ASTM D5599-00(2010)

(Test Method)Standard Test Method for Determination of Oxygenates in Gasoline by Gas Chromatography and Oxygen Selective Flame Ionization Detection

Standard Test Method for Determination of Oxygenates in Gasoline by Gas Chromatography and Oxygen Selective Flame Ionization Detection

SIGNIFICANCE AND USE

In gasoline blending, the determination of organic oxygenated compounds is important. Alcohols, ethers, and other oxygenates are added to gasoline to increase the octane number and to reduce tailpipe emissions of carbon monoxide. They must be added in the proper concentration and ratios to meet regulatory limitations and to avoid phase separation and problems with engine performance or efficiency.

This test method provides sufficient oxygen-to-hydro-carbon selectivity and sensitivity to allow determination of oxygenates in gasoline samples without interference from the bulk hydrocarbon matrix.

SCOPE

1.1 This test method covers a gas chromatographic procedure for the quantitative determination of organic oxygenated compounds in gasoline having a final boiling point not greater than 220°C and oxygenates having a boiling point limit of 130°C. It is applicable when oxygenates are present in the 0.1 to 20 % by mass range.

1.2 This test method is intended to determine the mass concentration of each oxygenate compound present in a gasoline. This requires knowledge of the identity of each oxygenate being determined (for calibration purposes). However, the oxygen-selective detector used in this test method exhibits a response that is proportional to the mass of oxygen. It is, therefore, possible to determine the mass concentration of oxygen contributed by any oxygenate compound in the sample, whether or not it is identified. Total oxygen content in a gasoline may be determined from the summation of the accurately determined individual oxygenated compounds. The summed area of other, uncalibrated or unknown oxygenated compounds present, may be converted to a mass concentration of oxygen and summed with the oxygen concentration of the known oxygenated compounds.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5599 − 00(Reapproved 2010)

Standard Test Method for

Determination of Oxygenates in Gasoline by Gas

Chromatography and Oxygen Selective Flame Ionization

Detection

This standard is issued under the fixed designation D5599; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method covers a gas chromatographic proce- 2.1 ASTM Standards:

dure for the quantitative determination of organic oxygenated D1744 Test Method for Determination of Water in Liquid

compounds in gasoline having a final boiling point not greater Petroleum Products by Karl Fischer Reagent

than 220°C and oxygenates having a boiling point limit of D4175 Terminology Relating to Petroleum, Petroleum

130°C. It is applicable when oxygenates are present in the 0.1 Products, and Lubricants

to 20 % by mass range. D4307 Practice for Preparation of Liquid Blends for Use as

Analytical Standards

1.2 This test method is intended to determine the mass

E594 Practice for Testing Flame Ionization Detectors Used

concentration of each oxygenate compound present in a gaso-

in Gas or Supercritical Fluid Chromatography

line.This requires knowledge of the identity of each oxygenate

E1064 Test Method for Water in Organic Liquids by Coulo-

being determined (for calibration purposes). However, the

metric Karl Fischer Titration

oxygen-selective detector used in this test method exhibits a

E1510 Practice for Installing Fused Silica Open Tubular

response that is proportional to the mass of oxygen.Itis,

Capillary Columns in Gas Chromatographs

therefore, possible to determine the mass concentration of

oxygen contributed by any oxygenate compound in the sample,

3. Terminology

whether or not it is identified. Total oxygen content in a

3.1 Definitions:

gasoline may be determined from the summation of the

3.1.1 independent reference standards—calibration samples

accurately determined individual oxygenated compounds. The

of the oxygenates which are purchased or prepared from

summed area of other, uncalibrated or unknown oxygenated

materials independent of the quality control check standards

compounds present, may be converted to a mass concentration

and used for intralaboratory accuracy.

of oxygen and summed with the oxygen concentration of the

3.1.2 oxygenate, n—an oxygen-containing compound, such

known oxygenated compounds.

as an alcohol or ether, which may be used as a fuel or fuel

1.3 The values stated in SI units are to be regarded as

supplement. D4175

standard. No other units of measurement are included in this

3.1.3 quality control check standards—calibration samples

standard.

