ASTM D6892-03(2008)

(Test Method)Standard Test Method for Pour Point of Petroleum Products (Robotic Tilt Method)

Standard Test Method for Pour Point of Petroleum Products (Robotic Tilt Method)

SIGNIFICANCE AND USE

The pour point of a petroleum product is an index of the lowest temperature of its utility for certain applications. Flow characteristics, such as pour point, can be critical for the correct operation of lubricating systems, fuel systems, and pipeline operations.

Petroleum blending operations require precise measurement of the pour point.

Test results from this test method can be determined at either 1 or 3°C intervals.

This test method yields a pour point in a format similar to Test Method D 97 or IP 15, when the 3°C interval results are reported.

Note 2—Since some users may wish to report their results in a format similar to Test Method D 97 or IP 15 (in 3°C intervals) the precision data were derived for the 3°C intervals. For statements on bias relative to Test Method D 97 or IP 15, see the research report.

This test method has comparable repeatability and better reproducibility relative to Test Method D 97 or IP 15 as measured in the 1998 interlaboratory program (see Section 13).

FIG. 1 Schematic of Cooling/Heating Block and Cooling Circulating Bath

SCOPE

1.1 This test method covers the determination of the pour point of petroleum products by an automatic instrument that tilts the test jar to detect movement of the surface of the test specimen with an optical device, after being removed from a regulated, stepped-bath cooling jacket.

1.2 This test method is designed to cover the range of temperatures from −57 to +51°C; however, the range of temperatures included in the 1998 interlaboratory test program only covered the temperature range from −51 to −11°C.

1.3 Test results from this test method can be determined at either 1 or 3°C testing intervals.

1.4 This test method is not intended for use with crude oils.

Note 1—The applicability of this test method on residual fuel samples has not been verified. For further information on the applicability, refer to 13.4.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6892 − 03(Reapproved 2008)

Standard Test Method for

Pour Point of Petroleum Products (Robotic Tilt Method)

This standard is issued under the fixed designation D6892; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 Energy Institute Standard:

IP15Test Method for Pour Point of Petroleum Products

1.1 This test method covers the determination of the pour

point of petroleum products by an automatic instrument that

3. Terminology

tilts the test jar to detect movement of the surface of the test

specimen with an optical device, after being removed from a 3.1 Definitions:

regulated, stepped-bath cooling jacket. 3.1.1 pour point, n—in petroleum products, the lowest

temperature at which movement of the test specimen is

1.2 This test method is designed to cover the range of

observed under prescribed conditions of test.

temperatures from −57 to +51°C; however, the range of

temperatures included in the 1998 interlaboratory test program 3.2 Definitions of Terms Specific to This Standard:

only covered the temperature range from −51 to −11°C. 3.2.1 no-flow point, n—in petroleum products, the tempera-

ture of the test specimen at which a wax crystal structure or

1.3 Test results from this test method can be determined at

viscosity increase, or both, impedes movement of the surface

either 1 or 3°C testing intervals.

of the test specimen under the conditions of the test.

1.4 This test method is not intended for use with crude oils.

3.2.1.1 Discussion—The no-flow point occurs when, upon

NOTE 1—The applicability of this test method on residual fuel samples

cooling, the formation of wax crystal structures or viscosity

has not been verified. For further information on the applicability, refer to

increase,orboth,hasprogressedtothepointwheretheapplied

13.4.

observation device no longer detects movement under the

1.5 The values stated in SI units are to be regarded as

conditions of the test. The preceding observation temperature

standard. No other units of measurement are included in this

at which flow of the test specimen is last observed is the pour

standard.

point.

1.6 This standard does not purport to address all of the

3.2.2 tilting, vt—technique of movement where the test jar

safety concerns, if any, associated with its use. It is the

in a vertical position is moved towards a horizontal position to

responsibility of the user of this standard to establish appro-

induce specimen movement.

priate safety and health practices and determine the applica-

3.2.2.1 Discussion—When the test jar is tilted and held in a

bility of regulatory limitations prior to use.

horizontal position for 5 s without detection of movement of

the surface of the specimen, this is the no-flow point and the

2. Referenced Documents

test is complete.

