ASTM D4212-10(2014)

(Test Method)Standard Test Method for Viscosity by Dip-Type Viscosity Cups

Standard Test Method for Viscosity by Dip-Type Viscosity Cups

SIGNIFICANCE AND USE

5.1 Viscosity is a measure of the fluidity of a material. Viscosity data are useful in the determination of the ease of stirring, pumping, dip coating, or other flow-related properties of paints and related fluids.

5.2 This type of cup is used to measure viscosity because it is easy to use, robust, and may be used in tanks, reservoirs, and reactors.

5.3 There are other types of apparatus for measuring viscosity in the laboratory that provide better precision and bias, including the Ford viscosity cup (Test Method D1200), and the Brookfield viscometer (Test Methods D2196).

5.4 Certain higher shear rate devices such as cone/plate viscometers (Test Method D4287) provide more information about sprayability, roll coatability, and other high-shear rate related properties of coatings.

SCOPE

1.1 This test method covers the determination of viscosity of paints, varnishes, lacquers, inks, and related liquid materials by dip-type viscosity cups. This test method is recommended for viscosity control work within one plant or laboratory and should be used to check compliance with specifications only when sufficient controls have been instituted to ensure adequate comparability of results.

1.2 Viscosity cups are designed for testing of Newtonian and near-Newtonian liquids. If the test material is non-Newtonian, for example, shear-thinning or thixotropic, another method, such as Test Methods D2196, should be used. Under controlled conditions, comparisons of the viscosity of non-newtonian materials may be helpful, but viscosity determination methods using controlled shear rate or shear stress are preferred.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4212 − 10(Reapproved 2014)

Standard Test Method for

Viscosity by Dip-Type Viscosity Cups

This standard is issued under the fixed designation D4212; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E1 Specification for ASTM Liquid-in-Glass Thermometers

1.1 This test method covers the determination of viscosity

3. Terminology

of paints, varnishes, lacquers, inks, and related liquid materials

3.1 Definitions:

by dip-type viscosity cups. This test method is recommended

3.1.1 near-Newtonian liquid, n—a liquid in which the varia-

for viscosity control work within one plant or laboratory and

tion of viscosity with shear rate is small and the effect on

should be used to check compliance with specifications only

viscosity of mechanical disturbances such as stirring is negli-

when sufficient controls have been instituted to ensure ad-

gible.

equate comparability of results.

3.1.2 Newtonian liquid, n—a liquid in which the viscosity is

1.2 Viscosity cups are designed for testing of Newtonian

independent of the shear stress or shear rate. If the ratio of

and near-Newtonian liquids. If the test material is non-

shear stress to shear rate is not constant, the liquid is non-

Newtonian, for example, shear-thinning or thixotropic, another

Newtonian.

method, such as Test Methods D2196, should be used. Under

controlled conditions, comparisons of the viscosity of non-

4. Summary of Test Method

newtonian materials may be helpful, but viscosity determina-

tion methods using controlled shear rate or shear stress are 4.1 The cup is completely immersed in the material to be

preferred.

tested,withdrawn,andthetimeforthematerialtoflowthrough

a hole in the base of the cup is measured.

1.3 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information

5. Significance and Use

only.

5.1 Viscosity is a measure of the fluidity of a material.

1.4 This standard does not purport to address all of the

Viscosity data are useful in the determination of the ease of

safety concerns, if any, associated with its use. It is the

stirring, pumping, dip coating, or other flow-related properties

responsibility of the user of this standard to establish appro-

of paints and related fluids.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

5.2 This type of cup is used to measure viscosity because it

is easy to use, robust, and may be used in tanks, reservoirs, and

2. Referenced Documents

reactors.

2.1 ASTM Standards:

5.3 There are other types of apparatus for measuring vis-

D1200 Test Method for Viscosity by Ford Viscosity Cup

cosity in the laboratory that provide better precision and bias,

D2196 Test Methods for Rheological Properties of Non-

including the Ford viscosity cup (Test Method D1200), and the

Newtonian Materials by Rotational (Brookfield type)

Brookfield viscometer (Test Methods D2196).

