ASTM F2897-11

(Specification)Standard Specification for Tracking and Traceability Encoding System of Natural Gas Distribution Components (Pipe, Tubing, Fittings, Valves, and Appurtenances)

Standard Specification for Tracking and Traceability Encoding System of Natural Gas Distribution Components (Pipe, Tubing, Fittings, Valves, and Appurtenances)

ABSTRACT

This specification defines requirements for the data used in the tracking and traceability base-62 encoding system. It provides the format of the resultant code to characterize various components used in fuel gas piping systems. In this specification, the final output is a 16 digit alpha-numeric code that defines a standardized approach or methodology for encoding certain characteristics of components that have been established based on consensus recommendations from the respective stakeholder group members. The gas distribution component traceability identifier is also provided in this specification wherein the gas distribution component traceability identifier shall be comprised of sixteen alphanumeric characters that specify respective attributes for a given component. The gas distribution component traceability identifiers also include identifications of component manufacturer, identification of component manufacturer's lot code, the component production date, the component material, the component size, and the component type.

SCOPE

1.1 This specification defines requirements for the data used in the tracking and traceability base-62 encoding system and the format of the resultant code to characterize various components used in fuel gas piping systems.

1.2 The final output of this specification is a 16 digit alpha-numeric code that defines a standardized approach or methodology for encoding certain characteristics of components that have been established based on consensus recommendations from the respective stakeholder group members. The means of marking or affixing the code to the components, and the means of reading and/or transferring the data or codes are outside the scope of this specification.

Note 1—To facilitate compliance with this specification, a web based application has been developed to manage and maintain unique identifiers for certain characteristics including manufacturer identification numbers, material types, and component types as specified in this document. The web based application also provides a calculator to help users and manufacturers apply the base-62 encoding system outlined in this specification. The URL for the website is: http://www.componentid.org.

1.3 The web based application is only intended to serve as a useful resource for managing the respective manufacturer identification numbers, codes, and other identifiers as per this specification. Any changes to the contents of the web based application are contingent upon subsequent changes to this specification. This specification shall have primacy.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F2897 – 11

Standard Specification for

Tracking and Traceability Encoding System of Natural Gas

Distribution Components (Pipe, Tubing, Fittings, Valves, and

Appurtenances)

This standard is issued under the fixed designation F2897; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 ANSI Standards:

B31.8 Gas Transmission and Distribution Piping System

1.1 This specification defines requirements for the data used

B1.20.1 1983 Pipe Threads, General Purpose, Inch

in the tracking and traceability base-62 encoding system and

2.3 CFR Standards:

the format of the resultant code to characterize various com-

49 CFR Part 192 Pipeline Safety Requirements

ponents used in fuel gas piping systems.

1.2 The final output of this specification is a 16 digit

3. Terminology

alpha-numeric code that defines a standardized approach or

3.1 Definitions—Definitions are in accordance with Termi-

methodology for encoding certain characteristics of compo-

nology F412, and abbreviations are in accordance with Termi-

nents that have been established based on consensus recom-

nology D1600, unless otherwise specified.

mendations from the respective stakeholder group members.

3.2 The gas industry terminology used in this specification

The means of marking or affixing the code to the components,

is in accordance withANSI B31.8 or 49 CFR Part 192, unless

and the means of reading and/or transferring the data or codes

otherwise indicated.

are outside the scope of this specification.

3.3 character, n—an integer from zero (0) to nine (9) or a

NOTE 1—To facilitate compliance with this specification, a web based

letter that is upper case and/or lower case from a to z or A to

application has been developed to manage and maintain unique identifiers

Z.

for certain characteristics including manufacturer identification numbers,

3.4 component, n—pipe, tubing, fittings, valves, and appur-

material types, and component types as specified in this document. The

tenances unless specifically stated otherwise.

web based application also provides a calculator to help users and

3.5 digit, n—an integer from zero (0) to nine (9).

manufacturers apply the base-62 encoding system outlined in this speci-

fication. The URL for the website is: http://www.componentid.org.

