ASTM D2513-20

(Specification)Standard Specification for Polyethylene (PE) Gas Pressure Pipe, Tubing, and Fittings

Standard Specification for Polyethylene (PE) Gas Pressure Pipe, Tubing, and Fittings

ABSTRACT

This specification covers the requirements and test methods for material, dimensions, hydrostatic burst strength, tensile strength, chemical resistance, sustained pressure, heat fusion, and impact resistance of plastic pipes, tubing, and fittings used for direct burial and reliner applications in fuel gas mains and services for the distribution of natural gas. This specification does not cover threaded pipe. The plastic used to make the pipes and fittings shall be virgin plastic or reworked plastic having Plastics Pipe Institute (PPI) long-term hydrostatic design stress and hydrostatic design basis rating.

SCOPE

1.1 This specification covers requirements and test methods for material dimensions and tolerances, hydrostatic burst strength, chemical resistance, and rapid crack resistance of polyethylene pipe, tubing, and fittings for use in fuel gas pipelines for direct burial and reliner applications. The pipe and fittings covered by this specification are intended for use in the transmission and distribution of natural gas. Requirements for the qualifying of polyethylene systems for use with liquefied petroleum gas are also covered.

1.1.1 This specification does not cover threaded pipe. Design considerations are discussed in Appendix X1. In-plant quality control programs are specified in Annex A1 and Annex A2.

1.1.2 See Specification F2619/F2619M for polyethylene piping for pressure or non-pressure oil and gas producing applications to convey fluids such as oil, dry or wet gas, multiphase fluids, and non-potable oilfield water.

1.2 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 The following is an index of the annexes and appendix in this specification:

Annex

Subject

Annex A1

In-Plant Quality Control for all materials up to 12 in.

Annex A2

In-Plant Quality Control for PE materials 14 in. and larger.

Appendixes

Subject

Appendix X1

Design Consideration

1.5 The following precautionary caveat pertains only to the test method portion, Section 6, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

- Status

- Published

- Publication Date

- 30-Nov-2020

- Technical Committee

- F17 - Plastic Piping Systems

- Drafting Committee

- F17.60 - Gas

- Current Stage

Relations

- Effective Date

- 01-Apr-2024

- Effective Date

- 01-Feb-2024

- Refers

ASTM D1238-23a - Standard Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastometer - Effective Date

- 15-Nov-2023

- Refers

ASTM F1563-23 - Standard Specification for Tools to Squeeze-off Polyethylene (PE) Gas Pipe or Tubing - Effective Date

- 01-Nov-2023

- Effective Date

- 01-Nov-2023

- Effective Date

- 01-Oct-2023

- Effective Date

- 29-Sep-2023

- Effective Date

- 01-Apr-2020

- Effective Date

- 01-Apr-2020

- Effective Date

- 01-Sep-2019

- Effective Date

- 01-Aug-2019

- Effective Date

- 01-Aug-2019

- Effective Date

- 01-Jan-2019

- Effective Date

- 01-Jan-2019

- Effective Date

- 01-Sep-2018

ASTM D2513-20 - Standard Specification for Polyethylene (PE) Gas Pressure Pipe, Tubing, and Fittings

REDLINE ASTM D2513-20 - Standard Specification for Polyethylene (PE) Gas Pressure Pipe, Tubing, and Fittings

Frequently Asked Questions

ASTM D2513-20 is a technical specification published by ASTM International. Its full title is "Standard Specification for Polyethylene (PE) Gas Pressure Pipe, Tubing, and Fittings". This standard covers: ABSTRACT This specification covers the requirements and test methods for material, dimensions, hydrostatic burst strength, tensile strength, chemical resistance, sustained pressure, heat fusion, and impact resistance of plastic pipes, tubing, and fittings used for direct burial and reliner applications in fuel gas mains and services for the distribution of natural gas. This specification does not cover threaded pipe. The plastic used to make the pipes and fittings shall be virgin plastic or reworked plastic having Plastics Pipe Institute (PPI) long-term hydrostatic design stress and hydrostatic design basis rating. SCOPE 1.1 This specification covers requirements and test methods for material dimensions and tolerances, hydrostatic burst strength, chemical resistance, and rapid crack resistance of polyethylene pipe, tubing, and fittings for use in fuel gas pipelines for direct burial and reliner applications. The pipe and fittings covered by this specification are intended for use in the transmission and distribution of natural gas. Requirements for the qualifying of polyethylene systems for use with liquefied petroleum gas are also covered. 1.1.1 This specification does not cover threaded pipe. Design considerations are discussed in Appendix X1. In-plant quality control programs are specified in Annex A1 and Annex A2. 1.1.2 See Specification F2619/F2619M for polyethylene piping for pressure or non-pressure oil and gas producing applications to convey fluids such as oil, dry or wet gas, multiphase fluids, and non-potable oilfield water. 1.2 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification. 1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard. 1.4 The following is an index of the annexes and appendix in this specification: Annex Subject Annex A1 In-Plant Quality Control for all materials up to 12 in. Annex A2 In-Plant Quality Control for PE materials 14 in. and larger. Appendixes Subject Appendix X1 Design Consideration 1.5 The following precautionary caveat pertains only to the test method portion, Section 6, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. 1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

ABSTRACT This specification covers the requirements and test methods for material, dimensions, hydrostatic burst strength, tensile strength, chemical resistance, sustained pressure, heat fusion, and impact resistance of plastic pipes, tubing, and fittings used for direct burial and reliner applications in fuel gas mains and services for the distribution of natural gas. This specification does not cover threaded pipe. The plastic used to make the pipes and fittings shall be virgin plastic or reworked plastic having Plastics Pipe Institute (PPI) long-term hydrostatic design stress and hydrostatic design basis rating. SCOPE 1.1 This specification covers requirements and test methods for material dimensions and tolerances, hydrostatic burst strength, chemical resistance, and rapid crack resistance of polyethylene pipe, tubing, and fittings for use in fuel gas pipelines for direct burial and reliner applications. The pipe and fittings covered by this specification are intended for use in the transmission and distribution of natural gas. Requirements for the qualifying of polyethylene systems for use with liquefied petroleum gas are also covered. 1.1.1 This specification does not cover threaded pipe. Design considerations are discussed in Appendix X1. In-plant quality control programs are specified in Annex A1 and Annex A2. 1.1.2 See Specification F2619/F2619M for polyethylene piping for pressure or non-pressure oil and gas producing applications to convey fluids such as oil, dry or wet gas, multiphase fluids, and non-potable oilfield water. 1.2 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification. 1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard. 1.4 The following is an index of the annexes and appendix in this specification: Annex Subject Annex A1 In-Plant Quality Control for all materials up to 12 in. Annex A2 In-Plant Quality Control for PE materials 14 in. and larger. Appendixes Subject Appendix X1 Design Consideration 1.5 The following precautionary caveat pertains only to the test method portion, Section 6, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. 1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

ASTM D2513-20 is classified under the following ICS (International Classification for Standards) categories: 23.040.20 - Plastics pipes; 23.040.45 - Plastics fittings. The ICS classification helps identify the subject area and facilitates finding related standards.

ASTM D2513-20 has the following relationships with other standards: It is inter standard links to ASTM F1473-24, ASTM D3261-24, ASTM D1238-23a, ASTM F1563-23, ASTM F2897-23a, ASTM D2565-23, ASTM D1898-68(1989), ASTM F2619/F2619M-20, ASTM F412-20, ASTM F2619/F2619M-19, ASTM D2290-19a, ASTM F1563-01(2019), ASTM F412-19, ASTM D2290-19, ASTM D1599-18. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ASTM D2513-20 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D2513 −20 An American National Standard

Standard Specification for

Polyethylene (PE) Gas Pressure Pipe, Tubing, and Fittings

This standard is issued under the fixed designation D2513; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety, health, and

1.1 This specification covers requirements and test methods

environmental practices and determine the applicability of

for material dimensions and tolerances, hydrostatic burst

regulatory limitations prior to use.

strength, chemical resistance, and rapid crack resistance of

1.6 This international standard was developed in accor-

polyethylene pipe, tubing, and fittings for use in fuel gas

dance with internationally recognized principles on standard-

pipelines for direct burial and reliner applications. The pipe

ization established in the Decision on Principles for the

andfittingscoveredbythisspecificationareintendedforusein

Development of International Standards, Guides and Recom-

the transmission and distribution of natural gas. Requirements

mendations issued by the World Trade Organization Technical

for the qualifying of polyethylene systems for use with

Barriers to Trade (TBT) Committee.

liquefied petroleum gas are also covered.

1.1.1 This specification does not cover threaded pipe. De-

2. Referenced Documents

sign considerations are discussed in Appendix X1. In-plant

2.1 ASTM Standards:

qualitycontrolprogramsarespecifiedinAnnexA1andAnnex

2.1.1 Terminology:

A2.

D1600TerminologyforAbbreviatedTermsRelatingtoPlas-

1.1.2 See Specification F2619/F2619M for polyethylene

tics

piping for pressure or non-pressure oil and gas producing

F412Terminology Relating to Plastic Piping Systems

applications to convey fluids such as oil, dry or wet gas,

2.1.2 Test Methods for:

multiphase fluids, and non-potable oilfield water.

D638Test Method for Tensile Properties of Plastics

1.2 Thetextofthisspecificationreferencesnotes,footnotes,

D1238Test Method for Melt Flow Rates of Thermoplastics

and appendixes which provide explanatory material. These

by Extrusion Plastometer

notesandfootnotes(excludingthoseintablesandfigures)shall

D1598Test Method for Time-to-Failure of Plastic Pipe

not be considered as requirements of the specification.

