ASTM D4547-98

(Practice)Standard Guide for Sampling Waste and Soils for Volatile Organic Compounds

Standard Guide for Sampling Waste and Soils for Volatile Organic Compounds

SCOPE

1.1 This practice describes field sampling of solid wastes for subsequent volatile organics analysis in the laboratory. This practice is also intended to apply to soils and sediments that may contain volatile waste constituents.

1.2 Both the collection of the sample and the method of containing the sample for shipment to the laboratory are considered.

1.3 This practice concerns only sampling methods to be used in the field; it does not cover laboratory preparation of containers or solutions or other laboratory techniques related to processing or analysis of the samples.

1.4 It is recommended that this standard be used in conjunction with Guide D4687.

1.5 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see Section 6.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4547 – 98

Standard Guide for

Sampling Waste and Soils for Volatile Organic Compounds

This standard is issued under the fixed designation D 4547; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Title 49 Transportation, Code of Federal Regulations

(CFR), Part 172, List of Hazardous Substances and

1.1 This guide describes recommended procedures for the

Reportable Quantities

collection, handling, and preparation of solid waste, soil, and

sediment samples for subsequent determination of volatile

3. Terminology

organic compounds (VOCs). This class of compounds includes

3.1 sample, n—a portion of material taken from a larger

low molecular weight aromatics, hydrocarbons, halogenated

quantity for the purpose of estimating properties or composi-

hydrocarbons, ketones, acetates, nitriles, acrylates, ethers, and

tion of the larger quantity. (E 856)

sulfides with boiling points below 200° Celsius (C) that are

3.2 subsample, n—a portion of a sample taken for the

insoluble or slightly soluble in water.

purpose of estimating properties or composition of the whole

1.2 Methods of sample collection, handling, and preparation

sample. (D 6051)

for analysis are described.

3.2.1 Discussion—A subsample, by definition, is also a

1.3 This guide does not cover the details of sampling design,

sample.

laboratory preparation of containers, and the analysis of the

samples.

4. Summary of Guide

1.4 It is recommended that this guide be used in conjunction

4.1 This guide addresses the use of tools for sample collec-

with Guide D 4687.

tion and transfer, conditions for sample storage, sample pres-

1.5 This standard does not purport to address all of the

ervation, and two common means of sample preparation for

safety concerns, if any, associated with its use. It is the

analysis. Special attention is given to each step from sample

responsibility of the user of this standard to establish appro-

collection to analysis to limit the loss of VOC s by volatiliza-

priate safety and health practices and determine the applica-

tion of biodegradation. The sample collected and analyzed

bility of regulatory limitations prior to use.

should be representative of the parent material sampled. The

two methods cited for the preparation of samples for VOC

2. Referenced Documents

analysis are methanol extraction and vapor partitioning (that is,

2.1 ASTM Standards:

2 purge-and-trap and headspace). The method of sample prepa-

D 3550 Practice for Ring-Lined Barrel Sampling of Soils

ration for VOC analysis is dependent on the data quality

D 4687 Guide for General Planning of Waste Sampling

2 objectives (see Practice D 5792). Although the equilibrium-

D 4700 Guide for Soil Sampling from the Vadose Zone

–driven proportions of VOC’s in the different phases change

D 5058 Test Methods for Compatibility of Screening

3 during sample preparation and analysis, the overall intent of

Analysis of Waste

the methods in this guide are to minimize VOC losses.

D 5792 Practice for Generation of Environmental Data

Related to Waste Management Activities: Development of

5. Significance and Use

Data Quality Objectives

5.1 This guide describes sample collection and handling

D 6051 Guide for Composite Sampling and Field Subsam-

3 procedures designed to minimize losses of VOCs. The princi-

pling for Environmental Waste Management Activities

pal mechanisms for the loss of VOCs from materials during

E 856 Definitions of Terms and Abbreviations Relating to

collection and handling are volatilization and biodegradation.

Physical and Chemical Characteristics of Refuse-Derived

Susceptibility of various VOCs to these two loss mechanisms

Fuel

is both compound and matrix specific. In general, compounds

2.2 Federal Standard:

with higher vapor pressures are more susceptible to volatiliza-

tion than compounds with lower vapor pressures. Also, aero-

bically degradable compounds are generally more susceptible

This guide is under the jurisdiction of ASTM Committee D34 on Waste

to biodegradation than anaerobically degradable compounds.

Management and is the direct responsibility of Subcommittee D34.01.02 on

Monitoring.

In some cases, the formation of other compounds not originally

Current edition approved Sept. 10, 1998. Published November 1998. Originally

published as D 4547–91. Last previous edition D 4547–91.

