ASTM D792-98

(Test Method)Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement

Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement

SCOPE

1.1 These test methods describe the determination of the specific gravity (relative density) and density of solid plastics in forms such as sheets, rods, tubes, or molded items.

1.2 Two test methods are described:

1.2.1 Test Method A --For testing solid plastics in water, and

1.2.2 Test Method B--For testing solid plastics in liquids other than water.

Note 1--Alternatively, Test Method D1505 may be applied to many such forms, as well as to films and sheeting.

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 2--This standard is not equivalent to ISO 1183 Method A.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 792 – 98

Standard Test Methods for

Density and Specific Gravity (Relative Density) of Plastics

by Displacement

This standard is issued under the fixed designation D 792; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope * E 380 Practice for Use of the International System of Units

(SI) (the Modernized Metric System)

1.1 These test methods describe the determination of the

E 691 Practice for Conducting an Interlaboratory Study to

specific gravity (relative density) and density of solid plastics

Determine the Precision of a Test Method

in forms such as sheets, rods, tubes, or molded items.

1.2 Two test methods are described:

3. Terminology

1.2.1 Test Method A—For testing solid plastics in water, and

3.1 General—The units, symbols, and abbreviations used in

1.2.2 Test Method B—For testing solid plastics in liquids

these test methods are in accordance with Practice E 380.

other than water.

3.2 Definitions:

NOTE 1—Alternatively, Test Method D 1505 may be applied to many

3.2.1 specific gravity (relative density)—the ratio of the

such forms, as well as to films and sheeting.

mass in air of a unit volume of the impermeable portion of the

1.3 The values stated in SI units are to be regarded as the

material at 23°C to the mass in air of equal density of an equal

standard.

volume of gas-free distilled water at the same temperature. The

1.4 This standard does not purport to address all of the

form of expression shall be:

safety concerns, if any, associated with its use. It is the

Specific gravity ~relative density! 23/23°C

responsibility of the user of this standard to establish appro-

~or sp gr 23/23°C!

priate safety and health practices and determine the applica-

NOTE 3—This definition is essentially equivalent to the definition for

bility of regulatory limitations prior to use.

apparent specific gravity and apparent density in Terminology E 12,

because the small percentage difference introduced by not correcting for

NOTE 2—There is no similar or equivalent ISO standard.

the buoyancy of air is insignificant for most purposes.

2. Referenced Documents

3.2.2 density—the mass in air in kilograms per cubic metre

2.1 ASTM Standards:

of impermeable portion of the material at 23°C. The form of

D 618 Practice for Conditioning Plastics and Electrical

expression shall be:

Insulating Materials for Testing

23 3

D , kg/m ~Notes 2-4!

D 891 Test Methods for Specific Gravity, Apparent, of

3 3

NOTE 4—The SI unit of density, as defined in Practice E 380 is kg/m .

Liquid Industrial Chemicals

3 3

To convert density in g/cm to density in kg/m , multiply by 1000.

D 1505 Test Method for Density of Plastics by the Density-

2 NOTE 5—Specific gravity 23/23°C can be converted to density 23°C,

Gradient Technique

kg/m , by use of the following equation:

D 1622 Test Method for Apparent Density of Rigid Cellular

23 C 3

Plastics D , kg/m 5 sp gr 23/23°C 3 997.6

D 1898 Practice for Sampling of Plastics

4. Summary of Test Method

E 1 Specification for ASTM Thermometers

4.1 Determine the mass of a specimen of the solid plastic in

E 12 Terminology Relating to Density and Specific Gravity

air. It is then immersed in a liquid, its apparent mass upon

of Solids, Liquids, and Gases

immersion is determined, and its specific gravity (relative

density) calculated.

These test methods are under the jurisdiction of ASTM Committee D-20 on

Plastics and are the direct responsibility of Subcommittee D20.70 on Analytical

5. Significance and Use

Methods (Section D20.70.01).

5.1 The specific gravity or density of a solid is a property

Current edition approved Aug. 10, 1998. Published November 1998. Originally

published as D 792 – 44. Last previous edition D 792 – 91. that can be measured conveniently to identify a material, to

Annual Book of ASTM Standards, Vol 08.01.

Annual Book of ASTM Standards, Vol 15.05.

