ASTM D5708-05

(Test Method)Standard Test Methods for Determination of Nickel, Vanadium, and Iron in Crude Oils and Residual Fuels by Inductively Coupled Plasma (ICP) Atomic Emission Spectrometry

Standard Test Methods for Determination of Nickel, Vanadium, and Iron in Crude Oils and Residual Fuels by Inductively Coupled Plasma (ICP) Atomic Emission Spectrometry

SIGNIFICANCE AND USE

These test methods cover, in single procedures, the determination of Ni, V, and Fe in crude oils and residual oils. These test methods complement Test Method D 1548, which covers only the determination of vanadium.

When fuels are combusted, vanadium present in the fuel can form corrosive compounds. The value of crude oils can be determined, in part, by the concentrations of nickel, vanadium, and iron. Nickel and vanadium, present at trace levels in petroleum fractions, can deactivate catalysts during processing. These test methods provide a means of determining the concentrations of nickel, vanadium, and iron.

SCOPE

1.1 These test methods cover the determination of nickel, vanadium, and iron in crude oils and residual fuels by inductively coupled plasma (ICP) atomic emission spectrometry. Two different test methods are presented.

1.2 Test Method A (Sections and )ICP is used to analyze a sample dissolved in an organic solvent. This test method uses oil-soluble metals for calibration and does not purport to quantitatively determine or detect insoluble particulates.

1.3 Test Method B (Sections )ICP is used to analyze a sample that is decomposed with acid.

1.4 The concentration ranges covered by these test methods are determined by the sensitivity of the instruments, the amount of sample taken for analysis, and the dilution volume. A specific statement is given in . Typically, the low concentration limits are a few tenths of a mg/kg. Precision data are provided for the concentration ranges specified in Section .

1.5 &si-value;

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5708–05

Standard Test Methods for

Determination of Nickel, Vanadium, and Iron in Crude Oils

and Residual Fuels by Inductively Coupled Plasma (ICP)

1

Atomic Emission Spectrometry

This standard is issued under the fixed designation D5708; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D1548 Test Method for Vanadium in Navy Special Fuel

3

Oil

1.1 These test methods cover the determination of nickel,

D4057 Practice for Manual Sampling of Petroleum and

vanadium, and iron in crude oils and residual fuels by

Petroleum Products

inductively coupled plasma (ICP) atomic emission spectrom-

D4177 Practice for Automatic Sampling of Petroleum and

etry. Two different test methods are presented.

Petroleum Products

1.2 Test Method A (Sections 7-11 and 18-22)—ICP is used

D5185 Test Method for Determination of Additive Ele-

to analyze a sample dissolved in an organic solvent. This test

ments, Wear Metals, and Contaminants in Used Lubricat-

method uses oil-soluble metals for calibration and does not

ing Oils and Determination of Selected Elements in Base

purport to quantitatively determine or detect insoluble particu-

Oils by Inductively Coupled Plasma Atomic Emission

lates.

Spectrometry (ICP-AES)

1.3 Test Method B (Sections 12-22)—ICPis used to analyze

D6299 Practice for Applying Statistical Quality Assurance

a sample that is decomposed with acid.

and Control Charting Techniques to Evaluate Analytical

1.4 The concentration ranges covered by these test methods

Measurement System Performance

are determined by the sensitivity of the instruments, the

amount of sample taken for analysis, and the dilution volume.

3. Summary of Test Method

A specific statement is given in 15.2. Typically, the low

3.1 Test Method A—Approximately 10 g of the sample are

concentration limits are a few tenths of a mg/kg. Precision data

dissolved in an organic solvent (Warning—Combustible. Va-

are provided for the concentration ranges specified in Section

por is harmful.) to give a specimen solution containing 10 %

21.