of the oxygenates for intralaboratory repeatability.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Summary of Test Method

responsibility of the user of this standard to establish appro-

4.1 An internal standard of a noninterfering oxygenate, for

priate safety and health practices and determine the applica-

example, 1,2-dimethoxyethane (ethylene glycol dimethyl

bility of regulatory limitations prior to use.

ether) is added in quantitative proportion to the gasoline

sample. A representative aliquot of the sample and internal

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.04.0L on Gas Chromatography Methods. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2010. Published November 2010. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1994. Last previous edition approved in 2005 as D5599 – 00 (2005). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D5599-00R10. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5599 − 00 (2010)

standard is injected into a gas chromatograph equipped with a tubing containing a nickel-based catalyst. It is installed within

capillary column operated to ensure separation of the oxygen- or before the FID and is operated in the range from 350 to

ates. Hydrocarbons and oxygenates are eluted from the 450°C, depending on the instrument’s manufacturer.

column, but only oxygenates are detected with the oxygen-

NOTE 2—Gasolines with high sulfur content may cause a loss in

selective flame ionization detector (OFID).Adiscussion of this

detector sensitivity thereby limiting the number of samples that can be

detector is presented in Section 6.

analyzed before the catalyst needs replacement.

4.2 Calibration mixtures are used for determining the reten-

7. Apparatus

tion times and relative mass response factors of the oxygenates

of interest. Suggested calibrant materials are listed in 8.2.

7.1 Gas Chromatograph—Any gas chromatograph can be

used having the following performance characteristics:

4.3 The peak area of each oxygenate in the gasoline is

measured relative to the peak area of the internal standard. A 7.1.1 Column Temperature Programmer—The chromato-

graph must be capable of reproducible linear temperature

quadratic least-squares fit of the calibrated data of each

oxygenate is applied and the concentration of each oxygenate programming over a range sufficient for separation of the

calculated. components of interest.

7.1.2 Sample Introduction System—Any system capable of

NOTE 1—While 1,2-dimethoxyethane has been found to be an appro-

introducing a representative 0.1 to 1.0-µL liquid sample into

priate internal standard, other oxygenates may be used provided they are

not present in the sample and do not interfere with any compound of the split inlet device of the gas chromatograph. Microlitre

interest.

syringes, autosamplers, and liquid sampling valves have been

used successfully. The split injector should be capable of

5. Significance and Use

accurate split control in the range from 10:1 to 500:1.

5.1 In gasoline blending, the determination of organic

7.1.3 Carrier and Detector Gas Control—Constant flow

oxygenated compounds is important. Alcohols, ethers, and control of carrier and detector gases is critical to optimum and

other oxygenates are added to gasoline to increase the octane

consistent analytical performance. Control is best provided by

number and to reduce tailpipe emissions of carbon monoxide. the use of pressure regulators and fixed flow restrictors. The

They must be added in the proper concentration and ratios to gas flow rates are measured by any appropriate means. The

meet regulatory limitations and to avoid phase separation and supply pressure of the gas delivered to the gas chromatograph

problems with engine performance or efficiency. must be at least 70 kPa (10 psig) greater than the regulated gas

at the instrument to compensate for the system back pressure.

5.2 This test method provides sufficient oxygen-to-hydro-

In general, a supply pressure of 550 kPa (80 psig) will be

carbon selectivity and sensitivity to allow determination of

satisfactory.

oxygenates in gasoline samples without interference from the

bulk hydrocarbon matrix.