Viscometer

5.4 Certain higher shear rate devices such as cone/plate

D4287 Test Method for High-Shear Viscosity Using a Cone/

viscometers (Test Method D4287) provide more information

Plate Viscometer

about sprayability, roll coatability, and other high-shear rate

related properties of coatings.

This test method is under the jurisdiction of ASTM Committee D01 on Paint

6. Apparatus

and Related Coatings, Materials, andApplications and is the direct responsibility of

Subcommittee D01.24 on Physical Properties of Liquid Paints and Paint Materials.

6.1 Zahn Viscosity Cup—No. 1 through No. 5 Zahn viscos-

Current edition approved Dec. 1, 2014. Published December 2014. Originally

ity cups made of corrosion- and solvent-resistant materials.

approved in 1982. Last previous edition approved in 2010 as D4212 – 10. DOI:

10.1520/D4212-10R14.

The nominal capacity of the cup is 44 mL, but may vary from

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

43 to 49 mL, depending on the manufacturer. A diagram of a

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ZahncupisgiveninFig.1.Thedimensions,includingorifices,

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. are only approximate because the cups are not made to a

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4212 − 10 (2014)

NOTE 1—Dimensions are approximate only and may vary with the manufacturer and from batch to batch.

FIG. 1 Zahn Cup Nominal Dimensions

uniform specification. Each manufacturer produces a different 6.2 Shell Viscosity Cup —No. 1 through No. 6 Shell vis-

cup and considerable variation between batches from some cosity cups made of stainless steel with a capacity of 23 mL

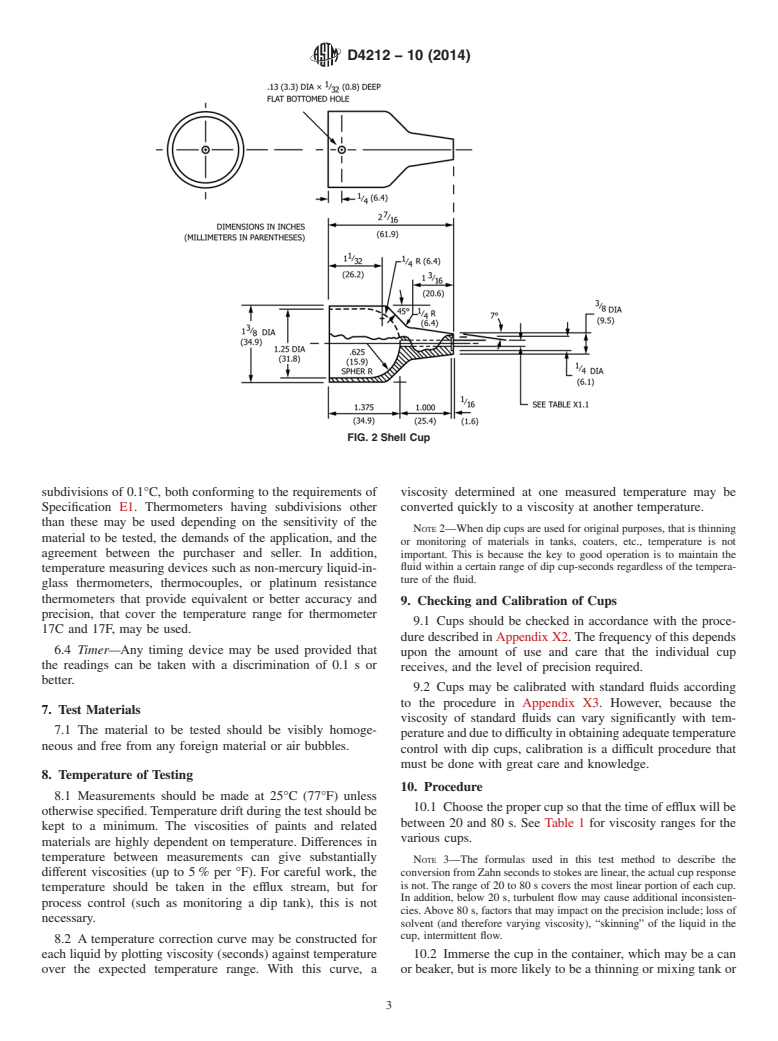

manufacturers has been noted in the past. This is a major and a 25-mm (1-in.) long capillary in the bottom and conform-

reason why Zahn cups should not be referenced in specifica- ing to the dimensions shown in Fig. 2.