Under Constant Internal Pressure

1.3 Thevaluesstatedininch-poundunitsaretoberegarded

D1599Test Method for Resistance to Short-Time Hydraulic

as standard. The values given in parentheses are mathematical

Pressure of Plastic Pipe, Tubing, and Fittings

conversions to SI units that are provided for information only

D2122Test Method for Determining Dimensions of Ther-

and are not considered standard.

moplastic Pipe and Fittings

D2290Test Method for Apparent Hoop Tensile Strength of

1.4 The following is an index of the annexes and appendix

Plastic or Reinforced Plastic Pipe

in this specification:

D2837Test Method for Obtaining Hydrostatic Design Basis

Annex Subject

forThermoplasticPipeMaterialsorPressureDesignBasis

Annex A1 In-Plant Quality Control for all materials up to 12 in.

Annex A2 In-Plant Quality Control for PE materials 14 in. and larger.

for Thermoplastic Pipe Products

F1473Test Method for Notch Tensile Test to Measure the

Appendixes Subject

Resistance to Slow Crack Growth of Polyethylene Pipes

Appendix Design Consideration

X1

and Resins

1.5 The following precautionary caveat pertains only to the

2.1.3 Practices for:

test method portion, Section 6, of this specification. This

D543Practices for Evaluating the Resistance of Plastics to

standard does not purport to address all of the safety concerns,

Chemical Reagents

D618Practice for Conditioning Plastics for Testing

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.60 on Gas. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Dec. 1, 2020. Published December 2020. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1966. Last previous edition approved in 2019 as D2513–19. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D2513-20. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2513−20

D1435Practice for Outdoor Weathering of Plastics Rupture Data to Determine Long-Term Hydrostatic

D1898Practice for Sampling of Plastics (Withdrawn 1998) Strength of Thermoplastic Pipe Materials

D2774PracticeforUndergroundInstallationofThermoplas- ISO 12162Thermoplastic Materials for Pipes and Fittings

tic Pressure Piping for Pressure Applications—Classification and

D2565Practice for Xenon-Arc Exposure of Plastics In- Designation—Overall Service (Design) Coefficient

tended for Outdoor Applications ISO 13477Thermoplastics pipes for the conveyance of

F2620PracticeforHeatFusionJoiningofPolyethylenePipe fluids – Determination of resistance to rapid crack propa-

and Fittings gation (RCP) – Small scale steady-state test (S4 test)

G155Practice for Operating XenonArc LightApparatus for ISO 13478Thermoplastics pipe for the conveyance of fluids

Exposure of Non-Metallic Materials – Determination of resistance to rapid crack propagation

2.1.4 Specification for: (RCP) – Full-scale test (FST)

D2683Specification for Socket-Type Polyethylene Fittings

2.6 Plastic Pipe Institute

for Outside Diameter-Controlled Polyethylene Pipe and

PPI TR-3HDB/HDS /PDB/ SDB/MRS Policies

Tubing

PPI TR-4HDB/HDS/SDB/PDB/MRS Listed Materials

D3261SpecificationforButtHeatFusionPolyethylene(PE)

PPI TR-33Generic Butt Fusion Joining for Polyethylene

Plastic Fittings for Polyethylene (PE) Plastic Pipe and

Gas Pipe

Tubing

PPI TR-41Generic Saddle Fusion Joining Procedure for

D3350Specification for Polyethylene Plastics Pipe and Fit-

Polyethylene Gas Piping

tings Materials

PPI TN-30/2006Requirements for the Use of Rework Ma-

F1055Specification for Electrofusion Type Polyethylene

terials in Polyethylene Gas Pipe

Fittings for Outside Diameter Controlled Polyethylene

PPITR-9 Recommended Design Factors and Design Coef-

and Crosslinked Polyethylene (PEX) Pipe and Tubing

ficients for Thermoplastic Pressure pipe

F1563Specification for Tools to Squeeze-off Polyethylene

2.7 Other Documents:

(PE) Gas Pipe or Tubing

National Fire Protection Association: NFPA 58Storage and

F2138Specification for Excess FlowValves for Natural Gas

Handling Liquefied Petroleum Gases

Service

F2619/F2619MSpecificationforHigh-DensityPolyethylene 3. Terminology

(PE) Line Pipe

3.1 Definitions—Definitions are in accordance with Termi-

F2897Specification for Tracking and Traceability Encoding

nology F412, and abbreviations are in accordance with Termi-

System of Natural Gas Distribution Components (Pipe,

nology D1600, unless otherwise specified.

Tubing, Fittings, Valves, and Appurtenances)

3.2 The gas industry terminology used in this specification

2.2 ANSI Standards:

is in accordance with ANSIB31.8 or OPS 49 CFR Part 192,

B16.40 Manually Operated Thermoplastic Gas Shutoffs

unless otherwise indicated.

and Valves in Gas Distribution Systems

3.3 Theterm pipeusedhereinreferstobothpipeandtubing

B 31.8Gas Transmission and Distribution Piping Systems

unless specifically stated otherwise.

2.3 Federal Specifications:

3.4 re-rounding equipment—equipment used to reform the

Fed. Std. No. 123Marking for Shipment (Civil Agencies)

pipe and permanently reduce ovality to 5% or less.

OPS 49 CFR Part 192Title 49, Code of Federal Regula-

tions

3.5 rounding equipment—equipment, devices, clamps, and

so forth, used to temporarily hold the pipe round while

2.4 Military Standards:

out-of-roundness measurements are made, or a joining proce-

MIL-STD-129 Marking for Shipment and Storage

dure (heat fusion, electrofusion, or mechanical) is performed.

MIL-STD-1235(ORD) Single- and Multi-Level Continuous

Sampling Procedures and Tables for Inspection by Attri-

3.6 pipe material designated code—the pipe material des-

butes

ignation code shall consist of the abbreviation for the type of

2.5 ISO Standards :

plastic (PE) followed by Arabic numerals which describe the

ISO 4437 Buried polyethylene (PE) pipes for the supply of

short term properties in accordance with applicable Specifica-

gaseous fuels-Metric series-Specifications

tion D3350, the hydrostatic design stress for water at 73.4°F

ISO 9080 Thermoplastics Pipes for the Transport of

(23°C) in units of 100 psi with any decimal figures dropped.

Fluids—Methods of Extrapolation of Hydrostatic Stress

Wherethehydrostaticdesignstresscodecontainslessthantwo

figures, a zero is used before the number. Thus, a complete

material designation code shall consist of PE and four figures

The last approved version of this historical standard is referenced on

for PE materials. For example, PE2708 is a grade PE27

www.astm.org.

polyethylene with an 800psi design stress for water at 73.4°F

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org.

Available from DLA Document Services, Building 4/D, 700 Robbins Ave.,

Philadelphia, PA 19111-5094, http://quicksearch.dla.mil. Available from Plastics Pipe Institute (PPI), 105 Decker Court, Suite 825,

Available from International Organization for Standardization (ISO), 1, ch. de Irving, TX 75062, http://www.plasticpipe.org.

la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http:// Available from National Fire Protection Association (NFPA), 1 Batterymarch

www.iso.ch. Park, Quincy, MA 02169-7471, http://www.nfpa.org.

D2513−20

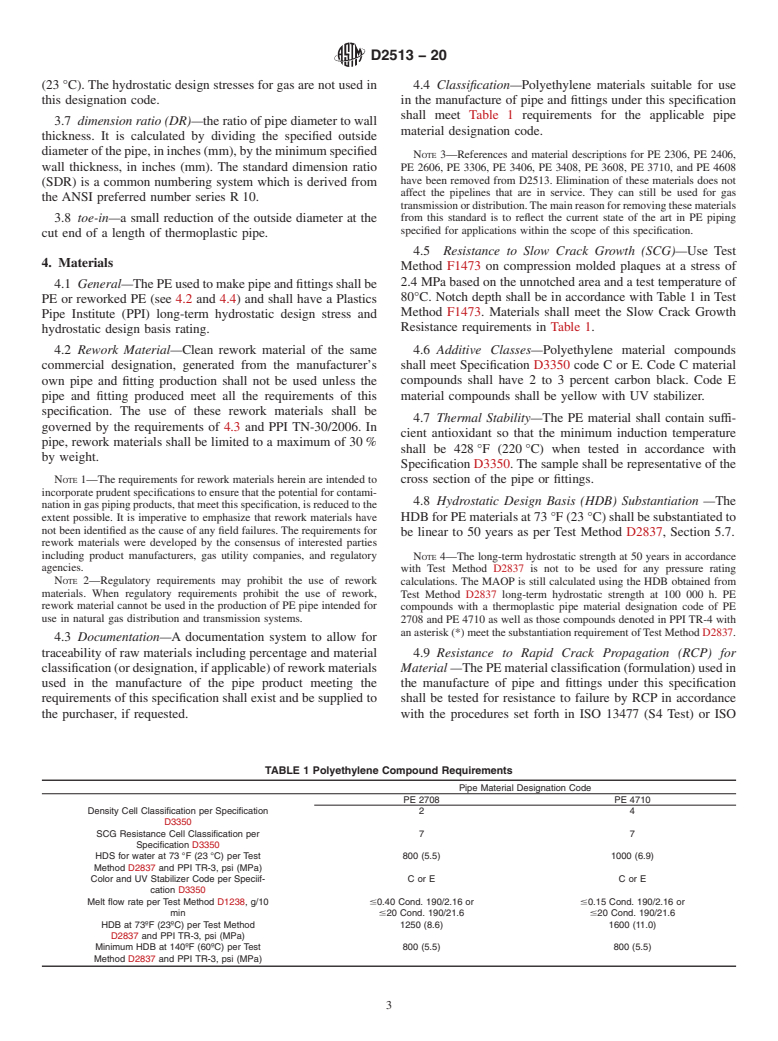

(23°C).The hydrostatic design stresses for gas are not used in 4.4 Classification—Polyethylene materials suitable for use

this designation code. in the manufacture of pipe and fittings under this specification

shall meet Table 1 requirements for the applicable pipe

3.7 dimension ratio (DR)—theratioofpipediametertowall

material designation code.

thickness. It is calculated by dividing the specified outside

diameterofthepipe,ininches(mm),bytheminimumspecified

NOTE 3—References and material descriptions for PE 2306, PE 2406,

wall thickness, in inches (mm). The standard dimension ratio PE 2606, PE 3306, PE 3406, PE 3408, PE 3608, PE 3710, and PE 4608

have been removed from D2513. Elimination of these materials does not

(SDR) is a common numbering system which is derived from

affect the pipelines that are in service. They can still be used for gas

the ANSI preferred number series R10.

transmissionordistribution.Themainreasonforremovingthesematerials

3.8 toe-in—a small reduction of the outside diameter at the from this standard is to reflect the current state of the art in PE piping

specified for applications within the scope of this specification.

cut end of a length of thermoplastic pipe.

