ASTM F2720/F2720M-20

(Specification)Standard Specification for Glass Fiber Reinforced Polyethylene (PE-GF) Spiral Wound Large Diameter Pipe

Standard Specification for Glass Fiber Reinforced Polyethylene (PE-GF) Spiral Wound Large Diameter Pipe

SCOPE

1.1 This specification covers requirements and test methods for materials, dimensions, workmanship, joining systems, and marking for large diameter, 12 in. [300 mm] and larger, inside diameter controlled glass fiber reinforced polyethylene (PE-GF) spiral wound pipe with electrofusion joints. The piping is intended for new construction and renewal of existing piping systems used for the transport of water, slurries, municipal sewage, domestic sewage, effluents, etc., in pressure systems.

Note 1: Pipe produced to this specification should be installed in accordance with Practice D2774 or F1668, where applicable, and with the manufacturer’s recommendations.

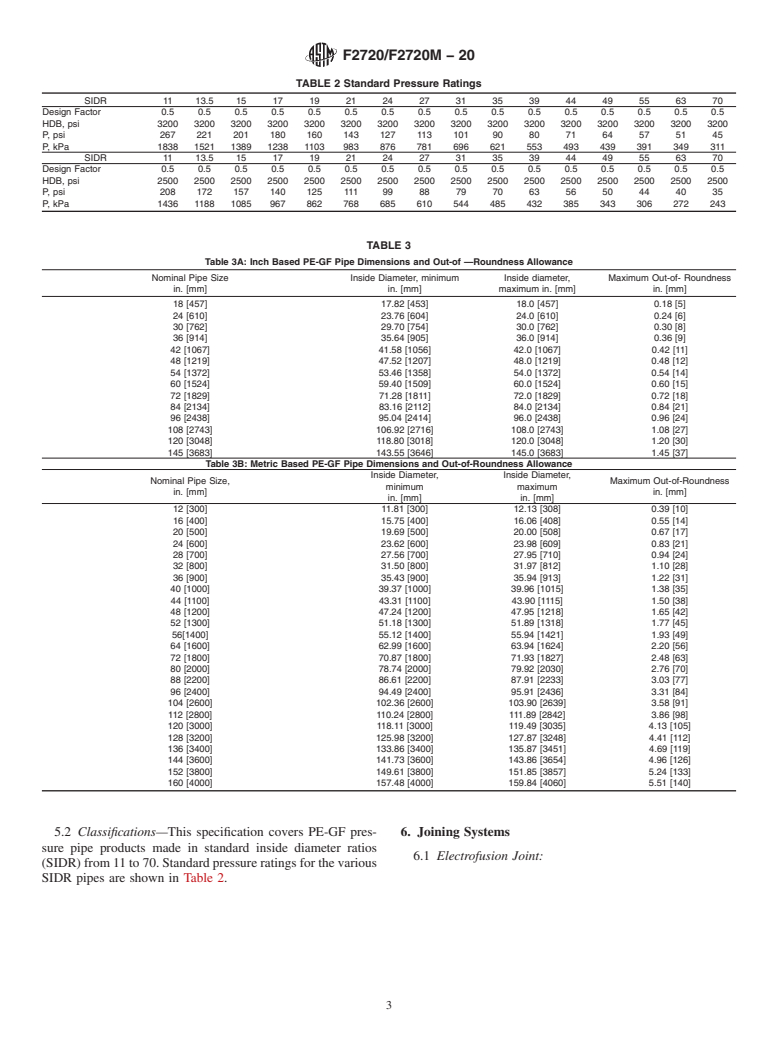

1.2 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text the SI units are shown in brackets. The values stated in each system may not be exact equivalents: therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 All pipes produced under this specification are pressure-rated.

1.4 This specification includes criteria for choice of raw material and test methods for evaluation of raw material, together with performance requirements and test methods for determining conformance with the requirements.