tions between producer and user only when controls sufficient 6.2.1 Nominal Shell cup orifice diameters are listed in Table

to ensure adequate cup-to-cup and operator-to-operator com- X2.1. Cup Nos. 1 through 2 ⁄2 are recommended for use with

parison are included. (See Appendix X1 for additional infor- reduced rotogravure inks; No. 2 is for use with flexographic

mation on Zahn Cups.) inks; Nos. 3 through 4 are used for industrial enamels,

lacquers, flexographic, and gravure inks; Nos. 5 and 6 are used

NOTE1—Thevariouscupnumbersareforidentificationoftheviscosity

for heavy materials.

ranges within the series only and should not be used for comparison

between different kinds of cups, that is, a No. 2 Zahn cup has no

6.3 Calibration Thermometer—ASTM Saybolt Viscosity

relationship whatsoever with a No. 2 Shell cup.

Thermometer 17F having a range of 66 to 80°F and subdivi-

6.1.1 Nominal Zahn cup orifice diameters are listed in Table

sions of 0.2°F, or 17C having a range of 19 to 27°C and

X2.1. Cup No. 1 with the smallest orifice is used for determin-

ing the viscosity of thin-bodied materials. Cup No. 2 is for use

Shell cups may be obtained from the Norcross Corp., 255 Newtonville Ave.,

Newton, MA02158. This committee is not aware of any other source for flow cups

with clears, lacquers, enamels, and press-side adjustment of

having properties similar enough to the Shell cup to be included in this test method.

flexographic inks; cups Nos. 3 and 4 are for use with more

If you have knowledge of a cup that should be considered, please provide details to

viscous paints and inks (No. 3 for manufacturing of flexog-

ASTM International Headquarters. Your comments will receive careful consider-

raphic inks); and cup No. 5 is used for silk screen inks. ation at a meeting of the responsible technical committee, which you may attend.

D4212 − 10 (2014)

FIG. 2 Shell Cup

subdivisions of 0.1°C, both conforming to the requirements of viscosity determined at one measured temperature may be

Specification E1. Thermometers having subdivisions other converted quickly to a viscosity at another temperature.

than these may be used depending on the sensitivity of the

NOTE 2—When dip cups are used for original purposes, that is thinning

material to be tested, the demands of the application, and the

or monitoring of materials in tanks, coaters, etc., temperature is not

agreement between the purchaser and seller. In addition, important. This is because the key to good operation is to maintain the

fluid within a certain range of dip cup-seconds regardless of the tempera-

temperature measuring devices such as non-mercury liquid-in-

ture of the fluid.

glass thermometers, thermocouples, or platinum resistance

thermometers that provide equivalent or better accuracy and

9. Checking and Calibration of Cups

precision, that cover the temperature range for thermometer

9.1 Cups should be checked in accordance with the proce-

17C and 17F, may be used.

dure described in Appendix X2.The frequency of this depends

6.4 Timer—Any timing device may be used provided that

upon the amount of use and care that the individual cup

the readings can be taken with a discrimination of 0.1 s or

receives, and the level of precision required.

better.

9.2 Cups may be calibrated with standard fluids according

to the procedure in Appendix X3. However, because the

7. Test Materials

viscosity of standard fluids can vary significantly with tem-

7.1 The material to be tested should be visibly homoge-

peratureandduetodifficultyinobtainingadequatetemperature

neous and free from any foreign material or air bubbles.

control with dip cups, calibration is a difficult procedure that

must be done with great care and knowledge.