Annual Book of ASTM Standards, Vol 14.03.

5 6

Discontinued; see 1995 Annual Book of ASTM Standards, Vol 15.05. Annual Book of ASTM Standards, Vol 14.02.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 792

follow physical changes in a sample, to indicate degree of 9.2 Sample Holder, corrosion-resistant.

uniformity among different sampling units or specimens, or to 9.3 Sinker—A sinker for use with specimens of plastics that

indicate the average density of a large item. have specific gravities less than 1.000. The sinker shall: (1)be

5.2 Changes in density of a single specimen may be due to corrosion-resistant; (2) have a specific gravity of not less than

changes in crystallinity, loss of plasticizer, absorption of 7.0; (3) have smooth surfaces and a regular shape; and (4)be

solvent, or to other causes. Portions of a sample may differ in slightly heavier than necessary to sink the specimen. The

density because of difference in crystallinity, thermal history, sinker should have an opening to facilitate attachment to the

porosity, and composition (types or proportions of resin, specimen and wire.

plasticizer, pigment, or filler). 9.4 Immersion Vessel—A beaker or other wide-mouthed

vessel for holding the water and immersed specimen.

NOTE 6—Reference is made to Test Method D 1622.

9.5 Thermometer—A thermometer with an accuracy of

5.3 Density is useful for calculating strength-weight and

61°C is required if the test is not performed in the standard

cost-weight ratios.

laboratory atmosphere of Practice D 618, (refer to 17.4).

6. Sampling

10. Materials

6.1 The sampling units used for the determination of spe-

10.1 Water—The water shall be substantially air-free and

cific gravity (relative density) shall be representative of the

distilled or demineralized water.

quantity of product for which the data are required, in

NOTE 8—Water may be rendered substantially air-free by boiling and

accordance with Practice D 1898.

cooling or by shaking under vacuum in a heavy-walled vacuum flask.

6.1.1 If it is known or suspected that the sample consists of

(Precaution: Use gloves and shielding.) If the water does not wet the

two or more layers or sections having different specific

specimen, a few drops of a wetting agent shall be added. If this solution

gravities, either complete finished parts or complete cross

does not wet the specimen, Method B shall be used.

sections of the parts or shapes shall be used as the specimens,

11. Test Specimen

or separate specimens shall be taken and tested from each

layer. The specific gravity (relative density) of the total part

11.1 The test specimen shall be a single piece of the material

cannot be obtained by adding the specific gravity of the layers,

under test of any size and shape that can conveniently be

unless relative percentages of the layers are taken into account.

prepared and tested, provided that its volume shall be not less

than 1 cm and its surface and edges shall be made smooth. The

7. Conditioning

thickness of the specimen should be at least 1 mm for each 1

7.1 Conditioning—Condition the test specimens at

g of weight. A specimen weighing 1 to 5 g usually will be

23 6 2°C and 50 6 5 % relative humidity for not less than 40

found convenient, but specimens up to approximately 50 g may

h prior to test in accordance with Procedure A of Practice

be used (Note 9). Care should be taken in cutting specimens to

D 618, for those tests where conditioning is required. In cases

avoid changes in density resulting from compressive stresses or

of disagreement, the tolerances shall be 1°C and 62 % relative

frictional heating.

humidity.

NOTE 9—Specifications for certain plastics require a particular method

7.2 Test Conditions—Conduct tests in the standard labora-

of specimen preparation and should be consulted if applicable.

tory atmosphere of 23 6 2°C and 50 6 5 % relative humidity,

11.2 The specimen shall be free from oil, grease, and other

unless otherwise specified in the test methods or in this

foreign matter.

specification. In cases of disagreement, the tolerances shall be

1°C and 62 % relative humidity.

12. Procedure

TEST METHOD A FOR TESTING SOLID PLASTICS

12.1 Measure and record the water temperature.

IN WATER (SPECIMENS 1 TO 50 g)

12.2 Weigh the specimen in air to the nearest 0.1 mg for

specimens of mass 1 to 10 g or to the nearest mg for specimens

8. Scope

of mass more than 10 to 50 g.

