ASTM F2324-13

(Test Method)Standard Test Method for Prerinse Spray Valves

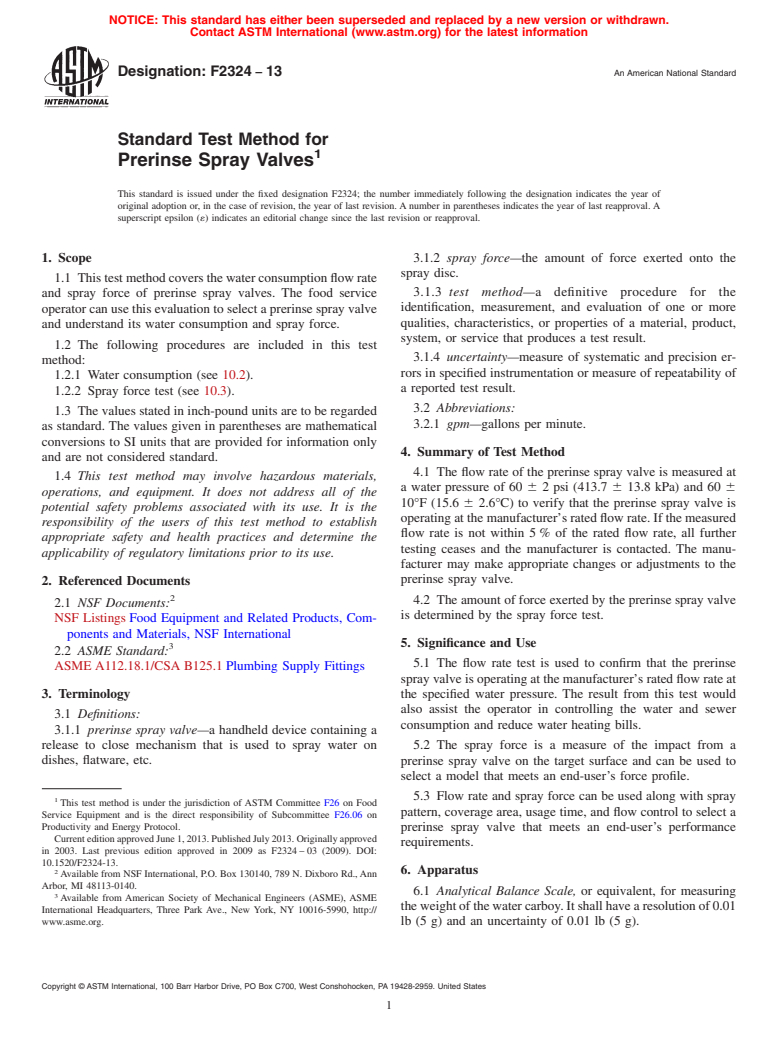

Standard Test Method for Prerinse Spray Valves

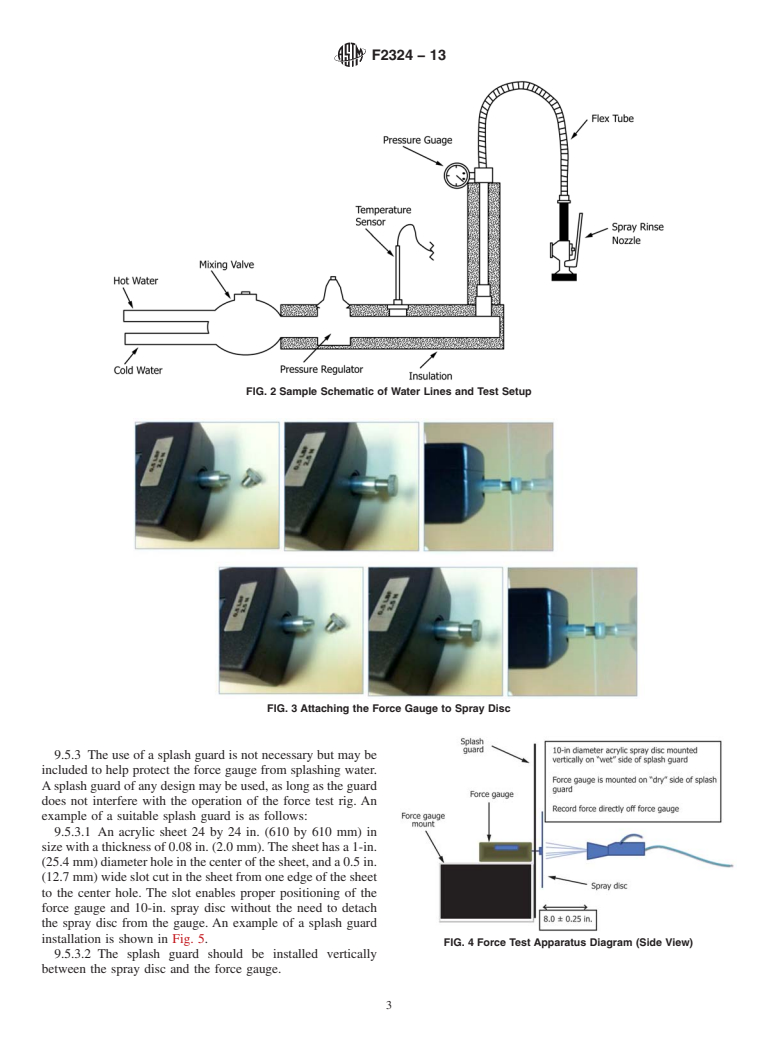

SIGNIFICANCE AND USE

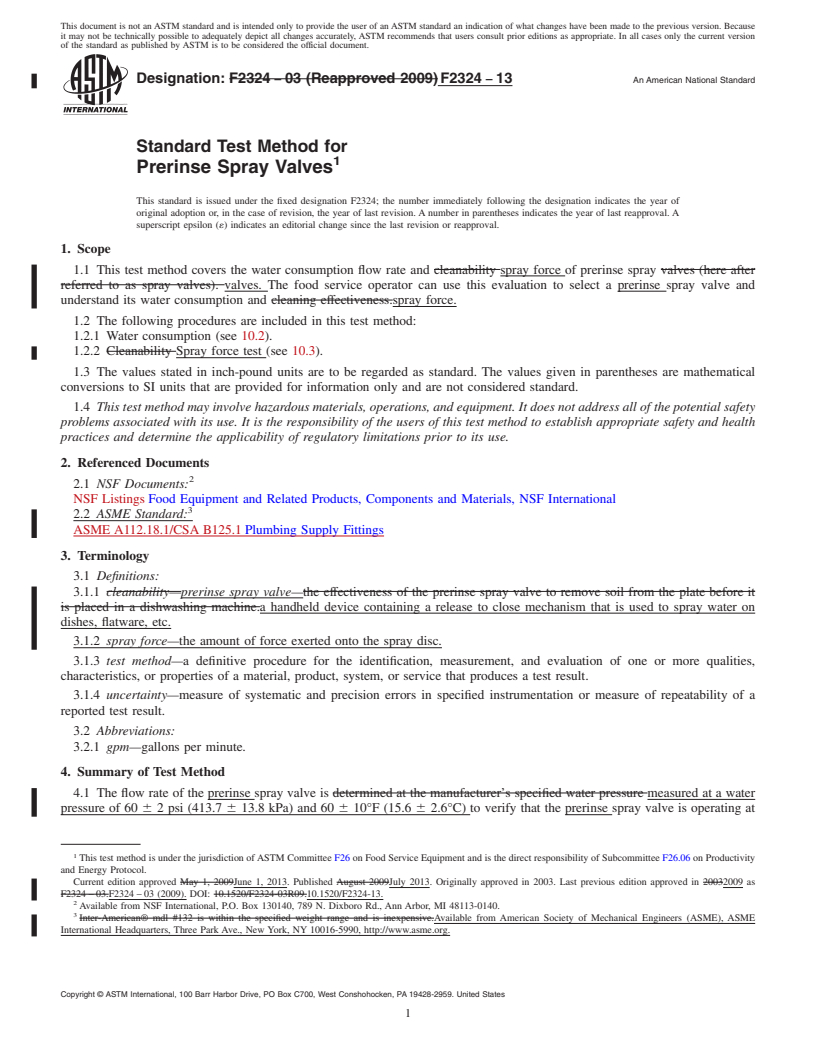

5.1 The flow rate test is used to confirm that the prerinse spray valve is operating at the manufacturer's rated flow rate at the specified water pressure. The result from this test would also assist the operator in controlling the water and sewer consumption and reduce water heating bills.