3.6 FPT, n—internal taper thread as defined under ANSI/

ASME B1.20.1, or commonly referred to as “female pipe

1.3 The web based application is only intended to serve as

thread”.

a useful resource for managing the respective manufacturer

3.7 MPT, n—external taper thread as defined under ANSI/

identification numbers, codes, and other identifiers as per this

ASME B1.20.1, or commonly referred to as “male pipe

specification. Any changes to the contents of the web based

thread”.

application are contingent upon subsequent changes to this

3.8 traceability, n—identify the origin of materials and

specification. This specification shall have primacy.

parts used to manufacturer a given component; and/or the

2. Referenced Documents product processing or manufacturing history.

3.9 tracking, v—knowing, documenting, and/or collecting

2.1 ASTM Standards:

information related to the distribution and location of a given

D1600 Terminology for Abbreviated Terms Relating to

component after delivery from the manufacturer or supplier.

Plastics

D2513 Specification for Polyethylene (PE) Gas Pressure

4. Gas Distribution Component Traceability Identifier

Pipe, Tubing, and Fittings

4.1 General—The gas distribution component traceability

F412 Terminology Relating to Plastic Piping Systems

identifier shall be comprised of sixteen (16) alphanumeric

characters that specify respective attributes (data set) for a

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

given component.

Piping Systems and is the direct responsibility of Subcommittee F17.60 on Gas.

Current edition approved Feb. 1, 2011. Published February 2011. DOI: 10.1520/

F2897–11.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036, http://www.ansi.org.

Standards volume information, refer to the standard’s Document Summary page on Available from the Superintendent of Documents, U.S. Government Printing

the ASTM website. Office, Washington D.C. 20402.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2897 – 11

TABLE 2 Positional Values for Base-62 Encoding System

4.1.1 The specified number of characters and order for each

data set shall conform to Table 1. Positional Positional

Character Character

Value Value

4.1.2 The specified number of characters shall be developed

0036 A

using the base-62 encoding system per section 4.8 and the

1137 B

initial input data requirements per Section 5.

2238 C

4.1.3 The gas distribution component traceability identifier

3339 D

4440 E

shall be in a format suitable for downloading the character

5541 F

codes into database systems owned and maintained by the end

6642 G

user.

7743 H

8844 I

NOTE 2—An illustrative example is provided in Appendix X2.

9945 J

10 a 46 K

4.2 Identification of Component Manufacturer—Each com-

11 b 47 L

ponent manufacturer shall be identified by a unique two

12 c 48 M

13 d 49 N

character code which shall be assigned after completing the

14 e 50 O

required registration and activated by the webmaster of the

15 f 51 P

website http://www.componentid.org. The manufacturer iden-

16 g 52 Q

17 h 53 R

tification code shall be unique to that particular company and

18 i 54 S

can only be used by that respective manufacturer/supplier.

19 j 55 T

4.3 Identification of Component Manufacturer’s Lot Code—

20 k 56 U

21 l 57 V

The component manufacturer’s lot code shall be identified by

22 m 58 W

a four character code that is developed using the base-62

23 n 59 X

encoding system per 4.8. The four character code shall be

24 o 60 Y

25 p 61 Z

unique in a manner to help ascertain information related to the

26 q

origin of materials, product processing history, and other

27 r

information that is agreed upon between the manufacturer and 28 s

29 t

end user.

30 u

4.4 Identification of Component Production Date—Thepro-

31 v

duction date code shall be identified by a three character code 32 w

33 x

that is developed using the base-62 encoding system per 4.8.

34 y

4.5 Identification of Component Material—The primary

35 z

material used to manufacture the pipe or component shall be

identified by a single character code per 5.4.

4.6 Identification of Component Type—Each component

type shall be identified by a two character code per 5.5.

NOTE 3—Detailed examples of converting an initial integer string to a

4.7 Identification of Component Size—Eachcomponentsize corresponding base-62 alphanumeric character string and vice-versa can

be found in Appendix X1.

shall be identified by a three character code that is developed

NOTE 4—The positional value is the value corresponding to the

using the sizing calculation outlined in 5.6 and the base-62

respective character. For example, the positional value corresponding to

encoding system per 4.8.

thecharacter“r”is27.Thepositionalvaluecorrespondingtothecharacter

4.8 Base-62 Encoding System:

“T” is 55.

4.8.1 The base-62 positional encoding system shall utilize

integer values between zero and nine and both uppercase and 5. Input Data String

lowercasealphabetcharacterswiththeassignedplacevaluesas

5.1 Component Manufacturer—Each component manufac-

shown in Table 2.

turer shall establish a unique two (2) digit identifier by

4.8.2 The assigned place values shown in Table 2 shall be

completing the required registration and activated by the

usedtoconverttheinitialinputdataintothefinalalphanumeric

webmaster of the website http://www.componentid.org. The

code.

manufacturer identification code shall be unique to that par-

ticular company and can only be used by that respective

TABLE 1 Specified Number of Characters and Order for Gas manufacturer.