8.1 This test method involves weighing a one-piece speci-

12.3 Attach to the balance a piece of fine wire sufficiently

men of 1 to 50 g in water, using a sinker with plastics that are

long to reach from the hook above the pan to the support for the

lighter than water. This test method is suitable for plastics that

immersion vessel. Attach the specimen to the wire such that it

are wet by, but otherwise not affected by water.

is suspended about 25 mm above the vessel support.

9. Apparatus

NOTE 10—The specimen may be weighed in air after hanging from the

wire. In this case, record the mass of the specimen, a 5 (mass of

9.1 Analytical Balance—A balance with a precision within

specimen + wire, in air) − (mass of wire in air).

0.1 mg, accuracy within 0.05 % relative (that is, 0.05 % of the

mass of the specimen in air), and equipped with a stationary 12.4 Mount the immersion vessel on the support, and

support for the immersion vessel above the balance pan (“pan

completely immerse the suspended specimen (and sinkers, if

straddle”). used) in water (10.1) at a temperature of 23 6 2°C. The vessel

must not touch wire or specimen. Remove any bubbles

NOTE 7—Assurance that the balance meets the performance require-

adhering to the specimen, wire, or sinker, paying particular

ments should be provided by frequent checks on adjustments of zero point

attention to holes in the specimen and sinker. Usually these

and sensitivity and by periodic calibration for absolute accuracy, using

standard masses. bubbles can be removed by rubbing them with another wire. If

D 792

the bubbles cannot be removed by this method or if bubbles are

where:

continuously formed (as from dissolved gases), the use of

a 5 apparent mass of specimen, without wire or sinker, in

vacuum is recommended (Note 12). Determine the mass of the

air,

b 5 apparent mass of specimen (and of sinker, if used)

suspended specimen to the required precision (12.2) (Note 11).

completely immersed and of the wire partially im-

Record this apparent mass as b (the mass of the specimen,

mersed in liquid, and

sinker, if used, and the partially immersed wire in liquid).

w 5 apparent mass of totally immersed sinker (if used) and

Unless otherwise specified, weigh rapidly in order to minimize

of partially immersed wire.

absorption of water by the specimen.

13.2 Calculate the density of the plastic as follows:

NOTE 11—It may be necessary to change the sensitivity adjustment of

23C 3

D , kg/m 5 sp gr 23/23°C 3 997.6

the balance to overcome the damping effect of the immersed specimen.

NOTE 12—Some specimens may contain absorbed or dissolved gases,

14. Report

or irregularities which tend to trap air bubbles; any of these may affect the

14.1 Report the following information:

density values obtained. In such cases, the immersed specimen may be

14.1.1 Complete identification of the material or product

subjected to vacuum in a separate vessel until evolution of bubbles has

tested, including method of specimen preparation and condi-

substantially ceased before weighing (see Test Method B). It must also be

tioning,

demonstrated that the use of this technique leads to results of the required

14.1.2 Average specific gravity (relative density) for all

degree of precision.

specimens from a sampling unit, reported as sp gr 23/

12.5 Weigh the wire (and sinker, if used) in water with

23C 3

23°C 5 ___, or average density reported as D 5 ___ kg/m ,

immersion to the same depth as used in the previous step

14.1.3 A measure of the degree of variation of specific

(Notes 13 and 14). Record this height as w (mass of the wire in

gravity or density within the sampling unit such as the standard

liquid).

deviation and number of determinations on a homogeneous

material or the averages plus these measures of dispersion on

NOTE 13—It is convenient to mark the level of immersion by means of

different layers or areas of a nonhomogeneous product,

a shallow notch filed in the wire. The finer the wire, the greater the

14.1.4 Report the temperature of the water.

tolerance which may be permitted in adjusting the level of immersion

14.1.5 Any evidence of porosity of the material or speci-

between weighings. With wire Awg No. 36 or finer, disregard its degrees

of immersion and, if no sinker is used, use the mass of the wire in air as men,

w.

14.1.6 The method of test (Method A of Methods D 792),

NOTE 14—If the wire is left attached to the balance arm during a series and

of determinations, the mass a may be determined either with the aid of a

14.1.7 Date of test.

tare on the other arm of the balance or as in Note 12. In such cases, care

15. Precision and Bias

must be taken that the change of mass of the wire (for example, from

visible water) between readings does not exceed the desired precision.

15.1 See Section 23.

12.6 Repeat the procedure for the required number of

TEST METHOD B FOR TESTING SOLID PLASTICS

specimens. Two specimens per sample are recommended.