5.2 The spray force is a measure of the impact from a prerinse spray valve on the target surface and can be used to select a model that meets an end-user’s force profile.

5.3 Flow rate and spray force can be used along with spray pattern, coverage area, usage time, and flow control to select a prerinse spray valve that meets an end-user’s performance requirements.

SCOPE

1.1 This test method covers the water consumption flow rate and spray force of prerinse spray valves. The food service operator can use this evaluation to select a prerinse spray valve and understand its water consumption and spray force.

1.2 The following procedures are included in this test method:

1.2.1 Water consumption (see 10.2).

1.2.2 Spray force test (see 10.3).

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This test method may involve hazardous materials, operations, and equipment. It does not address all of the potential safety problems associated with its use. It is the responsibility of the users of this test method to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to its use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2324 − 13 An American National Standard

Standard Test Method for

1

Prerinse Spray Valves

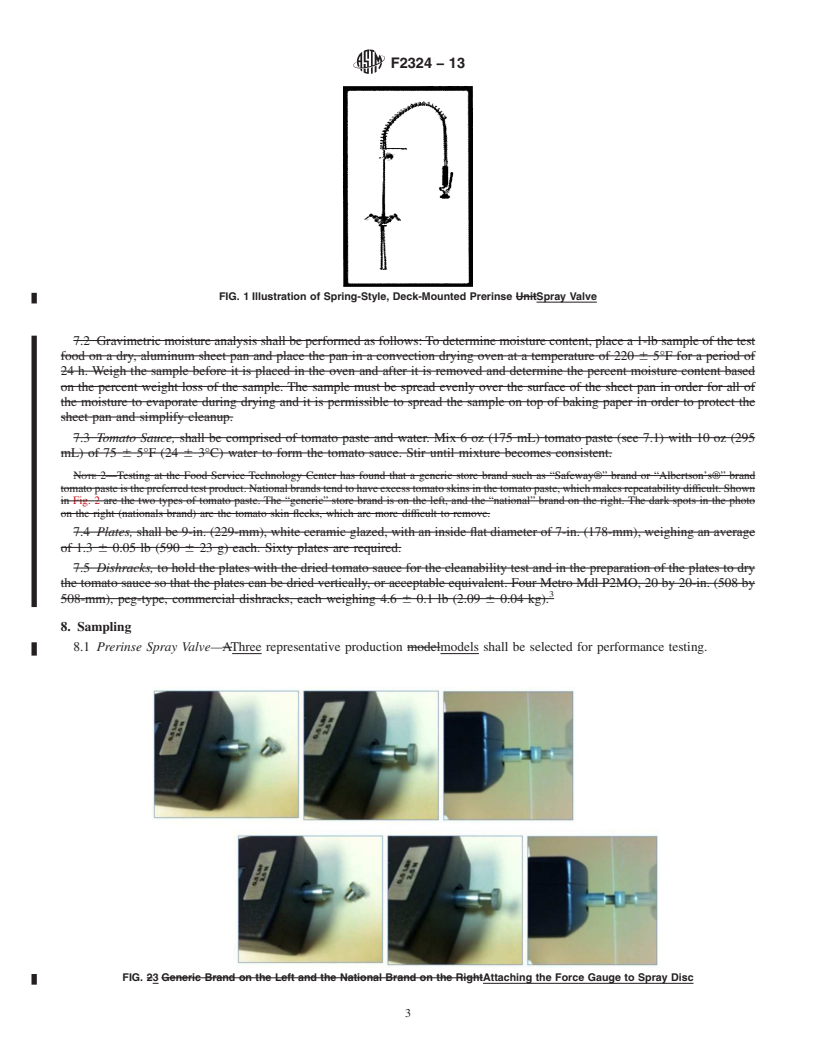

This standard is issued under the fixed designation F2324; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 spray force—the amount of force exerted onto the

spray disc.

