ASTM D4212-10

(Test Method)Standard Test Method for Viscosity by Dip-Type Viscosity Cups

Standard Test Method for Viscosity by Dip-Type Viscosity Cups

SIGNIFICANCE AND USE

Viscosity is a measure of the fluidity of a material. Viscosity data are useful in the determination of the ease of stirring, pumping, dip coating, or other flow-related properties of paints and related fluids.

This type of cup is used to measure viscosity because it is easy to use, robust, and may be used in tanks, reservoirs, and reactors.

There are other types of apparatus for measuring viscosity in the laboratory that provide better precision and bias, including the Ford viscosity cup (Test Method D1200), and the Brookfield viscometer (Test Methods D2196).

Certain higher shear rate devices such as cone/plate viscometers (Test Method D4287) provide more information about sprayability, roll coatability, and other high-shear rate related properties of coatings.

SCOPE

1.1 This test method covers the determination of viscosity of paints, varnishes, lacquers, inks, and related liquid materials by dip-type viscosity cups. This test method is recommended for viscosity control work within one plant or laboratory and should be used to check compliance with specifications only when sufficient controls have been instituted to ensure adequate comparability of results.

1.2 Viscosity cups are designed for testing of Newtonian and near-Newtonian liquids. If the test material is non-Newtonian, for example, shear-thinning or thixotropic, another method, such as Test Methods D2196, should be used. Under controlled conditions, comparisons of the viscosity of non-newtonian materials may be helpful, but viscosity determination methods using controlled shear rate or shear stress are preferred.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4212 − 10

StandardTest Method for

1

Viscosity by Dip-Type Viscosity Cups

This standard is issued under the fixed designation D4212; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E1 Specification for ASTM Liquid-in-Glass Thermometers

1.1 This test method covers the determination of viscosity

3. Terminology

of paints, varnishes, lacquers, inks, and related liquid materials

3.1 Definitions:

by dip-type viscosity cups. This test method is recommended

3.1.1 near-Newtonian liquid, n—a liquid in which the varia-

for viscosity control work within one plant or laboratory and

tion of viscosity with shear rate is small and the effect on

should be used to check compliance with specifications only

viscosity of mechanical disturbances such as stirring is negli-

when sufficient controls have been instituted to ensure ad-

gible.

equate comparability of results.

3.1.2 Newtonian liquid, n—a liquid in which the viscosity is

1.2 Viscosity cups are designed for testing of Newtonian

independent of the shear stress or shear rate. If the ratio of

and near-Newtonian liquids. If the test material is non-

shear stress to shear rate is not constant, the liquid is non-

Newtonian, for example, shear-thinning or thixotropic, another

Newtonian.

method, such as Test Methods D2196, should be used. Under

controlled conditions, comparisons of the viscosity of non-

4. Summary of Test Method

newtonian materials may be helpful, but viscosity determina-

tion methods using controlled shear rate or shear stress are 4.1 The cup is completely immersed in the material to be

preferred.

tested,withdrawn,andthetimeforthematerialtoflowthrough

a hole in the base of the cup is measured.

1.3 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information

5. Significance and Use

only.

5.1 Viscosity is a measure of the fluidity of a material.

1.4 This standard does not purport to address all of the

Viscosity data are useful in the determination of the ease of

safety concerns, if any, associated with its use. It is the

stirring, pumping, dip coating, or other flow-related properties

responsibility of the user of this standard to establish appro-

of paints and related fluids.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

5.2 This type of cup is used to measure viscosity because it

is easy to use, robust, and may be used in tanks, reservoirs, and

2. Referenced Documents

reactors.

2

2.1 ASTM Standards:

5.3 There are other types of apparatus for measuring vis-

D1200 Test Method for Viscosity by Ford Viscosity Cup

cosity in the laboratory that provide better precision and bias,

D2196 Test Methods for Rheological Properties of Non-

including the Ford viscosity cup (Test Method D1200), and the

Newtonian Materials by Rotational (Brookfield type)

Brookfield viscometer (Test Methods D2196).