4.5 Resistance to Slow Crack Growth (SCG)—Use Test

4. Materials

Method F1473 on compression molded plaques at a stress of

2.4MPabasedontheunnotchedareaandatesttemperatureof

4.1 General—ThePEusedtomakepipeandfittingsshallbe

80°C. Notch depth shall be in accordance with Table1 in Test

PE or reworked PE (see 4.2 and 4.4) and shall have a Plastics

Method F1473. Materials shall meet the Slow Crack Growth

Pipe Institute (PPI) long-term hydrostatic design stress and

Resistance requirements in Table 1.

hydrostatic design basis rating.

4.2 Rework Material—Clean rework material of the same 4.6 Additive Classes—Polyethylene material compounds

commercial designation, generated from the manufacturer’s shall meet Specification D3350 code C or E. Code C material

own pipe and fitting production shall not be used unless the compounds shall have 2 to 3 percent carbon black. Code E

pipe and fitting produced meet all the requirements of this material compounds shall be yellow with UV stabilizer.

specification. The use of these rework materials shall be

4.7 Thermal Stability—The PE material shall contain suffi-

governed by the requirements of 4.3 and PPI TN-30/2006. In

cient antioxidant so that the minimum induction temperature

pipe, rework materials shall be limited to a maximum of 30%

shall be 428°F (220°C) when tested in accordance with

by weight.

Specification D3350.The sample shall be representative of the

NOTE 1—The requirements for rework materials herein are intended to cross section of the pipe or fittings.

incorporateprudentspecificationstoensurethatthepotentialforcontami-

4.8 Hydrostatic Design Basis (HDB) Substantiation —The

nationingaspipingproducts,thatmeetthisspecification,isreducedtothe

extent possible. It is imperative to emphasize that rework materials have HDBforPEmaterialsat73°F(23°C)shallbesubstantiatedto

not been identified as the cause of any field failures.The requirements for

be linear to 50 years as per Test Method D2837, Section 5.7.

rework materials were developed by the consensus of interested parties

including product manufacturers, gas utility companies, and regulatory

NOTE 4—The long-term hydrostatic strength at 50 years in accordance

agencies. with Test Method D2837 is not to be used for any pressure rating

NOTE 2—Regulatory requirements may prohibit the use of rework

calculations. The MAOP is still calculated using the HDB obtained from

materials. When regulatory requirements prohibit the use of rework, Test Method D2837 long-term hydrostatic strength at 100 000 h. PE

rework material cannot be used in the production of PE pipe intended for

compounds with a thermoplastic pipe material designation code of PE

use in natural gas distribution and transmission systems. 2708 and PE 4710 as well as those compounds denoted in PPI TR-4 with

anasterisk(*)meetthesubstantiationrequirementofTestMethodD2837.

4.3 Documentation—A documentation system to allow for

traceability of raw materials including percentage and material 4.9 Resistance to Rapid Crack Propagation (RCP) for

classification(ordesignation,ifapplicable)ofreworkmaterials Material—ThePEmaterialclassification(formulation)usedin

used in the manufacture of the pipe product meeting the the manufacture of pipe and fittings under this specification

requirementsofthisspecificationshallexistandbesuppliedto shall be tested for resistance to failure by RCP in accordance

the purchaser, if requested. with the procedures set forth in ISO 13477 (S4 Test) or ISO

TABLE 1 Polyethylene Compound Requirements

Pipe Material Designation Code

PE 2708 PE 4710

Density Cell Classification per Specification 24

D3350

SCG Resistance Cell Classification per 77

Specification D3350

HDS for water at 73 °F (23 °C) per Test 800 (5.5) 1000 (6.9)

Method D2837 and PPI TR-3, psi (MPa)

Color and UV Stabilizer Code per Speciif- CorE CorE

cation D3350

Melt flow rate per Test Method D1238, g/10 #0.40 Cond. 190/2.16 or #0.15 Cond. 190/2.16 or

min #20 Cond. 190/21.6 #20 Cond. 190/21.6

HDB at 73ºF (23ºC) per Test Method 1250 (8.6) 1600 (11.0)

D2837 and PPI TR-3, psi (MPa)

Minimum HDB at 140ºF (60ºC) per Test 800 (5.5) 800 (5.5)

Method D2837 and PPI TR-3, psi (MPa)

D2513−20

measuringtheductilitypropertiesofthepipematerialexposedtoartificial

13478(FullScaleTest(FST)).Thedataobtainedshallbemade

weathering. These requirements and test methods are based on expected

available upon request without limitations on disclosure, and

UV exposure levels in North America. Alternate requirements and

shallnotsubsequentlybesubjecttodisclosurelimitationswhen

alternatedeterminationmethodsmaybeappropriateinotherregionsofthe

used by others. The values obtained are applicable to all pipes

world. As an example ISO 4437 standard requires a minimum resistance

with the wall thickness of the pipe tested and all thinner wall

to an accumulation of 3.6GJ for non-black polyethylene materials.

pipes. In case of conflict, the RCP results of ISO 13478 shall

4.11 Qualification for LPG Service—Materials that qualify

apply.

for natural gas service and that carry a recommended HDB for

140°F in accordance with 5.6, also qualify for LPG service

NOTE 5—While S4 or FST testing of any combination of outside

diameterandSDRispermittedinfulfillmentoftherequirementfortesting without the need for further testing.

PE material resistance to RCP, S4 testing of SDR 9 or SDR 11 PE pipe

NOTE10—ThetermsLPGandLPGgasaresynonymousandonlyapply

specimens is currently the most common industry practice.

to a particular kind of fuel gas. For compositions and properties of LPG

NOTE 6—Caution should be exercised in applying the RCP test results

gases see NFPA 58, Appendix B.

obtainedononeSDRorDRofpipeacrossaseriesofpipeSDR’sorDR’s

produced from the same PE material classification (formulation). Indus-

trial research to clarify the relationships between FST and S4 testing is

5. Requirements

ongoing at this time, particularly as it relates to the applicability of RCP

5.1 General—Pipe shall be supplied in either coils or

testresultsobtainedononeSDRorDRofpipetootherSDR’sorDR’sof

straightlengths.Anypipesuppliedincoilsmustmeetthesame

pipe produced from the same PE material classification (formulation).

Consult the resin manufacturer regarding the applicability of RCP test

requirements before and after coiling.

results across diameters or SDR’s, or both. Additional information

5.2 Workmanship—The pipe and fittings shall be homoge-

regarding the use of RCP data is presented in ISO 4437.

neous throughout and free of visible cracks, holes, foreign

4.10 UV Resistance—PE materials shall be Code C or E as

inclusion, blisters, and dents, or other injurious defects. The

defined in Specification D3350. Code C material shall contain

pipe and fittings shall be as uniform as commercially practi-

2 to 3 percent well dispersed carbon black, and due to the

cable in color, opacity, density, and other physical properties.

absorptive properties of the carbon black, is considered to be

5.3 Pipe and Tubing Dimensions and Tolerances:

stabilized against deterioration from unprotected exposure to

5.3.1 Dimension—The dimensions shall be specified by

UV for not less than 10 years. Code E material shall be

stabilized and protected against deterioration from unprotected wall thickness and outside diameter.

5.3.1.1 Diameters—The outside diameter shall meet the

UV exposure for not less than 3 years.

requirements given in Table 2 or Table 3 when measured in

4.10.1 PE compounds designated as Code C containing 2 to

accordance with 6.5.

3% carbon black shall be considered stabilized against dete-

5.3.1.2 Toe-In—Whenmeasuredinaccordancewith6.5.1.1,

rioration for not less than 10 years without the need for

additional testing. Black PE pipe coextruded with yellow theoutsidediameteratthecutendofthepipeshallnotbemore

than 1.5% smaller than the undistorted outside diameter.

stripe(s) shall be considered stabilized against deterioration

from unprotected exposure to UV for not less than 10 years. Measurementoftheundistortedoutsidediametershallbemade

no closer than 1.5 pipe diameters or 11.8 in. (300 mm),

NOTE 7—Consult with pipe manufacturer on UV Resistance of black

whichever distance is less, from the cut end of the pipe.

pipes with yellow stripe(s) for conformance to the performance require-

Undistorted outside diameter shall meet the requirements of

ments of code “C” material.

