ASTM D3412-95

(Test Method)Standard Test Method for Coefficient of Friction, Yarn to Yarn

Standard Test Method for Coefficient of Friction, Yarn to Yarn

SCOPE

1.1 This test method covers the measurement of frictional properties for both continuous filament and spun-staple yarns under boundary friction conditions.

1.2 This test method has been used with yarns having linear densities ranging from 1.5 to 200 tex, but may be used with yarns outside these ranges (15 to 1800 denier).

Note 1--For coefficient of friction, yarn to metal, see Test Method D3108.

1.3 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 3412 – 95

Standard Test Method for

Coefficient of Friction, Yarn to Yarn

This standard is issued under the fixed designation D 3412; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope body sliding, rolling, or flowing over another body with which

it is in contact.

1.1 This test method covers the measurement of frictional

3.1.4 radian, n—the plane angle between two radii of a

properties for both continuous filament and spun-staple yarns

circle which intersects the circumference of the circle making

under boundary friction conditions.

an arc equal in length to the radius.

1.2 This test method has been used with yarns having linear

3.1.4.1 Discussion—A radian is equal to 180° divided by p

densities ranging from 1.5 to 200 tex, but may be used with

and is approximately 57.3°.

yarns outside these ranges (15 to 1800 denier).

3.1.5 stick-slip, n—a phenomenon occurring when bound-

NOTE 1—For coefficient of friction, yarn to metal, see Test Method

ary lubrication is deficient, manifested by alternative periods of

D 3108.

sticking and slipping of the surfaces in contact.

1.3 The values stated in SI units are to be regarded as the

3.1.5.1 Discussion—At the specified sliding speed, in yarn

standard. The inch-pound units given in parentheses are for

friction testing, stick-slip cycles are long enough that they can

information only.

be readily recorded. During sticking, the frictional force slowly

1.4 This standard does not purport to address all of the

rises to a peak value, at which the slipping occurs with the

safety concerns, if any, associated with its use. It is the

frictional force rapidly decreasing to a minimum value.

responsibility of the user of this standard to establish appro-

3.1.6 wrap angle, n—in yarn friction testing, the cumulative

priate safety and health practices and determine the applica-

angular contact of the test specimen against the friction-

bility of regulatory limitations prior to use.

inducing device, expressed in radians.

3.1.7 For definitions of other textile terms used in this

2. Referenced Documents

method, refer to Terminology D 123.

2.1 ASTM Standards:

4. Summary of Test Method

D 123 Terminology Relating to Textiles

D 1776 Practice for Conditioning Textiles for Testing

4.1 A length of yarn is moved at a known speed in contact

D 1907 Test Method for Yarn Number by the Skein

with itself or similar yarn at a specified wrap angle. The input

Method

and output tensions are measured and the coefficient of friction

D 2258 Practice for Sampling Yarn for Testing

calculated. Alternatively, apparatus may be used in which the

D 3108 Test Method for Coefficient of Friction, Yarn to

ratio of input to output tension is measured allowing the

Solid Material

coefficient of friction to be indicated directly.

4.2 Two optional procedures are included. Option 1 is based

3. Terminology

on the Twisted Strand Method, using a wrap angle of 15.71 rad

3.1 Definitions:

(900°). Option 2 is based on the Capstan Method, using a wrap

3.1.1 boundary friction, n—friction at low sliding speeds

angle of 3.14 radians (180°).

(0.02 m/min or less) where lubrication occurs under thin-film

NOTE 2—Editions of Test Method D 3412 prior to the 1986 revision

lubricant conditions.

incorrectly stated the wrap angle for Option 1 to be 18.85 rad. This is

3.1.2 coeffıcient of friction, n—the ratio of the tangential

incorrect, since 3 turns of the swivel pulley do not result in a wrap angle

force that is needed to maintain uniform relative motion

of 18.85 radians. This has now been corrected to 15.71 rad. This should be

between two contacting surfaces to the perpendicular force

taken into account in comparing with earlier results.

holding them in contact.