2.1 ASTM Standards:

D97Test Method for Pour Point of Petroleum Products 4. Summary of Test Method

D4057Practice for Manual Sampling of Petroleum and

4.1 After insertion of the specimen into the automatic pour

Petroleum Products

point apparatus and initiation of the testing program, the

D4177Practice for Automatic Sampling of Petroleum and

specimen is heated and then cooled according to a prescribed

Petroleum Products

profile. The specimen surface is examined periodically for

movement using an optical camera system mounted on top of

the specimen test jar, while tilting the specimen test jar. The

This test method is under the jurisdiction of ASTM Committee D02 on test jar is removed from the jacketed cooling chamber prior to

PetroleumProductsandLubricantsandisthedirectresponsibilityofSubcommittee

eachexamination.Thelowesttemperature,whenmovementof

D02.07 on Flow Properties.

the surface of the specimen is detected, is recorded as the pour

Current edition approved Dec. 15, 2008. Published February 2009.Originally

point determined by this Test Method D6892.

approved in 2003. Last previous edition approved in 2003 as D6892–03. DOI:

10.1520/D6892-03R08.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR,

the ASTM website. U.K., http://www.energyinst.org.uk.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6892 − 03 (2008)

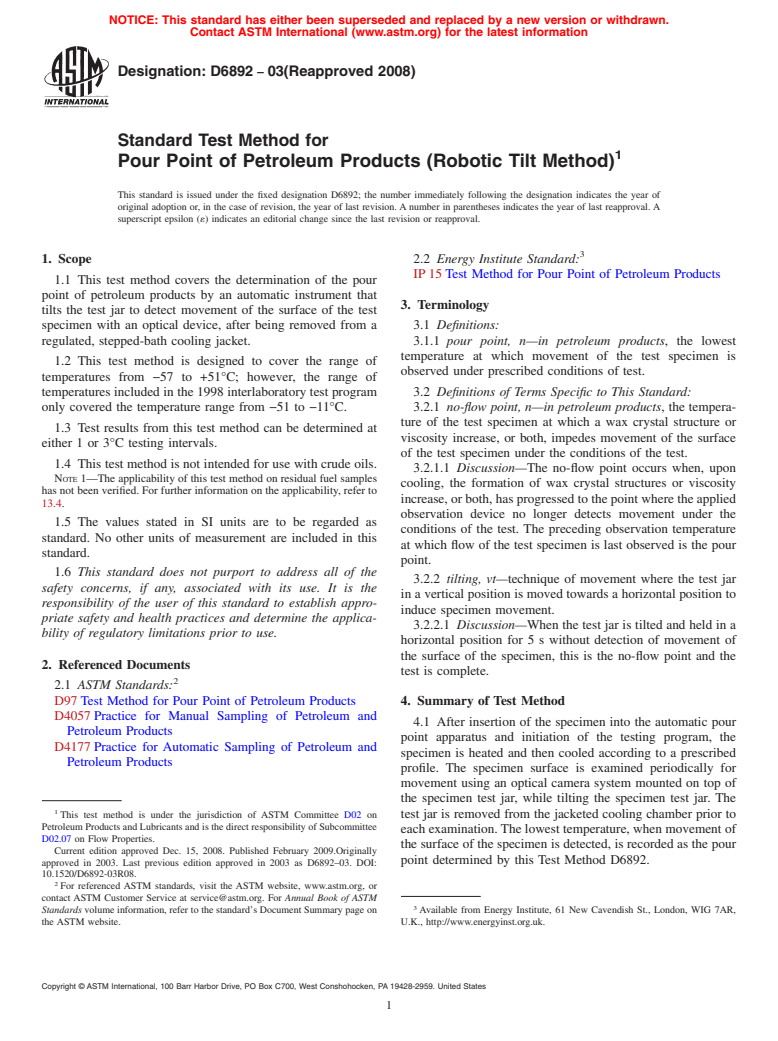

FIG. 1 Schematic of Cooling/Heating Block and Cooling Circulating Bath

5. Significance and Use

5.1 Thepourpointofapetroleumproductisanindexofthe

lowest temperature of its utility for certain applications. Flow

characteristics, such as pour point, can be critical for the

correct operation of lubricating systems, fuel systems, and

pipeline operations.

