ASTM D3806-98(2004)

(Test Method)Standard Test Method of Small-Scale Evaluation of Fire-Retardant Paints (2-Foot Tunnel Method)

Standard Test Method of Small-Scale Evaluation of Fire-Retardant Paints (2-Foot Tunnel Method)

SIGNIFICANCE AND USE

A number of laboratory procedures are used to evaluate the effectiveness of fire-retardant and fire-resistant treatments and coatings. In general, these methods measure the three stages of fire development: (1) ignition; (2) flame spread (rate of growth of the fire); and (3) conflagration extent. While all three are of extreme importance, flame spread has been recognized as the main factor associated with testing fire-retardant coatings.

Flame spread ratings based upon Test Method E 84 have acquired common acceptance by regulatory agencies, but such large-scale tests are seldom practical during the development or modification of a fire-retardant coating.

This test method provides the relative flame spread of experimental coatings using small test specimens. By calibrating the 2-foot tunnel with Test Method E 84-rated fire-retardant paint, results obtained by this test method should be indicative of those obtained with a large specimen in the Test Method E 84 tunnel.

SCOPE

1.1 This test method determines the protection a coating affords its substrate, and the comparative burning characteristics of coatings by evaluating the flame spread over the surface when ignited under controlled conditions in a small tunnel. This establishes a basis for comparing surface-burning characteristics of different coatings without specific consideration of all the end-use parameters that might affect surface-burning characteristics under actual fire conditions.

1.2 In addition to the experimental flamespread rate, the weight of panel consumed, time of afterflaming and afterglow, char dimensions and index, and height of intumescence may be measured in this test. However, a relationship should not be presumed among these measurements.

1.3 This standard should be used to measure and describe the properties of materials, products, or assemblies in response to heat and flame under controlled laboratory conditions, and should not be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under actual fire conditions. However, results of this test may be used as elements of a fire risk assessment which takes into account all of the factors which are pertinent to an assessment of the fire hazard of a particular end use.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3806–98(Reapproved2004)

Standard Test Method of

Small-Scale Evaluation of Fire-Retardant Paints (2-Foot

Tunnel Method)

This standard is issued under the fixed designation D3806; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method determines the protection a coating 2.1 ASTM Standards:

affords its substrate, and the comparative burning characteris- C220 Specification for Flat Asbestos-Cement Sheets

ticsofcoatingsbyevaluatingtheflamespreadoverthesurface D344 Test Method for Relative Hiding Power of Paints by

when ignited under controlled conditions in a small tunnel. the Visual Evaluation of Brushouts

This establishes a basis for comparing surface-burning charac- D1475 Test Method For Density of Liquid Coatings, Inks,

teristics of different coatings without specific consideration of and Related Products

all the end-use parameters that might affect surface-burning D2196 Test Methods for Rheological Properties of Non-

characteristics under actual fire conditions. Newtonian Materials by Rotational (Brookfield type) Vis-

1.2 In addition to the experimental flamespread rate, the cometer

weight of panel consumed, time of afterflaming and afterglow, E84 Test Method for Surface Burning Characteristics of

chardimensionsandindex,andheightofintumescencemaybe Building Materials

measured in this test. However, a relationship should not be 2.2 Federal Standard:

presumed among these measurements. Fed. Spec. TT-V-119 Varnish, Spar, Phenolic Resin

1.3 This standard should be used to measure and describe

3. Significance and Use

the properties of materials, products, or assemblies in response

3.1 Anumber of laboratory procedures are used to evaluate

to heat and flame under controlled laboratory conditions, and

shouldnotbeusedtodescribeorappraisethefirehazardorfire the effectiveness of fire-retardant and fire-resistant treatments

and coatings. In general, these methods measure the three

risk of materials, products, or assemblies under actual fire

stages of fire development: (1) ignition; (2) flame spread (rate

conditions. However, results of this test may be used as

elements of a fire risk assessment which takes into account all of growth of the fire); and (3) conflagration extent. While all

three are of extreme importance, flame spread has been

of the factors which are pertinent to an assessment of the fire

hazard of a particular end use. recognized as the main factor associated with testing fire-

retardant coatings.

1.4 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information 3.2 Flame spread ratings based uponTest Method E84 have

acquired common acceptance by regulatory agencies, but such

only.

1.5 This standard does not purport to address all of the large-scale tests are seldom practical during the development

or modification of a fire-retardant coating.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 3.3 This test method provides the relative flame spread of

experimental coatings using small test specimens. By calibrat-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. ingthe2-foottunnelwithTestMethodE84-ratedfire-retardant

paint, results obtained by this test method should be indicative

ofthoseobtainedwithalargespecimenintheTestMethodE84

tunnel.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

This test method is under the jurisdiction of ASTM Committee D01 on Paint contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

and Related Coatings, Materials, andApplications and is the direct responsibility of Standards volume information, refer to the standard’s Document Summary page on

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials. the ASTM website.

