ASTM F2819-10(2015)e2

(Test Method)Standard Test Methods for Measurement of Straightness of Bar, Rod, Tubing and Wire to be used for Medical Devices

Standard Test Methods for Measurement of Straightness of Bar, Rod, Tubing and Wire to be used for Medical Devices

SIGNIFICANCE AND USE

5.1 Significance—With the birth of minimally invasive surgery in the 1960s, there has been a requirement for guide wires. The guide wires serve as the access line by which procedures like balloon angioplasty and stent placement are conducted. A guide wire typically consists of a mandrel, coil and in some cases a safety wire is used. The market for guide wires continues to grow as the number of procedures increases. For successful manufacturing of guide wires, linearity or straightness of 304 stainless steel and nitinol wire that is used for the manufacture of guide wire mandrels is critical to their end use performance. Users of guide wires require that they must navigate a tortuous anatomy.

5.1.1 A second part of minimally invasive surgery is the use of machined or formed wire, tube, or rod. In this case, straightness of rod, tube, and wire that is going to be machined or subjected to a forming practice such as bending needs to be very linear or straight so it is accurately fed into the equipment that is used for the machining or forming practice. Laser machining is an example of a machining operation that requires a wobble-free piece of rod, tubing, or wire so that it can be properly fed into the alignment bushings of the laser. Wire forming equipment also requires wobble-free material for the same reason.

5.2 Use—These test methods can be used by users and producers of medical grade bar, rod, tubing, and wire to specify requirements to evaluate and confirm the straightness of material. Depending upon the type of material and its metallurgical condition, it may be possible to reprocess the material to reduce its non-linearity.

SCOPE

1.1 This standard covers the various test methods to be used for measurement of straightness of bar, rod, tubing, and wire. These test methods apply primarily to bar, rod, tubing, and wire that are ordered in the straightened and cut-to-length condition. They also apply to small diameter tubing and wire that has been specially processed to roll off a spool in the straightened condition.

1.2 These test methods apply to straightness of round wire that has a diameter between 0.05 and 4.78 mm (0.002 and 0.188 in.). They also apply to flatness (camber) of flat-shaped wire or ribbon with a maximum dimension between 0.05 and 4.78 mm (0.002 and 0.188 in.). For flatness (camber) measurement, refer to Test Method F2754/F2754M.

Note 1: The current version of Test Method F2754/F2754M covers a different diameter range (0.0127 to 4.78 mm (0.0005 to 0.188 in.)) and does not include superelastic NiTi. These exceptions would not affect the camber measurement as conducted by Test Method F2754/F2754M.

1.3 These test methods apply to straightness of round tubing that has an outer diameter between 0.05 and 6.35 mm (0.002 and 0.25 in.).

1.4 These test methods apply to straightness of round rod that has a diameter between 4.78 and 6.35 mm (0.188 and 0.25 in). It also applies to flatness (camber) of flat and shaped rod with a maximum dimension between 4.78 and 6.35 mm (0.188 and 0.25 in). For measurement of flatness (camber), refer to Test Method F2754/F2754M.

Note 2: The current version of Test Method F2754/F2754M covers a different diameter range (0.0127 to 4.78 mm (0.0005 to 0.188 in.)) and does not include superelastic NiTi. These exceptions would not affect the camber measurement as conducted by Test Method F2754/F2754M.

1.5 These test methods apply to straightness of round bar that has a diameter between 6.35 and 101.6 mm (0.25 and 4 in). It also applies to flatness (camber) of flat and shaped bar with a maximum dimension between 6.35 and 101.6 mm (0.25 and 4 in). For measurement of flatness (camber), refer to Test Method F2754/F2754M.

Note 3: The current version of Test Method F2754/F2754M covers a different diameter range (0.0127 to 4.78 mm (0.0005 to 0.188 in.)) and does not include superelastic NiTi. These exceptions would not affect the camber measu...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´2

Designation: F2819 −10 (Reapproved 2015)

Standard Test Methods for

Measurement of Straightness of Bar, Rod, Tubing and Wire

to be used for Medical Devices

This standard is issued under the fixed designation F2819; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Editorial corrections were made in June 2016.

ε NOTE—Subsection 11.1.3 was corrected editorially in September 2017.

1. Scope It also applies to flatness (camber) of flat and shaped bar with

a maximum dimension between 6.35 and 101.6 mm (0.25 and

1.1 This standard covers the various test methods to be used

4 in). For measurement of flatness (camber), refer to Test

for measurement of straightness of bar, rod, tubing, and wire.

Method F2754/F2754M.

Thesetestmethodsapplyprimarilytobar,rod,tubing,andwire

that are ordered in the straightened and cut-to-length condition.