8. Temperature of Testing

10. Procedure

8.1 Measurements should be made at 25°C (77°F) unless

10.1 Choose the proper cup so that the time of efflux will be

otherwise specified.Temperature drift during the test should be

between 20 and 80 s. See Table 1 for viscosity ranges for the

kept to a minimum. The viscosities of paints and related

various cups.

materials are highly dependent on temperature. Differences in

temperature between measurements can give substantially

NOTE 3—The formulas used in this test method to describe the

different viscosities (up to 5 % per °F). For careful work, the conversionfromZahnsecondstostokesarelinear,theactualcupresponse

is not. The range of 20 to 80 s covers the most linear portion of each cup.

temperature should be taken in the efflux stream, but for

In addition, below 20 s, turbulent flow may cause additional inconsisten-

process control (such as monitoring a dip tank), this is not

cies.Above 80 s, factors that may impact on the precision include; loss of

necessary.

solvent (and therefore varying viscosity), “skinning” of the liquid in the

cup, intermittent flow.

8.2 A temperature correction curve may be constructed for

each liquid by plotting viscosity (seconds) against temperature 10.2 Immerse the cup in the container, which may be a can

over the expected temperature range. With this curve, a or beaker, but is more likely to be a thinning or mixing tank or

D4212 − 10 (2014)

TABLE 1 Approximate Viscosity Ranges, cST (mm /s) (Roughly

cups from the same manufacturer must be used or other action

Corresponding to 20 to 80 s Flow Time)

taken to ensure compatibility of results. The following criteria

Cup Number Zahn Cup Shell Cup

can be used for judging the acceptability of results at the 95 %

A

1 5–60 2–20

confidence level:

2 20–250 10–50

13.1.1 Zahn Cups—Precision was determined on the basis

2 ⁄2 . 20–80

of an interlaboratory test in which six laboratories used new

3 100–800 30–120

3 ⁄2 . 40–170

Zahn cups (all from the same set from the same manufacturer)

4 200–1200 70–270

to test eight paints covering a broad range of viscosities. The

5 400–1800 125–520

within-laboratory coefficient of variation was 3.7 % and the

6 . 320–1300

A

between-laboratories coefficient of variation was 11.5 %.

The lower limit for the Zahn No. 1 cup is 35 s rather than 20 s.

Based on these coefficients the following criteria should be

used for judging the acceptability of results at the 95 %

confidence level:

even a resin reactor. Stir or agitate the fluid well to give

uniform temperature and density. Allow the cup to remain in 13.1.1.1 Repeatability—Two results, each the mean of two

measurements, obtained by the same operator should be

the fluid for 1 to 5 min to attain thermal equilibrium. (Because

of their greater mass, Shell cups should remain in the fluid for considered suspect if they differ by more than 11 % of their

mean value.

the full 5 min.)

13.1.1.2 Reproducibility—Two results, each the mean of

NOTE 4—Dip cups are not recommended for use with thixotropic (time

two measurements, obtained by operators in different labora-

dependent) materials but if used for them (such as gravure or flexographic

tories should be considered suspect if they differ by more than

inks), more vigorous agitation will be necessary to break up the structure

before the measurement is made.

33 % of their mean value.

10.3 Lift the cup vertically out of the material in a quick,

NOTE 6—The values used to determine the precision were obtained

steady motion. As the top edge of the cup breaks the surface,

underidealconditions(asinglesetofcups),reproducibilityinpracticecan

be just as good, by employing strict controls and good techniques.

start the timer. During the time of flow, hold the cup vertically

no more than 15.2 cm (6 in.) above the level of the liquid. Stop

13.1.1.3 Bias—Bias does not apply to this test method as no

the timer at the first definite break in the stream at the base of

acceptable standards exist.

the cup. The efflux time in seconds constitutes the viscosity. It

NOTE 7—Since the precision values were obtained under ideal condi-

is common to make only a single measurement, but for greater

tions (a single set of cups), reproducibility in practice probably is poorer

precision and accuracy the mean of two or more measurements

than that given (perhaps as bad as 50 %).

should be taken.