Table 2 or Table 3.

4.10.2 PE compounds designated as Code E shall be con-

5.3.1.3 Wall Thickness—The wall thickness shall be as

sidered stabilized against deterioration from unprotected expo-

specified in Table 3 or Table 4 when measured in accordance

sure to UV for not less than 3 years when meeting the

with 6.5.1.2. The minimum wall thickness at any point of

followingcriteriafollowingexposuretoactualoutdoor(natural

measurementshallbenotlessthantheminimumwallthickness

sunlight) weathering for up to 3 years in accordance with

specified in Table 3 or Table 4.

Practice D1435 or accelerated weathering in accordance with

5.3.1.4 Wall Thickness Eccentricity Range—The wall thick-

PracticeD2565andPracticeG155fortheequivalentofatleast

ness eccentricity range shall be within 12% when measured in

3 years natural sunlight: (a) all tensile bar specimens tested in

accordance with 6.5.1.3.

accordancewithTestMethodD638shallhaveanelongationat

5.3.1.5 Ovality—The ovality (cross section) of 3 in. IPS

break value greater than 400% indicating the equivalency of

(88.9 mm) and smaller pipe shall not exceed 5% when

the PE material before and after UV exposure against the

measured in accordance with 6.5.3. Measurements of coiled

elongation at break requirement in Specification D3350; and

pipe shall be made on a sample cut from the coil, and in case

(b) all tensile bar specimens tested in accordance with Test

of disagreement, conditioned per 6.3.

Method D638 shall retain a minimum of 50% of their original

elongation at break values. Test data shall be made available

NOTE 11—Other factors, that is, installation compaction, static soil

loading, and dynamic vehicular loads may increase the ovality; therefore,

from the manufacturer upon request.

5%waschosenasthelimitfortheamountcontributedbymanufacturing,

NOTE8—StudieshaveshownHDPEexposedtoXenonArcviaPractice packing, in-plant storage, and shipping. For further information, see (1) .

G155-ACycle 1 give approximately 4.4 times the acceleration to outdoor

Florida exposure.Therefore approximately 2000 hours XenonArc testing

would equal about 1-year outdoor exposure in Florida or 2-years in

southern Canada.

The boldface numbers in parentheses refer to a list of references at the end of

NOTE 9—The determination for UV resistance is often based on this standard.

D2513−20

TABLE 2 Outside Diameters and Tolerances for Plastic Pipe, in. (mm)

Nominal Maximum Out-of-Roundness

Pipe Outside Diameter Tolerance

SDR 17

Size

SDR 32.5 SDR 26 SDR 21 SDR 13.5

SDR 11

⁄2 0.840 (21.3) ±0.004 (±0.102) . . 0.03(0.762) 0.016(0.406)

⁄4 1.050 (26.7) ±0.004 (±0.102) . . 0.03(0.762) 0.02(0.508)

1 1.315 (33.4) ±0.005 (±0.127) . . 0.03(0.762) 0.02(0.508)

1 ⁄4 1.660 (42.1) ±0.005 (±0.127) . . 0.03(0.762) 0.024(0.61)

1 ⁄2 1.900 (48.3) ±0.006 (±0.152) . . 0.06(1.524) 0.024(0.61)

2 2.375 (60.3) ±0.006 (±0.152) . . 0.06(1.524) 0.024(0.61)

2 ⁄2 2.875 (73.0) ±0.007 (±0.179) . . 0.06(1.524) 0.03(0.762)

3 3.500 (88.9) ±0.008 (±0.203) . . 0.06(1.524) 0.03(0.762)

3 ⁄2 4.000 (101.6) ±0.008 (±0.203) . . 0.1(2.5) 0.03(0.762)

4 4.500 (114.3) ±0.009 (±0.229) . . 0.1(2.5) 0.03(0.762)

5 5.563 (141.3) ±0.010 (±0.254) . . 0.1(2.5) 0.06(1.524)

6 6.625 (168.3) ±0.011 (±0.279) 0.12(3) 0.11(2.74) 0.1(2.5) 0.07(1.778)

8 8.625 (219.1) ±0.013 (±0.330) 0.24(6.1) 0.16(4.06) 0.12(3) 0.08(2.04)

10 10.750 (273.0) ±0.015 (±0.381) 0.24(6.1) 0.2(5.08) 0.14(3.58) 0.1(2.5)

12 12.750 (323.8) ±0.017 (±0.432) 0.28(7.12) 0.2(5.08) 0.14(3.58) 0.1(2.5)

14 14.000 (355.6) ±0.063 (±1.60) 0.308(7.82) 0.224(5.68) 0.154(3.91) 0.112(2.84)

16 16.000 (406.4) ±0.072 (±1.83) 0.352(8.94) 0.256(6.50) 0.176(4.47) 0.128(3.25)

18 18.000 (457.2) ±0.081 (±2.06) 0.396(10.05) 0.288(7.31) 0.198(5.02) 0.144(3.65)

20 20.000 (508.0) ±0.090 (±2.29) 0.44(11.1) 0.32(8.12) 0.22(5.58) 0.16(4.06)

22 22.000 (558.8) ±0.099 (±2.51) 0.484(12.29) 0.352(8.94) 0.242(6.14) 0.176(4.47)

24 24.000 (609.6) ±0.108 (±2.74) 0.528(13.41) 0.384(9.75) 0.264(6.70) 0.192(4.87)

TABLE 3 PE Tubing-Diameters, Wall Thicknesses, and

5.4 Minimum Hydrostatic Burst Pressure/Apparent Tensile

Tolerances, in. (mm)

Strength (Quick Burst)—The pipe or system shall fail in a

Nominal Minimum Wall

ductile manner when tested in accordance with Test Method

Outside

Tubing Tolerance Wall Thickness

Diameter

D1599.Forpipesizesabove4-in.nominaldiameter,thetesting

Size (CTS) Thickness Tolerance

1 lab shall be allowed to replace the quick burst test (Test

⁄4 0.375 (9.52) ±0.004 (±0.10) 0.062 (1.58) +0.006 (+0.15)

⁄8 0.500 (12.7) ±0.004 (±0.10) 0.062 (1.58) +0.006 (+0.15) Method D1599) by the apparent ring tensile strength test (Test

⁄2 0.625 (15.9) ±0.004 (±0.10) 0.062 (1.58) +0.006 (+0.15)

Method D2290). The minimum apparent tensile strength at

⁄2 0.625 (15.9) ±0.004 (±0.10) 0.090 (2.27) +0.009 (+0.23)

yieldwhendeterminedinaccordancewith6.8shallbe2520psi

⁄2 0.625 (15.9) ±0.004 (±0.10) 0.104 (2.64) +0.010 (+0.25)

⁄4 0.875 (22.2) ±0.004 (±0.10) 0.062 (1.58) +0.006 (+0.15)

(17.4 MPa) for PE 2708 pipe or 2900 psi (20.0 MPa) for PE

⁄4 0.875 (22.2) ±0.004 (±0.10) 0.077 (1.95) +0.008 (+0.20)

4710 pipe.

⁄4 0.875 (22.2) ±0.004 (±0.10) 0.090 (2.27) +0.009 (+0.23)

1 1.125 (28.6) ±0.005 (±0.13) 0.062 (1.58) +0.007 (+0.18)

NOTE 13—The requirements in 5.3.1.1 and 5.3.1.3 are for laboratory

1 1.125 (28.6) ±0.005 (±0.13) 0.090 (2.27) +0.011 (+0.28)

proof testing only and should not be interpreted as applicable to on-site

1 1.125 (28.6) ±0.005 (±0.13) 0.099 (2.51) +0.012 (+0.31)

1 1.125 (28.6) ±0.005 (±0.13) 0.101 (2.56) +0.012 (+0.31)

testing for acceptance of installed systems larger than 12 in. See

1 1.125 (28.6) ±0.005 (±0.13) 0.121 (3.07) +0.015 (+0.38)

appropriate installation standards or manufacturer’s recommendations for

1 ⁄4 1.375 (34.9) ±0.005 (±0.13) 0.062 (1.58) +0.007 (+0.18)

field test procedures.

1 ⁄4 1.375 (34.9) ±0.005 (±0.13) 0.090 (2.27) +0.011 (+0.28)

1 ⁄4 1.375 (34.9) ±0.005 (±0.13) 0.121 (3.07) +0.015 (+0.38)

5.5 Chemical Resistance—The pipe and fittings shall not

1 ⁄4 1.875 (47.6) ±0.006 (±0.15) 0.062 (1.58) +0.007 (+0.18)

increase in weight more than 0.5% (1.0% for toluene in

methanol).Where the test specimen is a pipe ring, the material

shall not change more than 612% in apparent tensile yield

(1)Before or during installation, coiled pipe larger than 3

strengthwhenmeasuredinaccordancewith6.9.Wherethetest

in. IPS (88.9 mm) shall be processed by the installer through

specimen is a plaque, the material shall not change more than

re-rounding equipment that corrects ovality to 5% or less.

612% in tensile strength at yield when measured in accor-

NOTE12—Ovalityisapackagingconditionthatoccurswhenroundable

dance with Test Method D638.

pipe is wound into a coil—the pipe flattens out as it is coiled. Ovality is

correctedwhenjoiningequipmentisappliedtoroundablepipe,orbyfield

NOTE 14—This pipe test is only an indication of what will happen as a

processing roundable pipe through re-rounding and straightening equip-

result of short term exposure to these chemicals. For longterm results,

ment during installation.

additional testing is required.