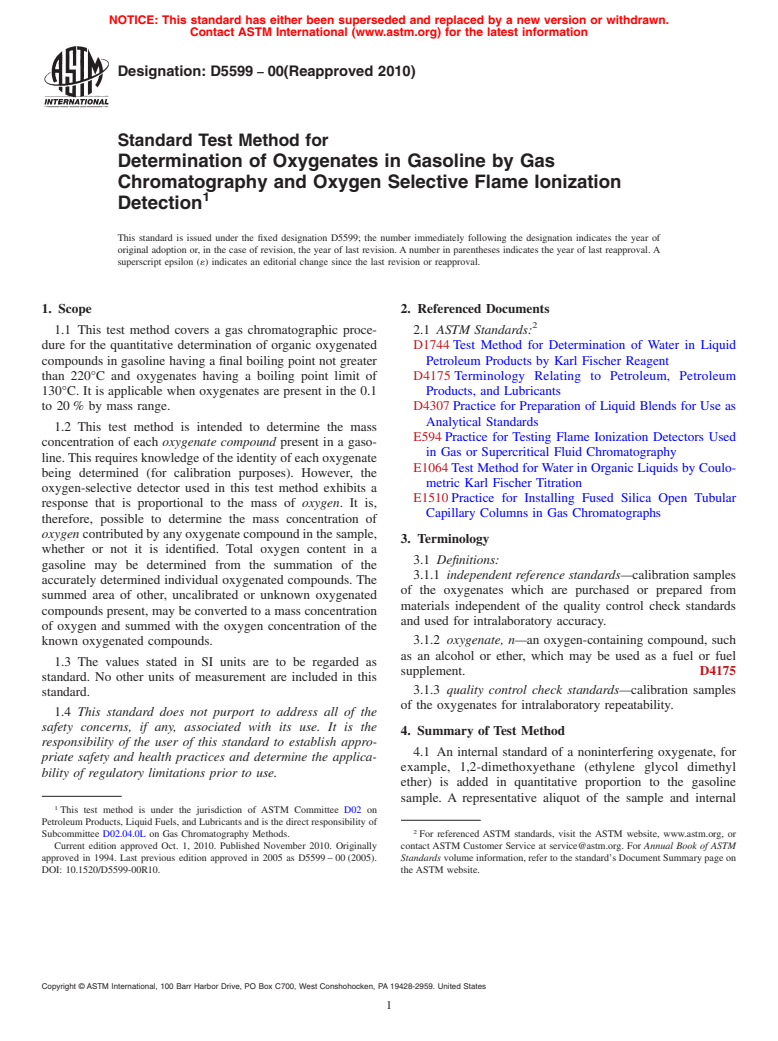

7.2 OFID Detector System, consisting of a cracking reactor,

methanizer, and FID.Aschematic of a typical OFID system is

6. Theory of OFID Operation

shown in Fig. 1.

7.2.1 The detector must meet or exceed the typical specifi-

6.1 The detection system selective for organic oxygen

cationsgiveninTable 1ofPracticeE594whileoperatinginthe

consists of a cracking reactor, hydrogenating reactor

normal FID mode as specified by the manufacturer.

(methanizer), and a flame ionization detector (FID). The

7.2.2 In the OFID mode, the detector shall meet or exceed

cracking reactor, connected immediately after the gas chro-

matographic capillary column, consists of a Pt/Rh capillary the following specifications: (a) equal to or greater than 10

linearity, (b) less than 100-ppm mass oxygen (1-ng O/s)

tube. Carbon monoxide (CO) is formed from compounds

containing oxygen according to the following reaction: sensitivity, ( c) greater than 10 selectivity for oxygen com-

pounds over hydrocarbons, (d) no interference from coeluting

C H O→zCO1 y/2 H 1 x 2 z C (1)

~ ! ~ !

x y z 2

compounds when 0.1 to 1.0-µLsample is injected, (e) equimo-

6.2 An excess layer of carbon is created in the Pt/Rh tube of

lar response for oxygen.

the cracking reactor from the introduction of hydrocarbons

7.3 Column—A 60-m by 0.25-mm inside diameter fused

from the sample or, if so designed, from a hydrocarbon (for

silica open tubular column containing a 1.0-µm film thickness

example,pentaneorhexane)dopingsystem,orboth.Thislayer

of bonded methyl silicone liquid phase is used. Equivalent

of carbon facilitates the cracking reaction and suppresses

columns which provide separation of all oxygenates of interest

hydrocarbon response.

may be used.