13.1.2 Shell Cups—Precision was determined on the basis

NOTE 5—The cup should not be held by the loop handle during the

of an interlaboratory test in which four laboratories tested

measurement process. Most manufacturers equip the cup with a ring

seven paints covering a broad range of viscosities. The

through the loop handle. Holding the cup by this ring will help to ensure

within-laboratory coefficient of variation was 3.2 % and the

that the cup hangs vertically.

between-laboratories coefficient of variation was 6.3 %. Based

11. Care of Cups on these coefficients the following criteria should be used for

judging the acceptability of results at the 95 % confidence

11.1 Following each determination, clean the cup with a

level:

suitable solvent and a soft brush. Use no metal tools in contact

13.1.2.1 Repeatability—Two results, each the mean of two

with the instrument as nicks or wear of the drilled orifice affect

measurements, obtained by the same operator should be

the accuracy of the cup.

considered suspect if they differ by more than 9 % of their

12. Report mean value.

13.1.2.2 Reproducibility—Two results, each the mean of

12.1 Report the efflux time to the nearest 0.2 s for Zahn or

two measurements, obtained by operators in different labora-

Shell cup No. ___, manufactured by _____, (in the case of

tories should be considered suspect if they differ

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4212 − 10 D4212 − 10 (Reapproved 2014)

Standard Test Method for

Viscosity by Dip-Type Viscosity Cups

This standard is issued under the fixed designation D4212; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of viscosity of paints, varnishes, lacquers, inks, and related liquid materials by

dip-type viscosity cups. This test method is recommended for viscosity control work within one plant or laboratory and should be

used to check compliance with specifications only when sufficient controls have been instituted to ensure adequate comparability

of results.

1.2 Viscosity cups are designed for testing of Newtonian and near-Newtonian liquids. If the test material is non-Newtonian, for

example, shear-thinning or thixotropic, another method, such as Test Methods D2196, should be used. Under controlled conditions,

comparisons of the viscosity of non-newtonian materials may be helpful, but viscosity determination methods using controlled

shear rate or shear stress are preferred.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D1200 Test Method for Viscosity by Ford Viscosity Cup

D2196 Test Methods for Rheological Properties of Non-Newtonian Materials by Rotational (Brookfield type) Viscometer

D4287 Test Method for High-Shear Viscosity Using a Cone/Plate Viscometer

E1 Specification for ASTM Liquid-in-Glass Thermometers

3. Terminology

3.1 Definitions:

3.1.1 near-Newtonian liquid, n—a liquid in which the variation of viscosity with shear rate is small and the effect on viscosity

of mechanical disturbances such as stirring is negligible.

3.1.2 Newtonian liquid, n—a liquid in which the viscosity is independent of the shear stress or shear rate. If the ratio of shear

stress to shear rate is not constant, the liquid is non-Newtonian.

4. Summary of Test Method

4.1 The cup is completely immersed in the material to be tested, withdrawn, and the time for the material to flow through a hole

in the base of the cup is measured.

5. Significance and Use

5.1 Viscosity is a measure of the fluidity of a material. Viscosity data are useful in the determination of the ease of stirring,

pumping, dip coating, or other flow-related properties of paints and related fluids.

5.2 This type of cup is used to measure viscosity because it is easy to use, robust, and may be used in tanks, reservoirs, and

reactors.

This test method is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.24 on Physical Properties of Liquid Paints and Paint Materials.

Current edition approved July 1, 2010Dec. 1, 2014. Published July 2010December 2014. Originally approved in 1982. Last previous edition approved in 20052010 as

D4212 – 99 (2005).D4212 – 10. DOI: 10.1520/D4212-10.10.1520/D4212-10R14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4212 − 10 (2014)

5.3 There are other types of apparatus for measuring viscosity in the laboratory that provide better precision and bias, including

the Ford viscosity cup (Test Method D1200), and the Brookfield viscometer (Test Methods D2196).

5.4 Certain higher shear rate devices such as cone/plate viscometers (Test Method D4287) provide more information about

sprayability, roll coatability, and other high-shear rate related properties of coatings.