5.3.1.6 Length—The pipe shall be supplied in straight

5.6 Melt Index—Melt index is the flow rate of PE material

lengths or coils as agreed upon between the manufacturer and

when measured in accordance with Test Method D1238,

the purchaser. The length shall not be less than the minimum

condition 190/2.16 (formerly Condition E). Materials that

length agreed upon when corrected to 73°F (23°C).

recordzeroflowundercondition190/2.16shallbemeasuredin

5.3.1.7 When sizes other than those listed in Table 2, Table

3 or Table 4 are used, tolerances shall be: for outside diameter, accordance with condition 190/21.6 (formerly condition F).

The melt index of pipe/fitting shall meet the designated

use same tolerance of next smaller size; for wall thickness, use

same tolerance percentage as shown in the tables. category in Table 5. The sample shall be representative of the

D2513−20

A,B

TABLE 4 Wall Thicknesses and Tolerances for Plastic Pipe, in (mm)

Nominal Pipe Size

C

DR Minimum Tolerance

(IPS)

D

⁄2 0.062 (1.58) +0.007 (+0.178)

11.0 0.076 (1.93) +0.009 (+0.229)

9.33 0.090 (2.29) +0.011 (+0.279)

D

⁄4 0.090 (2.29) +0.011 (+0.279)

11.0 0.095 (2.41) +0.011 (+0.279)

Sch 40 0.113 (2.87) +0.014 (+0.356)

D

1 0.090 (2.29) +0.011 (+0.279)

13.5 0.097 (2.46) +0.012 (+0.305)

11.0 0.120 (3.05) +0.014 (+0.356)

9.9 0.133 (3.38) +0.016 (+0.406)

9.33 0.140 (3.56) +0.017 (+0.432)

D

1 ⁄4 0.090 (2.29) +0.011 (+0.279)

17.0 0.098 (2.49) +0.012 (+0.305)

13.5 0.123 (3.12) +0.015 (+0.381)

Sch 40 0.140 (3.56) +0.017 (+0.432)

11.0 0.151 (3.84) +0.018 (+0.457)

10.0 0.166 (4.22) +0.020 (+0.508)

9.33 0.178 (4.52) +0.021 (+0.533)

6.0 0.277 (7.04) +0.033 (+0.838)

D

1 ⁄2 0.090 (2.29) +0.011 (+0.279)

17 0.112 (2.85) +0.013 (+0.330)

13.5 0.141 (3.58) +0.017 (+0.432)

Sch 40 0.145 (3.68) +0.017 (+0.432)

11 0.173 (4.39) +0.021 (+0.533)

2 21 0.113 (2.87) +0.014 (+0.356)

17 0.140 (3.56) +0.017 (+0.432)

Sch 40 0.154 (3.91) +0.018 (+0.457)

13.5 0.176 (4.47) +0.021 (+0.533)

11 0.216 (5.49) +0.026 (+0.660)

9.33 0.255 (6.48) +0.031 (+0.787)

2 ⁄2 21 0.137 (3.48) +0.016 (+0.406)

17 0.169 (4.29) +0.020 (+0.508)

13.5 0.213 (5.41) +0.026 (+0.660)

11 0.261 (6.63) +0.031 (+0.787)

3 21 0.167 (4.24) +0.020 (+0.508)

17 0.206 (5.23) +0.025 (+0.635)

Sch 40 0.216 (5.49) +0.026 (+0.660)

13.5 0.259 (6.58) +0.031 (+0.787)

11.5 0.304 (7.72) +0.036 (+0.914)

11 0.318 (8.08) +0.038 (+0.965)

9.33 0.375 (9.53) +0.045 (+1.143)

3 ⁄2 21 0.190 (4.83) +0.023 (+0.584)

17 0.236 (5.99) +0.028 (+0.711)

13.5 0.296 (7.52) +0.036 (+0.914)

11 0.363 (9.22) +0.044 (+1.118)

4 21 0.214 (5.44) +0.026 (+0.660)

19 0.237 (6.02) +0.028 (+0.711)

17 0.265 (6.73) +0.032 (+0.813)

13.5 0.333 (8.46) +0.040 (+1.016)

11.5 0.391 (9.93) +0.047 (+1.194)

11.0 0.409 (10.39) +0.049 (+1.246)

9.33 0.482 (12.24) +0.058 (+1.473)

5 21.6 0.258 (6.55) +0.031 (+0.787)

21 0.265 (6.73) +0.032 (+0.813)

17 0.327 (8.31) +0.039 (+0.991)

13.5 0.412 (10.46) +0.050 (+1.270)

11 0.506 (12.85) +0.061 (+1.549)

6 32.5 0.204 (5.18) +0.024 (+0.610)

26 0.255 (6.48) +0.031 (+0.787)

23.7 0.280 (7.11) +0.034 (+0.864)

21 0.315 (8.00) +0.038 (+0.965)

17 0.390 (9.91) +0.047 (+1.194)

13.5 0.491 (12.47) +0.059 (+1.499)

D2513−20

TABLE4 Continued

Nominal Pipe Size

C

DR Minimum Tolerance

(IPS)

11.5 0.576 (14.63) +0.069 (+1.753)

11.0 0.602 (15.29) +0.072 (+1.829)

8 32.5 0.265 (6.73) +0.032 (+0.813)

26 0.332 (8.43) +0.040 (+1.016)

21 0.411 (10.44) +0.049 (+1.245)

17 0.507 (12.90) +0.061 (+1.549)

13.5 0.639 (16.23) +0.077 (+1.956)

11.5 0.750 (19.05) +0.090 (+2.286)

11 0.784 (19.91) +0.094 (+2.388)

10 32.5 0.331 (8.41) +0.040 (+1.016)

26 0.413 (10.49) +0.050 (+1.270)

21 0.512 (13.00) +0.061 (+1.549)

17 0.632 (16.05) +0.076 (+1.930)

13.5 0.796 (20.22) +0.096 (+2.438)

11.5 0.935 (23.75) +0.112 (+2.845)

11 0.977 (24.82) +0.117 (+2.972)

12 32.5 0.392 (9.96) +0.047 (+1.194)

26 0.490 (12.45) +0.059 (+1.499)

21 0.607 (15.42) +0.073 (+1.854)

17 0.750 (19.05) +0.090 (+2.286)

13.5 0.944 (23.98) +0.113 (+2.870)

11.5 1.109 (28.17) +0.133 (+3.378)

11 1.159 (29.44) +0.139 (+3.531)

14 32.5 0.431 (10.942) +0.052 (+1.313)

26 0.538 (13.677) +0.065 (+1.641)

21 0.667 (16.933) +0.080 (+2.032)

17 0.824 (20.918) +0.099 (+2.510)

13.5 1.037 (26.341) +0.124 (+3.161)

11.5 1.217 (30.922) +0.146 (+3.711)

11 1.273 (32.327) +0.153 (+3.879)

16 32.5 0.492 (12.505) +0.059 (+1.501)

26 0.615 (15.631) +0.074 (+1.876)

21 0.762 (19.352) +0.091 (+2.322)

17 0.941 (23.906) +0.113 (+2.869)

13.5 1.185 (30.104) +0.142 (+3.612)

11.5 1.391 (35.339) +0.167 (+4.241)

11 1.455 (36.945) +0.175 (+4.433)

18 32.5 0.554 (14.068) +0.066 (+1.688)

26 0.692 (17.585) +0.083 (+2.110)

21 0.857 (21.771) +0.103 (+2.613)

17 1.059 (26.894) +0.127 (+3.227)

13.5 1.333 (33.867) +0.160 (+4.064)

11.5 1.565 (39.757) +0.188 (+4.771)

11 1.636 (41.564) +0.196 (+4.988)

20 32.5 0.615 (15.631) +0.074 (+1.876)

26 0.769 (19.538) +0.092 (+2.345)

21 0.952 (24.190) +0.114 (+2.903)

17 1.176 (29.882) +0.141 (+3.586)

13.5 1.481 (37.630) +0.178 (+4.516)

11.5 1.739 (44.174) +0.209 (+5.301)

11 1.818 (46.182) +0.218 (+5.542)

22 32.5 0.677 (17.194) +0.081 (+2.063)

26 0.846 (21.492) +0.102 (+2.579)

21 1.048 (26.610) +0.126 (+3.193)

17 1.294 (32.871) +0.155 (+3.944)

13.5 1.630 (41.393) +0.196 (+4.967)

11.5 1.913 (48.591) +0.230 (+5.831)

11 2.000 (50.800) +0.240 (+6.096)

24 32.5 0.738 (18.757) +0.089 (+2.251)

26 0.923 (23.446) +0.111 (+2.814)

21 1.143 (29.029) +0.137 (+3.483)

D2513−20

TABLE4 Continued

Nominal Pipe Size

C

DR Minimum Tolerance

(IPS)

17 1.412 (35.859) +0.169 (+4.303)

13.5 1.778 (45.156) +0.213 (+5.419)

11.5 2.087 (53.009) +0.250 (+6.361)

11 2.182 (55.418) +0.262 (+6.650)

A

The sizes listed in Table 4 are those commercially available sizes used by the gas industry.

B

The minimum is the lowest wall thickness of the pipe at any cross section. The maximum permitted wall thickness, at any cross section, is the minimum wall thickness

plus the stated tolerance. All tolerances are on the plus side of the minimum requirement.

C

The DR shown are designations commonly accepted by the gas industry and do not calculate exactly.

D

These wall thicknesses are minimum and are not a function of the dimension ratios.

TABLE 5 Pipe Category

Category

Property Test Method

AB C D E F G H

Temperature, . . . 100 (38) 120 (49) 140 (60) 160 (71) 180 (82) 200 (93) . . . .

