ASTM D7753-12(2020)

(Test Method)Standard Test Method for Hydrocarbon Types and Benzene in Light Petroleum Distillates by Gas Chromatography

Standard Test Method for Hydrocarbon Types and Benzene in Light Petroleum Distillates by Gas Chromatography

SIGNIFICANCE AND USE

5.1 Knowledge of the olefinic, aromatic, and benzene content is very important in quality specifications of petroleum products, such as spark ignition fuels (gasoline) and hydrocarbon solvents. Fast and accurate determination of hydrocarbon types and benzene of petroleum distillates and products is also important in optimization of process units.

5.2 This test method provides a fast standard procedure for determination of hydrocarbon types and benzene in light oxygenate-free petroleum distillates and products.

SCOPE

1.1 This test method covers and provides for the quantitative determination of total saturates, total olefins, total aromatics and benzene in light petroleum distillates having a final boiling point below 215 °C by multidimensional gas chromatography. Each hydrocarbon grouping as well as benzene can be reported in both volume and mass percent.

1.2 This test method is applicable to light petroleum distillates such as oxygenate-free motor gasoline or spark ignition fuels, naphthas and hydrocarbon solvents over the content ranges from 1 % (V/V) to 70 % (V/V) total olefins, 1 % (V/V) to 80 % (V/V) total aromatics and 0.2 % to 10 % (V/V) benzene. This test method may apply to concentrations outside these ranges, but the precision has not been determined. Interlaboratory testing for precision used full range blending streams, such as FCC, reformates and spark ignition fuel or blended motor gasolines.

1.3 This test method is not intended to determine oxygenated components. Light petroleum distillate products such as motor gasoline may contain oxygenates. Oxygenates such as methyl tert-butyl ether (MTBE), tert-amyl methyl ether (TAME), ethyl tert-butyl ether (ETBE), ethanol and methanol etc. will coelute with specific hydrocarbon groups. If there is any suspicion the sample contains oxygenates, the absence of oxygenates should be confirmed by other standard test methods such as Test Methods D4815, D5599, or D6839 before using this test method.

1.4 This test method is not applicable for the determination of individual hydrocarbon components with the exception of benzene. Test Method D6733 may be used to determine a large number of individual hydrocarbons to complement this test method.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7753 − 12 (Reapproved 2020)

Standard Test Method for

Hydrocarbon Types and Benzene in Light Petroleum

Distillates by Gas Chromatography

This standard is issued under the fixed designation D7753; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method covers and provides for the quantita-

responsibility of the user of this standard to establish appro-

tive determination of total saturates, total olefins, total aromat-

priate safety, health, and environmental practices and deter-

ics and benzene in light petroleum distillates having a final

mine the applicability of regulatory limitations prior to use.

boiling point below 215 °C by multidimensional gas chroma-

1.7 This international standard was developed in accor-

tography. Each hydrocarbon grouping as well as benzene can

dance with internationally recognized principles on standard-

be reported in both volume and mass percent.

ization established in the Decision on Principles for the

1.2 This test method is applicable to light petroleum distil-

Development of International Standards, Guides and Recom-

lates such as oxygenate-free motor gasoline or spark ignition

mendations issued by the World Trade Organization Technical

fuels, naphthas and hydrocarbon solvents over the content

Barriers to Trade (TBT) Committee.

ranges from 1 % (V/V) to 70 % (V/V) total olefins, 1 % (V⁄V)

2. Referenced Documents

to 80 % (V/V) total aromatics and 0.2 % to 10 % (V⁄V)

benzene. This test method may apply to concentrations outside

2.1 ASTM Standards:

these ranges, but the precision has not been determined.

D4815 Test Method for Determination of MTBE, ETBE,

Interlaboratory testing for precision used full range blending

TAME, DIPE, tertiary-Amyl Alcohol and C to C Alco-

1 4

streams, such as FCC, reformates and spark ignition fuel or

hols in Gasoline by Gas Chromatography

blended motor gasolines.

D5599 Test Method for Determination of Oxygenates in

Gasoline by Gas Chromatography and Oxygen Selective

1.3 This test method is not intended to determine oxygen-

Flame Ionization Detection

ated components. Light petroleum distillate products such as

D6733 Test Method for Determination of Individual Com-

motor gasoline may contain oxygenates. Oxygenates such as

ponents in Spark Ignition Engine Fuels by 50-Metre

methyl tert-butyl ether (MTBE), tert-amyl methyl ether

Capillary High Resolution Gas Chromatography

(TAME), ethyl tert-butyl ether (ETBE), ethanol and methanol

D6839 Test Method for Hydrocarbon Types, Oxygenated

etc. will coelute with specific hydrocarbon groups. If there is

Compounds, and Benzene in Spark Ignition Engine Fuels

any suspicion the sample contains oxygenates, the absence of

by Gas Chromatography

oxygenatesshouldbeconfirmedbyotherstandardtestmethods

such as Test Methods D4815, D5599,or D6839 before using

3. Terminology

this test method.