6.3 The carbon monoxide formed in the cracking reactor is

7.4 Integrator—Use of an electronic integrating device or

convertedtomethaneinthehydrogenatingreactoraccordingto

computer is required. The device and software should have the

the following reaction:

following capabilities:

CO13H →CH 1H O (2)

2 4 2

7.4.1 Graphic presentation of the chromatogram,

The CH is subsequently detected with an FID. 7.4.2 Digital display of chromatographic peak areas,

7.4.3 Identification of peaks by retention time,

6.4 The methanizer consists either of a short porous layer

7.4.4 Calculation and use of response factors, and

opentubular(PLOT)glasscapillarytubeinternallycoatedwith

aluminum oxide with adsorbed nickel catalyst or stainless steel 7.4.5 Internal standard calculation and data presentation.

D5599 − 00 (2010)

FIG. 1 Schematic of an OFID

8. Reagents and Materials 8.5.3 Helium or nitrogen as column carrier gas, 99.995 mol

% minimum purity, or a blend of 95 % helium/5 % hydrogen,

8.1 Purity of Reagents—Reagents grade chemicals shall be

depending on the instrument’s manufacturer. (Warning—

used in all tests. Unless otherwise indicated, it is intended that

Helium and nitrogen are compressed gases under high pres-

all reagents shall conform to the specifications of the Commit-

sure.)

tee onAnalytical Reagents of theAmerican Chemical Society,

8.5.4 Additional purification of the carrier, air, and hydro-

where such specifications are available. Other grades may be

gen is recommended. Use molecular sieves, Drierite, charcoal,

used, provided it is first ascertained that the reagent is of

or other suitable agents to remove water, oxygen, and hydro-

sufficiently high purity to permit its use without lessening the

carbons from the gases.

accuracy of the determination.

8.6 Sample Container—Glass vials with crimp-on or screw-

8.2 CalibrantMaterials—Thefollowingcompoundsmaybe

down sealing caps with self-sealing polytetrafluoroethylene

used for calibrating the detector: methanol, ethanol,

(PTFE)-faced rubber membranes are used to prepare calibra-

n-propanol, iso-propanol, n-butanol, tert-butanol, sec-butanol,

tion standards and samples for analysis.

iso-butanol, tert-pentanol, methyl tert-butylether (MTBE),

tert-amylmethylether (TAME), ethyl tert-butylether (ETBE),

9. Preparation of Apparatus

di-iso-propylether (DIPE). (Warning—These materials are

9.1 Chromatograph and OFID—Place instrument and de-

very flammable and may be harmful or fatal when ingested,

tector into operation in accordance with the manufacturer’s

inhaled, or allowed to be absorbed through the skin.)

instructions. Install the capillary column according to Practice

8.3 Internal Standard—Use one of the compounds listed in

E1510. Adjust the operating conditions to provide for separa-

8.2thatisnotpresentinthesample.Ifallofthematerialsin8.2

tion of all oxygenates of interest. Typical conditions used with

are likely to be present in the test sample, use another organic

the column specified in 7.3 are listed in Table 1.

oxygenate of high-grade purity that is separated from all other

oxygenates present (for example, 1,2-dimethoxyethane).