2 4

Annual Book of ASTM Standards, Vol 04.08. Available from Superintendent of Documents, U.S. Government Printing

Annual Book of ASTM Standards, Vol 11.04. Office, Washington, DC 20402.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 4547

present in the material can occur. Loss or gain of VOCs leads nary testing be performed to adequately characterize the waste

to analytical results that are both unrepresentative of the field materials so that when the user applies the procedures cited in

conditions and ambiguous. this guide, there will be no chemical reaction which may

5.2 Ancillary information concerning sample collection and jeopardize the user’s safety.

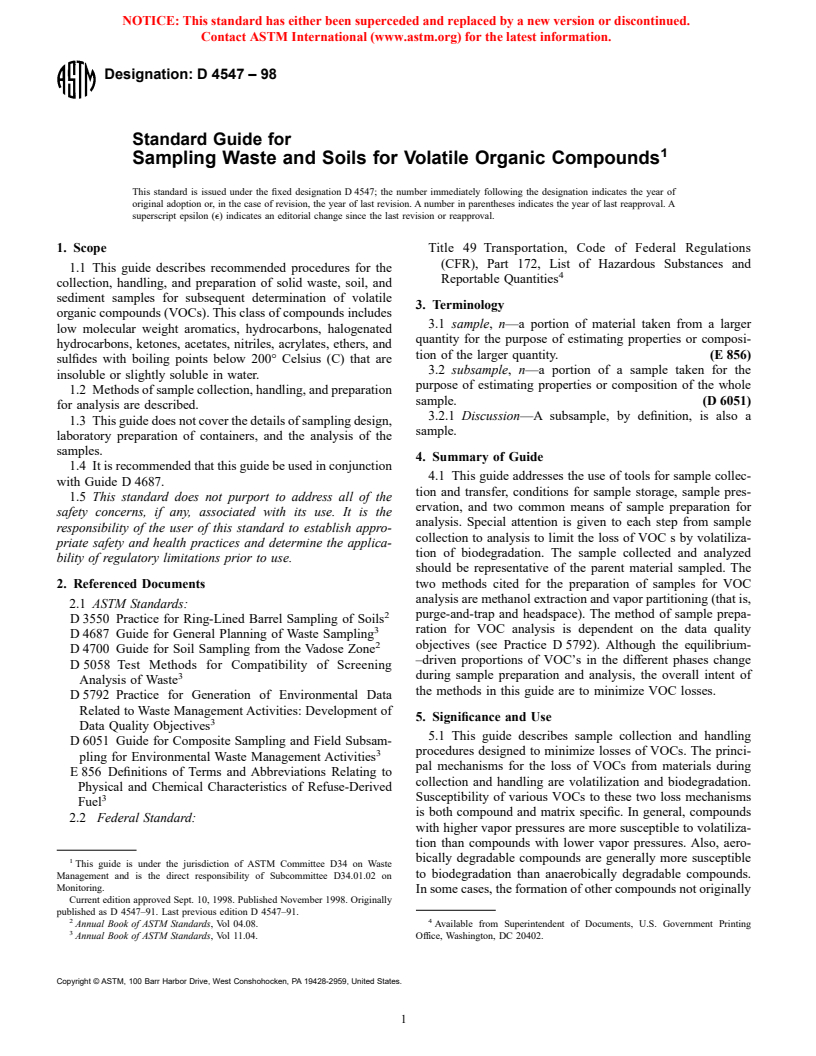

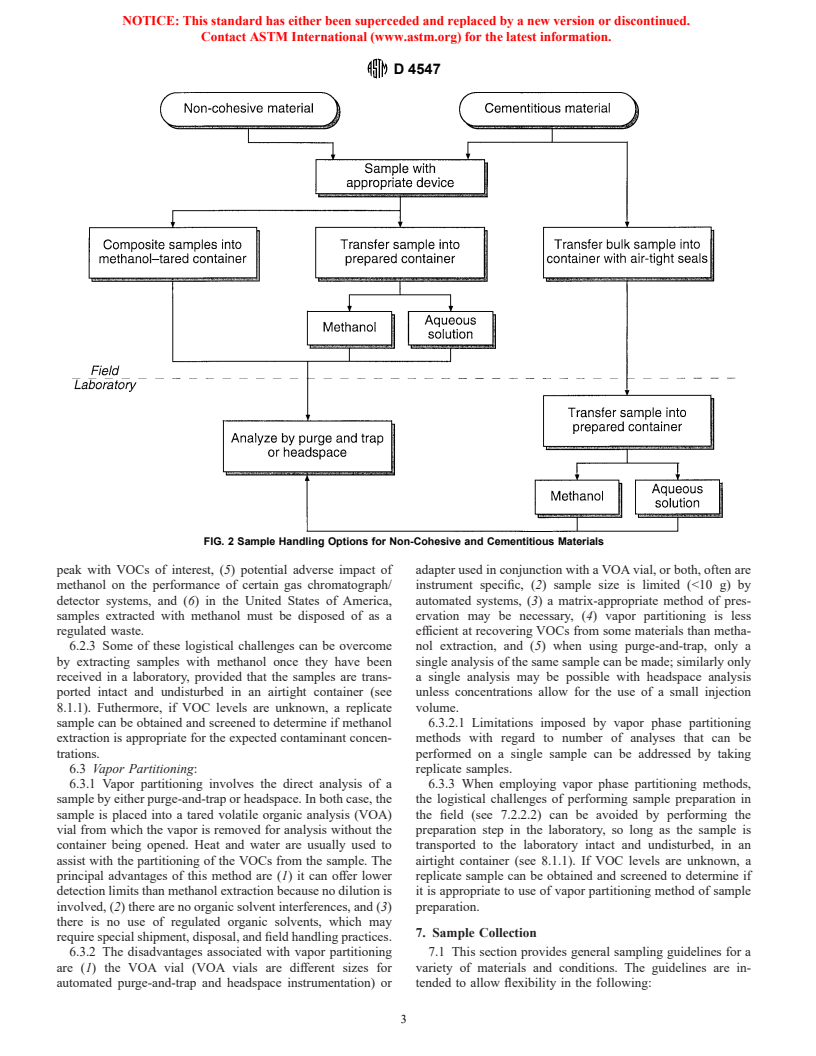

handling for VOC analysis is provided in Appendix X1 and 6.1.2 Figs. 1 and 2 are flow diagrams showing some

Appendix X2. These appendixes and cited references are

different options for combining sample collection, handling

recommended reading for those unfamiliar with many chal- and preparation methods for instrumental analysis.

lenges presented during the collection and handling of samples

6.2 Methanol Extraction:

for VOC analysis.

6.2.1 This method involves the extraction of VOCs from a

sample with methanol and the subsequent transfer of an aliquot

6. Selection of Sample Preparation Method for VOC

of the extract to water for either purge-and-trap or headspace

Analysis

analysis. Advantages of methanol extraction are (1) large

6.1 Introduction: samples or composite samples, or both, can be collected to

enhance representatives (see Guide D 6051), (2) biodegrada-

6.1.1 Sample collection, handling, and preservation meth-

ods should be compatible with the method used to prepare the tion is inhibited, (3) an efficient extraction of VOCs from the

sample for VOC analysis, and meet the project’s data quality matrix materials can be achieved with methanol due to its

objectives (see Practice D 5792). Preparation of a sample for strong affinity for these compounds and favorable wetting

instrumental analysis can be initiated either in the field or properties, (4) a subsample can be analyzed several times, and