3.1 Definitions of Terms Specific to This Standard:

1.4 This test method is not applicable for the determination

3.1.1 aromatics, n—mass or volume % of monocyclic

of individual hydrocarbon components with the exception of

aromatics and polycyclic aromatics (for example,

benzene.Test Method D6733 may be used to determine a large

+

naphthalenes), aromatic olefins and C cyclodienes com-

number of individual hydrocarbons to complement this test

pounds.

method.

+

3.1.2 C aromatics, n—mass or volume % of all other

1.5 The values stated in SI units are to be regarded as

aromatics compounds (see 3.1.1) in sample not including

standard. No other units of measurement are included in this

benzene.

standard.

3.1.3 olefins, n—mass or volume % of alkenes, plus cy-

cloalkenes and some di-olefins.

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.04.0L on Gas Chromatography Methods. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2020. Published December 2020. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2012. Last previous edition approved in 2016 as D7753 – 12 (2016). Standards volume information, refer to the standard’s Document Summary page on

DOI:10.1520/D7753-12R20. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7753 − 12 (2020)

3.1.4 olefins trap, n—specific column utilized to selectively 6. Interferences

retain olefins from mixture of olefins and saturates. The trap +

6.1 C aliphatic hydrocarbon compounds (not including

must have good reversibility to capture and release olefins by

C ) may not be fully separated from benzene in the polar

changing the temperature.

column, thus the determination of aromatics and benzene may

3.2 Acronyms: be affected.

3.2.1 BCEF-N,N-bis(α-cyanoethyl) formamide—gas chro-

6.2 Different types of oxygenated compounds in some

matography stationary phase.

petroleumproductswillelutewithspecifichydrocarbongroups

and interfere with the analysis of the hydrocarbons.

