ASTM D3427-19

(Test Method)Standard Test Method for Air Release Properties of Hydrocarbon Based Oils

Standard Test Method for Air Release Properties of Hydrocarbon Based Oils

SIGNIFICANCE AND USE

5.1 Agitation of lubricating oil with air in equipment, such as bearings, couplings, gears, pumps, and oil return lines, may produce a dispersion of finely divided air bubbles in the oil. If the residence time in the reservoir is too short to allow the air bubbles to rise to the oil surface, a mixture of air and oil will circulate through the lubricating oil system. This may result in an inability to maintain oil pressure (particularly with centrifugal pumps), incomplete oil films in bearings and gears, and poor hydraulic system performance or failure.

5.2 This test method measures the time for the entrained air content to fall to the relatively low value of 0.2 % volume under a standardized set of test conditions and hence permits the comparison of the ability of oils to separate entrained air under conditions where a separation time is available. The significance of this test method has not been fully established. However, entrained air can cause sponginess and lack of sensitivity of the control of turbine and hydraulic systems. This test may not be suitable for ranking oils in applications where residence times are short and gas contents are high.

SCOPE

1.1 This test method covers the ability of turbine, hydraulic, and gear oils to separate entrained air.

Note 1: This test method was developed for hydrocarbon based oils. It may be used for some synthetic fluids; however, the precision statement applies only to hydrocarbon based oils.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D3427 − 19

Designation 313–01

Standard Test Method for

1

Air Release Properties of Hydrocarbon Based Oils

This standard is issued under the fixed designation D3427; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* E1Specification for ASTM Liquid-in-Glass Thermometers

3

2.2 DIN Standard:

1.1 Thistestmethodcoverstheabilityofturbine,hydraulic,

DIN 51381

and gear oils to separate entrained air.

NOTE 1—This test method was developed for hydrocarbon based oils.

3. Terminology

Itmaybeusedforsomesyntheticfluids;however,theprecisionstatement

3.1 Definitions of Terms Specific to This Standard:

applies only to hydrocarbon based oils.

3.1.1 air release time, n—the number of minutes needed for

1.2 The values stated in SI units are to be regarded as

air entrained in the oil to reduce in volume to 0.2% under the

standard. No other units of measurement are included in this

conditions of this test and at the specified temperature.

standard.