NOTE 3—The current version of Test Method F2754/F2754M covers a

different diameter range (0.0127 to 4.78 mm (0.0005 to 0.188 in.)) and

They also apply to small diameter tubing and wire that has

does not include superelastic NiTi. These exceptions would not affect the

been specially processed to roll off a spool in the straightened

camber measurement as conducted by Test Method F2754/F2754M.

condition.

1.6 These test methods apply to ferrous and non-ferrous

1.2 These test methods apply to straightness of round wire

alloys including linear-elastic or superelastic nitinol. Refer to

that has a diameter between 0.05 and 4.78 mm (0.002 and

Terminology F2005 for more details on NiTi terminology.

0.188 in.). They also apply to flatness (camber) of flat-shaped

1.7 The values stated in either SI units or inch-pound units

wire or ribbon with a maximum dimension between 0.05 and

are to be regarded separately as standard. The values stated in

4.78 mm (0.002 and 0.188 in.). For flatness (camber)

each system may not be exact equivalents; therefore, each

measurement, refer to Test Method F2754/F2754M.

system shall be used independently of the other. Combining

NOTE 1—The current version of Test Method F2754/F2754M covers a

different diameter range (0.0127 to 4.78 mm (0.0005 to 0.188 in.)) and

values from the two systems may result in non-conformance

does not include superelastic NiTi. These exceptions would not affect the

with the standard.

camber measurement as conducted by Test Method F2754/F2754M.

1.8 This standard does not purport to address all of the

1.3 These test methods apply to straightness of round tubing

safety concerns, if any, associated with its use. It is the

that has an outer diameter between 0.05 and 6.35 mm (0.002

responsibility of the user of this standard to establish appro-

and 0.25 in.).

priate safety, health, and environmental practices and deter-

1.4 These test methods apply to straightness of round rod

mine the applicability of regulatory limitations prior to use.

that has a diameter between 4.78 and 6.35 mm (0.188 and 0.25

1.9 This international standard was developed in accor-

in). It also applies to flatness (camber) of flat and shaped rod

dance with internationally recognized principles on standard-

with a maximum dimension between 4.78 and 6.35 mm (0.188

ization established in the Decision on Principles for the

and 0.25 in). For measurement of flatness (camber), refer to

Development of International Standards, Guides and Recom-

Test Method F2754/F2754M.

mendations issued by the World Trade Organization Technical

NOTE 2—The current version of Test Method F2754/F2754M covers a

Barriers to Trade (TBT) Committee.

different diameter range (0.0127 to 4.78 mm (0.0005 to 0.188 in.)) and

does not include superelastic NiTi. These exceptions would not affect the

2. Referenced Documents

camber measurement as conducted by Test Method F2754/F2754M.

2.1 ASTM Standards:

1.5 These test methods apply to straightness of round bar

F2005 Terminology for Nickel-Titanium Shape Memory

thathasadiameterbetween6.35and101.6mm(0.25and4in).

Alloys

F2754/F2754M Test Method for Measurement of Camber,

These test methods are under the jurisdiction of ASTM Committee F04 on

Medical and Surgical Materials and Devices and is the direct responsibility of

Subcommittee F04.15 on Material Test Methods. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

CurrenteditionapprovedMay1,2015.PublishedJuly2015.Originallyapproved contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in 2010. Last previous edition approved in 2010 as F2819 – 10. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

F2819-10R15E02. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´2

F2819 − 10 (2015)

Cast, Helix and Direction of Helix of Coiled Wire card is used to rotate the center of the sample back and forth on

2.2 Other Standards: the flat surface. The opposite ends of the sample should rotate

smoothly without wobble as is defined in 3.2.2 of these test

GGG-P-463 U.S. Federal Specification: Plate, Surface

(Granite) methods.