5.2 Petroleum blending operations require precise measure-

ment of the pour point.

5.3 Test results from this test method can be determined at

either 1 or 3°C intervals.

5.4 This test method yields a pour point in a format similar

toTest Method D97 or IP15, when the 3°C interval results are

reported.

NOTE 2—Since some users may wish to report their results in a format

similar to Test Method D97 or IP15 (in 3°C intervals) the precision data

were derived for the 3°C intervals. For statements on bias relative to Test

Method D97 or IP15, see the research report.

FIG. 2 Picture of Apparatus

5.5 Thistestmethodhascomparablerepeatabilityandbetter

reproducibility relative to Test Method D97 or IP15 as

measuredinthe1998interlaboratoryprogram(seeSection13).

the specimen. The apparatus shall be equipped with a user

6. Apparatus

interface, cooling/heating block assembly with cylindrical

jacket with an inside diameter of 44.2 to 45.8 mm, and about

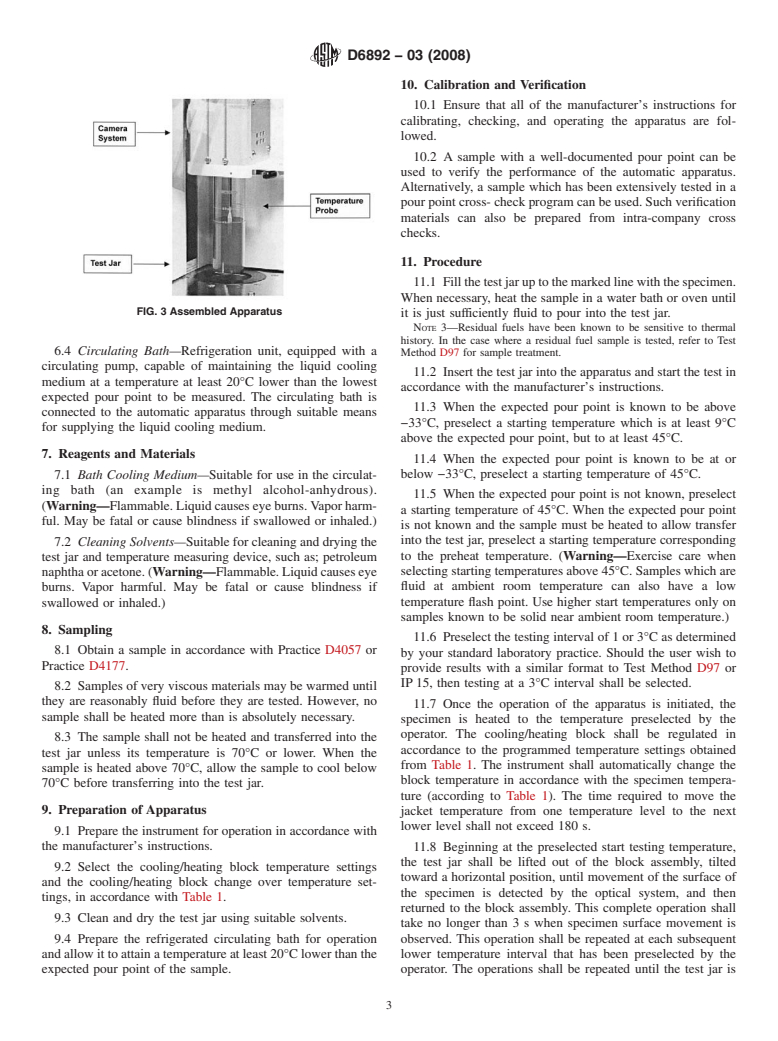

6.1 Automatic Apparatus —Theautomaticpourpointappa-

115 mm in depth to accept the test jar) robotic mechanisms for

ratus described in this test method (see Fig. 2) consists of a

lifting,tilting,replacingthetestjar,opticalcamerasystem,and

microprocessor controlled measuring unit that is capable of

a temperature measuring device.