1.1 Thistestmethodcoversthewaterconsumptionflowrate

3.1.3 test method—a definitive procedure for the

and spray force of prerinse spray valves. The food service

identification, measurement, and evaluation of one or more

operatorcanusethisevaluationtoselectaprerinsesprayvalve

qualities, characteristics, or properties of a material, product,

and understand its water consumption and spray force.

system, or service that produces a test result.

1.2 The following procedures are included in this test

3.1.4 uncertainty—measure of systematic and precision er-

method:

rors in specified instrumentation or measure of repeatability of

1.2.1 Water consumption (see 10.2).

a reported test result.

1.2.2 Spray force test (see 10.3).

3.2 Abbreviations:

1.3 The values stated in inch-pound units are to be regarded

3.2.1 gpm—gallons per minute.

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only

4. Summary of Test Method

and are not considered standard.

4.1 The flow rate of the prerinse spray valve is measured at

1.4 This test method may involve hazardous materials,

a water pressure of 60 6 2 psi (413.7 6 13.8 kPa) and 60 6

operations, and equipment. It does not address all of the

10°F (15.6 6 2.6°C) to verify that the prerinse spray valve is

potential safety problems associated with its use. It is the

operatingatthemanufacturer’sratedflowrate.Ifthemeasured

responsibility of the users of this test method to establish

flow rate is not within 5% of the rated flow rate, all further

appropriate safety and health practices and determine the

testing ceases and the manufacturer is contacted. The manu-

applicability of regulatory limitations prior to its use.

facturer may make appropriate changes or adjustments to the

prerinse spray valve.

2. Referenced Documents

2

4.2 The amount of force exerted by the prerinse spray valve

2.1 NSF Documents:

is determined by the spray force test.

NSF ListingsFood Equipment and Related Products, Com-

ponents and Materials, NSF International

5. Significance and Use

3

2.2 ASME Standard:

5.1 The flow rate test is used to confirm that the prerinse

ASME A112.18.1/CSA B125.1Plumbing Supply Fittings

sprayvalveisoperatingatthemanufacturer’sratedflowrateat

3. Terminology

the specified water pressure. The result from this test would

also assist the operator in controlling the water and sewer

3.1 Definitions:

consumption and reduce water heating bills.

3.1.1 prerinse spray valve—a handheld device containing a

release to close mechanism that is used to spray water on 5.2 The spray force is a measure of the impact from a

dishes, flatware, etc.

prerinse spray valve on the target surface and can be used to

select a model that meets an end-user’s force profile.

5.3 Flow rate and spray force can be used along with spray

1

This test method is under the jurisdiction of ASTM Committee F26 on Food

pattern, coverage area, usage time, and flow control to select a

Service Equipment and is the direct responsibility of Subcommittee F26.06 on

Productivity and Energy Protocol.

prerinse spray valve that meets an end-user’s performance

CurrenteditionapprovedJune1,2013.PublishedJuly2013.Originallyapproved

requirements.

in 2003. Last previous edition approved in 2009 as F2324–03 (2009). DOI:

10.1520/F2324-13.

2 6. Apparatus

Available from NSF International, P.O. Box 130140, 789 N. Dixboro Rd.,Ann

Arbor, MI 48113-0140.

