ASTM F2324-03(2009)

(Test Method)Standard Test Method for Prerinse Spray Valves

Standard Test Method for Prerinse Spray Valves

SIGNIFICANCE AND USE

The flow rate test is used to confirm that the spray valve is operating at the manufacturer's rated flow rate at the specified water pressure. This test would also assist the operator in controlling the water and sewer consumption and reduce the water heating bills.

The cleanability test is used to verify the spray valve's effectiveness at cleaning the plates before they are sent into the dishwashing machine.

SCOPE

1.1 This test method covers the water consumption flow rate and cleanability of prerinse spray valves (here after referred to as spray valves). The food service operator can use this evaluation to select a spray valve and understand its water consumption and cleaning effectiveness.

1.2 The following procedures are included in this test method:

1.2.1 Water consumption (see 10.2).

1.2.2 Cleanability (see 10.3).

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This test method may involve hazardous materials, operations, and equipment. It does not address all of the potential safety problems associated with its use. It is the responsibility of the users of this test method to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to its use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2324 − 03(Reapproved 2009) An American National Standard

Standard Test Method for

Prerinse Spray Valves

This standard is issued under the fixed designation F2324; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope qualities, characteristics, or properties of a material, product,

system, or service that produces a test result.

1.1 Thistestmethodcoversthewaterconsumptionflowrate

3.1.3 uncertainty—measure of systematic and precision er-

and cleanability of prerinse spray valves (here after referred to

rors in specified instrumentation or measure of repeatability of

as spray valves). The food service operator can use this

a reported test result.

evaluation to select a spray valve and understand its water

consumption and cleaning effectiveness.

3.2 Abbreviations:

3.2.1 gpm—gallons per minute.

1.2 The following procedures are included in this test

method:

4. Summary of Test Method

1.2.1 Water consumption (see 10.2).

1.2.2 Cleanability (see 10.3).

4.1 The flow rate of the spray valve is determined at the

manufacturer’sspecifiedwaterpressuretoverifythatthespray

1.3 The values stated in inch-pound units are to be regarded

valve is operating at the manufacturer’s rated flow rate. If the

as standard. The values given in parentheses are mathematical

measured rate is not within 5% of the rated flow rate, all

conversions to SI units that are provided for information only

further testing ceases and the manufacturer is contacted. The

and are not considered standard.

manufacturer may make appropriate changes or adjustments to

1.4 This test method may involve hazardous materials,

the spray valve.

operations, and equipment. It does not address all of the

4.2 Thesprayvalve’swaterflowrateismeasuredat60 61

potential safety problems associated with its use. It is the

psi (2.9 6 0.5 kPa) settings at a temperature of 120 6 4°F (49

responsibility of the users of this test method to establish

6 2°C).

appropriate safety and health practices and determine the

applicability of regulatory limitations prior to its use.

4.3 The spray valve’s cleanability (effectiveness) is deter-

mined at 60 6 1 psi (2.9 6 0.5 kPa), with a water temperature

2. Referenced Documents

of 120 6 4°F (49 6 2°C).

2.1 NSF Documents:

5. Significance and Use

NSF ListingsFood Equipment and Related Products, Com-

5.1 Theflowratetestisusedtoconfirmthatthesprayvalve

ponents and Materials, NSF International

is operating at the manufacturer’s rated flow rate at the

specified water pressure. This test would also assist the

3. Terminology

operator in controlling the water and sewer consumption and

3.1 Definitions:

reduce the water heating bills.

3.1.1 cleanability—the effectiveness of the prerinse spray

5.2 The cleanability test is used to verify the spray valve’s

valve to remove soil from the plate before it is placed in a

effectivenessatcleaningtheplatesbeforetheyaresentintothe

dishwashing machine.

dishwashing machine.

3.1.2 test method—a definitive procedure for the

identification, measurement, and evaluation of one or more

6. Apparatus

6.1 Analytical Balance Scale, or equivalent, for measuring

the weight of the plates and water container. It shall have a

This test method is under the jurisdiction of ASTM Committee F26 on Food

resolution of 0.01 lb (5 g) and an uncertainty of 0.01 lb (5 g).

Service Equipment and is the direct responsibility of Subcommittee F26.06 on

6.2 Calibrated Exposed Junction Thermocouple Probes,

Productivity and Energy Protocol.

