ASTM D446-12

(Specification)Standard Specifications and Operating Instructions for Glass Capillary Kinematic Viscometers

Standard Specifications and Operating Instructions for Glass Capillary Kinematic Viscometers

SCOPE

1.1 These specifications cover operating instructions for glass capillary kinematic viscometers of all the types described in detail in Annex A1, Annex A2, and Annex A3 as follows:

Modified Ostwald viscometers, Annex A1

Suspended-level viscometers, Annex A2

Reverse-flow viscometers, Annex A3

1.2 The calibration of the viscometers is described in Section 6.

1.3 This standard covers some widely used viscometers suitable for use in accordance with Test Method D445. Other viscometers of the glass capillary type which are capable of measuring kinematic viscosity within the limits of precision given in Test Method D445 may be used.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D446 −12

Designation: 71/2/95

Standard Specifications and Operating Instructions for

1

Glass Capillary Kinematic Viscometers

This standard is issued under the fixed designation D446; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* ISO 3105 Glass Capillary Kinematic Viscometers—

Specifications and Operating Instructions

1.1 These specifications cover operating instructions for

ISO5725Basic Methods for the Determination of Repeat-

glasscapillarykinematicviscometersofallthetypesdescribed

ability and Reproducibility of a Standard Measurement

in detail in Annex A1, Annex A2, and Annex A3 as follows:

Method

Modified Ostwald viscometers, Annex A1

ISO17025General Requirements for the Competence of

Suspended-level viscometers, Annex A2

Reverse-flow viscometers, Annex A3 Testing and Calibration Laboratories

ISO Guide25General Requirements for the Calibration and

1.2 The calibration of the viscometers is described in

Testing Laboratories

Section 6.

4

2.3 NIST Standards:

1.3 This standard covers some widely used viscometers

NIST1297Guidelines for Evaluating and Expressing the

suitable for use in accordance with Test Method D445. Other

Uncertainty of NIST Measurement Results

viscometers of the glass capillary type which are capable of

measuring kinematic viscosity within the limits of precision

3. Materials and Manufacture

given in Test Method D445 may be used.

3.1 Fully annealed, low-expansion borosilicate glass shall

1.4 The values stated in SI units are to be regarded as

be used for the construction of all viscometers. The size

standard. No other units of measurement are included in this

number,serialnumber,andmanufacturer’sdesignationshallbe

standard.

permanently marked on each viscometer. All timing marks

shall be etched and filled with an opaque color, or otherwise

2. Referenced Documents

made a permanent part of the viscometer. See detailed descrip-

2

2.1 ASTM Standards:

tion of each type of viscometer in Annex A1, Annex A2, and

D445Test Method for Kinematic Viscosity of Transparent

Annex A3.

and Opaque Liquids (and Calculation of DynamicViscos-

3.2 With the exception of the FitzSimons and Atlantic

ity)

viscometers, all viscometers are designed to fit through a

D2162Practice for Basic Calibration of MasterViscometers

51-mm hole in the lid of a constant-temperature bath having a

and Viscosity Oil Standards

3 liquid depth of at least 280 mm; and it is assumed that the

2.2 ISO Documents:

surfaceoftheliquidwillbenotmorethan45mmfromthetop

ISO 3104Petroleum Products—Transparent and Opaque

of the bath lid. For certain constant-temperature baths, espe-

Liquids—Determination of Kinematic Viscosity and Cal-

cially at low or high temperatures, it may be necessary to

culation of Dynamic Viscosity

constructtheviscometerswiththeuppermosttubeslongerthan

shown to ensure adequate immersion in the constant-

1

These specifications and operating instructions are under the jurisdiction of

temperature bath. Viscometers so modified can be used to

ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and

measure kinematic viscosity within the precision of the test

are the direct responsibility of Subcommittee D02.07 on Flow Properties.

method.Thelengthsoftubesandbulbsonthefiguresshouldbe

Current edition approved Dec. 1, 2012. Published March 2013. Originally

held within 610% or 610 mm, whichever is less, such that

approvedin1966asD2515–66.RedesignatedD446in1977.Lastpreviousedition

approved in 2007 as D446–07. DOI: 10.1520/D0446-12.

the calibration constant of the viscometer does not vary by

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

more than 615% from the nominal value.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St., Available from National Institute of Standards and Technology (NIST), 100

4th Floor, New York, NY 10036. Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