5. Significance and Use

3.1.3 friction, n—the resistance to the relative motion of one

5.1 This test method for testing yarn-to-yarn friction is

being used, but is not recommended, for acceptance testing of

This test method is under the jurisdiction of ASTM Committee D-13 on Textiles

commercial shipments since between-laboratory precision is

and is the direct responsibility of Subcommittee D 13.58 on Yarn Test Methods,

known to be poor.

General.

Current edition approved May 15, 1995. Published July 1995. Originally 5.1.1 In some cases, the purchaser and supplier may have to

published as D 3412 – 75T. Last previous edition D 3412 – 89.

test a commercial shipment of one or more specific materials

Annual Book of ASTM Standards, Vol 07.01.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 3412

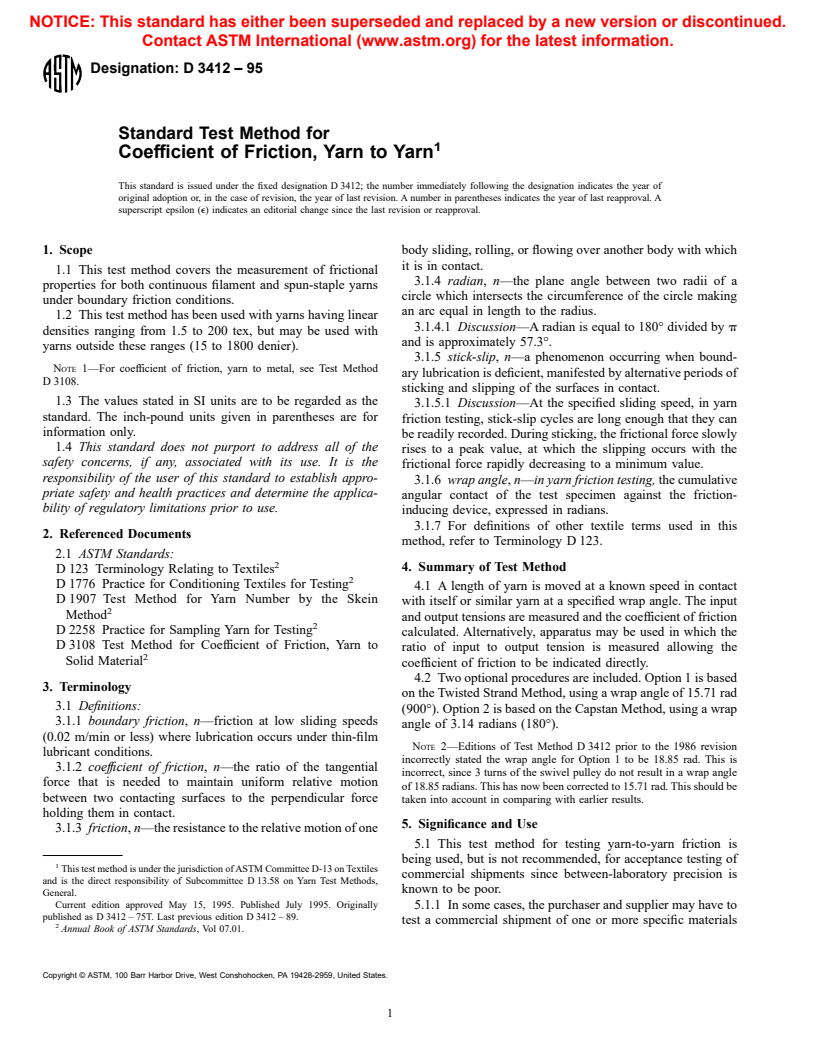

FIG. 1 Twisted Strand Yarn-to-Yarn Friction Apparatus—Twisted-Yarn Method

by the best available method even though the method has not 6.1.1 Friction Testing Apparatus (Indirect) —Apparatus in

been recommended for acceptance testing of commercial which the input tension is measured, or controlled to a set

shipments. In case of a dispute arising from differences in value, the output tension is measured, and the coefficient of

reported test results when using Test Method D 3412 for friction is calculated within or outside the apparatus.