6. Apparatus

6.1 Zahn Viscosity Cup—No. 1 through No. 5 Zahn viscosity cups made of corrosion- and solvent-resistant materials. The

nominal capacity of the cup is 44 mL, but may vary from 43 to 49 mL, depending on the manufacturer. A diagram of a Zahn cup

is given in Fig. 1. The dimensions, including orifices, are only approximate because the cups are not made to a uniform

specification. Each manufacturer produces a different cup and considerable variation between batches from some manufacturers

has been noted in the past. This is a major reason why Zahn cups should not be referenced in specifications between producer and

user only when controls sufficient to ensure adequate cup-to-cup and operator-to-operator comparison are included. (See Appendix

X1 for additional information on Zahn Cups.)

NOTE 1—The various cup numbers are for identification of the viscosity ranges within the series only and should not be used for comparison between

different kinds of cups, that is, a No. 2 Zahn cup has no relationship whatsoever with a No. 2 Shell cup.

6.1.1 Nominal Zahn cup orifice diameters are listed in Table X2.1. Cup No. 1 with the smallest orifice is used for determining

the viscosity of thin-bodied materials. Cup No. 2 is for use with clears, lacquers, enamels, and press-side adjustment of

flexographic inks; cups Nos. 3 and 4 are for use with more viscous paints and inks (No. 3 for manufacturing of flexographic inks);

and cup No. 5 is used for silk screen inks.

NOTE 1—Dimensions are approximate only and may vary with the manufacturer and from batch to batchbatch.

FIG. 1 Zahn Cup Nominal Dimensions

D4212 − 10 (2014)