°F (°C)

Hydrostatic D2837 400 (2.8) 500 (3.4) 630 (4.3) 800 (5.5) 1000 (6.9) 1250 (8.6) 1600 (11.0) 2000 (13.8)

Design

Basis, psi

(MPa)

A BC

Melt Index D1238 >0.5 0.2–0.5 0.01–0.3 <0.01 . . .

Examples: CDB - At 140ºF (60ºC) the HDB is 800 psi (5.5 MPa). The approximate melt index range is 0.2 to 0.5 g/10 min for this PE pipe.

A

DF - At 160ºF (71ºC) the HDB is 1250 psi (8.6 MPa) .

A

The Melt Index information in this table is intended to provide guidance relating to heat fusion joining of PE materials, not for classification of materials. This property

is not applicable to non-PE materials or to mechanical fittings. See 7.5.

B

Typically melt flow measured under condition 190/21.6 is less than 4.01 g/10 min.

C

WhenaPEpipeorfittingismarkedper7.2or7.5withtheletter“E,”itaffirmsthatthemanufacturerhasverifiedtheapplicabilityofgenericfusionjoiningwiththeirproducts

in accordance with PPI TR-33 and PPI TR-41 by joining to itself and to other “E” materials and testing the joints in accordance with applicable regulations. However,

qualification of joining procedures by operators in accordance with applicable regulations may still be required. Information about manufacturers who have verified PPI

TR-33 and PPI TR-41 generic fusion joining with their products is found in PPI TR-33 and PPI TR-41. Consult PPI and the manufacturer for additional information.

cross section of the pipe or fitting and diced to an appropriate when the wall thickness of the pipe being produced in

size by a method not producing heat. accordance with this standard exceeds that of the pipe used to

establish the resistance to RCP for the PE compound. In these

5.7 Sustained Pressure 73 °F (23 °C)—Fittingsshallnotfail

circumstances, additional testing for resistance to failure by

in less than 1000 h when tested in accordance with Test

RCPin accordance with the procedures set forth in ISO 13477

MethodD1598.ForPE2708materials,thestressshallbe1320

(S4 Test) or ISO 13478 (Full Scale Test (FST)) shall be

psi, for PE 4710 materials, the stress shall be 1600 psi.

conducted. In cases of conflict, the RCP results of ISO 13478

5.8 Elevated Temperature Service—piping materials in-

shall apply. The data obtained shall be made available upon

tendedforuseattemperaturesabove100°F(38°C)shallhave

request without limitations on disclosure, and shall not subse-

the PPI hydrostatic design basis (HDB) determined at the

quently be subject to disclosure limitations when used by

specific temperature in accordance with Test Method D2837.

others.

The 100 000-h intercept (long-term strength) shall be catego-

NOTE17—TherequirementsandtestingforresistancetoRCPspecified

rized in accordance with Table 5 and be listed as the “hydro-

in this specification do not provide information for all possible conditions

static design basis of XXX psi at XXX °F (°C) for (compound

of use. The user should consult with the manufacturer and other

name).”

appropriate sources such as resin suppliers, research, academia, etc., to

determine that the RCP resistance provided by the pipe producer is

NOTE15—Manydesignfactorsforelevatedtemperatureservicecannot

sufficient for the intended use.

be covered in this specification. Users should consult applicable codes for

limitations on pertinent maximum temperatures. 5.11 Inside Surface Ductility for Pipe—The inside surface

NOTE 16—In the absence of an HDB established at the specified

of pipe shall be ductile as shown by testing in accordance with

temperature,theHDBofahighertemperaturemaybeusedindetermining

5.11.1, 5.11.2, and 5.11.3. Before testing, specimens shall be

a design pressure rating at the specified temperature by arithmetic

conditioned in accordance with Practice D618 for 40 h at 73.4

interpolation.

6 3.6°F (23 6 2°C) and 50% relative humidity.

5.9 HDB Validation for PE Pipe—The 73°F (23°C) Hy-

NOTE18—IDductilitytestingmayalsobeconductedforqualitycontrol

drostatic Design Basis (HDB) of PE pipe shall be validated by

purposes, however, there is no known data that identifies one test as

thepipeproducerusingthePEvalidationprocedureasoutlined

inferior, equal, or superior to the others, therefore, results from one test

inTestMethodD2837.ForMDPEmaterials,theHDBof1250

should not be evaluated against the results from either of the other two

psi shall be validated; for HDPE materials, the HDB of 1600

tests.

psi shall be validated.

5.11.1 Bend-back Test Method:

5.10 Resistance to Rapid Crack Propagation (RCP) for 5.11.1.1 From the pipe, squarely cut a ring of pipe with a

Pipe—Additional testing for resistance to RCP is required minimumwidthof1 ⁄4(32mm).Theentirewallthicknessmay

D2513−20

be tested, or material may be removed from the OD surface of 5.13 Joints:

the pipe, while maintaining an undisturbed ID surface, to 5.13.1 Heat Fusion:

produce a ring with ⁄8-in. (9.5-mm) wall thickness. 5.13.1.1 Heatfusionjointsofthermoplasticpipeandfittings

shallbemadeinaccordancewithPracticeF2620andtheuser’s

NOTE 19—The ring may be tested in its entirety, or may be cut into

written procedure.

representative sectors to produce bend-back test specimens.

5.13.1.2 PE butt fusion joining shall be between compo-

5.11.1.2 In a well-lit area at 73.4 6 3.6°F (23 6 2°C)

nents (pipes, fittings, or valves) having the same SDR or DR.

perform the following procedure within 5 min: (a) Bend the

Butt fusion between unlike SDR or DR components shall be

specimen inside-out (reverse-bend so that the pipe ID surface

allowed only if it has been demonstrated that long term

is on the outside surface of the bent specimen). (b) Using an

performance is not adversely affected. The minimum require-

apparatus such as a vise or other suitable bending equipment,

ment to demonstrate long term performance shall be the

close the legs of the specimen together. When the specimen

validation procedure for PE in Test Method D2837. The

legs are closed together, the top of the bend-back specimen

Hydrostatic Design Basis (HDB) of the PE material shall be

shall protrude 1 to 1 ⁄4 in. (25 to 32 mm) or two wall

validated using specimens containing butt fusion joints result-

thicknesses, whichever is greater, above the point of closure

ing from different SDRs or DRs. Pipe/pipe joints of the given

(jaws). (c) With the unaided (naked) eye, visually examine the

PE material that pass shall validate pipe/pipe, pipe/fitting, or

protruding reverse-bent pipe ID surface for signs of brittle

fitting/fitting joints of the same SDR ratio for that PE material.

cracking or crazing.

5.13.2 Mechanical—Mechanicalfittingsshallbeinstalledin

5.11.1.3 Any indication of brittle cracking or crazing indi-

accordance with the user’s written procedures and the fitting

cates failure.

manufacturer’s installation instructions. The joint shall be

5.11.2 Elongation-at-Break Test Method :

tested in accordance with the specific design category as

5.11.2.1 Five Test Method D638 Type IV specimens cut in

outlined in 6.10.

thelongitudinaldirectionfromlocationsequallyspacedaround

5.13.3 Electrofusion—Electrofusion joints shall be made in

thecircumferenceofthepipeshallbetestedinaccordancewith

accordance to user’s written procedures and the fitting manu-

Test Method D638 at a cross-head separation speed of 2 in.

facturer’s installation instructions.

(50.8 mm) min, and at 73.4 6 3.6°F (23 6 2°C). If the

5.14 Fittings:

specimenthicknessmustbereducedbymachining,thepipeID

5.14.1 Socket-type fusion fittings shall meet the require-

surface shall be left unaltered.

ments of Specification D2683.

NOTE 20—If the specimen thickness is reduced, the machined side of 5.14.2 Butt-type fusion fittings shall meet the requirements

the specimen must be smooth and the thickness of the specimen in the

of Specification D3261.

gage length must be uniform. Surface cuts or scratches and nonuniform

5.14.3 Electrofusion fittings should meet the requirements

thicknessinthespecimengagelengthcandetrimentallyaffecttestresults.

of Specification F1055.

5.11.2.2 The percent elongation at break for each test

5.15 PE Valves—All PE gas valves shall meet the require-

specimen shall exceed 400%.

ments of ANSI Standard B16.40.

5.11.3 Thermal Stability Test Method—Specimens of the

5.16 Excess Flow Valves—Allexcessflowvalvesshallmeet

pipe inside wall surface not more than 0.005 in. (0.13 mm)

the requirements of Specification F2138.

thick shall demonstrate a minimum induction temperature of

428°F (220°C) when tested in accordance with the Test

6. Test Methods

Method for Thermal Stability in Specification D3350.