Current edition approved May 1, 2009. Published August 2009. Originally

with a range from 50 to 200°F (10 to 93°C), with a resolution

approved in 2003. Last previous edition approved in 2003 as F2324–03. DOI:

of 0.2°F (0.1°C) and an uncertainty of 1.0°F (0.5°C), for

10.1520/F2324-03R09.

measuring water line temperatures. Calibrated K-type 24-GA

Available from NSF International, P.O. Box 130140, 789 N. Dixboro Rd.,Ann

Arbor, MI 48113-0140. thermocouple wire with stainless steel sheath and ceramic

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2324 − 03 (2009)

insulation is the recommended choice for measuring the water and after it is removed and determine the percent moisture

line temperatures. The thermocouple probe can be fed through content based on the percent weight loss of the sample. The

acompressionfittingsoastosubmerseexposedjunctioninthe samplemustbespreadevenlyoverthesurfaceofthesheetpan

water lines. in order for all of the moisture to evaporate during drying and

itispermissibletospreadthesampleontopofbakingpaperin

6.3 Carboy, or equivalent container, for measuring for

order to protect the sheet pan and simplify cleanup.

weight of the water during the flow rate test. A 5-gal (19-L)

carboy water bottle has been found to be suitable (the carboy 7.3 Tomato Sauce, shall be comprised of tomato paste and

is the standard water bottle that is used for water coolers). water. Mix 6 oz (175 mL) tomato paste (see 7.1) with 10 oz

(295 mL) of 75 6 5°F (24 6 3°C) water to form the tomato

NOTE 1—The 5-gal (19-L) carboy container is the preferred container.

sauce. Stir until mixture becomes consistent.

Withanarrowopening,thecarboycapturesallthewaterduringthetestat

higher water pressure which can result in excess splashing.

NOTE2—TestingattheFoodServiceTechnologyCenterhasfoundthat

a generic store brand such as “Safeway®” brand or “Albertson’s®” brand

6.4 Hot Water Temperature Control Valve, to maintain and

tomato paste is the preferred test product. National brands tend to have

limit mixed hot water to the spray valve during testing. It shall

excess tomato skins in the tomato paste, which makes repeatability

haveadoublethrottlingdesigntocontrolboththehotandcold

difficult.ShowninFig.2arethetwotypesoftomatopaste.The“generic”

watersupplytothemixedoutlet.Theflowcharacteristicsofthe

store brand is on the left, and the “national” brand on the right. The dark

valve shall have a resolution temperature control of 64°F

spotsinthephotoontheright(nationalsbrand)arethetomatoskinflecks,

which are more difficult to remove.

(62°C)combinedwithlowpressuredropcheckvalvesinboth

the hot and cold water inlets to protect against cross flow.

7.4 Plates, shall be 9-in. (229-mm), white ceramic glazed,

with an inside flat diameter of 7-in. (178-mm), weighing an

6.5 Measuring Spoons, used to portion out one level table-

average of 1.3 6 0.05 lb (590 6 23 g) each. Sixty plates are

spoon of tomato sauce on each plate for the cleanability test.

required.

6.6 Pressure Gage, for measuring pressure of water to the

7.5 Dishracks,toholdtheplateswiththedriedtomatosauce

spray valve. The gage shall have a resolution of 0.5 psig (3.4

for the cleanability test and in the preparation of the plates to

kPa)andamaximumuncertaintyof1%ofthemeasuredvalue.

dry the tomato sauce so that the plates can be dried vertically,

6.7 Spring-Style Pre-Rinse Unit, Deck-Mounted, with a

or acceptable equivalent. Four Metro Mdl P2MO, 20 by 20-in.

36-in. (915-mm) flex hose which will have the testing sample

(508 by 508-mm), peg-type, commercial dishracks, each

spray valve attach at the end of the flex hose. See Fig. 1.

weighing 4.6 6 0.1 lb (2.09 6 0.04 kg).

6.8 Stopwatch, with a 0.1-s resolution.

8. Sampling

6.9 Temperature Sensor,formeasuringwatertemperaturein

8.1 Prerinse Spray Valve—A representative production

the range from 50 to 200°F (10 to 93°C), with a resolution of

model shall be selected for performance testing.

0.5°F (0.3°C) and an uncertainty of 61°F (0.5°C).

7. Reagents and Materials 9. Preparation of Apparatus

9.1 Attach the spray valve to a 36-in., spring-style (flex

7.1 Tomato Paste, shall be 100% pure and shall have a

moisture content of 70 6 2.5%. Stabilize paste at room tubing) prerinse unit in accordance with the manufacturer’s

instructions.Theminimumflowrateoftheflextubing,withno

temperature (75 6 5°F (24 6 3°C)).

sprayvalveconnected,shallbe7gpm(26L/min)atapressure

7.2 Gravimetric moisture analysis shall be performed as

of 60 6 2 psi (2.9 6 0.5 kPa).

follows:To determine moisture content, place a 1-lb sample of

thetestfoodonadry,aluminumsheetpanandplacethepanin NOTE 3—Specifying a minimum flow rate for the flex tubing ensures

that the prerinse spray nozzle is performing to the manufacturer’s

a convection drying oven at a temperature of 220 6 5°F for a

specifications and prevents the flex tubing from dictating the flow rate of

periodof24h.Weighthesamplebeforeitisplacedintheoven

the prerinse valve.