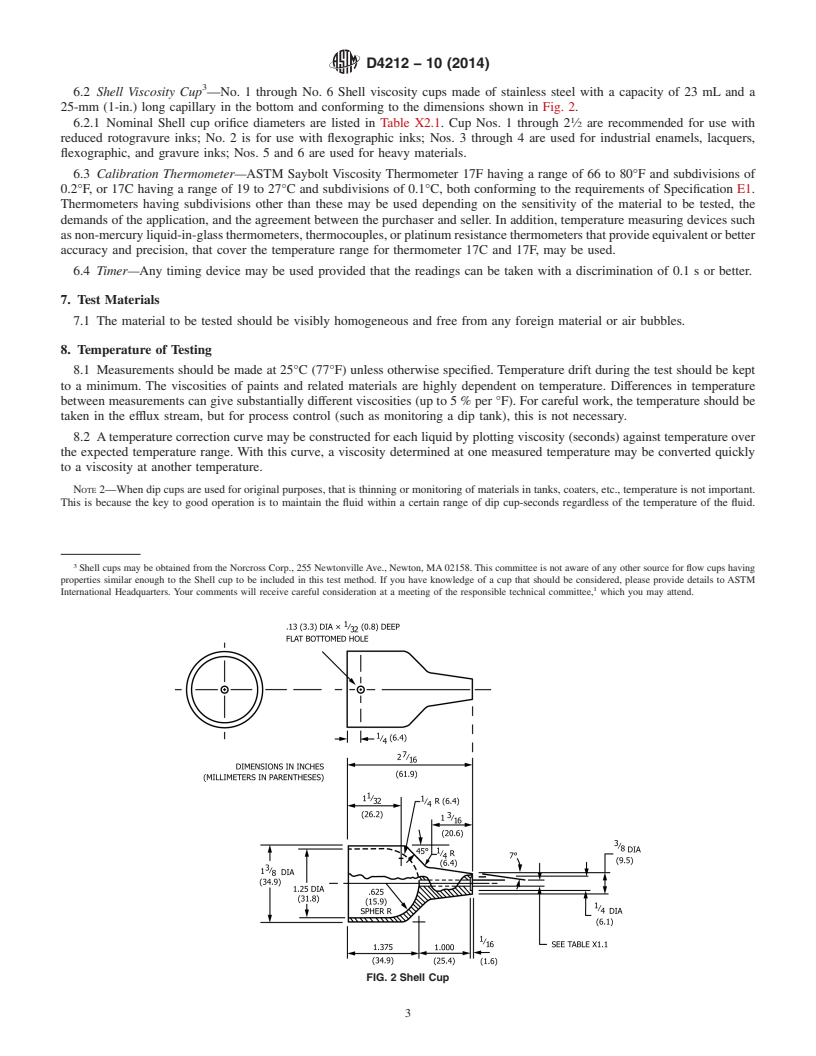

6.2 Shell Viscosity Cup —No. 1 through No. 6 Shell viscosity cups made of stainless steel with a capacity of 23 mL and a

25-mm (1-in.) long capillary in the bottom and conforming to the dimensions shown in Fig. 2.

6.2.1 Nominal Shell cup orifice diameters are listed in Table X2.1. Cup Nos. 1 through 2 ⁄2 are recommended for use with

reduced rotogravure inks; No. 2 is for use with flexographic inks; Nos. 3 through 4 are used for industrial enamels, lacquers,

flexographic, and gravure inks; Nos. 5 and 6 are used for heavy materials.

6.3 Calibration Thermometer—ASTM Saybolt Viscosity Thermometer 17F having a range of 66 to 80°F and subdivisions of

0.2°F, or 17C having a range of 19 to 27°C and subdivisions of 0.1°C, both conforming to the requirements of Specification E1.

Thermometers having subdivisions other than these may be used depending on the sensitivity of the material to be tested, the

demands of the application, and the agreement between the purchaser and seller. In addition, temperature measuring devices such

as non-mercury liquid-in-glass thermometers, thermocouples, or platinum resistance thermometers that provide equivalent or better

accuracy and precision, that cover the temperature range for thermometer 17C and 17F, may be used.

6.4 Timer—Any timing device may be used provided that the readings can be taken with a discrimination of 0.1 s or better.

7. Test Materials

7.1 The material to be tested should be visibly homogeneous and free from any foreign material or air bubbles.

8. Temperature of Testing

8.1 Measurements should be made at 25°C (77°F) unless otherwise specified. Temperature drift during the test should be kept

to a minimum. The viscosities of paints and related materials are highly dependent on temperature. Differences in temperature

between measurements can give substantially different viscosities (up to 5 % per °F). For careful work, the temperature should be

taken in the efflux stream, but for process control (such as monitoring a dip tank), this is not necessary.

8.2 A temperature correction curve may be constructed for each liquid by plotting viscosity (seconds) against temperature over

the expected temperature range. With this curve, a viscosity determined at one measured temperature may be converted quickly

to a viscosity at another temperature.

NOTE 2—When dip cups are used for original purposes, that is thinning or monitoring of materials in tanks, coaters, etc., temperature is not important.

This is because the key to good operation is to maintain the fluid within a certain range of dip cup-seconds regardless of the temperature of the fluid.

Shell cups may be obtained from the Norcross Corp., 255 Newtonville Ave., Newton, MA 02158. This committee is not aware of any other source for flow cups having

properties similar enough to the Shell cup to be included in this test method. If you have knowledge of a cup that should be considered, please provide details to ASTM

International Headquarters. Your comments will receive careful consideration at a meeting of the responsible technical committee, which you may attend.

FIG. 2 Shell Cup

D4212 − 10 (2014)

9. Checking and Calibration of Cups

9.1 Cups should be checked in accordance with the procedure described in Appendix X2. The frequency of this depends upon

the amount of use and care that the individual cup receives, and the level of precision required.

9.2 Cups may be calibrated with standard fluids according to the procedure in Appendix X3. However, because the viscosity

of standard fluids can vary significantly with temperature and due to difficulty in obtaining adequate temperature control with dip

cups, calibration is a difficult procedure that must be done with great care and knowledge.

10. Procedure

10.1 Choose the proper cup so that the time of efflux will be between 20 and 80 s. See Table 1 for viscosity ranges for the various

cups.

