ASTM E2008-08

(Test Method)Standard Test Method for Volatility Rate by Thermogravimetry

Standard Test Method for Volatility Rate by Thermogravimetry

SIGNIFICANCE AND USE

p>Process Capability—Process capability can be defined as the natural or inherent behavior of a stable process that is in a state of statistical control (1). A “state of statistical control” is achieved when the process exhibits no detectable patterns or trends, such that the variation seen in the data is believed to be random and inherent to the process. Process capability is linked to the use of control charts and the state of statistical control. A process must be studied to evaluate its state of control before evaluating process capability.

Process Control—There are many ways to implement control charts, but the most popular choice is to achieve a state of statistical control for the process under study. Special causes are identified by a set of rules based on probability theory. The process is investigated whenever the chart signals the occurrence of special causes. Taking appropriate actions to eliminate identified special causes and preventing their reappearance will ultimately obtain a state of statistical control. In this state, a minimum level of variation may be reached, which is referred to as common cause or inherent variation. For the purpose of this standard, this variation is a measure of the uniformity of process output, typically a product characteristic.

Process Capability Indices—The behavior of a process (as related to inherent variability) in the state of statistical control is used to describe its capability. To compare a process with customer requirements (or specifications), it is common practice to think of capability in terms of the proportion of the process output that is within product specifications or tolerances. The metric of this proportion is the percentage of the process spread used up by the specification. This comparison becomes the essence of all process capability measures. The manner in which these measures are calculated defines the different types of capability indices and their use. Two process capability indices are de...

SCOPE

1.1 This practice provides guidance for the use of capability indices for evaluating process capability and performance. Process capability indices compare the variability of a process quality measure against product specifications or tolerances and assume the process is in a state of statistical control. Process performance indices are useful in situations when the process is not in a state of statistical control.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2008 − 08

StandardTest Method for

1

Volatility Rate by Thermogravimetry

This standard is issued under the fixed designation E2008; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 This test method covers procedures for assessing the

E1142 Terminology Relating to Thermophysical Properties

volatility of solids and liquids at given temperatures using

E1582 Practice for Calibration of Temperature Scale for

thermogravimetry under prescribed experimental conditions.

Thermogravimetry

Results of this test method are obtained as volatility rates

E1860 Test Method for Elapsed Time Calibration of Ther-

expressed as mass per unit time. Rates ≥ 5 µg/min are

mal Analyzers

achievable with this test method.

E2040 Test Method for Mass Scale Calibration of Thermo-

1.2 Temperatures typical for this test method are within the

gravimetric Analyzers

range from 25 °C to 500 °C.This temperature range may differ

depending upon the instrumentation used. 3. Terminology

1.3 This test method is intended to provide a value for the 3.1 Definitions:

volatility rate of a sample using a thermogravimetric analysis 3.1.1 The following terms are applicable to this test method

measurement on a single representative specimen. It is the and can be found in Terminologies E473 and E1142:

responsibility of the user of this test method to determine the 3.1.1.1 thermogravimetric analysis (TGA),

need for and the number of repetitive measurements on fresh 3.1.1.2 thermogravimetry (TG),

specimens necessary to satisfy end use requirements. 3.1.1.3 volatility.

1.4 The values stated in SI units are to be regarded as 3.2 Definitions of Terms Specific to This Standard:

standard. No other units of measurement are included in this 3.2.1 volatility rate—the rate of conversion of a solid or

standard. liquid substance into the vapor state at a given temperature;

mass per unit time.

1.5 There is no ISO method equivalent to this standard.

1.6 This standard does not purport to address all of the

4. Summary of Test Method

safety concerns, if any, associated with its use. It is the

4.1 Asolid or liquid specimen is confined in an appropriate

responsibility of the user of this test method to establish

container with a pinhole opening between 0.33 and 0.38 mm.

appropriate safety and health practices and determine the

The confined specimen is heated within a thermogravimetric

applicability of regulatory limitations prior to use.