Current edition approved June 1, 2004. Published June 2004. Originally Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

approved in 1979. Last previous edition approved in 1998 as D3806–98. DOI: Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

10.1520/D3806-98R04. dodssp.daps.dla.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3806–98 (2004)

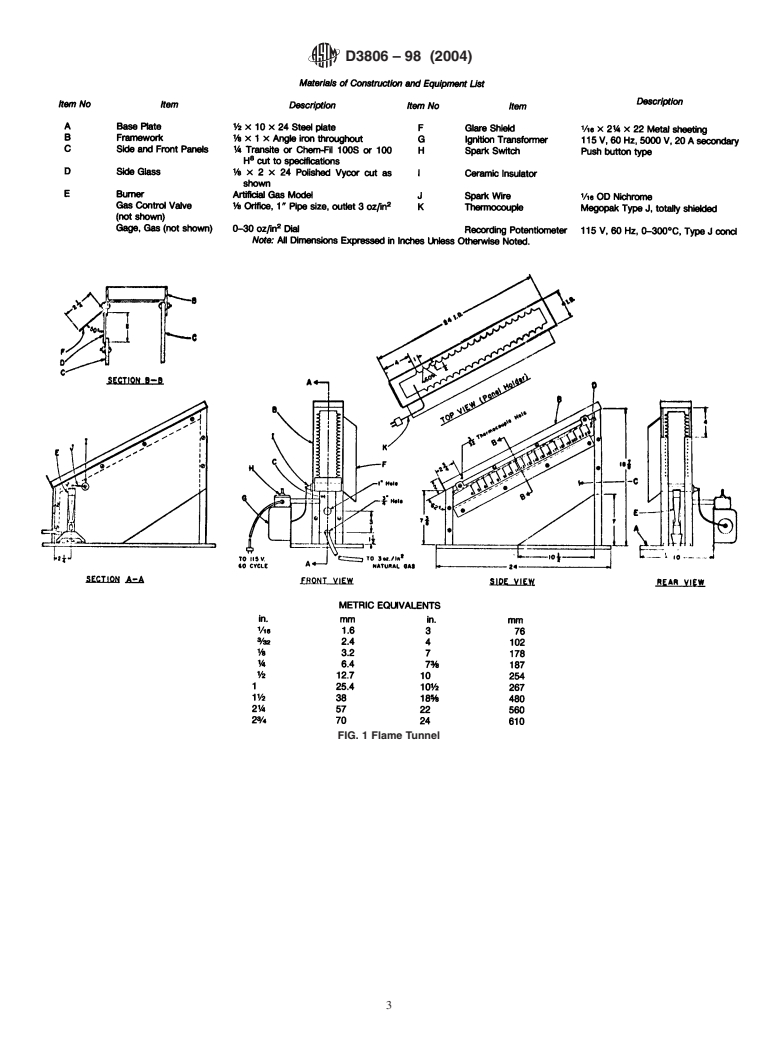

4. Apparatus 4.2 Burner, 215 mm (8.5 in.) high with 40–mm diameter,

10-mmthickgridforusewithnaturalgas.Theburnerisplaced

4.1 Flame Tunnel (seeFig.1A)—610-mm(two-foot)flame

57 mm (2 ⁄4 in.) in from the fire end of the tunnel and 25 mm

tunnelconsistingofasbestos-cementboardmountedonaniron

(1 in.) below the bottom side of the sample holder, that is, 30

framework and supplied with natural gas fuel of uniform

mm (1 ⁄8 in.) from the bottom of the specimen. See Fig. 1.

quality.

NOTE 2—Artificial gas or liquid petroleum (LP) gas may be used, but

4.1.1 The framework is constructed of 3 by 25 by 25-mm

burners designed for these types of gases must be used.