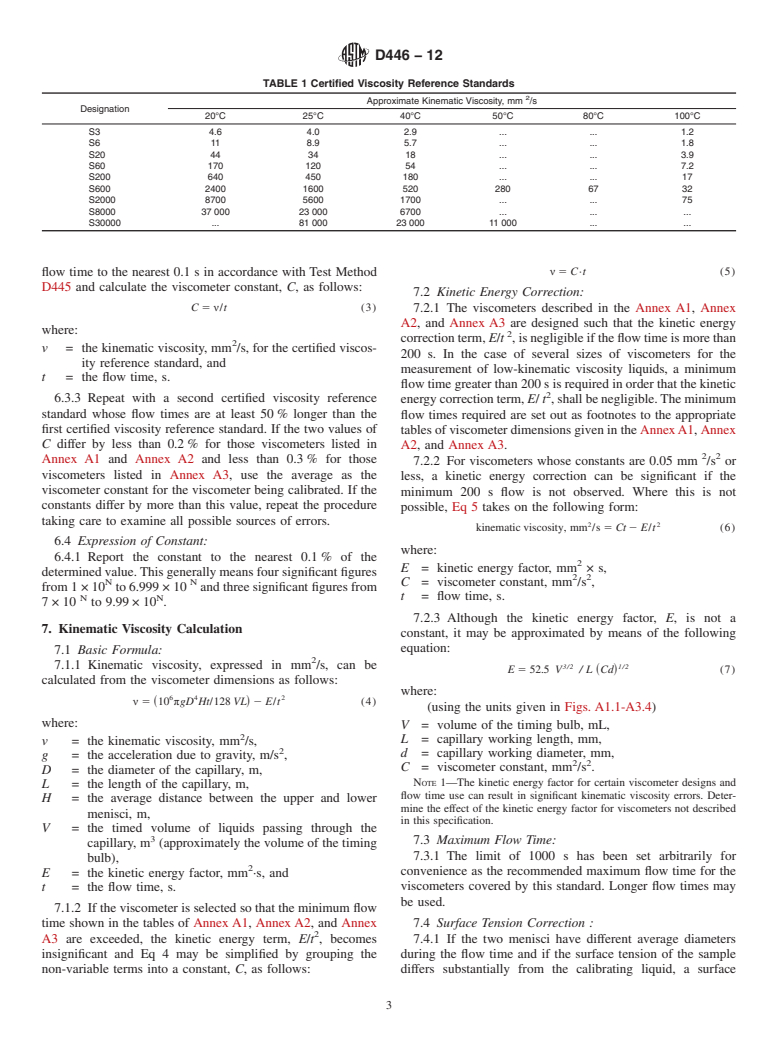

D446−12

4. Nomenclature for Figures eter which is to be calibrated in order that the kinetic energy

correction (see 7.1 and 7.2) may be less than 0.2%.

4.1 The

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D446 − 07 D446 − 12

Designation: 71/2/95

Standard Specifications and Operating Instructions for

1

Glass Capillary Kinematic Viscometers

This standard is issued under the fixed designation D446; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 These specifications cover operating instructions for glass capillary kinematic viscometers of all the types described in detail

in Annex A1, Annex A2, and Annex A3 as follows:

Modified Ostwald viscometers, Annex A1

Suspended-level viscometers, Annex A2

Reverse-flow viscometers, Annex A3

1.2 The calibration of the viscometers is described in Section 6.

1.3 This standard covers some widely used viscometers suitable for use in accordance with Test Method D445. Other

viscometers of the glass capillary type which are capable of measuring kinematic viscosity within the limits of precision given in

Test Method D445 may be used.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

2. Referenced Documents

2

2.1 ASTM Standards:

D445 Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (and Calculation of Dynamic Viscosity)

D2162 Practice for Basic Calibration of Master Viscometers and Viscosity Oil Standards

3

2.2 ISO Documents:

ISO 3104 Petroleum Products—Transparent and Opaque Liquids—Determination of Kinematic Viscosity and Calculation of

Dynamic Viscosity

ISO 3105 Glass Capillary Kinematic Viscometers—Specifications and Operating Instructions

ISO 5725 Basic Methods for the Determination of Repeatability and Reproducibility of a Standard Measurement Method

ISO 17025 General Requirements for the Competence of Testing and Calibration Laboratories

ISO Guide 25 General Requirements for the Calibration and Testing Laboratories

4

2.3 NIST Standards:

NIST 1297 Guidelines for Evaluating and Expressing the Uncertainty of NIST Measurement Results

3. Materials and Manufacture

3.1 Fully annealed, low-expansion borosilicate glass shall be used for the construction of all viscometers. The size number,

serial number, and manufacturer’s designation shall be permanently marked on each viscometer. All timing marks shall be etched

and filled with an opaque color, or otherwise made a permanent part of the viscometer. See detailed description of each type of

viscometer in Annex A1, Annex A2, and Annex A3.