9.2 Insulate the entire length of the water pipe from the

mixing valve to the inlet of the flex tubing with one-half inch

foam insulation. The insulation material shall have a thermal

resistance (R) value of not less than 4°F × ft × h/Btu (0.7°K ×

m /W).

9.3 Connectthemixingvalvetothemunicipalwatersupply

and set the mixing valve to maintain an outlet water tempera-

ture of 120 6 4°F (49 6 2°C). The mixing valve shall be

located within six feet of the inlet of the flex tubing.

9.4 Install a water line pressure regulator down stream of

the mixing valve. Install a pressure gage at the base of the flex

Inter-American® mdl #132 is within the specified weight range and is

FIG. 1 Illustration of Spring-Style, Deck-Mounted Prerinse Unit inexpensive.

F2324 − 03 (2009)

FIG. 2 Generic Brand on the Left and the National Brand on the Right

tubing. Adjust the pressure regulator so that the water line 10. Procedure

pressure to the prerinse valve can be maintained at 60 6 2 psi

10.1 General:

(2.9 6 0.5 kPa) when the water is flowing to the spray valve,

10.1.1 The following shall be obtained and recorded for

as the lever is fully pressed.

each run of every test:

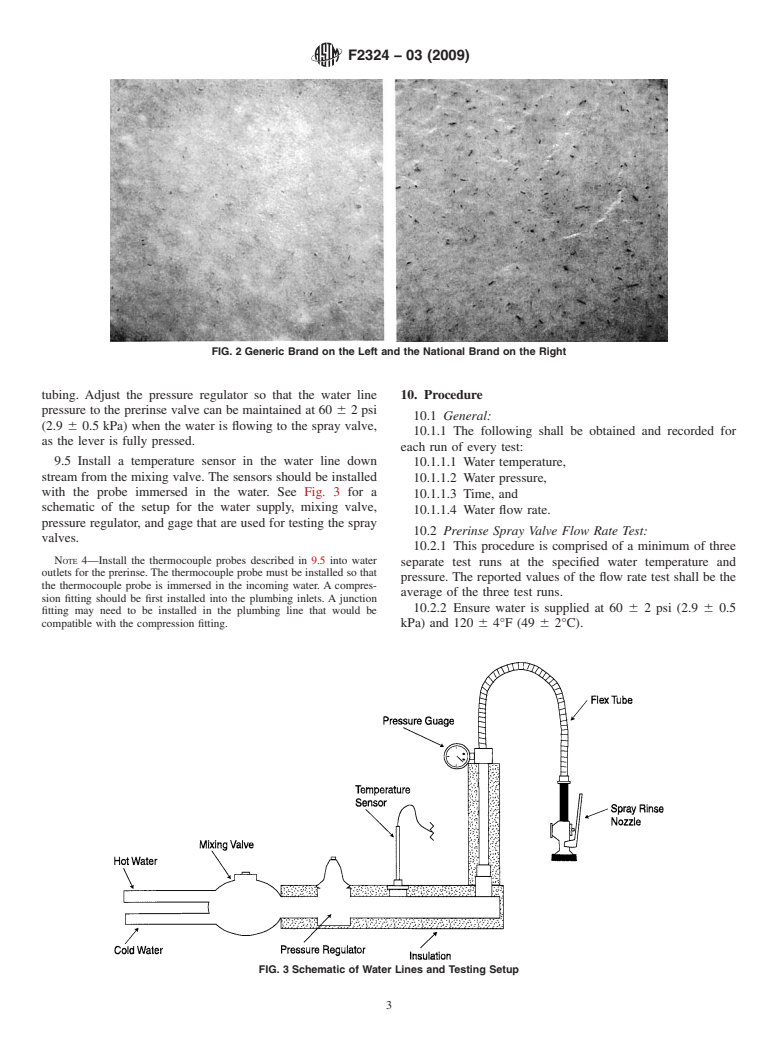

9.5 Install a temperature sensor in the water line down

10.1.1.1 Water temperature,

stream from the mixing valve. The sensors should be installed

10.1.1.2 Water pressure,

with the probe immersed in the water. See Fig. 3 for a

10.1.1.3 Time, and

schematic of the setup for the water supply, mixing valve,

10.1.1.4 Water flow rate.

pressure regulator, and gage that are used for testing the spray

10.2 Prerinse Spray Valve Flow Rate Test:

valves.