analyzer either to a temperature and held constant at that

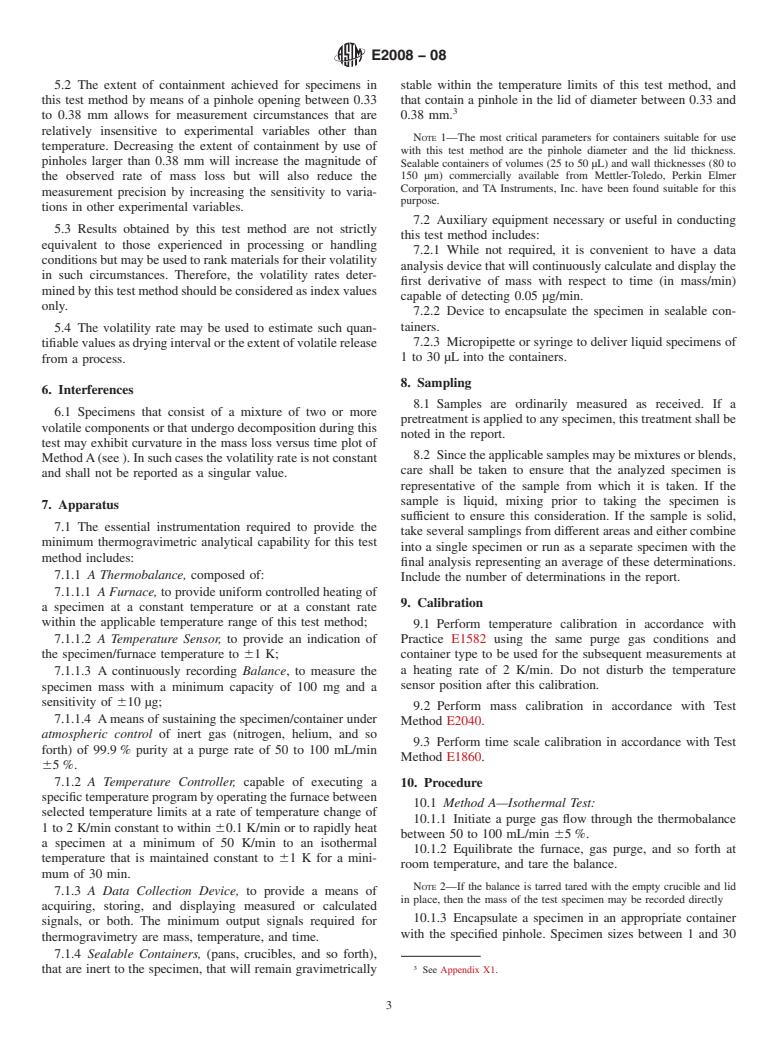

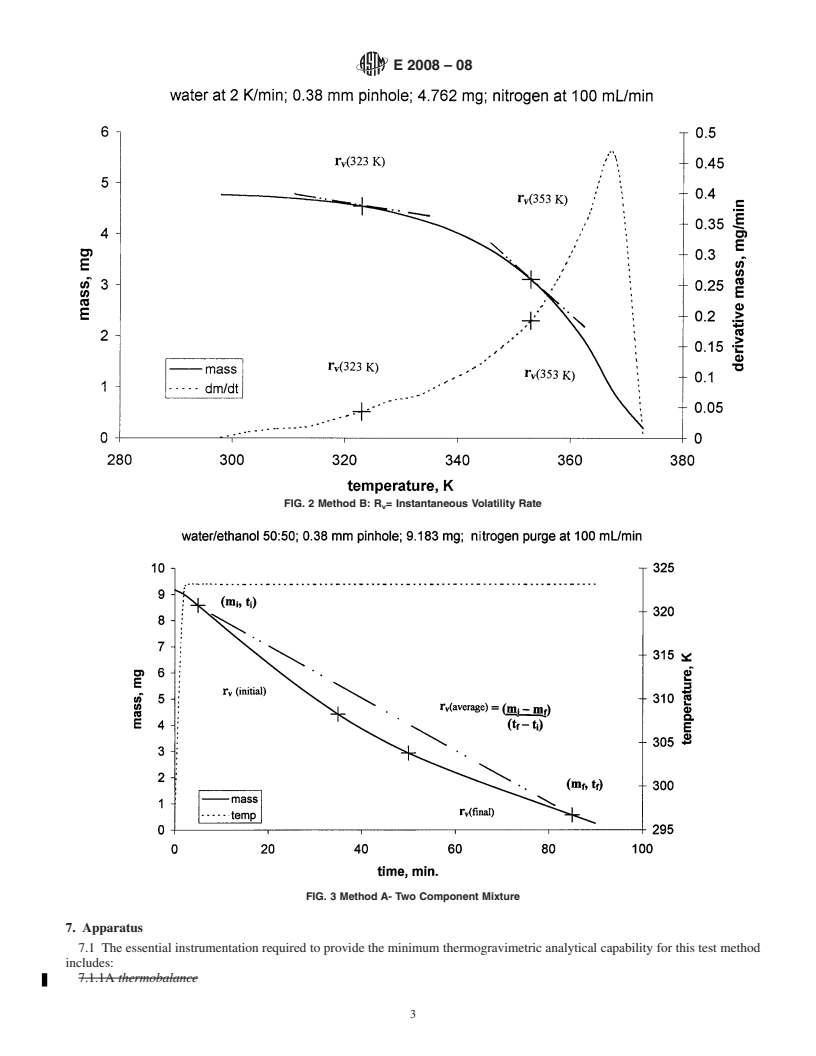

temperature for a fixed interval of time (Method A, Fig. 1)or

2. Referenced Documents

at a slow constant heating rate between temperature limits

2

2.1 ASTM Standards:

(Method B, Fig. 2). The mass of the specimen is measured

E177 Practice for Use of the Terms Precision and Bias in

continuously and it or its rate of change is displayed as a

ASTM Test Methods

function of time or temperature. The volatility rate at any

E473 Terminology Relating to Thermal Analysis and Rhe-

temperature is reported either as the average rate of mass loss

ology

per unit time from Method A or as the instantaneous rate of

mass loss (first derivative) per unit time from Method B.