1.3 This standard does not purport to address all of the

4. Summary of Test Method

safety concerns, if any, associated with its use. It is the

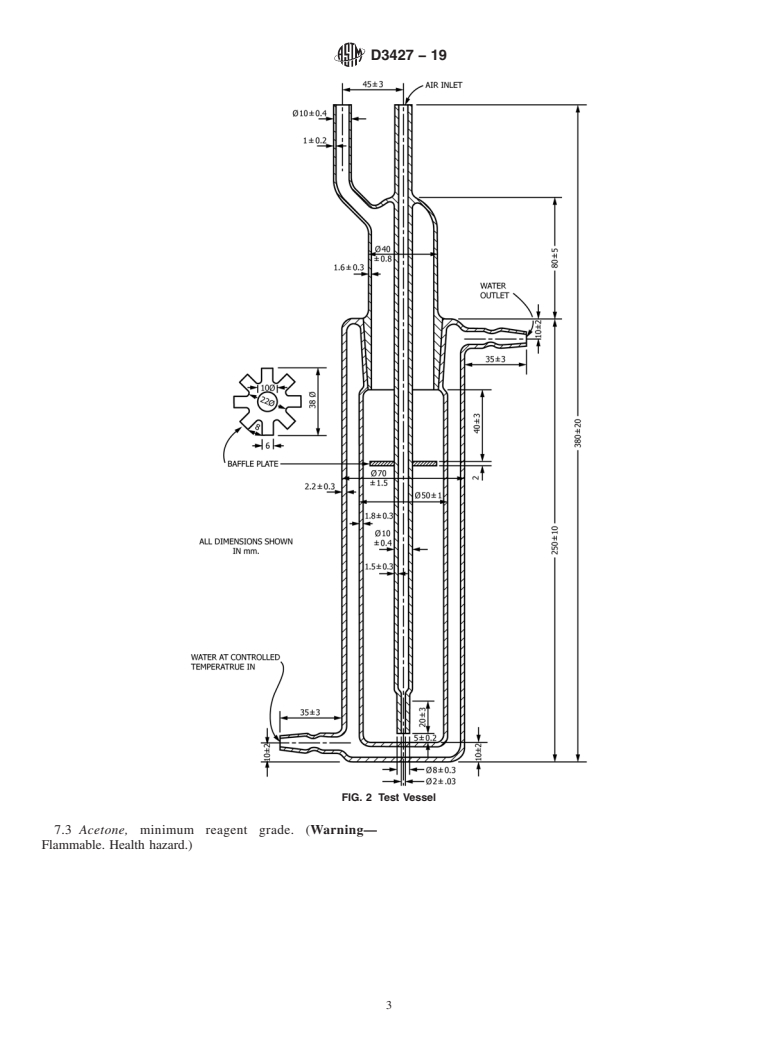

4.1 Compressed air is blown through the test oil, which has

responsibility of the user of this standard to establish appro-

been heated to a temperature of 25°C, 50°C, or 75°C. After

priate safety, health, and environmental practices and deter-

the air flow is stopped, the time required for the air entrained

mine the applicability of regulatory limitations prior to use.

in the oil to reduce in volume to 0.2% is recorded as the air

1.4 This international standard was developed in accor-

release time.

dance with internationally recognized principles on standard-

NOTE2—Byagreementbetweenthecustomerandthelaboratory,theoil

ization established in the Decision on Principles for the

may be heated at other temperatures. However, the precision at these

Development of International Standards, Guides and Recom-

different temperatures is not known at present.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

5. Significance and Use

2. Referenced Documents 5.1 Agitation of lubricating oil with air in equipment, such

2 as bearings, couplings, gears, pumps, and oil return lines, may

2.1 ASTM Standards:

produce a dispersion of finely divided air bubbles in the oil. If

D1193Specification for Reagent Water

the residence time in the reservoir is too short to allow the air

D1401TestMethodforWaterSeparabilityofPetroleumOils

bubbles to rise to the oil surface, a mixture of air and oil will

and Synthetic Fluids

circulate through the lubricating oil system. This may result in

D4057Practice for Manual Sampling of Petroleum and

aninabilitytomaintainoilpressure(particularlywithcentrifu-

Petroleum Products

gal pumps), incomplete oil films in bearings and gears, and

poor hydraulic system performance or failure.

1

This test method is under the jurisdiction of ASTM Committee D02 on

5.2 This test method measures the time for the entrained air

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

content to fall to the relatively low value of 0.2% volume

Subcommittee D02.C0.02 on Corrosion and Water/Air Separability.

Current edition approved Dec. 1, 2019. Published January 2020. Originally

under a standardized set of test conditions and hence permits

approved in 1975. Last previous edition approved in 2015 as D3427–15. DOI:

the comparison of the ability of oils to separate entrained air

10.1520/D3427-19.

under conditions where a separation time is available. The

This standard has been developed through the cooperative effort betweenASTM

significance of this test method has not been fully established.

International and the Energy Institute, London. The EI and ASTM International

logos imply that the ASTM International and EI standards are technically

However, entrained air can cause sponginess and lack of

equivalent, but does not imply that both standards are editorially identical.Adopted

sensitivityofthecontrolofturbineandhydraulicsystems.This

as a joint ASTM/IP standard in 2006.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from Beuth Verlag GmbH, Burggrafenstrasse 6, 1000 Berlin 30,

the ASTM website. Germany.

*A Summary of Changes section appea

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D3427 − 15 D3427 − 19

Designation 313–01

Standard Test Method for

1

Air Release Properties of Hydrocarbon Based Oils

This standard is issued under the fixed designation D3427; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the ability of turbine, hydraulic, and gear oils to separate entrained air.

NOTE 1—This test method was developed for hydrocarbon based oils. It may be used for some synthetic fluids; however, the precision statement applies

only to hydrocarbon based oils.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D1193 Specification for Reagent Water

D1401 Test Method for Water Separability of Petroleum Oils and Synthetic Fluids

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

E1 Specification for ASTM Liquid-in-Glass Thermometers

3

2.2 DIN Standard:

DIN 51 381

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 air release time, n—the number of minutes needed for air entrained in the oil to reduce in volume to 0.2 % under the

conditions of this test and at the specified temperature.