4.4 Gap Test (quantitative test method)—A common quan-

3. Terminology

titative method for measurement of straightness of wire with a

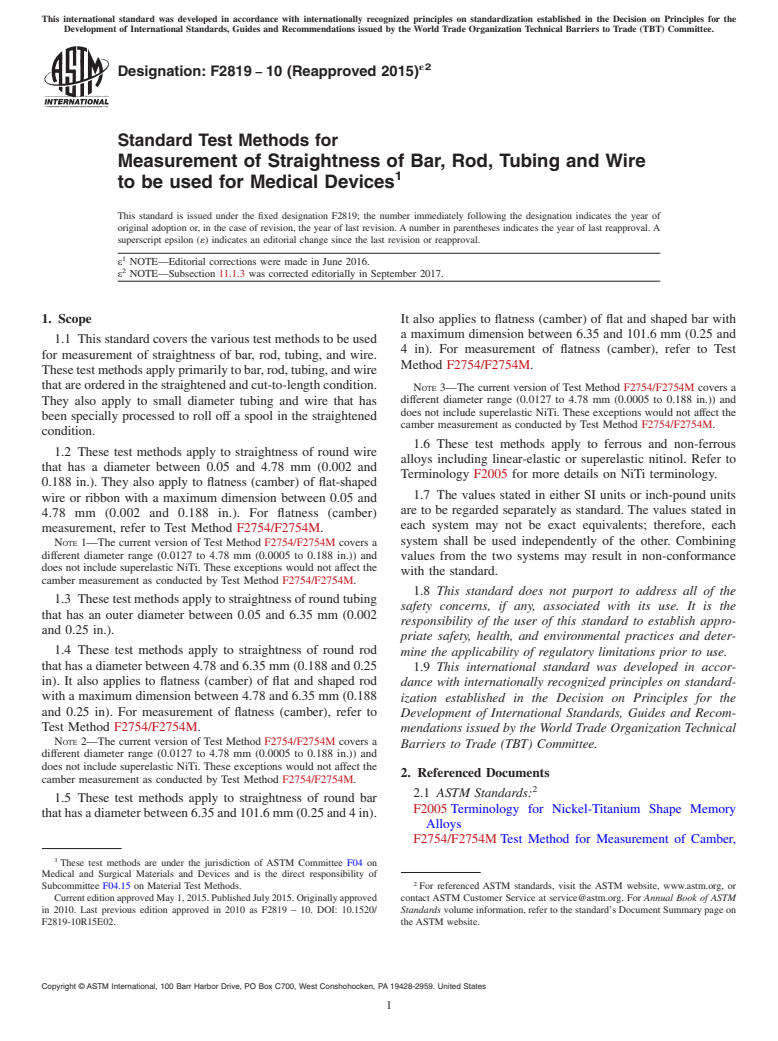

3.1 Fig. 1 and Fig. 2 show the physical meaning of

diameter less than 4.78 mm (0.188 in.) is the gap test. It can

straightness. Fig. 3 shows the definition of wobble in a straight

alsobeusedforrodwithadiameterbetween4.78and6.35mm

wire or tube as it is being rotated.

(0.188 and 0.25 in.), tubing with diameter 0.05 to 6.35 mm

(0.0002 to 0.25 in.) or bar with a diameter between 6.35 to

3.2 Definitions of Terms Specific to This Standard:

101.7 mm (0.25 to 4 in.), the gap test can be used to measure

3.2.1 straightness—Deviation of an axis or surface element

straightness. The gap test can also be used for flat or shaped

from linearity over a unit length in the unloaded (force and

wire and ribbon. In this method, a thickness gauge equal to the

momentfree)condition.Aperfectlystraightconditionisshown

gap must not fit between the rod, tubing, or bar and flat surface

in Fig. 1. A non-straight condition is shown in Fig. 2.

at any point along its length when rolled or rotated 360°. The

3.2.2 wobble—Elliptical rotation observed in a small diam-

gap defines the straightness of the rod, tubing, or bar.

eter wire or tube as it is being rotated around a central axis as

is shown in Fig. 3. 4.5 Total Indicator Readout (TIR) test (quantitative test

method)—In this method, a round rod with a diameter between

4. Summary of Test Method

4.78 and 6.35 mm (0.188 and 0.25 in.) or round bar with a

diameterbetween6.35to101.7mm(0.25to4in.),isplacedon

4.1 For bar, rod, tube, and wire, the deviation from the

two or more V-blocks. The test specimen is then rotated one

condition of resting flat on a smooth surface can be measured

revolution between two or more V-blocks that are a fixed

by using a quantitative or qualitative test method. Two quan-

distance (d) apart while measuring in the center with an

titative and two qualitative methods are the gap and TIR (Total

indicator. Total Indicator Readout (TIR) in the test specimen is

Indicator Readout) and inclined flat plate and finger roll tests,

then calculated.