Distribution Component Traceability Identifier

5.2 Component Manufacturer’s Lot Code—Each compo-

A

Data Number of Character(s) nent manufacturer shall establish a unique seven (7) digit

number for their lot code which shall be used as the input into

Component manufacturer 2

Component manufacturer’s lot code 4

the base-62 encoding system per 4.8. The 7 digit number shall

Component production date 3

consist of only integer values and cannot contain any other

Component material 1

characters such as alphabetic or ASCII characters.

Component type 2

Component size 3

B

NOTE 5—The 7 digit code can be developed freely by the manufacturer

Reserved 1

to define individual production lots in a unique way. Elements of the 7

A

The total number of characters is based on the final resultant after applying the

digit code may possibly include production site, extrusion line, injection

base-62 encoding system in this specification. For different initial input data, the

moldingequipmentnumber,operator,shift,etc.The7digitcodeshouldbe

requirements and format are in Section 5 of this specification.

B

This field is reserved for future use as needed. capable of providing pertinent traceability information upon request.

F2897 – 11

For those other materials which have subsequently deleted but still

5.3 Component Production Date—Each component manu-

allowed to be used for repair purposes only, for example. PVC, then PE

facturer shall provide the production date of the respective

will take precedence.

componentconsistingoffive(5)digitsasinputintothebase-62

encoding system per 4.8.

5.5 Component Type—Each component manufacturer shall

5.3.1 The first three digits shall correspond to the particular

assign a two (2) character code for their respective component

day of the year.

type from Table 4.

5.3.2 The final two digits shall correspond to the last two

NOTE 9—Thecomponenttypecodeswillbemanagedbythewebmaster

digits of the year.

through the website http://www.componentid.org. Additional code num-

NOTE 6—For example, the date input represented by 23410 implies the

bers are reserved for future use and will be activated upon revision of this

234th day of 2010.

specification.

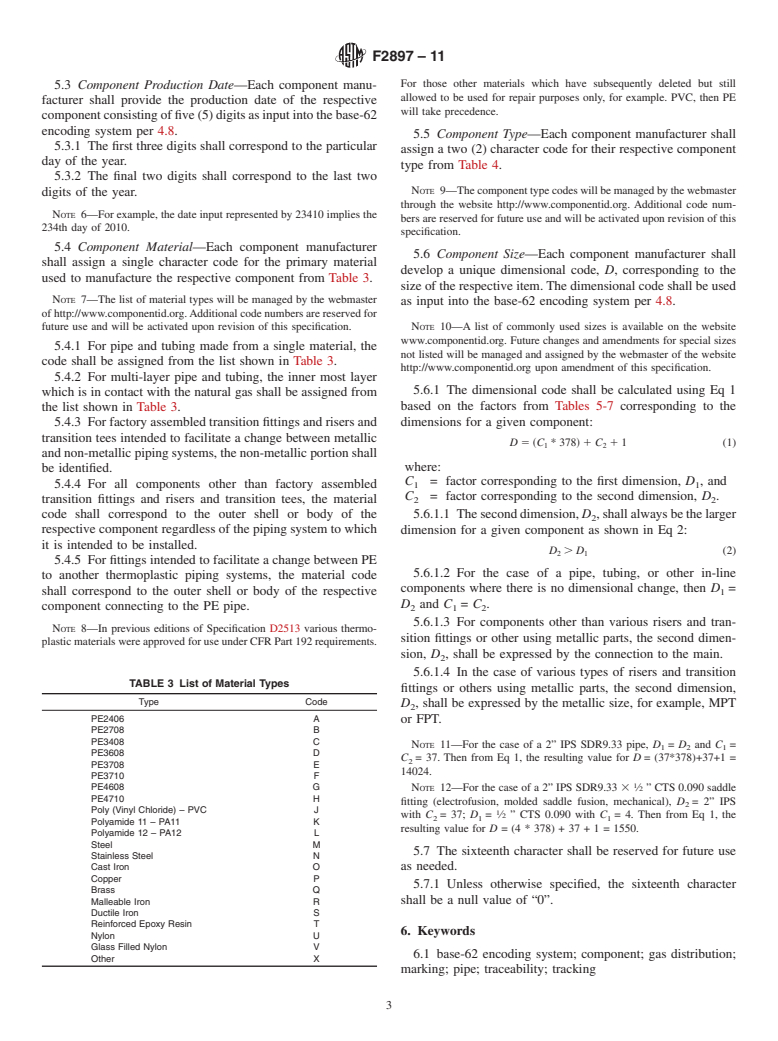

5.4 Component Material—Each component manufacturer

5.6 Component Size—Each component manufacturer shall

shall assign a single character code for the primary material

develop a unique dimensional code, D, corresponding to the

used to manufacture the respective component from Table 3.