6.1 Analytical Balance Scale, or equivalent, for measuring

3

Available from American Society of Mechanical Engineers (ASME), ASME

theweightofthewatercarboy.Itshallhavearesolutionof0.01

International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

www.asme.org. lb (5 g) and an uncertainty of 0.01 lb (5 g).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2324 − 13

6.2 Calibrated Exposed Junction Thermocouple Probes,

witharangefrom50to200°F(10to93.3°C),witharesolution

of 0.2°F (0.1°C) and an uncertainty of 1.0°F (0.5°C), for

measuring water line temperatures. Calibrated K-type 24-GA

thermocouple wire with stainless steel sheath and ceramic

insulation is the recommended choice for measuring the water

line temperatures. The thermocouple probe

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2324 − 03 (Reapproved 2009) F2324 − 13 An American National Standard

Standard Test Method for

1

Prerinse Spray Valves

This standard is issued under the fixed designation F2324; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the water consumption flow rate and cleanability spray force of prerinse spray valves (here after

referred to as spray valves). valves. The food service operator can use this evaluation to select a prerinse spray valve and

understand its water consumption and cleaning effectiveness.spray force.

1.2 The following procedures are included in this test method:

1.2.1 Water consumption (see 10.2).

1.2.2 Cleanability Spray force test (see 10.3).

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 This test method may involve hazardous materials, operations, and equipment. It does not address all of the potential safety

problems associated with its use. It is the responsibility of the users of this test method to establish appropriate safety and health

practices and determine the applicability of regulatory limitations prior to its use.

2. Referenced Documents

2

2.1 NSF Documents:

NSF Listings Food Equipment and Related Products, Components and Materials, NSF International

3

2.2 ASME Standard:

ASME A112.18.1/CSA B125.1 Plumbing Supply Fittings

3. Terminology

3.1 Definitions:

3.1.1 cleanability—prerinse spray valve—the effectiveness of the prerinse spray valve to remove soil from the plate before it

is placed in a dishwashing machine.a handheld device containing a release to close mechanism that is used to spray water on

dishes, flatware, etc.

3.1.2 spray force—the amount of force exerted onto the spray disc.

3.1.3 test method—a definitive procedure for the identification, measurement, and evaluation of one or more qualities,

characteristics, or properties of a material, product, system, or service that produces a test result.

3.1.4 uncertainty—measure of systematic and precision errors in specified instrumentation or measure of repeatability of a

reported test result.

3.2 Abbreviations:

3.2.1 gpm—gallons per minute.

4. Summary of Test Method

4.1 The flow rate of the prerinse spray valve is determined at the manufacturer’s specified water pressure measured at a water

pressure of 60 6 2 psi (413.7 6 13.8 kPa) and 60 6 10°F (15.6 6 2.6°C) to verify that the prerinse spray valve is operating at

1

This test method is under the jurisdiction of ASTM Committee F26 on Food Service Equipment and is the direct responsibility of Subcommittee F26.06 on Productivity

and Energy Protocol.

Current edition approved May 1, 2009June 1, 2013. Published August 2009July 2013. Originally approved in 2003. Last previous edition approved in 20032009 as

F2324 – 03.F2324 – 03 (2009). DOI: 10.1520/F2324-03R09.10.1520/F2324-13.

2

Available from NSF International, P.O. Box 130140, 789 N. Dixboro Rd., Ann Arbor, MI 48113-0140.

3

Inter-American® mdl #132 is within the specified weight range and is inexpensive.Available from American Society of Mechanical Engineers (ASME), ASME

International Headquarters, Three Park Ave., New York, NY 10016-5990, http://www.asme.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2324 − 13

the manufacturer’s rated flow rate. If the measured flow rate is not within 5 % of the rated flow rate, all further testing ceases and

the manufacturer is contacted. The manufacturer may make appropriate changes or adjustments to the prerinse spray valve.

4.2 The spray valve’s water flow rate is measured at 60 6 1 psi (2.9 6 0.5 kPa) settings at a temperature of 120 6 4°F (49

6 2°C).

4.2 The spray valve’s cleanability (effectiveness) is determined at 60 6 1 psi (2.9 6 0.5 kPa), with a water temperature of 120

6 4°F (49 6 2°C).amount of force exerted by the prerinse spray valve is determined by the spray force test.

5. Significance and Use

5.1 The flow rate test is used to confirm that the prerinse spray valve is operating at the manufacturer’s rated flow rate at the

specified water pressure. This Th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.