4. Summary of Test Method

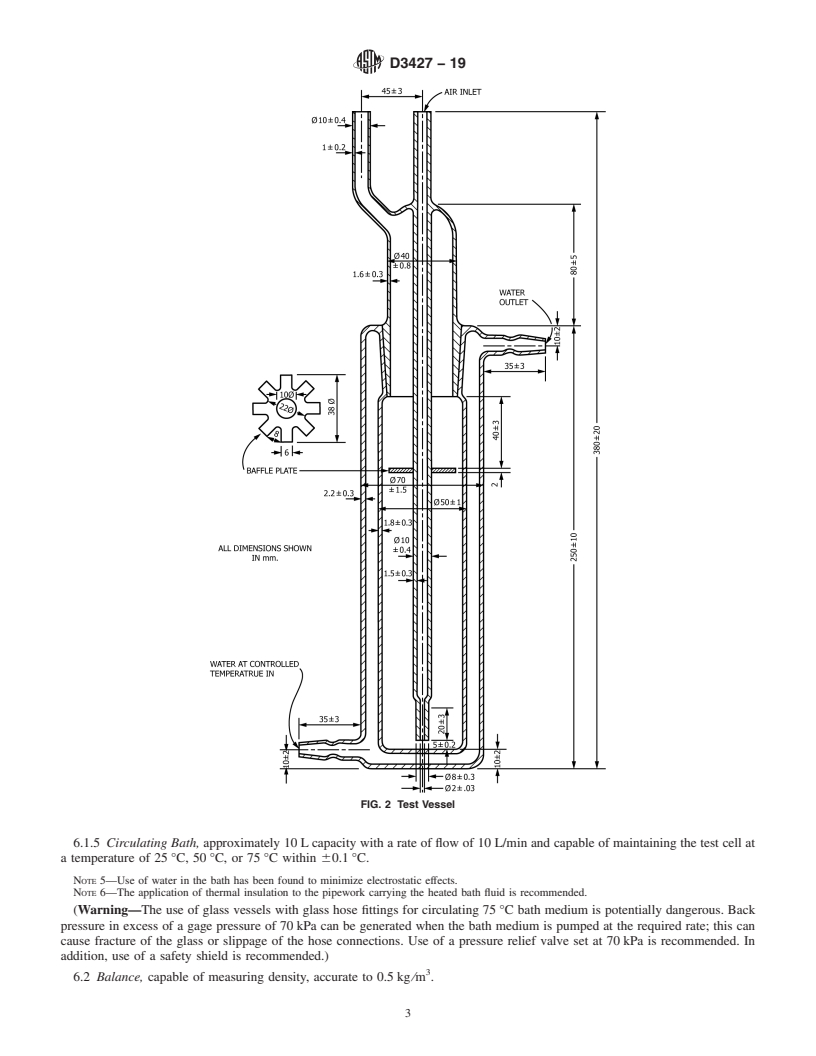

4.1 Compressed air is blown through the test oil, which has been heated to a temperature of 25 °C, 50 °C, or 75 °C. After the

air flow is stopped, the time required for the air entrained in the oil to reduce in volume to 0.2 % is recorded as the air release time.

NOTE 2—By agreement between the customer and the laboratory, the oil may be heated at other temperatures. However, the precision at these different

temperatures is not known at present.

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.C0.02 on Corrosion and Water/Air Separability.

Current edition approved Oct. 1, 2015Dec. 1, 2019. Published November 2015January 2020. Originally approved in 1975. Last previous edition approved in 20142015

ɛ1

as D3427 – 14aD3427 – 15. . DOI: 10.1520/D3427-15.10.1520/D3427-19.

This standard has been developed through the cooperative effort between ASTM International and the Energy Institute, London. The EI and ASTM International logos

imply that the ASTM International and EI standards are technically equivalent, but does not imply that both standards are editorially identical. Adopted as a joint ASTM/IP

standard in 2006.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Beuth Verlag GmbH, Burggrafenstrasse 6, 1000 Berlin 30, Germany.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3427 − 19

5. Significance and Use

5.1 Agitation of lubricating oil with air in equipment, such as bearings, couplings, gears, pumps, and oil return lines, may

produce a dispersion of finely divided air bubbles in the oil. If the residence time in the reservoir is too short to allow the air bubbles

to rise to the oil surface, a mixture of air and oil will circulate through the lubricating oil system. This may result in an inability

to maintain oil pressure (particularly with centrifugal pumps), incomplete oil films in bearings and gears, and poor hydraulic

system performance or failure.

5.2 Thi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.