size of the respective item.The dimensional code shall be used

NOTE 7—The list of material types will be managed by the webmaster

as input into the base-62 encoding system per 4.8.

of http://www.componentid.org.Additional code numbers are reserved for

future use and will be activated upon revision of this specification.

NOTE 10—A list of commonly used sizes is available on the website

www.componentid.org. Future changes and amendments for special sizes

5.4.1 For pipe and tubing made from a single material, the

not listed will be managed and assigned by the webmaster of the website

code shall be assigned from the list shown in Table 3.

http://www.componentid.org upon amendment of this specification.

5.4.2 For multi-layer pipe and tubing, the inner most layer

5.6.1 The dimensional code shall be calculated using Eq 1

which is in contact with the natural gas shall be assigned from

based on the factors from Tables 5-7 corresponding to the

the list shown in Table 3.

dimensions for a given component:

5.4.3 For factory assembled transition fittings and risers and

transition tees intended to facilitate a change between metallic

D 5 ~C * 378! 1 C 1 1 (1)

1 2

and non-metallic piping systems, the non-metallic portion shall

where:

be identified.

C = factor corresponding to the first dimension, D , and

5.4.4 For all components other than factory assembled 1 1

C = factor corresponding to the second dimension, D .

transition fittings and risers and transition tees, the material 2 2

code shall correspond to the outer shell or body of the 5.6.1.1 Theseconddimension, D ,shallalwaysbethelarger

respective component regardless of the piping system to which dimension for a given component as shown in Eq 2:

it is intended to be installed.

D . D (2)

2 1

5.4.5 For fittings intended to facilitate a change between PE

5.6.1.2 For the case of a pipe, tubing, or other in-line

to another thermoplastic piping systems, the material code

components where there is no dimensional change, then D =

shall correspond to the outer shell or body of the respective

D and C = C .

component connecting to the PE pipe.

2 1 2

5.6.1.3 For components other than various risers and tran-

NOTE 8—In previous editions of Specification D2513 various thermo-

sition fittings or other using metallic parts, the second dimen-

plastic materials were approved for use under CFR Part 192 requirements.

sion, D , shall be expressed by the connection to the main.

5.6.1.4 In the case of various types of risers and transition

TABLE 3 List of Material Types

fittings or others using metallic parts, the second dimension,

Type Code

D , shall be expressed by the metallic size, for example, MPT

PE2406 A or FPT.

PE2708 B

PE3408 C

NOTE 11—For the case of a 2” IPS SDR9.33 pipe, D = D and C =

1 2 1

PE3608 D

C = 37. Then from Eq 1, the resulting value for D = (37*378)+37+1 =

PE3708 E

14024.

PE3710 F

PE4608 G NOTE 12—For the case of a 2” IPS SDR9.33 3 ⁄2 ” CTS 0.090 saddle

PE4710 H

fitting (electrofusion, molded saddle fusion, mechanical), D = 2” IPS

Poly (Vinyl Chloride) – PVC J

with C = 37; D = ⁄2 ” CTS 0.090 with C = 4. Then from Eq 1, the

2 1 1

Polyamide 11 – PA11 K

resulting value for D=(4*378)+37+1= 1550.

Polyamide 12 – PA12 L

Steel M

5.7 The sixteenth character shall be reserved for future use

Stainless Steel N

Cast Iron O as needed.

Copper P

5.7.1 Unless otherwise specified, the sixteenth character

Brass Q

shall be a null value of “0”.

Malleable Iron R

Ductile Iron S

Reinforced Epoxy Resin T

6. Keywords

Nylon U

Glass Filled Nylon V

6.1 base-62 encoding system; component; gas distribution;

Other X

marking; pipe; traceability; tracking

F2897 – 11

TABLE 4 List of Component Types

Category Type – General Subcategory Type Character

Pipe Other 10

Straight 11

Coiled 12

Casing 13

Coupling Other 20

Socket fusion 21

Socket fusion with EFV 22

Electrofusion 23

Electrofusion with EFV 24

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.