4. Summary of Test Method

6.3 Commercial detergent, antioxidant, antiknock additives

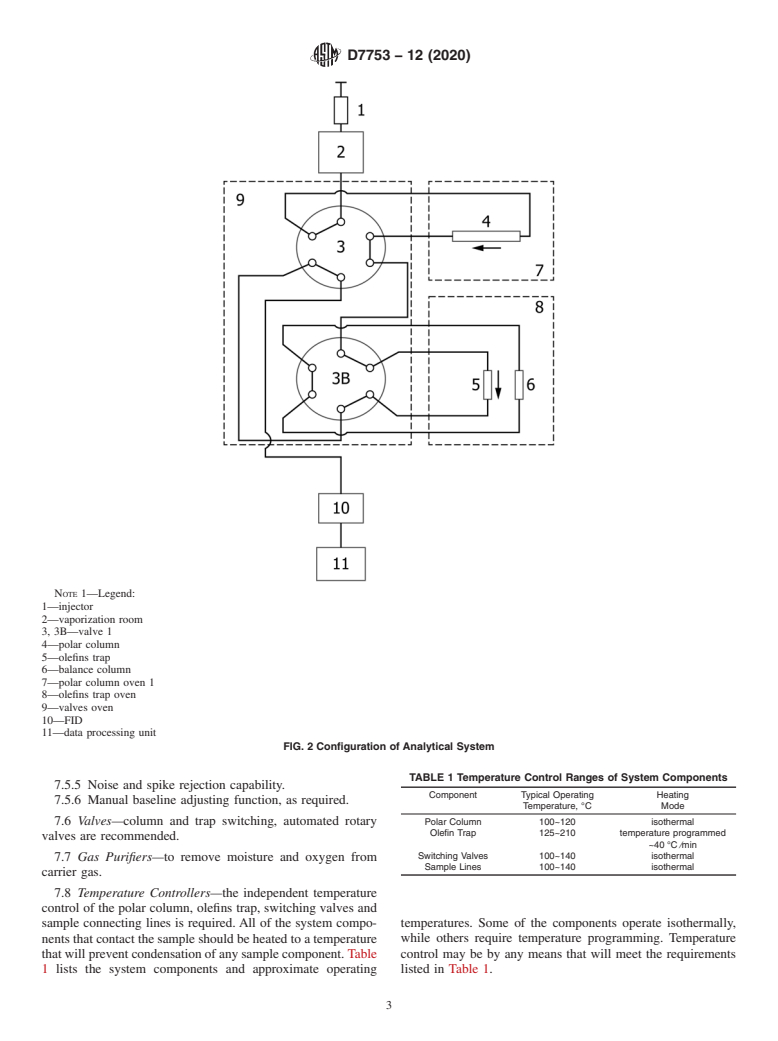

4.1 Fig. 1 shows a separation scheme of the various hydro-

and dyes utilized in some petroleum products have been found

carbon types and benzene analysis. The instrumental configu-

not to interfere with this test method.

ration is shown in Fig. 2. The valves are actuated at predeter-

6.4 Dissolved water in samples has been found not to

mined times to direct different components to different

interfere with this test method.

columns.As the analysis proceeds, different hydrocarbon types

and benzene elute and are detected by a flame ionization

7. Apparatus

detector (FID).

7.1 The analysis system is comprised of a gas chromato-

4.2 The mass concentration of different hydrocarbon types

graph with manual or automated sample injection, and specific

and benzene are determined by the application of average

hardware modifications. These modifications include columns,

relative response factors to the areas of the detected peaks

olefins trap, valves, and temperature controllers.

followed by normalization to 100 %.

7.2 Gas Chromatograph—capable of temperature pro-

4.3 The volume percent concentration of different hydrocar-

grammed operation at specified temperature, equipped with a

bon types and benzene can be determined by the application of

vaporization inlet that can be a packed column inlet, a flame

average density factors to the calculated mass concentration of

ionization detector (FID), and necessary flow controllers.

the detected peaks followed by normalization to 100 %.

7.3 Sample Introduction System—manual or automatic

4.4 This test method is not intended to determine com-

injector, capable of injecting a 0.1 µL volume of sample.

pounds that contain oxygenates, such as ethanol, etc. Such

Automated injector is recommended.

oxygenates interfere with the analysis of the hydrocarbons.

7.4 Gas Flow or Pressure Controllers—with adequate pre-

4.5 Analysis time of a sample is approximately 15 min.

cision to provide reproducible flow rate of carrier gas to the

chromatographic system, hydrogen and air for the flame

5. Significance and Use

ionization detector. Control of air pressure for automated

5.1 Knowledge of the olefinic, aromatic, and benzene con- valves operation is required.

tent is very important in quality specifications of petroleum

7.5 Data Acquisition System—chromatographic workstation

products, such as spark ignition fuels (gasoline) and hydrocar-

shall meet the following specifications:

bon solvents. Fast and accurate determination of hydrocarbon

7.5.1 Sampling rate of at least 10 points per second.

types and benzene of petroleum distillates and products is also

7.5.2 Capacity for 100 peaks for each analysis.

important in optimization of process units.

7.5.3 Normalized areas percent calculation with response

5.2 This test method provides a fast standard procedure for factors.

determination of hydrocarbon types and benzene in light 7.5.4 Area summation of peaks that are split or of groups of

oxygenate-free petroleum distillates and products. components that elute at specific retention times.

FIG. 1 Separation Scheme of Hydrocarbon Types and Benzene Analysis

D7753 − 12 (2020)

NOTE 1—Legend:

1—injector

2—vaporization room

3, 3B—valve 1

4—polar column

5—olefins trap

6—balance column

7—polar column oven 1

8—olefins trap oven

9—valves oven

10—FID

11—data processing unit

FIG. 2 Configuration of Analytical System

TABLE 1 Temperature Control Ranges of System Components

7.5.5 Noise and spike rejection capability.

Component Typical Operating Heating

7.5.6 Manual baseline adjusting function, as required.

Temperature, °C Mode

7.6 Valves—column and trap switching, automated rotary Polar Column 100~120 isothermal

Olefin Trap 125~210 temperature programmed

valves are recommended.

~40 °C ⁄min

Switching Valves 100~140 isothermal

7.7 Gas Purifiers—to remove moisture and oxygen from

Sample Lines 100~140 isothermal

carrier gas.

7.8 Temperature Controllers—the independent temperature

control of the polar column, olefins trap, switching valves and

sample connecting lines is required. All of the system compo- temperatures. Some of the components operate isothermally,

nents that contact the sample should be heated to a temperature while others require temperature programming. Temperature

thatwillpreventcondensationofanysamplecomponent.Table control may be by any means that will meet the requirements

1 lists the system components and approximate operating listed in Table 1.