laboratory. In either case, the sample should be placed into a (5) sample extracts can be archived (held up to two months,

tared volatile organic analysis (VOA) vial or bottle meeting the and perhaps longer, if verified that VOC losses have not

occurred (see 8.2.1.2)).

specifications given in 7.2.2. When working with an unchar-

acterized solid waste, it is advisable to perform compatibility 6.2.2 The primary disadvantages of methanol extraction are

tests (see Test Methods D 5058) between the sample material (1) samples may have to be shipped as a flammable liquid

and the solution (see 7.2.2.1 and 7.2.2.2) into which it will be depending on the amount of methanol present (U.S. DOT reg.

transferred in preparation for analysis. For instance, when 49CFR§172.101), (2) hazards to personnel due to methanol’s

collecting highly contaminated soils or waste of unknown toxicity and flammability, (3) detection limits are elevated due

composition, or both, it is strongly recommended that prelimi- to analyte dilution, (4) possible interference of the methanol

FIG. 1 Sample Handling Options for Cohesive Materials

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 4547

FIG. 2 Sample Handling Options for Non-Cohesive and Cementitious Materials

peak with VOCs of interest, (5) potential adverse impact of adapter used in conjunction with a VOA vial, or both, often are

methanol on the performance of certain gas chromatograph/ instrument specific, (2) sample size is limited (<10 g) by

detector systems, and (6) in the United States of America, automated systems, (3) a matrix-appropriate method of pres-

samples extracted with methanol must be disposed of as a ervation may be necessary, (4) vapor partitioning is less

regulated waste. efficient at recovering VOCs from some materials than metha-

6.2.3 Some of these logistical challenges can be overcome nol extraction, and (5) when using purge-and-trap, only a

by extracting samples with methanol once they have been single analysis of the same sample can be made; similarly only

received in a laboratory, provided that the samples are trans- a single analysis may be possible with headspace analysis

ported intact and undisturbed in an airtight container (see unless concentrations allow for the use of a small injection