acceptance testing of commercial shipments, the purchaser and 6.1.1.1 Yarn Input Tension Control—A means of controlling

the supplier should conduct comparative tests to determine if the yarn input tension to the nearest 5 % is required. A

there is a statistical bias between their laboratories. Competent demand-feed apparatus tensioned with a fixed weight is suit-

statistical assistance is recommended for the investigation of able.

bias. As a minimum, the two parties should take a group of test 6.1.1.2 Yarn Input Tension Measurement—The yarn input

specimens that are as homogeneous as possible and that are tension is measured to within 65.0 mN (60.5 gf), using a

from a lot of material of the type in question. The test suitable tension gage producing an electrical signal. The signal

specimens should then be randomly assigned in equal numbers is recorded as millinewtons (grams-force) or is used in com-

to each laboratory for testing. The average results from the two bination with the yarn output tension measured to calculate the

laboratories should be compared using Student’s t-test for coefficient of friction. If a demand-feed apparatus tensioned

unpaired data and an acceptable probability level chosen by the with a precise, known fixed mass is used, the yarn input tension

two parties before the testing is begun. If a bias is found, either need not be constantly measured and recorded.

its cause must be found and corrected or the purchaser and the 6.1.1.3 Yarn Output Tension Measurement—Yarn output

supplier must agree to interpret future test results with consid- tension is measured to within 65.0 mN (60.5 gf), using a

eration to the known bias. suitable tension gage producing an electrical signal. The signal

is recorded as millinewtons, (grams-force), or is used in

5.2 This test method is intended for the determination of

combination with the yarn input tension setting or measure-

yarn-to-yarn boundary friction coefficients measured over a

ment to calculate the coefficient of friction.

specified length of yarn.

6.1.2 Friction Testing Apparatus (Direct) —Apparatus in

5.3 The test method is useful for quality control, research,

which the ratio of output to input tensions are compared

and the characterization of yarn boundary lubricants.

directly and the coefficient of friction is indicated on a scale.

6.1.3 Auxilliary Equipment (Indirect and Direct):

NOTE 3—Because the geometry of the yarns is different, Options 1 and

6.1.3.1 Guide Pulley Arrangement—The upper and lower

2 should not be expected to give the same numerical values on the same

yarns. pulleys shalls be of the same diameter. The recommended

pulley diameter is 38 mm (1.5 in.). The separation distance

6. Apparatus

between the upper pulleys, 2 H, shall be 140 6 2 mm (5.5 6

0.1 in.). The separation distance between the axis of the lower

6.1 Option 1 (Twisted Strand Method)—A schematic dia-

pulley and a line connecting the upper pulley axes, V, shall be

gram of the elements required for twisted strand friction

measurement is shown in Fig. 1. The yarn is run over upper

pulleys and under a lower pulley and is intertwisted between

Equipment meeting these requirements may be obtained commercially from:

these pulleys. One end of the yarn (output) is taken up at a Custom Scientific Instruments Inc, 13 Wing Drive, Cedar Knolls, NJ 07292, and

Rothschild-Messinstruments, Traubstr 3, 8002 Zurich, Switzerland, represented in

controlled rate. The other end of yarn (input) is maintained at

the U.S. by Lawson Hemphill Sales Inc, PO Drawer 6388, Spartanburg, SC 29304.

a controlled tension. The number of intertwisting wraps, the 4

Equipment meeting these requirements may be obtained commercially from:

apex angle between the input and output yarns, and the input Rothschild-Messinstruments, Traubstr 3, 8002 Zurich, Switzerland, represented in

the U.S. by Lawson Hemphill Sales Inc, PO Drawer 6388, Spartanburg, SC 29304,

and output tensions are precisely known or recorded. From

and Shirley Developments Ltd, PO Box 6, Didsbury, Manchester M20 8SA,

these data the coefficient of yarn-on-yarn friction is calculated.