IN LIQUIDS OTHER THAN WATER (SPECIMENS 1

Determine acceptability of number of replicate test specimens

TO 50 g)

by comparing results with precision data given in Tables 1 and

16. Scope

2 of Section 23. Additional specimens may be required to give

the desired precision.

16.1 Test Method B uses a liquid other than water for testing

one-piece specimens, 1 to 50 g, of plastics that are affected by

13. Calculation water or which are lighter than water.

13.1 Calculate the specific gravity of the plastic as follows:

17. Apparatus

Sp gr 23/23°C 5 a/~a 1 w 2 b!

17.1 The apparatus shall include the balance, wire, and

immersion vessel of Section 8, and, optionally, the following:

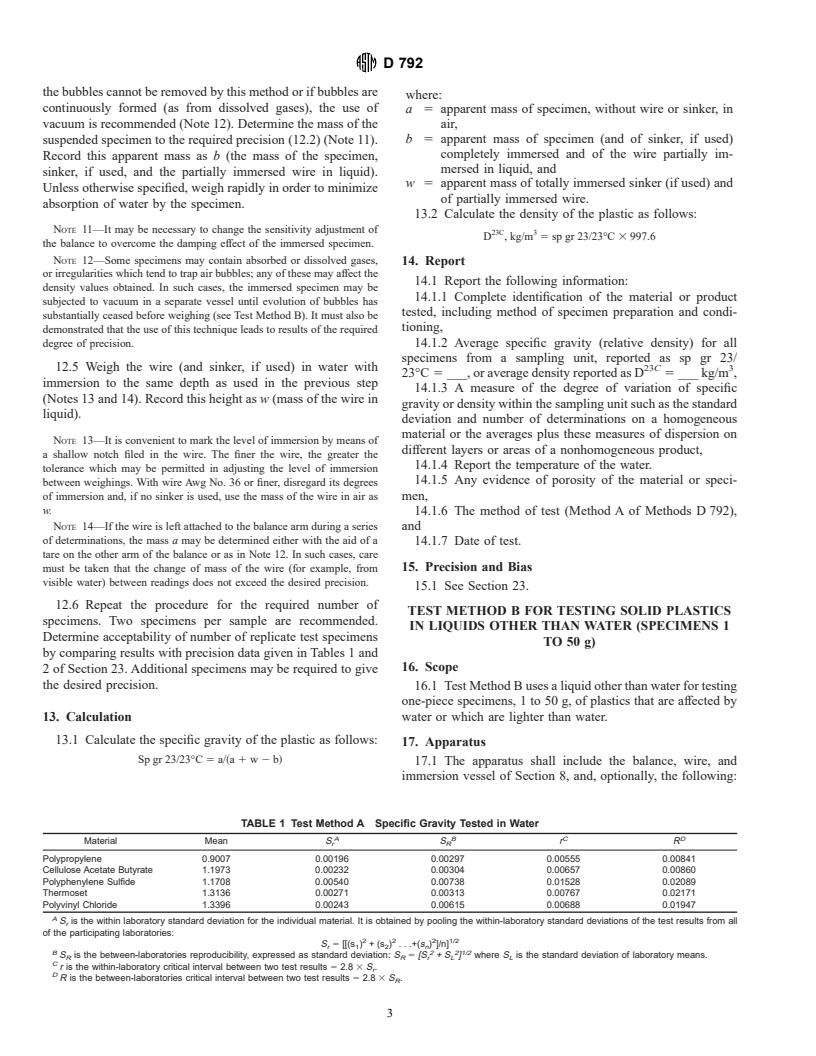

TABLE 1 Test Method A Specific Gravity Tested in Water

A B C D

Material Mean S S r R

r R

Polypropylene 0.9007 0.00196 0.00297 0.00555 0.00841

Cellulose Acetate Butyrate 1.1973 0.00232 0.00304 0.00657 0.00860

Polyphenylene Sulfide 1.1708 0.00540 0.00738 0.01528 0.02089

Thermoset 1.3136 0.00271 0.00313 0.00767 0.02171

Polyvinyl Chloride 1.3396 0.00243 0.00615 0.00688 0.01947

A

S is the within laboratory standard deviation for the individual ma

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.