ASTM F3328-18

(Practice)Standard Practice for the One-Step (Solvent Cement Only) Method of Joining Poly (Vinyl Chloride) (PVC) or Chlorinated Poly (Vinyl Chloride) (CPVC) Pipe and Piping Components with Tapered Sockets

Standard Practice for the One-Step (Solvent Cement Only) Method of Joining Poly (Vinyl Chloride) (PVC) or Chlorinated Poly (Vinyl Chloride) (CPVC) Pipe and Piping Components with Tapered Sockets

SIGNIFICANCE AND USE

5.1 Solvent cement bonder/installers shall follow all procedures to produce consistently strong and leak-free joints, either in shop operations or in the field.

SCOPE

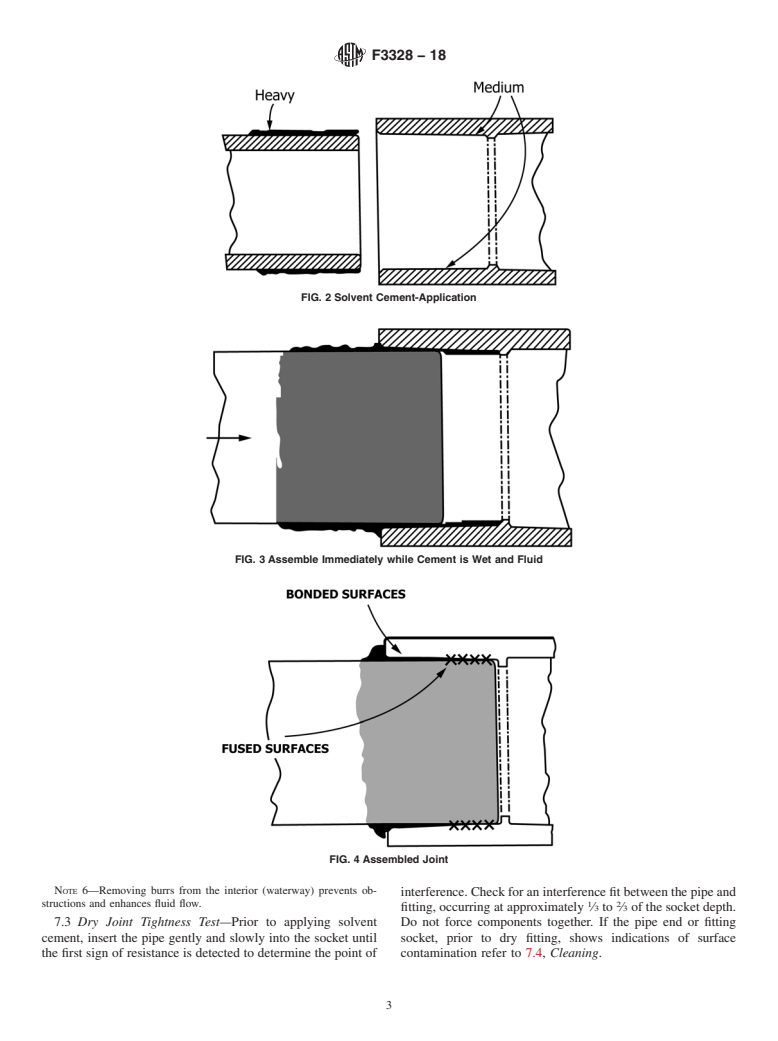

1.1 This practice describes a one-step (solvent cement only) method of joining pipe to fittings (and or piping components) that employ tapered sockets that provide an interference fit 1/3 to 2/3 ’s of the socket depth. This practice applies to poly(vinyl chloride) (PVC), or chlorinated poly(vinyl chloride) (CPVC).

1.2 This practice shall only be used with products (pipe, fitting, fitting component and solvent cement) where manufacturer’s literature and local codes reference this ASTM standard practice: ASTM F3328.

Note 1: Where conflicts occur between the code and the manufacturer’s installation instructions, the more restrictive provisions apply.

1.3 Due to inherent hazards associated with testing components and systems with compressed air or other compressed gases, some manufacturers do not allow pneumatic testing of their products. Consult with specific product/component manufacturers for their specific testing procedures prior to pneumatic testing.