England, represented in the U.S. by Lawson Hemphill Sales Inc, PO Drawer 6388,

The required elements are: Spartanburg, SC 29304.

D 3412

between shipping units, between packages or ends within a shipping unit,

280 6 2mm(11 6 0.1 in.). All pulleys shall be in the same

and between specimens from a single package so as to provide a sampling

plane. The lower pulley may optionally be mounted so that it

plan with a meaningful producer’s risk, consumer’s risk, acceptable

can be swiveled around an axis at right angles to its axis of

quality level, and limiting quality level.

rotation and then fixed in position in the same plane as the

7.2 Laboratory Sample—As a laboratory sample for accep-

upper pulleys.

tance testing, take at random from each shipping unit in the lot

6.1.3.2 Drive Unit—The yarn takeup shall run between 20

sample the number of packages or ends directed in an

and 100 mm/min (0.75 and 4.0 in./min).

applicable material specification or other agreement between

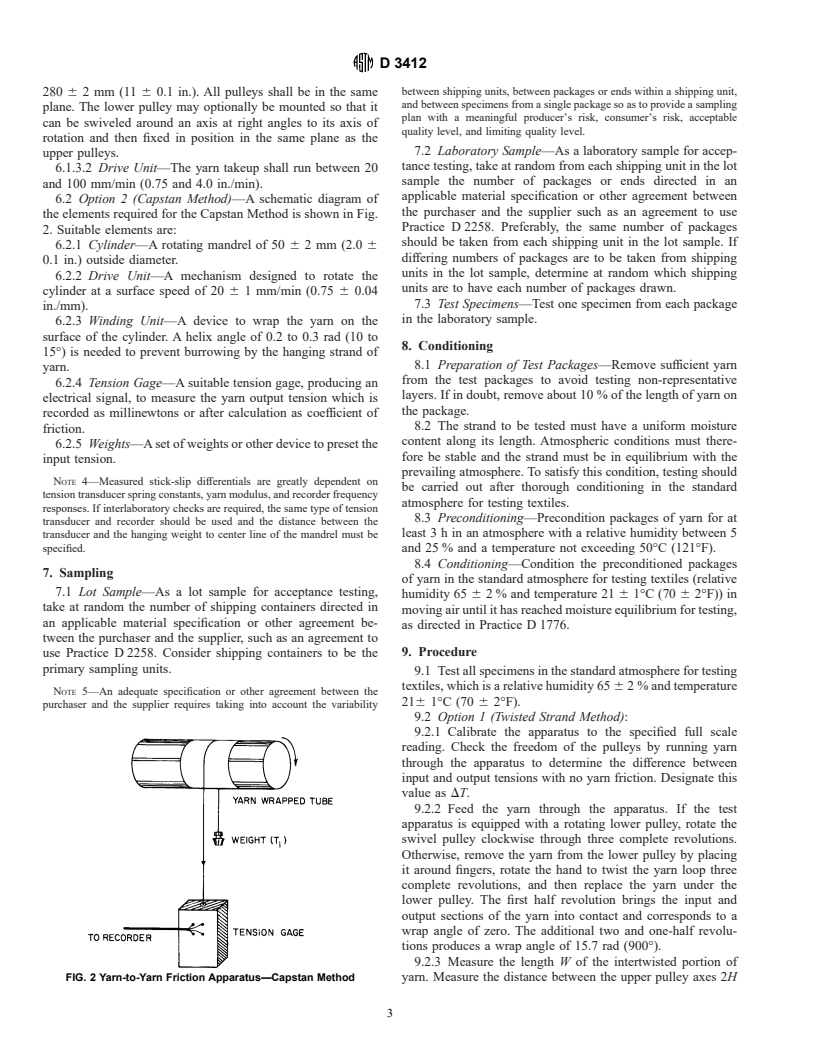

6.2 Option 2 (Capstan Method)—A schematic diagram of

the purchaser and the supplier such as an agreement to use

the elements required for the Capstan Method is shown in Fig.

