ASTM D1193-99

(Specification)Standard Specification for Reagent Water

Standard Specification for Reagent Water

SCOPE

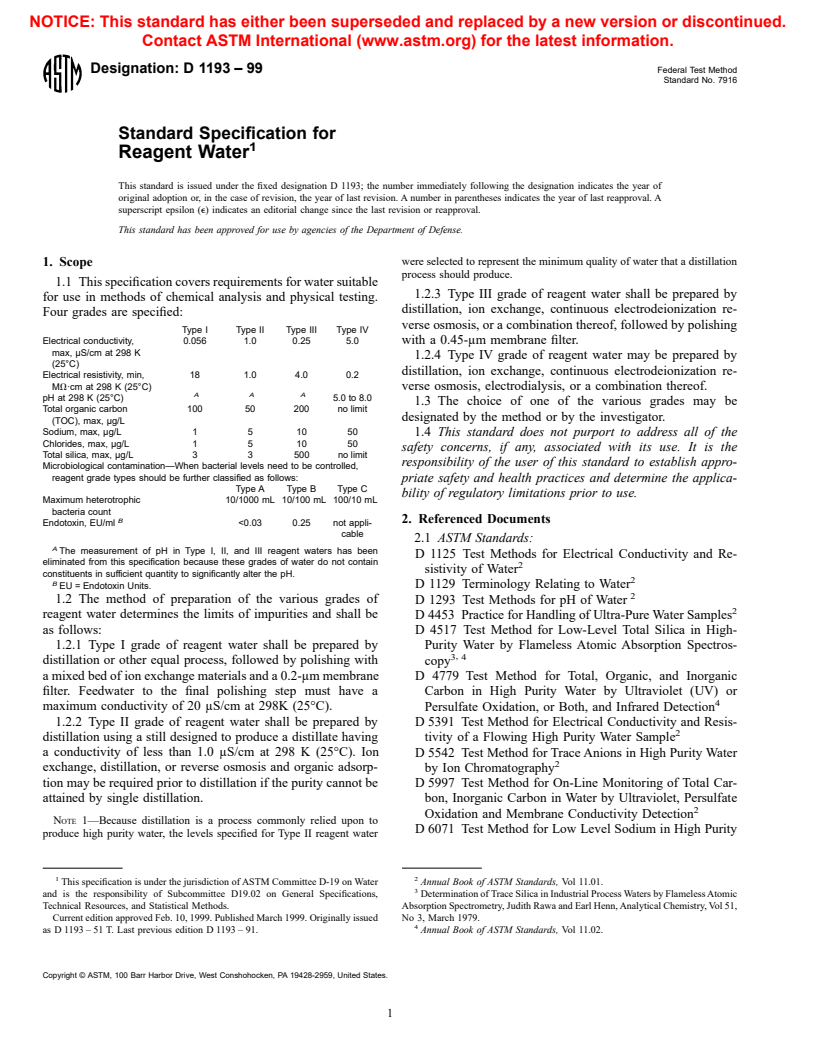

1.1 This specification covers requirements for water suitable for use in methods of chemical analysis and physical testing. Four grades are specified: Type IType IIType IIIType IVElectrical conductivity, max, µS/cm at 298 K (25oC)0.0561.00.255.0Electrical resistivity, min, Mcm at 298 K (25oC)181.0 4.00.2pH at 298 K (25oC)A AA 5.0 to 8.0Total organic carbon (TOC), max, µg/L5050200no limitSodium, max, µg/L1510 50Chlorides, max, µg/L1510 50Total silica, max, µg/L3 3500no limitMicrobiological contamination-When bacterial levels need to be controlled, reagent grade types should be further classified as follows:Type A Type BType CMaximum heterotrophic bacteria count10/1000 mL10/100 mL100/10 mLEndotoxin, EU/mlB 0.030.25not applicable AThe measurement of pH in Type I, II, and III reagent waters has been eliminated from this specification because these grades of water do not contain constituents in sufficient quantity to significantly alter the pH.

B EU = Endotoxin Units.

1.2 The method of preparation of the various grades of reagent water determines the limits of impurities and shall be as follows:

1.2.1 Type I grade of reagent water shall be prepared by distillation or other equal process, followed by polishing with a mixed bed of ion exchange materials and a 0.2-µm membrane filter. Feedwater to the final polishing step must have a maximum conductivity of 20 µS/cm at 298K (25oC).

1.2.2 Type II grade of reagent water shall be prepared by distillation using a still designed to produce a distillate having a conductivity of less than 1.0 µS/cm at 298 K (25oC). Ion exchange, distillation, or reverse osmosis and organic adsorption may be required prior to distillation if the purity cannot be attained by single distillation.

Note 1—Because distillation is a process commonly relied upon to produce high purity water, the levels specified for Type II reagent water were selected to represent the minimum quality of water that a distillation process should produce.