D7753 − 12 (2020)

8. Reagents and Materials t /t 5 1.59

benzene undecene

R /t 5 2.4

benzene undecene

8.1 Gases:

t /t 5 1.31

toluene benzene

8.1.1 Carrier Gas—Nitrogen or Helium. ILS precision of

R /t 5 1.25

toluene benzene

this test method was obtained using nitrogen as the carrier gas.

NOTE 1—

Better than 99.999 % pure. (Warning—Compressed gases

under high pressure.) Gas purifiers may be used to attain the

2~t 2 t ! ~t 2 t !

R2 R1 R2 R1

R 5 5˜

S

required purity or to ensure a stable signal baseline.

W 1W W

b2 b1 b1

8.1.2 Hydrogen—Better than 99.999 % pure. (Warning— where: t >t

R2 R1

Extremely flammable gas under high pressure.) Gas purifiers

8.2.2 Olefin Trap—The olefin trap shall have excellent

may be used to attain the required purity or to ensure a stable

reversibilityperformance.Atalowertemperature,forexample,

signal baseline.

130 °C, the trap shall retain the olefins in the sample and pass

8.1.3 Air, Compressed—<10 mg⁄kg each of total hydrocar-

all saturates before benzene elutes from the polar column.At a

bons and H O. (Warning—Compressed gas under high pres-

higher temperature, for example, 210 °C, the trap shall quan-

sure that supports combustion.) Gas purifiers may be used to

titatively release the retained olefins. The adsorbent of olefins

attain the required purity or to ensure a stable signal baseline.

usually is a silver ion based material. Any olefin trap which

8.2 Columns and Traps—This test method requires the use

satisfies the performance requirements can be used. The

of a polar column and a reversible olefin trap. The following

performance of the trap can be verified first with the system

containsguidelinesthataretobeusedtojudgecolumnandtrap

validation test sample (10.2) and, once established, can be

suitability. The guidelines describe temperatures as used in the

monitored either with the validation test sample or actual

current system. Alternatives can be used provided that the

production or consensus reference quality sample.

separation requirement as described is obtained.

8.2.1 Polar Column—At an optimal operating temperature,

8.3 System Gravimetric Validation Test Sample—

the column should meet the baseline separation between

Quantitative mixtures of pure hydrocarbons are used to verify

benzene and aliphatic components up to undecene; between

the operating temperature, valve switching times and valida-

toluene and benzene. The system validation test sample can be

tion of the system analysis accuracy. The validation sample

used to check the polar column separation performance. The

composition and approximate component concentrations are

retention time ratio of undecene and benzene (t /t )

benzene undecene shown in Table 2.

shall be larger than 1.5, the resolution shall be >2.0. The

8.4 Quality Control Samples—Production or consensus

retention time ratio of benzene and toluene (t /t )

toluene benzene

samples, or both, used to routinely monitor validation of

shall be larger than 1.25, the resolution shall be >1.1 (see Note

analysis system. Any production or interlaboratory or certified

1). A BCEF column which is 25 % BCEF coated on acid

reference sample which approximates similar compositions to

washing diatomite supporter is recommended as the polar

the samples to be analyzed may be designated as the quality

column. The length of the polar column is approximately 5 m

control sample. Quality control samples shall be selected such

and the inside diameter is approximately 2 mm. Other columns

which meet the separation requirements can be used. Fig. 3 is thattheyfallwithintherangeandcompositionofsamplestobe

a polar column separation performance check chromatogram analyzed. The quality control samples shall be stable for a

with system validation test sample. specified period of use and storage conditions. It is preferred

FIG. 3 Polar Column Separation Performance Check Chromatogram

D7753 − 12 (2020)

TABLE 2 System Validation Test Sample TABLE 4 Chromatographic Operating Conditions

Type Component Approximate Concentration, Condition Parameter

Mass %

Vaporization temperature, °C 200

Saturates Pentane 5.0 Polar column temperature, °C 110

Hexane 4.5 Olefins trapped temperature, °C .

Cyclohexane 4.0 Olefins desorption temperature, °C 200~220

Heptane 4.5 Column Switching valves 100-140

Methylcyclohexane 4.0 Sample lines 100-140

Octane 4.0 Carrier gas flow rate, mL/min 25~30

2,2,4-Trimethylpetane 6.0 (Nitrogen or helium)

Dimethylcyclohexane 3.0 Detector gas flow rate, mL/min

Nonane 3.0 Air 350~450

Decane

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.