6.1 General—The test methods in this specification cover

5.12 Squeeze-Off—Thisrequirementislimitedtopipesizes,

plastic pipe and fittings to be used for gas transmission and

wall thicknesses, squeeze procedures, and conditions deemed

distribution. Test methods that are applicable from other

suitable for squeeze-off in service by the pipe manufacturer.

specifications will be referenced in the paragraph pertaining to

There shall be no leakage or visual evidence of splitting,

that particular test.

cracking, breaking or reduction in 1000-h sustained pressure

6.2 Sampling—Takearepresentativesampleofthepipeand

category when pipe is tested as follows:

fittings sufficient to determine conformance with this specifi-

5.12.1 Prepare six randomly selected pipe specimens in

cation.About40ft(12m)ofpipeisrequiredtoperformallthe

accordance with Test Method D1598 except they shall be

tests prescribed. The number of fittings required varies, de-

unfilled.

pendinguponthesizeandtypeoffitting.Asamplingplanshall

5.12.2 The squeeze-off shall be effected at the mid-point of

be agreed upon by the purchaser and the manufacturer (see

the test specimen, 90° to the point of the measured minimum

Practice D1898).

wall thickness. Close the squeeze bars to the gap stop in

6.2.1 Pipe Test Specimens—Not less than 50% of the test

Specification F1563 and hold in constraint for 4 h. Remove

specimens required for any pressure test shall have at least a

squeeze bars and reround pipe by closing squeeze bars at a

partofthemarkingintheircentralsections.Thecentralsection

point 90° from the squeeze area.

is that portion of pipe which is at least one pipe diameter away

5.12.3 Immediately upon removal of the squeeze-off tool,

from an end closure.

fillthespecimenswithambienttemperaturewater,thatis,67 6

10°F (19.4 6 5.6°C), condition, and test in accordance with 6.3 Conditioning—For those tests where conditioning is

6.6. requiredorunlessotherwisespecified,conditionthespecimens

D2513−20

priortotestingforaminimumof1hinwateror4hinairat73.4 and the applicable fiber stress, whichever is greater. The test

6 3.6°F (23 6 2°C). fiber stress shall be 90% of the hydrostatic design basis

(HDB).

6.4 Test Conditions—Conduct the test in the standard labo-

ratory atmosphere of 73.4 6 3.6°F (23 6 2°C) and 50 65%

NOTE22—Air,methane,ornitrogenmaybesubstitutedforwaterasthe

test medium.

relative humidity, unless otherwise specified.

6.6.2 Maintainthespecimensatthepressuresrequired,held

6.5 Dimensions and Tolerances:

to 610 psi (0.07 MPa), for a period of 1000 h at the test

6.5.1 Pipe—Any length of pipe is used to determine the

temperature 63.6°F (62°C) as specified in 6.6.1.

dimensions. Coiled pipe shall be measured in the natural

6.6.3 Failure of two of the six specimens tested shall

springback condition, unless specified otherwise.

constitutefailureinthetes

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D2513 − 19 D2513 − 20 An American National Standard

Standard Specification for

Polyethylene (PE) Gas Pressure Pipe, Tubing, and Fittings

This standard is issued under the fixed designation D2513; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers requirements and test methods for material dimensions and tolerances, hydrostatic burst strength,

chemical resistance, and rapid crack resistance of polyethylene pipe, tubing, and fittings for use in fuel gas pipelines for direct

burial and reliner applications. The pipe and fittings covered by this specification are intended for use in the transmission and

distribution of natural gas. Requirements for the qualifying of polyethylene systems for use with liquefied petroleum gas are also

covered.

1.1.1 This specification does not cover threaded pipe. Design considerations are discussed in Appendix X1. In-plant quality

control programs are specified in Annex A1 and Annex A2.

1.1.2 See Specification F2619/F2619M for polyethylene piping for pressure or non-pressure oil and gas producing applications

to convey fluids such as oil, dry or wet gas, multiphase fluids, and non-potable oilfield water.

1.2 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes and

footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 The following is an index of the annexes and appendix in this specification:

Annex Subject

Annex A1 In-Plant Quality Control for all materials up to 12 in.

Annex A2 In-Plant Quality Control for PE materials 14 in. and larger.

Appendixes Subject

Appendix Design Consideration

X1

1.5 The following precautionary caveat pertains only to the test method portion, Section 6, of this specification. This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory

limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

This specification is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.60 on Gas.

Current edition approved Aug. 1, 2019Dec. 1, 2020. Published August 2019December 2020. Originally approved in 1966. Last previous edition approved in 20182019

as D2513 – 18a.D2513 – 19. DOI: 10.1520/D2513-19.10.1520/D2513-20.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2513 − 20

2. Referenced Documents

2.1 ASTM Standards:

2.1.1 Terminology:

D1600 Terminology for Abbreviated Terms Relating to Plastics

F412 Terminology Relating to Plastic Piping Systems

2.1.2 Test Methods for:

D638 Test Method for Tensile Properties of Plastics

D1238 Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastometer

D1598 Test Method for Time-to-Failure of Plastic Pipe Under Constant Internal Pressure

D1599 Test Method for Resistance to Short-Time Hydraulic Pressure of Plastic Pipe, Tubing, and Fittings

D2122 Test Method for Determining Dimensions of Thermoplastic Pipe and Fittings

D2290 Test Method for Apparent Hoop Tensile Strength of Plastic or Reinforced Plastic Pipe

D2837 Test Method for Obtaining Hydrostatic Design Basis for Thermoplastic Pipe Materials or Pressure Design Basis for

Thermoplastic Pipe Products

F1473 Test Method for Notch Tensile Test to Measure the Resistance to Slow Crack Growth of Polyethylene Pipes and Resins

2.1.3 Practices for:

D543 Practices for Evaluating the Resistance of Plastics to Chemical Reagents

D618 Practice for Conditioning Plastics for Testing

D1435 Practice for Outdoor Weathering of Plastics

D1898 Practice for Sampling of Plastics (Withdrawn 1998)

D2774 Practice for Underground Installation of Thermoplastic Pressure Piping

D2565 Practice for Xenon-Arc Exposure of Plastics Intended for Outdoor Applications

F2620 Practice for Heat Fusion Joining of Polyethylene Pipe and Fittings

G155 Practice for Operating Xenon Arc Light Apparatus for Exposure of Non-Metallic Materials

2.1.4 Specification for:

D2683 Specification for Socket-Type Polyethylene Fittings for Outside Diameter-Controlled Polyethylene Pipe and Tubing

D3261 Specification for Butt Heat Fusion Polyethylene (PE) Plastic Fittings for Polyethylene (PE) Plastic Pipe and Tubing

D3350 Specification for Polyethylene Plastics Pipe and Fittings Materials

F1055 Specification for Electrofusion Type Polyethylene Fittings for Outside Diameter Controlled Polyethylene and Crosslinked

Polyethylene (PEX) Pipe and Tubing

F1563 Specification for Tools to Squeeze-off Polyethylene (PE) Gas Pipe or Tubing

F2138 Specification for Excess Flow Valves for Natural Gas Service

F2619/F2619M Specification for High-Density Polyethylene (PE) Line Pipe

F2897 Specification for Tracking and Traceability Encoding System of Natural Gas Distribution Components (Pipe, Tubing,

Fittings, Valves, and Appurtenances)

2.2 ANSI Standards:

B 16.40 Manually Operated Thermoplastic Gas Shutoffs and Valves in Gas Distribution Systems

B 31.8 Gas Transmission and Distribution Piping Systems

2.3 Federal Specifications:

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

OPS 49 CFR Part 192 Title 49, Code of Federal Regulations

2.4 Military Standards:

MIL-STD-129 Marking for Shipment and Storage

MIL-STD-1235 (ORD) Single- and Multi-Level Continuous Sampling Procedures and Tables for Inspection by Attributes

2.5 ISO Standards :

ISO 4437 Buried polyethylene (PE) pipes for the supply of gaseous fuels-Metric series-Specifications

ISO 9080 Thermoplastics Pipes for the Transport of Fluids—Methods of Extrapolation of Hydrostatic Stress Rupture Data to

Determine Long-Term Hydrostatic Strength of Thermoplastic Pipe Materials

ISO 12162 Thermoplastic Materials for Pipes and Fittings for Pressure Applications—Classification and Designation—Overall

Service (Design) Coefficient

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Available from DLA Document Services, Building 4/D, 700 Robbins Ave., Philadelphia, PA 19111-5094, http://quicksearch.dla.mil.

Available from International Organization for Standardization (ISO), 1, ch. de la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://www.iso.ch.

D2513 − 20

ISO 13477 Thermoplastics pipes for the conveyance of fluids – Determination of resistance to rapid crack propagation (RCP)

– Small scale steady-state test (S4 test)

ISO 13478 Thermoplastics pipe for the conveyance of fluids – Determination of resistance to rapid crack propagation (RCP) –

Full-scale test (FST)

2.6 Plastic Pipe Institute

PPI TR-3 HDB/HDS /PDB/ SDB/MRS Policies

PPI TR-4 HDB/HDS/SDB/PDB/MRS Listed Materials

PPI TR-33 Generic Butt Fusion Joining for Polyethylene Gas Pipe

PPI TR-41 Generic Saddle Fusion Joining Procedure for Polyethylene Gas Piping

PPI TN-30/2006 Requirements for the Use of Rework Materials in Polyethylene Gas Pipe

PPI TR-9 Recommended Design Factors and Design Coefficients for Thermoplastic Pressure pipe

2.7 Other Documents:

National Fire Protection Association: NFPA 58 Storage and Handling Liquefied Petroleum Gases

3. Terminology

3.1 Definitions—Definitions are in accordance with Terminology F412, and abbreviations are in accordance with Terminology

D1600, unless otherwise specified.

3.2 The gas industry terminology used in this specification is in accordance with ANSI B31.8 or OPS 49 CFR Part 192, unless

otherwise indicated.

3.3 The term pipe used herein refers to both pipe and tubing unless specifically stated otherwise.

3.4 re-rounding equipment—equipment used to reform the pipe and permanently reduce ovality to 5 % or less.

3.5 rounding equipment—equipment, devices, clamps, and so forth, used to temporarily hold the pipe round while out-of-

roundness measurements are made, or a joining procedure (heat fusion, electrofusion, or mechanical) is performed.