(m/m) of sample. The solution is nebulized into the plasma,

1.5 The values stated in SI units are to be regarded as

and the intensities of the emitted light at wavelengths charac-

standard. The values given in parentheses are for information

teristic of the analytes are measured sequentially or simultane-

only.

ously. The intensities are related to concentrations by the

1.6 This standard does not purport to address all of the

appropriate use of calibration data.

safety concerns, if any, associated with its use. It is the

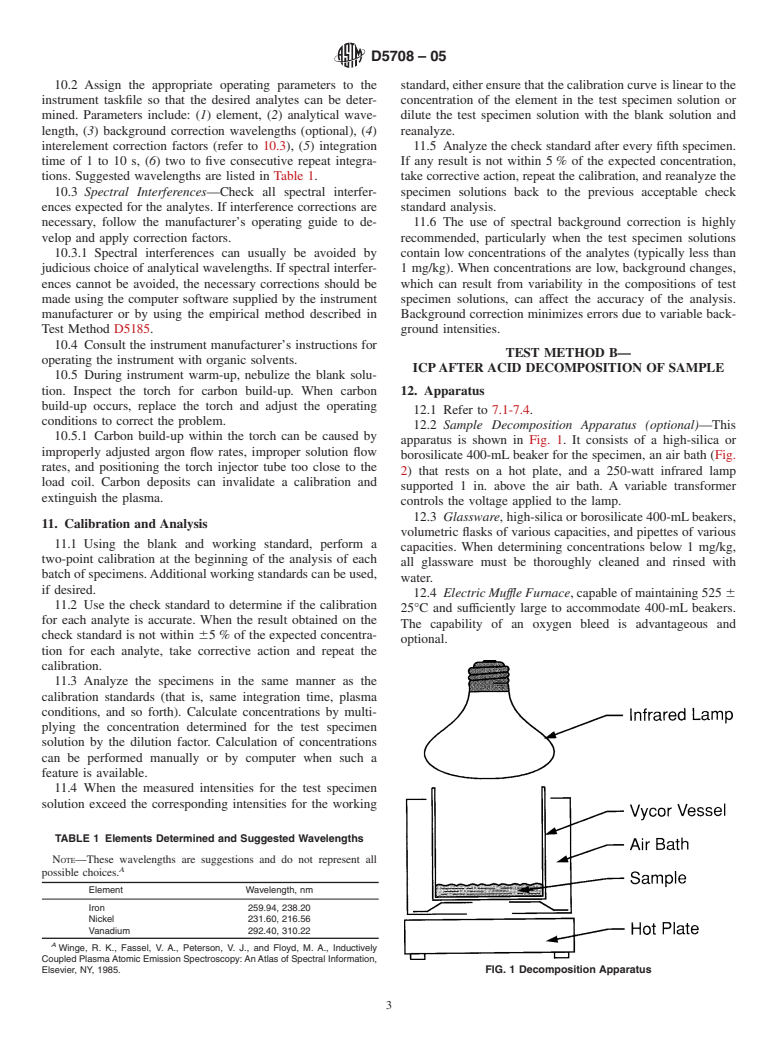

3.2 Test Method B—One to 20 g of sample are weighed into

responsibility of the user of this standard to establish appro-

a beaker and decomposed with concentrated sulfuric acid

priate safety and health practices and determine the applica-

(Warning—Poison. Causes severe burns. Harmful or fatal if

bility of regulatory limitations prior to use.

swallowed or inhaled.) by heating to dryness. Great care must

2. Referenced Documents be used in this decomposition because the acid fumes are

2

corrosive and the mixture is potentially flammable. The re-

2.1 ASTM Standards:

sidual carbon is burned off by heating at 525°C in a muffle

D1193 Specification for Reagent Water

furnace. The inorganic residue is digested with nitric acid

(Warning—Poison. Causes severe burns. Harmful or fatal if

1

These test methods are under the jurisdiction of ASTM Committee D02 on

swallowed or inhaled.), evaporated to incipient dryness, dis-

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

solved in dilute nitric acid, and made up to volume. The

D02.03 on Elemental Analysis.

solution is nebulized into the plasma of an atomic emission

Current edition approved Nov. 1, 2005. Published November 2005. Originally

approved in 1995. Last previous edition approved in 2002 as D5708–02. DOI:

spectrometer. The intensities of light emitted at characteristic

10.1520/D5708-05.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

3

the ASTM website. Withdrawn.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5708–05

wavelengths of the metals are measured sequentially or simul- 7.2 Nebulizer—The use of a high-solids nebulizer is op-

taneously.These in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.