heatingthespecimentoprogrammedtemperatures,coolingthe

specimen according to programmed cooling profiles, mechani-

6.2 Test Jar—Clear, cylindrical glass, flat bottom (dark-

cally manipulating the test jar according to the programmed

ened),31.5 60.5mminsidediameterand120 62mmheight

test procedure, while optically observing the surface of the

with a wall thickness of 1.25 6 0.25 mm. The jar shall be

specimen for movement, using a camera system mounted on

markedwithalinetoindicatesamplefillingheightcorrespond-

top of the specimen test jar and recording the temperature of

ing to 45 6 0.5 mL.

6.3 Temperature Probe—Capableofmeasurementfrom+70

The sole source of supply of the Herzog Model MP852 or HCP852 known to

to −80°C with a resolution of 0.1°C. The temperature probe

the committee at this time is Walter Herzog, Lauda, Germany. If you are aware of

shall be suspended in the center axis of the test jar and the top

alternative suppliers, please provide this information to ASTM International

ofthetemperaturesensingzoneimmersedbelowthesurfaceof

Headquarters.Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. the specimen.

D6892 − 03 (2008)

10. Calibration and Verification

10.1 Ensure that all of the manufacturer’s instructions for

calibrating, checking, and operating the apparatus are fol-

lowed.

10.2 A sample with a well-documented pour point can be

used to verify the performance of the automatic apparatus.

Alternatively, a sample which has been extensively tested in a

pourpointcross-checkprogramcanbeused.Suchverification

materials can also be prepared from intra-company cross

checks.

11. Procedure

11.1 Fillthetestjaruptothemarkedlinewiththespecimen.

When necessary, heat the sample in a water bath or oven until

FIG. 3 Assembled Apparatus

it is just sufficiently fluid to pour into the test jar.

NOTE 3—Residual fuels have been known to be sensitive to thermal

history. In the case where a residual fuel sample is tested, refer to Test

6.4 Circulating Bath—Refrigeration unit, equipped with a

Method D97 for sample treatment.

circulating pump, capable of maintaining the liquid cooling

11.2 Insert the test jar into the apparatus and start the test in

medium at a temperature at least 20°C lower than the lowest

accordance with the manufacturer’s instructions.

expected pour point to be measured. The circulating bath is

11.3 When the expected pour point is known to be above

connected to the automatic apparatus through suitable means

−33°C, preselect a starting temperature which is at least 9°C

for supplying the liquid cooling medium.

above the expected pour point, but to at least 45°C.

7. Reagents and Materials

11.4 When the expected pour point is known to be at or

below −33°C, preselect a starting temperature of 45°C.

7.1 Bath Cooling Medium—Suitable for use in the circulat-

ing bath (an example is methyl alcohol-anhydrous).

11.5 When the expected pour point is not known, preselect

(Warning—Flammable.Liquidcauseseyeburns.Vaporharm-

a starting temperature of 45°C. When the expected pour point

ful. May be fatal or cause blindness if swallowed or inhaled.)

is not known and the sample must be heated to allow transfer

into the test jar, preselect a starting temperature corresponding

7.2 Cleaning Solvents—Suitableforcleaninganddryingthe

to the preheat temperature. (Warning—Exercise care when

test jar and temperature measuring device, such as; petroleum

selectingstartingtemperaturesabove45°C.Sampleswhichare

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.