1

5. Significance and Use

ThistestmethodisunderthejurisdictionofASTMCommitteeE37onThermal

Measurements and is the direct responsibility of Subcommittee E37.01 on Calo-

5.1 Volatility of a material is not an equilibrium thermody-

rimetry and Mass Loss.

namic property but is a characteristic of a material related to a

Current edition approved Sept. 1, 2008. Published October 2008. Originally

approved in 1999. Last previous edition approved in 2007 as E2008 – 07. DOI:

thermodynamic property that is vapor pressure. It is influenced

10.1520/E2008-08.

by such factors as surface area, temperature, particle size, and

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

purge gas flow rate; that is, it is diffusion controlled.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standardsvolume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2008 − 08

FIG. 1 Method A: R = Average Volatility Rate

v

FIG. 2 Method B: R = Instantaneous Volatility Rate

v

2

---------------------- Page: 2 ----------------------

E2008 − 08

5.2 The extent of containment achieved for specimens in stable w

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E2008–07 Designation:E2008–08

Standard Test Method for

1

Volatility Rate by Thermogravimetry

This standard is issued under the fixed designation E 2008; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers procedures for assessing the volatility of solids and liquids at given temperatures using

thermogravimetry under prescribed experimental conditions. Results of this test method are obtained as volatility rates expressed

as mass per unit time. Rates$ 5 µg/min are achievable with this test method.

1.2 Temperatures typical for this test method are within the range from 25 °C to 500 °C. This temperature range may differ

depending upon the instrumentation used.

1.3 This test method is intended to provide a value for the volatility rate of a sample using a thermogravimetric analysis

measurement on a single representative specimen. It is the responsibility of the user of this test method to determine the need for

and the number of repetitive measurements on fresh specimens necessary to satisfy end use requirements.

1.4Computer- or electronic-based instruments, techniques, or data treatment equivalent to this test method may also be used.

NOTE1—Users of this test method are expressly advised that all such instruments or techniques may not be equivalent. It is the responsibility of the

user of this test method to determine the necessary equivalency prior to use.

1.5SI units are the standard.

1.6There is no ISO method equivalent to this standard.

1.7

1.4 SI units are the standard.

1.5 There is no ISO method equivalent to this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this test method to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E 177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E 473 Terminology Relating to Thermal Analysis and Rheology

E 691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E 1142 Terminology Relating to Thermophysical Properties

E 1582 Practice for Calibration of Temperature Scale for Thermogravimetry

E 1860 Test Method for Elapsed Time Calibration of Thermal Analyzers

E 2040 Test Method for Mass Scale Calibration of Thermogravimetric Analyzers

3. Terminology

3.1 Definitions:

3.1.1 The following terms are applicable to this test method and can be found in Terminologies E 473 and E 1142:

3.1.1.1 thermogravimetric analysis (TGA),

3.1.1.2 thermogravimetry (TG),

3.1.1.3 volatility.

3.2 Definitions of Terms Specific to This Standard:

1

This test method is under the jurisdiction ofASTM Committee E37 on Thermal Measurements and is the direct responsibility of Subcommittee E37.01 on Thermal Test

Methods and Practices.

Current edition approved MarchSept. 1, 20072008 Published June 2007.October 2008. Originally approved in 1999. Last previous edition approved in 20062007 as

E 2008 – 067.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standardsvolume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E2008–08

3.2.1 volatility rate—the rate of conversion of a solid or liquid substance into the vapor state at a given temperature; mass per

unit time.

4. Summary of Test Method

4.1 Asolid or liquid specimen is confined in an appropriate container with a pinhole opening between 0.33 and 0.38 mm. The

confined specimen is heated within a thermogravimetric analyzer either to a temperature and held constant at that temperature for

a fixed interval of time (MethodA, Fig. 1) or at a slow constant heating rate between temperature limits (Method B, Fig. 2). The

mass of the specimen is measured continuously and it or its rate of change is displayed as a function of time or temperature. The

volatility rate at any temperature is reported either as the average rate of mass loss per unit time from Metho

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.