Practice D 2258. Preferably, the same number of packages

2. Suitable elements are:

should be taken from each shipping unit in the lot sample. If

6.2.1 Cylinder—A rotating mandrel of 50 6 2 mm (2.0 6

differing numbers of packages are to be taken from shipping

0.1 in.) outside diameter.

units in the lot sample, determine at random which shipping

6.2.2 Drive Unit—A mechanism designed to rotate the

units are to have each number of packages drawn.

cylinder at a surface speed of 20 6 1 mm/min (0.75 6 0.04

7.3 Test Specimens—Test one specimen from each package

in./mm).

in the laboratory sample.

6.2.3 Winding Unit—A device to wrap the yarn on the

surface of the cylinder. A helix angle of 0.2 to 0.3 rad (10 to

8. Conditioning

15°) is needed to prevent burrowing by the hanging strand of

8.1 Preparation of Test Packages—Remove sufficient yarn

yarn.

from the test packages to avoid testing non-representative

6.2.4 Tension Gage—A suitable tension gage, producing an

layers. If in doubt, remove about 10 % of the length of yarn on

electrical signal, to measure the yarn output tension which is

the package.

recorded as millinewtons or after calculation as coefficient of

8.2 The strand to be tested must have a uniform moisture

friction.

content along its length. Atmospheric conditions must there-

6.2.5 Weights—A set of weights or other device to preset the

fore be stable and the strand must be in equilibrium with the

input tension.

prevailing atmosphere. To satisfy this condition, testing should

NOTE 4—Measured stick-slip differentials are greatly dependent on

be carried out after thorough conditioning in the standard

tension transducer spring constants, yarn modulus, and recorder frequency

atmosphere for testing textiles.

responses. If interlaboratory checks are required, the same type of tension

8.3 Preconditioning—Precondition packages of yarn for at

transducer and recorder should be used and the distance between the

least3hinan atmosphere with a relative humidity between 5

transducer and the hanging weight to center line of the mandrel must be

specified.

and 25 % and a temperature not exceeding 50°C (121°F).

8.4 Conditioning—Condition the preconditioned packages

7. Sampling

of yarn in the standard atmosphere for testing textiles (relative

7.1 Lot Sample—As a lot sample for acceptance testing,

humidity 65 6 2 % and temperature 21 6 1°C (70 6 2°F)) in

take at random the number of shipping containers directed in

moving air until it has reached moisture equilibrium for testing,

an applicable material specification or other agreement be-

as directed in Practice D 1776.

tween the purchaser and the supplier, such as an agreement to

9. Procedure

use Practice D 2258. Consider shipping containers to be the

primary sampling units.

9.1 Test all specimens in the standard atmosphere for testing

textiles, which is a relative humidity 65 6 2 % and temperature

NOTE 5—An adequate specification or other agreement between the

216 1°C (70 6 2°F).

purchaser and the supplier requires taking into account the variability

9.2 Option 1 (Twisted Strand Method):

9.2.1 Calibrate the apparatus to the specified full scale

reading. Check the freedom of the pulleys by running yarn

through the apparatus to determine the difference between

input and output tensions with no yarn friction. Designate this

value as DT.

9.2.2 Feed the yarn through the apparatus. If the test

apparatus is equipped with a rotating lower pulley, rotate the

swivel pulley clockwise through three complete revolutions.

Otherwise, remove the yarn from the lower pulley by placing

it around fingers, rotate the hand to twist the yarn loop three

complete revolutions, and then replace the yarn under the

lower pulley. The first half revolution brings the input and

output sections of the yarn into contact and corresponds to a

wrap angle of zero. The additional two and one-half revolu-

tions produces a wrap angle of 15.7 rad (900°).

9.2.3 Measure the length W of the intertwisted portion of

FIG. 2 Yarn-to-Yarn Friction Apparatus—Capstan Method yarn. Measure the distance between the upper pulley axes 2H

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.