Note 2: Pressurized (compressed) air or other compressed gases contain large amounts of stored energy which present serious safety hazards should a system fail for any reason.

1.4 Techniques covered are applicable to joining PVC to PVC, or CPVC to CPVC pipe and piping components with tapered sockets. In the remainder of this standard practice, the term “piping components with tapered sockets”, whether it be bell end pipe, spigot connections, or any other type of tapered connections, will be referred to as “fittings.”

1.5 Text of this practice references notes and footnotes that provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the practice.

1.6 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F3328 − 18 An American National Standard

Standard Practice for

the One-Step (Solvent Cement Only) Method of Joining Poly

(Vinyl Chloride) (PVC) or Chlorinated Poly (Vinyl Chloride)

1

(CPVC) Pipe and Piping Components with Tapered Sockets

This standard is issued under the fixed designation F3328; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.7 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This practice describes a one-step (solvent cement only)

responsibility of the user of this standard to establish appro-

method of joining pipe to fittings (and or piping components)

priate safety, health, and environmental practices and deter-

1

that employ tapered sockets that provide an interference fit ⁄3

mine the applicability of regulatory limitations prior to use.

2

to ⁄3 ’s of the socket depth. This practice applies to poly(vinyl

1.8 This international standard was developed in accor-

chloride) (PVC), or chlorinated poly(vinyl chloride) (CPVC).

dance with internationally recognized principles on standard-

1.2 This practice shall only be used with products (pipe,

ization established in the Decision on Principles for the

fitting, fitting component and solvent cement) where manufac-

Development of International Standards, Guides and Recom-

turer’s literature and local codes reference thisASTM standard

mendations issued by the World Trade Organization Technical

practice: ASTM F3328.

Barriers to Trade (TBT) Committee.

NOTE 1—Where conflicts occur between the code and the manufactur-

er’s installation instructions, the more restrictive provisions apply.

2. Referenced Documents

2

1.3 Due to inherent hazards associated with testing compo-

2.1 ASTM Standards:

nents and systems with compressed air or other compressed

D1600 Terminology forAbbreviatedTerms Relating to Plas-

gases, some manufacturers do not allow pneumatic testing of

tics

their products. Consult with specific product/component manu-

D2564 Specification for Solvent Cements for Poly(Vinyl

facturers for their specific testing procedures prior to pneu-

Chloride) (PVC) Plastic Piping Systems

matic testing.

F402 Practice for Safe Handling of Solvent Cements,

Primers, and Cleaners Used for Joining Thermoplastic

NOTE 2—Pressurized (compressed) air or other compressed gases

Pipe and Fittings

contain large amounts of stored energy which present serious safety

hazards should a system fail for any reason.

F412 Terminology Relating to Plastic Piping Systems

F493 Specification for Solvent Cements for Chlorinated

1.4 Techniques covered are applicable to joining PVC to

Poly(Vinyl Chloride) (CPVC) Plastic Pipe and Fittings

PVC, or CPVC to CPVC pipe and piping components with

tapered sockets. In the remainder of this standard practice, the

3. Terminology

term “piping components with tapered sockets”, whether it be

bell end pipe, spigot connections, or any other type of tapered

3.1 Definitions—Definitions are in accordance with Termi-

connections, will be referred to as “fittings.”

nology F412, and abbreviations are in accordance with Termi-

nology D1600, unless otherwise specified.

1.5 Text of this practice references notes and footnotes that

provide explanatory material. These notes and footnotes (ex-

4. Summary of Practice

cluding those in tables and figures) shall not be considered as

requirements of the practice.

4.1 In order to achieve consistently strong and leak-free

joining of Poly(Vinyl Chloride) (PVC) or Chlorinated Poly(Vi-

1.6 Units—The values stated in inch-pound units are to be

nyl Chloride) (CPVC) pipe and fittings, the following prin-

regarded as standard. The values given in parentheses are

ciples need to be clearly understood and followed:

mathematical conversions to SI units that are provided for

information only and are not considered standard.

1 2

This test method is under the jurisdiction of ASTM Committee F17 on Plastic For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Piping Systems and is the direct responsibility of Subcommittee F17.20 on Joining. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Aug. 1, 2018. Published August 2018. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

F3328–18 the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.