Section 5.1) for n =1.567 contaminating materials.The cleaning method specified by the

D

E430–97 (2003)

of specular gloss and distinctness-of-image gloss assigned the

aluminum mirror if metal surfaces are being measured; or the

black gloss standard if nonmetal surfaces are being measured.

If the instrument does not then read the appropriate interme-

diate standard within the limits set by the instrument manufac-

turer, refocus or restandardize following the manufacturer’s

instructions.

10. Procedure

10.1 Bringthespecimentotheinstrumentformeasurement.

Be sure the specimen is flat.

10.2 For Test MethodA, be certain that the specular sensor

is centered on the specimen-reflected specular light beam. The

full goniophotometer, shown in Fig. 3, identifies the specular

direction by the peak of the goniophotometric curve.

10.3 Rotate the specimen in its own plane to find the

orientation, giving the maximum specular signal. This speci-

men orientation is called the “machine direction” because it

generally coincides with the direction of travel of a sheet or

film material through a processing machine.

10.4 Record the following quantities:

10.4.1 For Test Method A, readings of (a) gloss reflectance

factor (specular gloss), R at 30°; (b) distinctness-of-image

s,30

gloss; (c) 2° reflection haze; H ; and (d) 5° reflection haze, H .

2 5

The quantities in (b), (c), and (d) may be either gloss

reflectance factors or values of H, which are their ratios to the

specular gloss reflectance factor recorded in (a).

10.4.2 For Test Method B, readings of (a) the 20° specular

gloss, R ; (b) the reflection haze, H; and (c) the luminous

s ,20

reflectance, Y.

10.5 Measure at least three areas of each specimen.

10.6 From these same areas, read 2° haze for the“ across-

machine direction,” being careful to flatten the test surface and

FIG. 2 Optical Diagram of the Apparatus for Method B

orient the specular beam in each case.

10.7 Take readings on the standards at the end of the series

of observations to ensure that the instrument h

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.