ASTM D3412-01

(Test Method)Standard Test Method for Coefficient of Friction, Yarn to Yarn

Standard Test Method for Coefficient of Friction, Yarn to Yarn

SCOPE

1.1 This test method covers the measurement of frictional properties for both continuous filament and spun-staple yarns under boundary friction conditions.

1.2 This test method has been used with yarns having linear densities ranging from 1.5 to 200 tex, but may be used with yarns outside these ranges (15 to 1800 denier).

Note 1--For coefficient of friction, yarn to metal, see Test Method D3108.

1.3 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3412–01

Standard Test Method for

1

Coefficient of Friction, Yarn to Yarn

This standard is issued under the fixed designation D 3412; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 coeffıcient of friction, n—the ratio of the tangential

force that is needed to maintain uniform relative motion

1.1 This test method covers the measurement of frictional

between two contacting surfaces to the perpendicular force

properties for both continuous filament and spun-staple yarns

holding them in contact.

under boundary friction conditions.

3.1.3 friction, n—theresistancetotherelativemotionofone

1.2 This test method has been used with yarns having linear

body sliding, rolling, or flowing over another body with which

densities ranging from 1.5 to 200 tex, but may be used with

it is in contact.

yarns outside these ranges (15 to 1800 denier).

3.1.4 radian, n—the plane angle between two radii of a

NOTE 1—For coefficient of friction, yarn to metal, see Test Method

circle which intersects the circumference of the circle making

D 3108.

an arc equal in length to the radius.

1.3 The values stated in SI units are to be regarded as the

3.1.4.1 Discussion—Aradian is equal to 180° divided by p

standard. The inch-pound units given in parentheses are for

and is approximately 57.3°.

information only.

3.1.5 stick-slip, n—a phenomenon occurring when bound-

1.4 This standard does not purport to address all of the

arylubricationisdeficient,manifestedbyalternativeperiodsof

safety concerns, if any, associated with its use. It is the

sticking and slipping of the surfaces in contact.

responsibility of the user of this standard to establish appro-

3.1.5.1 Discussion—At the specified sliding speed, in yarn

priate safety and health practices and determine the applica-

friction testing, stick-slip cycles are long enough that they can

bility of regulatory limitations prior to use.

bereadilyrecorded.Duringsticking,thefrictionalforceslowly

rises to a peak value, at which the slipping occurs with the

2. Referenced Documents

frictional force rapidly decreasing to a minimum value.

2

2.1 ASTM Standards:

3.1.6 wrap angle, n—in yarn friction testing,thecumulative

D 123 Terminology Relating to Textiles

angular contact of the test specimen against the friction-

D 1776 Practice for Conditioning and Testing Textiles

inducing device, expressed in radians.

D 1907 Test Method for Linear Density of Yarn (Yarn

3.1.7 For definitions of other textile terms used in this

Number)by the Skein Method

method, refer to Terminology D 123.

D 2258 Practice for Sampling Yarn for Testing

4. Summary of Test Method

D 3108 Test Method for Coefficient of Friction, Yarn to

Metal

4.1 A length of yarn is moved at a known speed in contact

with itself or similar yarn at a specified wrap angle. The input

3. Terminology

and output tensions are measured and the coefficient of friction

3.1 Definitions:

calculated. Alternatively, apparatus may be used in which the

3.1.1 boundary friction, n—friction at low sliding speeds

ratio of input to output tension is measured allowing the

(0.02 m/min or less) where lubrication occurs under thin-film

coefficient of friction to be indicated directly.

lubricant conditions.

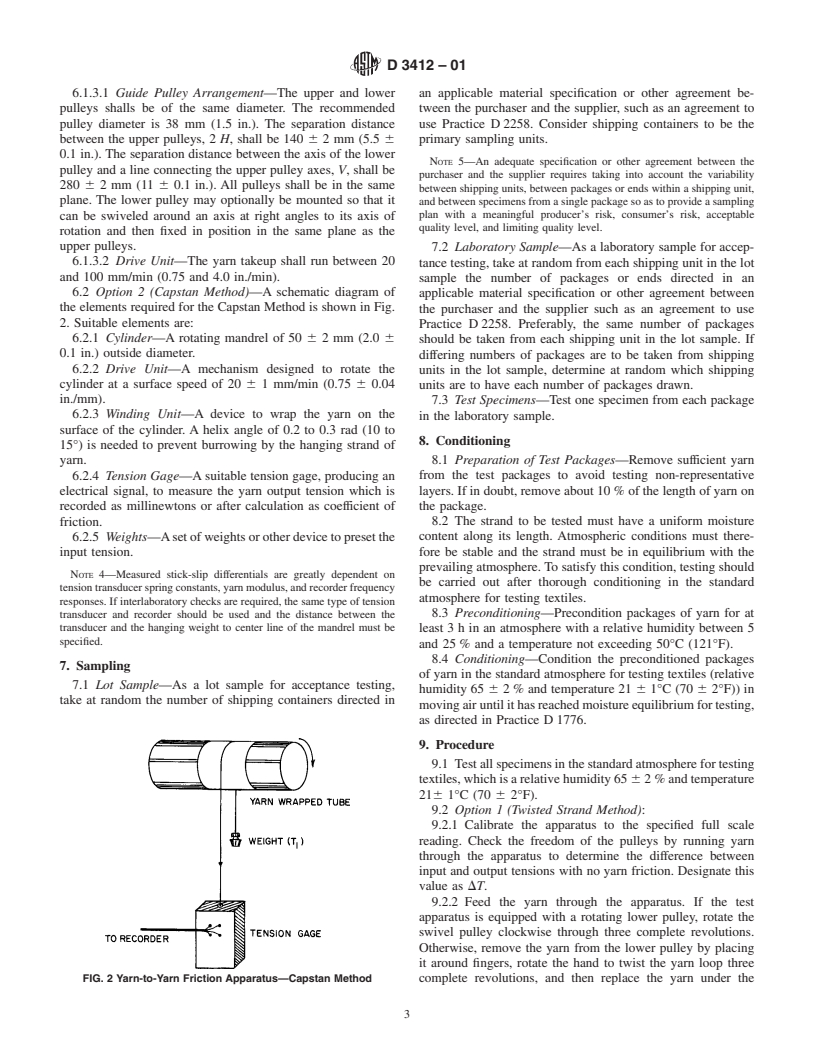

4.2 Two optional procedures are included. Option 1 is based

on theTwisted Strand Method, using a wrap angle of 15.71 rad

(900°). Option 2 is based on the Capstan Method, using a wrap

1

This test method is under the jurisdiction ofASTM Committee D13 onTextiles

angle of 3.14 radians (180°).

and is the direct responsibility of Subcommittee D 13.58 on Yarn Test Methods,

General.

NOTE 2—Editions of Test Method D 3412 prior to the 1986 revision

Current edition approved April 10, 2001. Published June 2001. Originally

incorrectly stated the wrap angle for Option 1 to be 18.85 rad. This is

published as D 3412 – 75T. Last previous edition D 3412 – 95.

2 incorrect, since 3 turns of the swivel pulley do not result in a wrap angle

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

of18.85radians.Thishasnowbeencorrectedto15.71rad.Thisshouldbe

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

taken into account in comparing with earlier results.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3412–01

5. Significance and Use a controlled tension. The number of intertwisting wraps, the

apex angle between the i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.