1.2.3 Type III grade of reagent water shall be prepared by distillation, ion exchange, continuous electrodeionization reverse osmosis, or a combination thereof, followed by polishing with a 0.45-µm membrane filter.

1.2.4 Type IV grade of reagent water may be prepared by distillation, ion exchange, continuous electrodeionization reverse osmosis, electrodialysis, or a combination thereof.

1.3 The choice of one of the various grades may be designated by the method or by the investigator.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 1193 – 99 Federal Test Method

Standard No. 7916

Standard Specification for

1

Reagent Water

This standard is issued under the fixed designation D 1193; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

were selected to represent the minimum quality of water that a distillation

1. Scope

process should produce.

1.1 This specification covers requirements for water suitable

1.2.3 Type III grade of reagent water shall be prepared by

for use in methods of chemical analysis and physical testing.

distillation, ion exchange, continuous electrodeionization re-

Four grades are specified:

verse osmosis, or a combination thereof, followed by polishing

Type I Type II Type III Type IV

Electrical conductivity, 0.056 1.0 0.25 5.0 with a 0.45-μm membrane filter.

max, μS/cm at 298 K

1.2.4 Type IV grade of reagent water may be prepared by

(25°C)

distillation, ion exchange, continuous electrodeionization re-

Electrical resistivity, min, 18 1.0 4.0 0.2

MV·cm at 298 K (25°C) verse osmosis, electrodialysis, or a combination thereof.

AA A

pH at 298 K (25°C) 5.0 to 8.0

1.3 The choice of one of the various grades may be

Total organic carbon 100 50 200 no limit

designated by the method or by the investigator.

(TOC), max, μg/L

Sodium, max, μg/L 1 5 10 50 1.4 This standard does not purport to address all of the

Chlorides, max, μg/L 1 5 10 50

safety concerns, if any, associated with its use. It is the

Total silica, max, μg/L 3 3 500 no limit

responsibility of the user of this standard to establish appro-

Microbiological contamination—When bacterial levels need to be controlled,

reagent grade types should be further classified as follows:

priate safety and health practices and determine the applica-

Type A Type B Type C

bility of regulatory limitations prior to use.

Maximum heterotrophic 10/1000 mL 10/100 mL 100/10 mL

bacteria count

B

2. Referenced Documents

Endotoxin, EU/ml <0.03 0.25 not appli-

cable

2.1 ASTM Standards:

A

The measurement of pH in Type I, II, and III reagent waters has been

D 1125 Test Methods for Electrical Conductivity and Re-

eliminated from this specification because these grades of water do not contain

2

sistivity of Water

constituents in sufficient quantity to significantly alter the pH.

2

B

EU = Endotoxin Units. D 1129 Terminology Relating to Water

2

1.2 The method of preparation of the various grades of D 1293 Test Methods for pH of Water

2

reagent water determines the limits of impurities and shall be

D 4453 Practice for Handling of Ultra-Pure Water Samples

as follows: D 4517 Test Method for Low-Level Total Silica in High-

1.2.1 Type I grade of reagent water shall be prepared by

Purity Water by Flameless Atomic Absorption Spectros-

3, 4

distillation or other equal process, followed by polishing with copy

a mixed bed of ion exchange materials and a 0.2-μm membrane

D 4779 Test Method for Total, Organic, and Inorganic

filter. Feedwater to the final polishing step must have a Carbon in High Purity Water by Ultraviolet (UV) or

4

maximum conductivity of 20 μS/cm at 298K (25°C). Persulfate Oxidation, or Both, and Infrared Detection

1.2.2 Type II grade of reagent water shall be prepared by D 5391 Test Method for Electrical Conductivity and Resis-

2

distillation using a still designed to produce a distillate having tivity of a Flowing High Purity Water Sample

a conductivity of less than 1.0 μS/cm at 298 K (25°C). Ion D 5542 Test Method for Trace Anions in High Purity Water

2

exchange, distillation, or reverse osmosis and organic adsorp- by Ion Chromatography

tion may be required prior to distillation if the purity cannot be D 5997 Test Method for On-Line Monitoring of Total Car-

attained by single distillation. bon, Inorganic Carbon in Water by Ultraviolet, Persulfate

2

Oxidation and Membrane Conductivity Detection

NOTE 1—Because distillation is a process commonly relied upon to

D 6071 Test Method for Low Level Sodium in High Purity

produce high purity water, the levels specified for Type II reagent water

1 2

This specification is under the jurisdiction of ASTM Committee D-19 on Water Annual Book of ASTM Standards, Vol 11.01.

3

and is the responsibility of Subcommittee D19.02 on General Specifications, Determination of Trace Silica in Industrial Process Waters by Flameless Atomic

Technical Resources, and Statistical Methods. Absorption Spectrometry, Judith Rawa and Earl Henn, Analytical Chemistry, Vol 51,

Current edition approved Feb. 10, 1999. Published March 1999. Originally issued No 3, March 1979.

4

as D 1193 – 51 T. Last p

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.