respectively

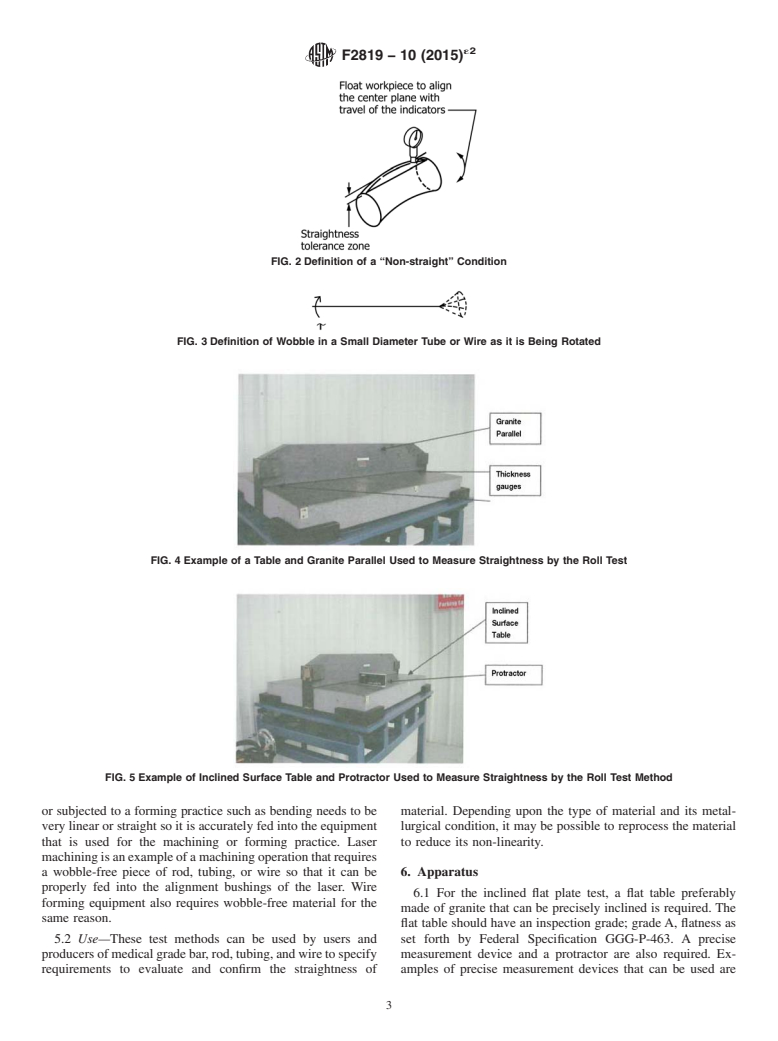

4.2 Inclined Flat Plate Test (qualitative test method that can

5. Significance and Use

be made quantitative)—Acommonmethodformeasurementof

5.1 Significance—With the birth of minimally invasive sur-

straightness of wire or tubing with a diameter less than 4.78

geryinthe1960s,therehasbeenarequirementforguidewires.

mm (0.188 in.) is the inclined flat plate test. In this method, a

The guide wires serve as the access line by which procedures

sectioned piece of material is allowed to roll down an inclined

like balloon angioplasty and stent placement are conducted. A

table as is illustrated by Fig. 4 and Fig. 5. The material passes

guide wire typically consists of a mandrel, coil and in some

the test if it rolls freely down the table without stopping as is

cases a safety wire is used. The market for guide wires

shown by Fig. 5.

continues to grow as the number of procedures increases. For

4.3 Finger-Roll Test (qualitative test method)—A second

successful manufacturing of guide wires, linearity or straight-

common method for measurement of straightness that is used

ness of 304 stainless steel and nitinol wire that is used for the

for wire and tubing with a diameter less than 0.25 mm (0.010

manufacture of guide wire mandrels is critical to their end use

in.) is the finger-roll test. In this test, a cut length of wire or

performance. Users of guide wires require that they must

tubing is laid on a flat surface. A finger, pencil, pen, or plastic

navigate a tortuous anatomy.

5.1.1 Asecond part of minimally invasive surgery is the use

of machined or formed wire, tube, or rod. In this case,

Available from IHS, 321 Inverness Drive South Englewood, CO 80112,

straightness of rod, tube, and wire that is going to be machined

http://www.global.ihs.com.

FIG. 1 Definition of a “Straight” Condition

´2

F2819 − 10 (2015)

FIG. 2 Definition of a “Non-straight” Condition

FIG. 3 Definition of Wobble in a Small Diameter Tube or Wire as it is Being Rotated

FIG. 4 Example of a Table and Granite Parallel Used to Measure Straightness by the Roll Test

FIG. 5 Example of Inclined Surface Table and Protractor Used to Measure Straightness by the Roll Test Method

or subjected to a forming practice such as bending needs to be material. Depending upon the type of material and its metal-

very linear or straight so it is accurately fed into the equipment lurgical condition, it may be possible to reprocess the material

that is used for the machining or forming practice. Laser to reduce its non-linearity.

machiningisanexampleofamachiningoperationthatrequires

a wobble-free piece of rod, tubing, or wire so that it can be 6. Apparatus

properly fed into the alignment bushings of the laser. Wire

6.1 For the inclined flat plate test, a flat table preferably

forming equipment also requires wobble-free material for the

made of granite that can be precisely inclined is required. The

same reason.

flat table should have an inspection grade; grade A, flatness as

5.2 Use—These test methods can be used by users and set forth by Federal Specification GGG-P-463. A precise

producersofmedicalgradebar,rod,tubing,andwiretospecify measurement device and a prot

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.