Viscometer

5.4 Certain higher shear rate devices such as cone/plate

D4287 Test Method for High-Shear Viscosity Using a Cone/

viscometers (Test Method D4287) provide more information

Plate Viscometer

about sprayability, roll coatability, and other high-shear rate

related properties of coatings.

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint

6. Apparatus

and Related Coatings, Materials, andApplications and is the direct responsibility of

Subcommittee D01.24 on Physical Properties of Liquid Paints and Paint Materials.

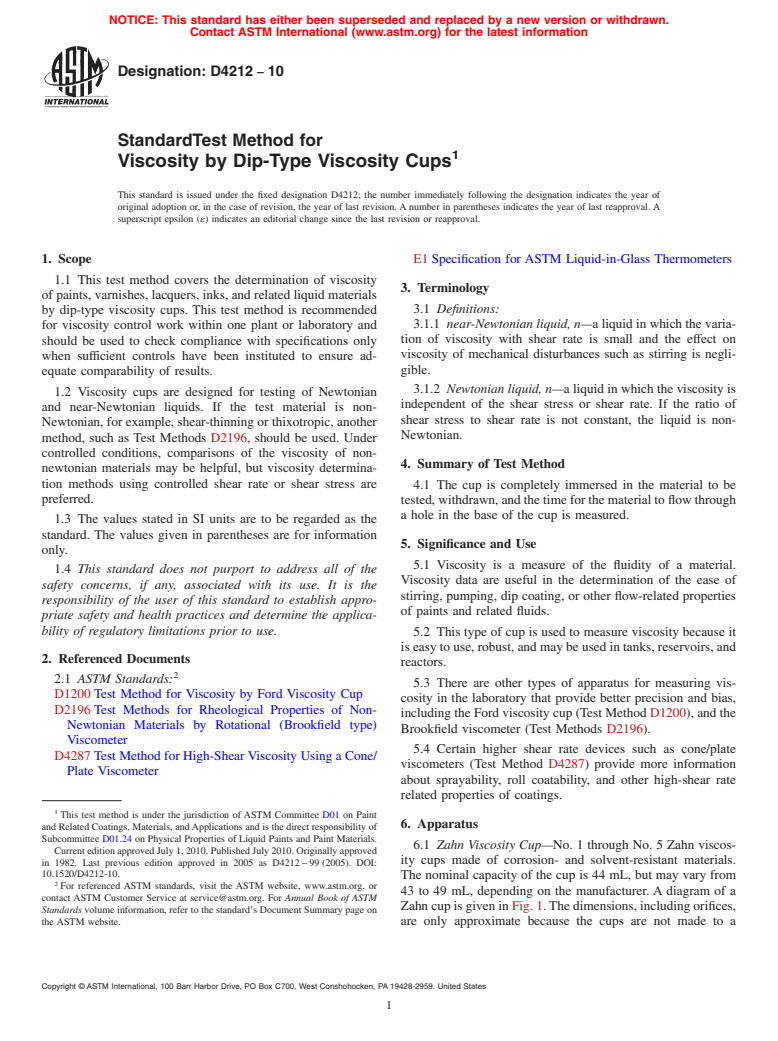

6.1 Zahn Viscosity Cup—No. 1 through No. 5 Zahn viscos-

Current edition approved July 1, 2010. Published July 2010. Originally approved

ity cups made of corrosion- and solvent-resistant materials.

in 1982. Last previous edition approved in 2005 as D4212 – 99 (2005). DOI:

10.1520/D4212-10.

The nominal capacity of the cup is 44 mL, but may vary from

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

43 to 49 mL, depending on the manufacturer. A diagram of a

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ZahncupisgiveninFig.1.Thedimensions,includingorifices,

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. are only approximate because the cups are not made to a

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4212 − 10

NOTE 1—Dimensions are approximate only and may vary with the manufacturer and from batch to batch

FIG. 1 Zahn Cup Nominal Dimensions

3

uniform specification. Each manufactur

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.