( ⁄8 by 1 by 1-in.) angle iron, the top of which provides a 610

4.3 Ignition Transformer, or other suitable ignition source,

by100-mm(24by4-in.)specimenholderinclinedat28°tothe

to generate a spark through a 2-mm ( ⁄16-in.) Nichrome wire to

horizontal. The framework is mounted on a 250 by 610 by

theburnerbarrel.Thetransformerisactivatedbyapush-button

13-mm (10 by 24 by ⁄2-in.) steel base.The specimen holder is

type spark switch.

elevated185mm(7 ⁄8in.)abovethebaseatthelower(fire)end

4.4 Gas Supply, of uniform quality controlled by a positive-

and 480 mm (18 ⁄8 in.) at the upper (flue) end.

flowpressureregulatoryvalve(0to152mm(0to6in.)water)

4.1.2 The fire end and sides of the tunnel are covered to the

and a gas flowmeter (0.6 to 5.0 SCFH).

extent shown in Fig. 1, with 6-mm ( ⁄4-in.) asbestos-cement

4.5 Insulating and Fire Resistant Backing for Test Panels,

5 6

board or 6-mm ( ⁄4-in.) inorganic reinforced-cement board

7 7

consisting of 100 by 605-mm (3 ⁄8 by 23 ⁄8-in.) pieces of

attached to the inside of the angle iron framework. The open

13-mm ( ⁄2-in.) asbestos-cement board or inorganic reinforced

flue end and the cut-out sides allow a natural draft through the

cementboardand ⁄2-in.steelplateappliedoneabovetheother

tunnel. Additional air access is provided by a 25–mm (1–in.)

with asbestos cement or the inorganic reinforced cement board

hole drilled in the cover at the fire end, centered and 115 mm

placed directly on top of the test panel.

(4 ⁄2 in.) above the base.

4.6 Thermocouple totally shielded (see Note 3), installed

4.1.3 Anobservationwindowmadeofa50-mm(2-in.)wide

through the hole in the side of the specimen holder so that its

strip of 3-mm ( ⁄8-in.) polished heat-resistant sheet glass is

tip rests on the back, cool side, of the test panel.

located just below the specimen holder, extending the full

NOTE 3—Some commercial tunnels are supplied with more than one

length of the tunnel, 610 mm (24 in.). This glass is marked by

thermocouple.

anyappropriatemethodat1-in.intervalsfrom4to22in.A560

1 1 4.7 Recording Potentiometer, 0 to 300°C range.

by 55 by 2-mm (22 by 2 ⁄4 by ⁄16-in.) sheet metal shield is

4.8 Audible Timer, set to sound at 15-s intervals to indicate

attached above the window, slanting downwards at an angle of

the time for flame-front measurements.

60° to shield the observation window. The angle iron panel

4.9 Constant Temperature and Humidity Room or Cabinet,

holder is notched along the bottom or supporting lip of the

maintained at 50 6 5% relative humidity and 23 6 2°C (73.5

angle at 25-mm (1-in.) intervals to assist in the measurements

6 3.5°F).

of the flame advance.

NOTE 1—Arule may also be mounted outside the observation window

5. Test Panels

to help measure the flame advancement.

5.1 Test Panels—SeeTable 1for a list of various woods and

1 7

their densities. Wood, 6 by 100 by 605-mm ( ⁄4 by 3 ⁄8 by

4.1.4 A 2.5-mm ( ⁄32-in.) hole is drilled in the side of the

23 ⁄8-in.) close grained, as nearly edge grain as possible and

specimen holder immediately above the center of the burner to

free from knots and imperfections. The panels should be solid

allow insertion of a thermocouple.

wood with surfaces planed and sanded (see Note 4). Kiln-dry

4.1.5 The tunnel should be placed in an area as free from

test panels to contain not more than 10 weight% of moisture

drafts as possible with facilities for removal or escape of

on an oven dry basis.

combustion products. (Standard laboratory hood with forced

draft off during test.)

NOTE 4—Douglas fir, 6.3–mm ( ⁄4 –in.) 3-ply, marine–grade plywood

may be used upon agreement between manufacturer and user. Asbestos-

cement board, steel, or concrete may be used upon agreement between

manufacturer and user.

The sole source of supply of a suitable cabinet and assembly known to the

5.1.1 Prior to coating, condition test panels for 14 days in

committeeatthistimeisDek-TronScientific,244East3rdSt.,Plainfield,NJ07060.

the controlled atmosphere of 50 6 5% relative humidity and

If you are aware of alternative suppliers, please provide this information toASTM

International Headquarters. Your comments will receive careful consideration at a

meeting of the responsible technical committee, which you may attend.

The sole source of supply of an asbestos-cement board, transite, known to the

committee at this time is Manville Corp., Denver CO 80217 If you are aware of The sole source of supply of a burner, Catalog No. 3–902 for artificial gas, or

alternative suppliers, please provide this information to ASTM International CatalogNo.3–900and3–902fornaturalgasandLPgas,respectively,knowntothe

Headquarters.Your comments will receive careful consideration at a meeting of the committee at this time is Fisher Scientific Co. If you are aware of alternative

responsible technical committee, which you may attend. suppliers, please provide this information to ASTM International Headquarters.