10.2.1 This procedure is comprised of a minimum of three

NOTE 4—Install the thermocouple probes described in 9.5 into water

separate test runs at the specified water temperature and

outlets for the prerinse. The thermocouple probe must be installed so that

pressure. The reported values of the flow rate test shall be the

the thermocouple probe is immersed in the incoming water. A compres-

average of the three test runs.

sion fitting should be first installed into the plumbing inlets. A junction

10.2.2 Ensure water is supplied at 60 6 2 psi (2.9 6 0.5

fitting may need to be installed in the plumbing line that would be

compatible with the compression fitting. kPa) and 120 6 4°F (49 6 2°C).

FIG. 3 Schematic of Water Lines and Testing Setup

F2324 − 03 (2009)

10.2.3 Weigh and record the weight of the carboy prior to

testing (or equivalent 5-gal (19-L) container).

10.2.4 Hold the spray valve over the opening of the carboy

container. Squeeze the spray valve handle to allow maximum

flow and begin recording the time elapsed. At the end of one

minute, record the weight of the water and container and

subtract the weight of the container.

10.2.5 Repeat 10.2.2-10.2.4 for the remaining test runs.

10.3 Preparation of the Plates for the Cleanability Test:

10.3.1 Prepare 60 plates with one leveled tablespoon of

tomato sauce on each plate.

10.3.2 The plates are to be dry and stabilized at a room

temperature of 75 6 5°F (24 6 3°C) before the tomato sauce

is portioned onto the plate.

10.3.3 Apply one level tablespoon (15 mL) of tomato sauce

FIG. 5 A Rack of Plates Drying

as described in 7.3 to a plate, and evenly distribute the tomato

saucearoundtheplatebyshakingandturningtheplate.Portion

out the tomato sauce one plate at a time. Make sure that the

10.4.3 Place an empty dishrack under the prerinse valve in

tomato sauce is not distributed onto the rim/lip of the plate. In

the sink.

addition, do not use a spoon or other utensil to spread the

10.4.4 Place a single plate with dried tomato sauce upright

tomatosauce,asthiswillleaveridgesinthesauceontheplate,

in the dishrack. The plate is to be placed in the dishrack at a

alteringtesttimes.Usingautensilwillalsopickupsomeofthe

distance from the tip of the spray valves to the top of the plate

sauce and make the amount of sauce on each plate different.

of 11 6 1 in. (279 6 25 mm) and 14 6 1 in. (356 6 25 mm)

See Fig. 4 for an illustration of the preparation of the plates.

from the bottom of the plate. Mark the location of the plate in

10.3.4 Place the plates with the tomato sauce in a dish rack

the dishrack, as this will be where all the testing plates will be

to let the tomato sauce dry on the plates at room temperature

placed. Fig. 6 shows a drawing plate in the dishrack with the

(75 6 5°F (24 6 3°C)). See Fig. 5.

cleaning distances.

NOTE 5—This can be accomplished by storing the dish loads in a room

10.4.5 Begin spraying the plate as time is recorded on the

with an ambient temperature of 75 6 5°F (24 6 3°C). Avoid any

stopwatch. The plate is to be sprayed in a side to side motion

circumstancesthatwouldresultinsomedishesbeingatdifferenttempera-

from the top to the bottom of the plate. Repeat this spray

tures from others, such as being stored in the air path of an HVAC supply

register.

pattern until all the tomato sauce has been rinsed from the

plate. Record the amount of time required to clear the plate.

10.3.5 Repeat 10.3.2-10.3.4 until all 20 plates are prepared.

Fig. 7 demonstrates a cleanability test.

Allow plates to dry for 24 h before testing.

10.4.6 Repeat 10.4.5 for the 59 remaining test plates.

10.4 Cleanability Performance Test:

10.4.1 This procedure shall be performed at the specified

11. Calculation and Report

water temperature and pressure. The reported values of the

11.1 Test Prerinse Spray Valve—Summarize the physical

cleanability procedure shall be the average of the sixty plates

and operating characteristic of the prerinse spray valve.

measured in seconds per plate (s/plate).

11.2 Apparatus and Procedure—Confirm that the testing

NOTE6—Thetestcanbedividedinto3groupsof20-plateracksifsixty

apparatus conformed to all of the specifications in Section 9.

plates are not available.

Describe any deviations from those specifications.

10.4.2 Ensure that the water supply is at 60 6 2 psi (2.9 6

0.5 kPa) and 120 6 4°F (49 6 2°C) with the nozzl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.