1

These specifications and operating instructions are under the jurisdiction of ASTM Committee D02 on Petroleum Products and Lubricants and are the direct responsibility

of Subcommittee D02.07 on Flow Properties.

Current edition approved Jan. 1, 2007Dec. 1, 2012. Published January 2007 March 2013. Originally approved in 1966 as D2515 – 66. Redesignated D446 in 1977. Last

previous edition approved in 20062007 as D446 – 06.D446 – 07. DOI: 10.1520/D0446-07.10.1520/D0446-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036.

4

Available from National Institute of Standards and Technology (NIST), 100 Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

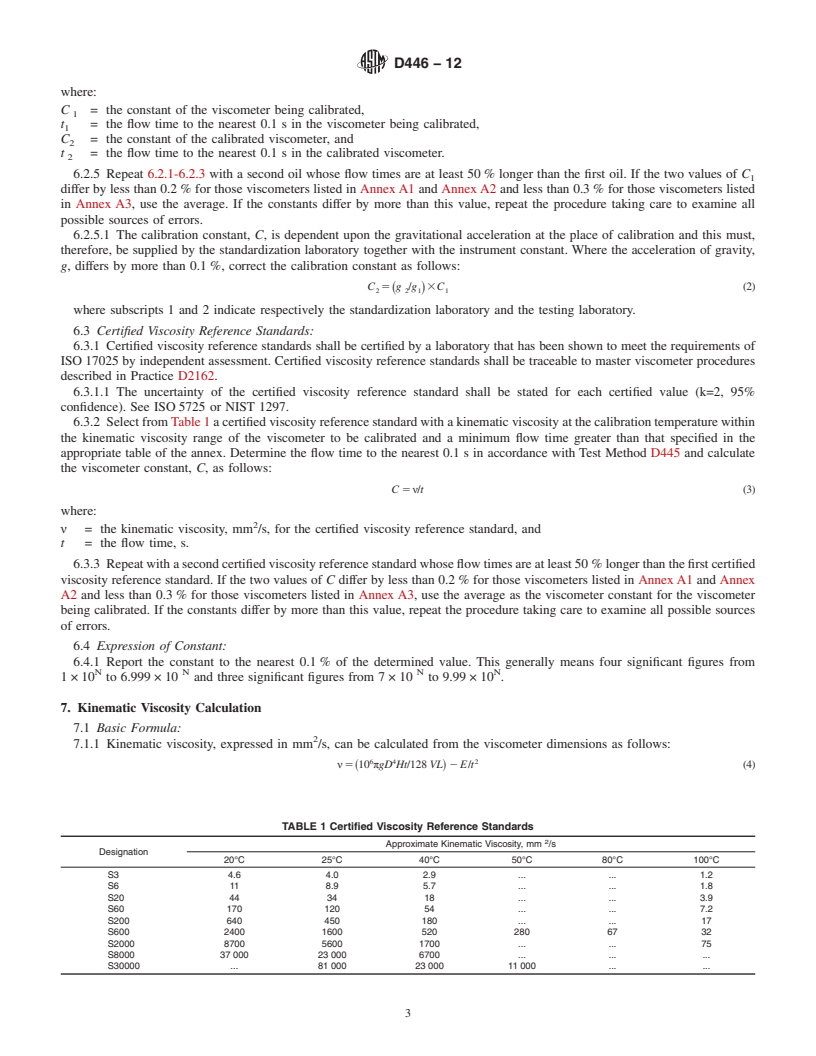

D446 − 12

3.2 With the exception of the FitzSimons and Atlantic viscometers, all viscometers are designed to fit through a 51-mm hole

in the lid of a constant-temperature bath having a liquid depth of at least 280 mm; and it is assumed that the surface of the liquid

will be not more than 45 mm from the top of the bath lid. For certain constant-temperature baths, especially at low or high

temperatures, it may be necessary to construct the viscometers with the uppermost tubes longer than shown to ensure adequate

immersion in the constant-temperature bath. Viscometers so modified can be used to measure kinematic viscosity within

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.