1.5 In referee decisions, the SI units shall be used for metric-sized pipe and inch-pound units for pipe sized per ANSI (ANSI B 36.10).

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F2720/F2720M −20 An American National Standard

Standard Specification for

Glass Fiber Reinforced Polyethylene (PE-GF) Spiral Wound

1

Large Diameter Pipe

ThisstandardisissuedunderthefixeddesignationF2720/F2720M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

1.1 This specification covers requirements and test methods

mendations issued by the World Trade Organization Technical

for materials, dimensions, workmanship, joining systems, and

Barriers to Trade (TBT) Committee.

marking for large diameter, 12 in. [300 mm] and larger, inside

diameter controlled glass fiber reinforced polyethylene (PE-

2. Referenced Documents

GF) spiral wound pipe with electrofusion joints. The piping is

2

2.1 ASTM Standards:

intended for new construction and renewal of existing piping

D618 Practice for Conditioning Plastics for Testing

systems used for the transport of water, slurries, municipal

D638 Test Method for Tensile Properties of Plastics

sewage, domestic sewage, effluents, etc., in pressure systems.

D790 Test Methods for Flexural Properties of Unreinforced

NOTE 1—Pipe produced to this specification should be installed in

accordance with Practice D2774 or F1668, where applicable, and with the and Reinforced Plastics and Electrical Insulating Materi-

manufacturer’s recommendations.

als

D792 Test Methods for Density and Specific Gravity (Rela-

1.2 The values stated in either inch-pound units or SI units

tive Density) of Plastics by Displacement

are to be regarded separately as standard.Within the text the SI

D1505 Test Method for Density of Plastics by the Density-

units are shown in brackets. The values stated in each system

Gradient Technique

may not be exact equivalents: therefore, each system shall be

D1598 Test Method for Time-to-Failure of Plastic Pipe

used independently of the other. Combining values from the

Under Constant Internal Pressure

two systems may result in non-conformance with the standard.

D1600 Terminology forAbbreviatedTerms Relating to Plas-

1.3 All pipes produced under this specification are pressure-

tics

rated.

D2122 Test Method for Determining Dimensions of Ther-

1.4 This specification includes criteria for choice of raw

moplastic Pipe and Fittings

material and test methods for evaluation of raw material,

D2657 Practice for Heat Fusion Joining of Polyolefin Pipe

together with performance requirements and test methods for

and Fittings

determining conformance with the requirements.

D2774 PracticeforUndergroundInstallationofThermoplas-

tic Pressure Piping

1.5 In referee decisions, the SI units shall be used for

D2837 Test Method for Obtaining Hydrostatic Design Basis

metric-sizedpipeandinch-poundunitsforpipesizedperANSI

forThermoplasticPipeMaterialsorPressureDesignBasis

(ANSI B 36.10).

for Thermoplastic Pipe Products

1.6 This standard does not purport to address all of the

D3350 Specification for Polyethylene Plastics Pipe and Fit-

safety concerns, if any, associated with its use. It is the

tings Materials

responsibility of the user of this standard to establish appro-

D3895 Test Method for Oxidative-Induction Time of Poly-

priate safety, health, and environmental practices and deter-

olefins by Differential Scanning Calorimetry

mine the applicability of regulatory limitations prior to use.

F412 Terminology Relating to Plastic Piping Systems

1.7 This international standard was developed in accor-

F1290 PracticeforElectrofusionJoiningPolyolefinPipeand

dance with internationally recognized principles on standard-

Fittings

F1668 Guide for Construction Procedures for Buried Plastic

1 Pipe

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.11 on

Composite.

2

Current edition approved Sept. 1, 2020. Published September 2020. Originally For referenced ASTM standards, visit the ASTM website, www.astm.org, or

approved in 2008. Last previous edition approved in 2009 as F2720/F2720M-09 contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

which was withdrawn in August 2016 and reinstated in September 2020. Standards volume information, refer to the standard’s Document Summary page on

DOI:10.1520/F2720_F2720M-20. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.