3.6 pipe material designated code—the pipe material designation code shall consist of the abbreviation for the type of plastic (PE)

followed by Arabic numerals which describe the short term properties in accordance with applicable Specification D3350, the

hydrostatic design stress for water at 73.4 °F (23 °C) in units of 100 psi with any decimal figures dropped. Where the hydrostatic

design stress code contains less than two figures, a zero is used before the number. Thus, a complete material designation code

shall consist of PE and four figures for PE materials. For example, PE2708 is a grade PE27 polyethylene with an 800psi design

stress for water at 73.4 °F (23 °C). The hydrostatic design stresses for gas are not used in this designation code.

3.7 dimension ratio (DR)—the ratio of pipe diameter to wall thickness. It is calculated by dividing the specified outside diameter

of the pipe, in inches (mm), by the minimum specified wall thickness, in inches (mm). The standard dimension ratio (SDR) is a

common numbering system which is derived from the ANSI preferred number series R 10.

3.8 toe-in—a small reduction of the outside diameter at the cut end of a length of thermoplastic pipe.

4. Materials

4.1 General—The PE used to make pipe and fittings shall be PE or reworked PE (see 4.2 and 4.4) and shall have a Plastics Pipe

Institute (PPI) long-term hydrostatic design stress and hydrostatic design basis rating.

4.2 Rework Material—Clean rework material of the same commercial designation, generated from the manufacturer’s own pipe

and fitting production shall not be used unless the pipe and fitting produced meet all the requirements of this specification. The

use of these rework materials shall be governed by the requirements of 4.3 and PPI TN-30/2006. In pipe, rework materials shall

be limited to a maximum of 30 % by weight.

NOTE 1—The requirements for rework materials herein are intended to incorporate prudent specifications to ensure that the potential for contamination

in gas piping products, that meet this specification, is reduced to the extent possible. It is imperative to emphasize that rework materials have not been

Available from Plastics Pipe Institute (PPI), 105 Decker Court, Suite 825, Irving, TX 75062, http://www.plasticpipe.org.

Available from National Fire Protection Association (NFPA), 1 Batterymarch Park, Quincy, MA 02169-7471, http://www.nfpa.org.

D2513 − 20

identified as the cause of any field failures. The requirements for rework materials were developed by the consensus of interested parties including product

manufacturers, gas utility companies, and regulatory agencies.

NOTE 2—Regulatory requirements may prohibit the use of rework materials. When regulatory requirements prohibit the use of rework, rework material

cannot be used in the production of PE pipe intended for use in natural gas distribution and transmission systems.

4.3 Documentation—A documentation system to allow for traceability of raw materials including percentage and material

classification (or designation, if applicable) of rework materials used in the manufacture of the pipe product meeting the

requirements of this specification shall exist and be supplied to the purchaser, if requested.

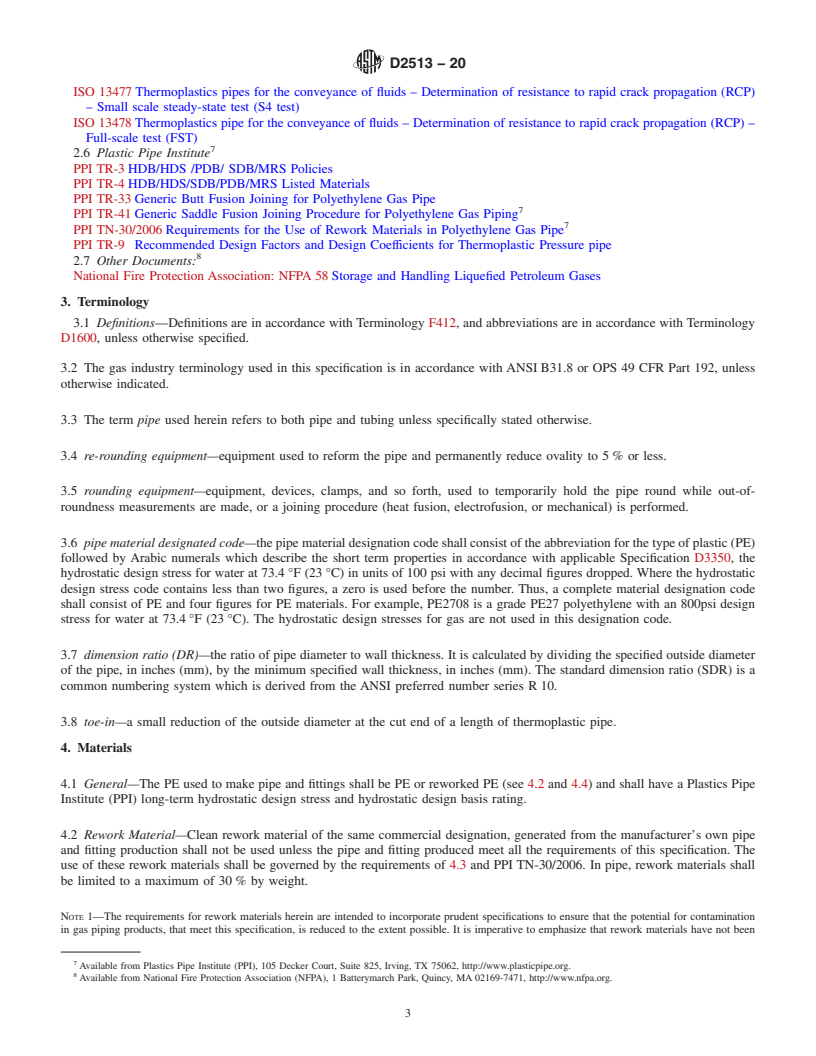

4.4 Classification—Polyethylene materials suitable for use in the manufacture of pipe and fittings under this specification shall

meet Table 1 requirements for the applicable pipe material designation code.

NOTE 3—References and material descriptions for PE 2306, PE 2406, PE 2606, PE 3306, PE 3406, PE 3408, PE 3608, PE 3710, and PE 4608 have been

removed from D2513. Elimination of these materials does not affect the pipelines that are in service. They can still be used for gas transmission or

distribution. The main reason for removing these materials from this standard is to reflect the current state of the art in PE piping specified for applications

within the scope of this specification.

4.5 Resistance to Slow Crack Growth (SCG)—Use Test Method F1473 on compression molded plaques at a stress of 2.4 MPa

based on the unnotched area and a test temperature of 80°C. Notch depth shall be in accordance with Table 1 in Test Method F1473.

Materials shall meet the Slow Crack Growth Resistance requirements in Table 1.

4.6 Additive Classes—Polyethylene material compounds shall meet Specification D3350 code C or E. Code C material compounds

shall have 2 to 3 percent carbon black. Code E material compounds shall be yellow with UV stabilizer.

4.7 Thermal Stability—The PE material shall contain sufficient antioxidant so that the minimum induction temperature shall be

428 °F (220 °C) when tested in accordance with Specification D3350. The sample shall be representative of the cross section of

the pipe or fittings.

4.8 Hydrostatic Design Basis (HDB) Substantiation —The HDB for PE materials at 73 °F (23 °C) shall be substantiated to be

linear to 50 years as per Test Method D2837, Section 5.7.

NOTE 4—The long-term hydrostatic strength at 50 years in accordance with Test Method D2837 is not to be used for any pressure rating calculations.

The MAOP is still calculated using the HDB obtained from Test Method D2837 long-term hydrostatic strength at 100 000 h. PE compounds with a

thermoplastic pipe material designation code of PE 2708 and PE 4710 as well as those compounds denoted in PPI TR-4 with an asterisk (*) meet the

substantiation requirement of Test Method D2837.

4.9 Resistance to Rapid Crack Propagation (RCP) for Material —The PE material classification (formulation) used in the

manufacture of pipe and fittings under this specification shall be tested for resistance to failure by RCP in accordance with the

procedures set forth in ISO 13477 (S4 Test) or ISO 13478 (Full Scale Test (FST)). The data obtained shall be made available upon

request without limitations on disclosure, and shall not subsequently be subject to disclosure limitations when used by others. The

values obtained are applicable to all pipes with the wall thickness of the pipe tested and all thinner wall pipes. In case of conflict,

the RCP results of ISO 13478 shall apply.

TABLE 1 Polyethylene Compound Requirements

Pipe Material Designation Code

PE 2708 PE 4710

Density Cell Classification per Specification 2 4

D3350

SCG Resistance Cell Classification per 7 7

Specification D3350

HDS for water at 73 °F (23 °C) per Test 800 (5.5) 1000 (6.9)

Method D2837 and PPI TR-3, psi (MPa)

Color and UV Stabilizer Code per Speciif- C or E C or E

cation D3350

Melt flow rate per Test Method D1238, g/10 #0.40 Cond. 190/2.16 or #0.15 Cond. 190/2.16 or

min #20 Cond. 190/21.6 #20 Cond. 190/21.6

HDB at 73ºF (23ºC) per Test Method 1250 (8.6) 1600 (11.0)

D2837 and PPI TR-3, psi (MPa)

Minimum HDB at 140ºF (60ºC) per Test 800 (5.5) 800 (5.5)

Method D2837 and PPI TR-3, psi (MPa)

D2513 − 20

NOTE 5—While S4 or FST testing of any combination of outside diameter and SDR is permitted in fulfillment of the requirement for testing PE material

resistance to RCP, S4 testing of SDR 9 or SDR 11 PE pipe specimens is currently the most common industry practice.

NOTE 6—Caution should be exercised in applying the RCP test results obtained on one SDR or DR of pipe across a series of pipe SDR’s or DR’s produced

from the same PE material classification (formulation). Industrial research to clarify the relationships between FST and S4 testing is ongoing at this time,