8.1.1). Futhermore, if VOC levels are unknown, a replicate volume.

sample can be obtained and screened to determine if methanol 6.3.2.1 Limitations imposed by vapor phase partitioning

extraction is appropriate for the expected contaminant concen- methods with regard to number of analyses that can be

trations. performed on a single sample can be addressed by taking

6.3 Vapor Partitioning: replicate samples.

6.3.1 Vapor partitioning involves the direct analysis of a 6.3.3 When employing vapor phase partitioning methods,

sample by either purge-and-trap or headspace. In both case, the the logistical challenges of performing sample preparation in

sample is placed into a tared volatile organic analysis (VOA) the field (see 7.2.2.2) can be avoided by performing the

vial from which the vapor is removed for analysis without the preparation step in the laboratory, so long as the sample is

container being opened. Heat and water are usually used to transported to the laboratory intact and undisturbed, in an

assist with the partitioning of the VOCs from the sample. The airtight container (see 8.1.1). If VOC levels are unknown, a

principal advantages of this method are (1) it can offer lower replicate sample can be obtained and screened to determine if

detection limits than methanol extraction because no dilution is it is appropriate to use of vapor partitioning method of sample

involved, (2) there are no organic solvent interferences, and (3) preparation.

there is no use of regulated organic solvents, which may

7. Sample Collection

require special shipment, disposal, and field handling practices.

6.3.2 The disadvantages associated with vapor partitioning 7.1 This section provides general sampling guidelines for a

are (1) the VOA vial (VOA vials are different sizes for variety of materials and conditions. The guidelines are in-

automated purge-and-trap and headspace instrumentation) or tended to allow flexibility in the following:

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 4547

7.1.1 The procedure for obtaining a sample from, for material requirements are less stringent.

example, walls of test pits, surface grid locations, waste piles, 7.2.2 VOA vials and bottles used for storage and preparation

building, and from bulk samples obtained with subsurface of samples for analysis should be made of glass and have

retrieval systems. airtight seals. To achieve and airtight seal, these containers

should have a thick septum cushion between the sealing

7.1.2 The design and dimensions of the equipment used to

material (polytetrafluoroethylene) and cap (rigid plastic screw

obtain and transfer samples of the appropriate size for analysis.

cap or aluminum crimp top). Polytetrafluoroethylene-lined

7.1.3 The selection and preparation of sample containers.

caps that do not have flexible septum backing often fail to

7.2 Preparation for Sampling:

achieve a liquid or airtight seal. Futhermore, the thickness of

7.2.1 All sampling and handling devices and vessels used to

the polytetrafluoroethylene used for a lined septum, should be

collect and store samples for analysis should be constructed of

at least 10 min. These VOA vials and bottles should be

nonreactive materials that will not sorb, leach or diffuse

prepared as described in 7.2.2.1 or 7.2.2.2 prior to adding the

constituents of interest. Examples of materials that meet these

sample to the container.

criteria are glass, stainless steel, and brass. Materials, such as

7.2.2.1 Preparation of Containers for Methanol

polytetrafluorethylene and many rigid plastics also can be used,

Extraction—The appropriate volume of analytical-grade

however, it should be recognized that they may have some

methanol (high-performance liquid chromatography or spec-

limited adsorptive properties or allow slow diffusive passage of

trographic) is added to the organic-free container by the

some VOCs. Materials which show limited reactivity can be

laboratory that supplies the container, by the sample collector,

use when they have a very short period of contact with the

or by a third party. The party that adds the methanol to the

sample or when they are necessary for making airtight (her-

container should also be responsible for providing trip blanks

metic) seals. Collection tools and storage containers made of

and introducing surrogate compounds (see Guide D 4687).

materials other than those cited in this section should only be

Once methanol has been placed in a container, it should be

used after they have demonstrated equivalency. All collection

opened only to add the sample(s) and to remove aliquots for

tools and storage containers should be cleaned in a manner

analysis. The tared weight of the container with methanol

consistent with their intended use.

should be recorded prior to adding the sample to the container.

7.2.1.1 There are often several steps to sampling, particu-

A predetermined volume of sample is added to the methanol.

larly if it involves obtaining bulk materials from subsurface

This sample volume corresponds to a weight in grams (g) that

regions. Most of the equipment used to obtain samples from

is equivalent to or less than the volume (mL) of methanol. The

the subsurface was originally developed for the geotechnical

ratio (typically 1:1 to 10:1, methanol to m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.