NOTE 3—The formulas used in this test method to describe the conversion from Zahn seconds to stokes are linear, the actual cup response is not. The

range of 20 to 80 s covers the most linear portion of each cup. In addition, below 20 s, turbulent flow may cause additional inconsistencies. Above 80

s, factors that may impact on the precision include; loss of solvent (and therefore varying viscosity), “skinning” of the liquid in the cup, intermittent flow.

10.2 Immerse the cup in the container, which may be a can or beaker, but is more likely to be a thinning or mixing tank or even

a resin reactor. Stir or agitate the fluid well to give uniform temperature and density. Allow the cup to remain in the fluid for 1

to 5 min to attain thermal equilibrium. (Because of their greater mass, Shell cups should remain in the fluid for the full 5 min.)

NOTE 4—Dip cups are not recommended for use with thixotropic (time dependent) materials but if used for them (such as gravure or flexographic inks),

more vigorous agitation will be necessary to break up the structure before the measurement is made.

10.3 Lift the cup vertically out of the material in a quick, steady motion. As the top edge of the cup breaks the surface, start

the timer. During the time of flow, hold the cup vertically no more than 15.2 cm (6 in.) above the level of the liquid. Stop the timer

at the first definite break in the stream at the base of the cup. The efflux time in seconds constitutes the viscosity. It is common

to make only a single measurement, but for greater precision and accuracy the mean of two or more measurements should be taken.

NOTE 5—The cup should not be held by the loop handle during the measurement process. Most manufacturers equip the cup with a ring through the

loop handle. Holding the cup by this ring will help to ensure that the cup hangs vertically.

11. Care of Cups

11.1 Following each determination, clean the cup with a suitable solvent and a soft brush. Use no metal tools in contact with

the instrument as nicks or wear of the drilled orifice affect the accuracy of the cup.

12. Report

12.1 Report the efflux time to the nearest 0.2 s for Zahn or Shell cup No. ___, manufactured by _____, (in the case of Zahn

cups) the temperature of the fluid (where measured), and whether the result is from a single measurement or the mean of two of

more measurements.

13. Precision and Bias

13.1 The most satisfactory results when using dip cups are obtained when viscosity is being controlled at a single location only.

However, when comparisons between locations are made, cups from the same manufacturer must be used or other action taken

to ensure compatibility of results. The following criteria can be used for judging the acceptability of results at the 95 % confidence

level:

13.1.1 Zahn Cups—Precision was determined on the basis of an interlaboratory test in which six laboratories used new Zahn

cups (all from the same set from the same manufacturer) to test eight paints covering a broad range of viscosities. The

within-laboratory coefficient of variation was 3.7 % and the between-laboratories coefficient of variation was 11.5 %. Based on

these coefficients the following criteria should be used for judging the acceptability of results at the 95 % confidence level:

TABLE 1 Approximate Viscosity Ranges, cST (mm /s) (Roughly

Corresponding to 20 to 80 s Flow Time)

Cup Number Zahn Cup Shell Cup

A

1 5–60 2–20

2 20–250 10–50

2 ⁄2 . 20–80

3 100–800 30–120

3 ⁄2 . 40–170

4 200–1200 70–270

5 400–1800 125–520

6 . 320–1300

A

The lower limit for the Zahn No. 1 cup is 35 s rather than 20 s.

D4212 − 10 (2014)

13.1.1.1 Repeatability—Two results, each the mean of two measurements, obtained by the same operator should be considered

suspect if they differ by more than 11 % of their mean value.

13.1.1.2 Reproducibility—Two results, each the mean of two measurements, obtained by operators in different laboratories

should be considered suspect if they differ by more than 33 % of their mean value.

NOTE 6—The values used to determine the precision were obtained under ideal conditions (a single set of cups), reproducibility in practice can be just

as good, by employing strict controls and good techniques.

13.1.1.3 Bias—Bias does not apply to this test method as no acceptable standards exist.

NOTE 7—Since the precision values were obtained under ideal conditions (a single set of cups), reproducibility in practice probably is poorer than th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.