The sole source of supply of inorganic reinforced-cement board, #100S and Your comments will receive careful consideration at a meeting of the responsible

3 3

100H, nominal 1600 to 1760 kg/m (100 to 110 lb/ft ), known to the committee at technical committee, which you may attend.

this time is Shameful Corp., 100 Spence Lane, Nashville, TN 37210. If you are The sole source of supply of a thermocouple, Megopak Type J, known to the

aware of alternative suppliers, please provide this information to ASTM Interna- committee at this time is Megopak Co. If you are aware of alternative suppliers,

tional Headquarters.Your comments will receive careful consideration at a meeting please provide this information to ASTM International Headquarters. Your com-

of the responsible technical committee, which you may attend. ments will receive careful consideration at a meeting of the responsible technical

Quartz or high-silica glass has been found satisfactory for this purpose. committee, which you may attend.

D3806–98 (2004)

FIG. 1 Flame Tunnel

D3806–98 (2004)

TABLE 1 Densities and Panel Weights of Various Woods (Conditioned at Relative Humidity 50 6 5% and 236 2°C

(73.5 6 3.5°F) for 14 days)

7 7 1

Density (9 to 10 % Moisture), Weight of 3 ⁄8 by 23 ⁄8 by ⁄4 in.

Type of Wood

3 3

kg/m (lb/ft ) Panel, g

Red cedar 345 to 360 (21.4 to 22.4) 130 to 140

Douglas fir 465 to 560 (29 to 35) 180 to 215

White pine-Ponderosa pine 360 to 420 (22.4 to 26.4) 140 to 160

Southern yellow pine 495 to 590 (31 to 37) 190 to 225

Redwood 435 to 450 (27.2 to 28.2) 165 to 175

23 6 2°C (73.5 6 3.5°F) toa9to10% moisture content.

where:

Refer to Table 1 for the density and weight per panel of each

W = weight of applied wet coating, g,

listed wood.

D = coating density, g/mL, and

5.1.2 Seal the ends of the panels with two coats of varnish S = spreading rate in m /L.

R

conforming to Fed. Spec. TT-V-119 after conditioning. Allow

7.5 Dry the coated panels under standard conditions (4.9)

each coat of varnish to air-dry 18 to 24 h.

until equilibrium weight is obtained, allowing sufficient time

forthecompleteevaporationofsolvents,anycuringthatmight

6. Calibration Standards

be required by the material, and for the attainment of equilib-

rium moisture content. Forty-eight hours are normally suffi-

6.1 Zero-Flame Spread—Asbestos-cement board, Type F

conforming to Specification C220, 13 by 100 by 605 mm ( ⁄2 cient except for certain coatings that may require longer

7 7

by 3 ⁄8 by 23 ⁄8 in.), conditioned as in 5.1.1. periods because they trap solvent or contain solvents that

evaporate very slowly.

NOTE 5—Inorganicreinforcedcementboard,6.3-mm( ⁄4-in.)thickmay

7.6 Apply and cure non-air–drying coatings as recom-

be substituted for asbestos cement.

mended by the supplier and condition as specified in 7.5.

6.2 Fire-Rated Standard—Atest panel, similar to that used

with test coatings, coated with Test Method E84 rated paint at

8. Calibration of the Tunnel

the manufacturer’s recommended spreading rate and condi-

tioned as in Section 7.

8.1 Calibrate the tunnel prior to each day’s operation with

the calibration standards described in Section 6.

NOTE 6—Do not use paint beyond manufacturer’s stated shelf life.

8.1.1 Place the zero flame-spread standard in the holder,

7. Preparation of Test Panels

smooth side down, and back it with the backing plate (4.5).

7.1 Thoroughly mix the coating under test by a suitable

8.1.2 Open the gas valve and adjust to a pressure of 1.3 kPa

2 3

means until it is uniform in composition and consistency. Test

(3 oz/in. ) and a constant flow of 38 mL/s (4.8 ft /h), and

Methods D2196 describes a suitable preparation procedure.

actuate the interval timer.

7.2 Determine the density of the coating in accordance with

NOTE 7—These conditions are specified for a natural gas supply

Test Method D1475 in grams per millilitre (or pounds per

3 3

providing 40 MJ/m (1055 BTU/ft ). For any other gas supply, adjust flow

gallon) for calculating the weight of the coating to be applied

to provide 1490 J/s (5085 BTU/h).

to the panel to comply with the specified spreading rate.

7.3 Brush apply the coating to conditioned test panels in as 8.1.2.1 When the timer sounds, ignite the burner using the

uniform a manner as possible to obtain the specified spreading ignition transformer. Observe the flame front, measure in

rate. A suitable procedure appears in Test Method D344. inches and record at 15-s intervals the flame position by

Appli

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.