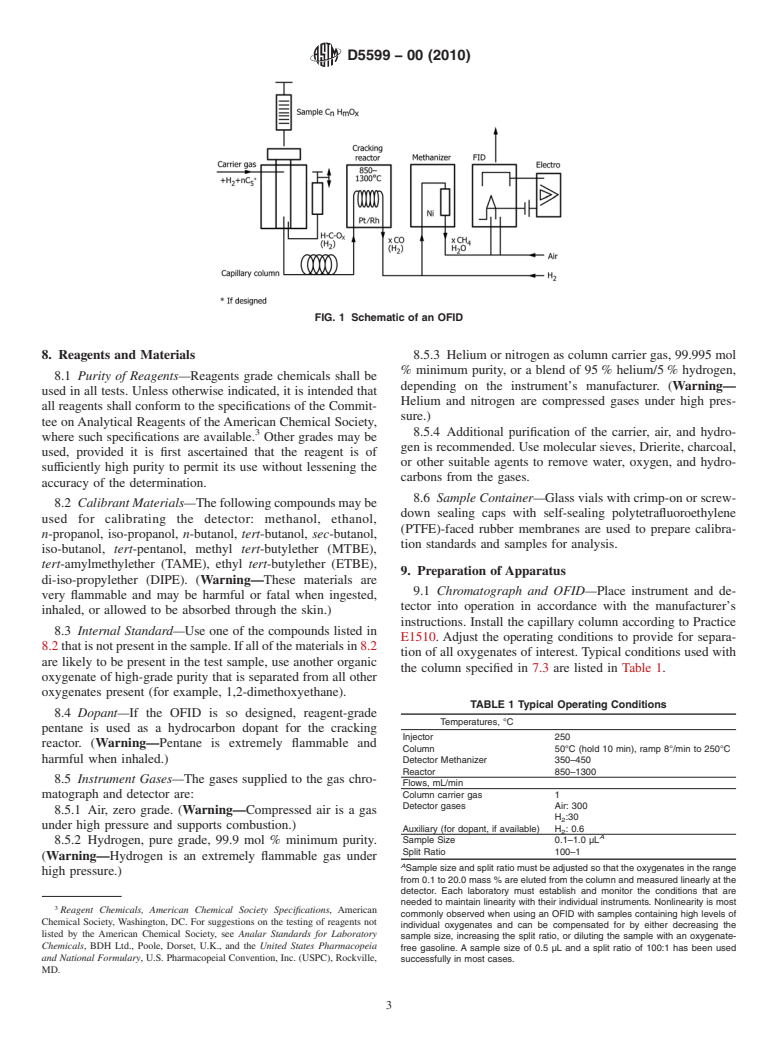

TABLE 1 Typical Operating Conditions

8.4 Dopant—If the OFID is so designed, reagent-grade

Temperatures, °C

pentane is used as a hydrocarbon dopant for the cracking

Injector 250

reactor. (Warning—Pentane is extremely flammable and

Column 50°C (hold 10 min), ramp 8°/min to 250°C

harmful when inhaled.)

Detector Methanizer 350–450

Reactor 850–1300

8.5 Instrument Gases—The gases supplied to the gas chro-

Flows, mL/min

Column carrier gas 1

matograph and detector are:

Detector gases Air: 300

8.5.1 Air, zero grade. (Warning—Compressed air is a gas

H :30

under high pressure and supports combustion.)

Auxiliary (for dopant, if available) H:0.6

A

8.5.2 Hydrogen, pure grade, 99.9 mol % minimum purity. Sample Size 0.1–1.0 µL

Split Ratio 100–1

(Warning—Hydrogen is an extremely flammable gas under

A

Sample size and split ratio must be adjusted so that the oxygenates in the range

high pressure.)

from 0.1 to 20.0 mass % are eluted from the column and measured linearly at the

detector. Each laboratory must establish and monitor the conditions that are

needed to maintain linearity with their individual instruments. Nonlinearity is most

Reagent Chemicals, American Chemical Society Specifications, American

commonly observed when using an OFID with samples containing high levels of

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

individual oxygenates and can be compensated for by either decreasing the

listed by the American Chemical Society, see Analar Standards for Laboratory

sample size, increasing the split ratio, or diluting the sample with an oxygenate-

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

free gasoline. A sample size of 0.5 µL and a split ratio of 100:1 has been used

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

successfully in most cases.

MD.

D5599 − 00 (2010)

9.2 System Performance—At the beginning of each day of

operation, inject an oxygenate-free gasoline sample into the

chromatograph to ensure minimum hydrocarbon response. If

hydrocarbon response is detected, the OFID is not operating

effectively and must be optimized according to the manufac-

turer’s instructions before the sample can be analyzed.

10. Calibration and Standardization

10.1 Retention Time Identification— Determine the reten-

tion time of each oxygenate component by injecting small

am

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.