ASTM D3108/D3108M-13(2020)

(Test Method)Standard Test Method for Coefficient of Friction, Yarn to Solid Material

Standard Test Method for Coefficient of Friction, Yarn to Solid Material

SIGNIFICANCE AND USE

5.1 Test Method D3108 for the determination of kinetic friction between yarn and solid materials may be used for the acceptance testing of commercial shipments of yarn, but caution is advised since between laboratory precision is known to be poor. Comparative tests as directed in 5.1.1 may be advisable.

5.1.1 If there are differences or practical significance between reported test results for two laboratories (or more), comparative tests should be performed to determine if there is a statistical bias between them, using competent statistical assistance. As a minimum, test samples that are as homogenous as possible, drawn from the material from which the disparate test results were obtained, and randomly assigned in equal numbers to each laboratory for testing. The test results from the two laboratories should be compared using a statistical test for unpaired data, at a probability level chosen prior to the testing series. If a bias is found, either its cause must be found and corrected, or future test results for that material must be adjusted in consideration of the known bias.

5.2 The frictional properties of textile yarns and of machinery components such as yarn guides are of general interest and have many applications. Because the frictional properties of yarns will affect the performance and life of yarn guides, sewing and knitting needles, and other contact surfaces, the modifying effects of surface finishes and lubricants are of special interest. Frictional properties also affect the quality and performance properties of yarns and subsequently of products made from them. As a consequence, frictional properties are of interest in research, control, and product design.

5.3 It is stressed that there is no coefficient of friction for a single body such as a yarn or a surface. A coefficient of friction measures the interaction between two bodies or elements such as a yarn running over a surface.

5.4 Although this method lays down standardized condition...

SCOPE

1.1 This test method covers the measurement of the kinetic frictional properties of a moving yarn in contact with a solid material.

Note 1: For determining yarn-to-yarn friction, refer to Test Method D3412.

1.2 This test method specifies a relative speed of 100 m/min. The test method may be used at other speeds, although with a possible change in precision and coefficient of friction.

1.3 This test method covers the measurement of the coefficient of kinetic friction between yarn and solid surface or surfaces of constant radius in the contact area. If a yarn of uniform value is used, comparisons of frictional properties of different solid materials can be made with relation to that yarn. If a given solid material is used, comparisons of frictional properties of different yarns, or yarns with different finishes, can be made with relation to that particular solid material.

1.4 This test method specifically recommends wrap angles of 1.57, 3.14 and 6.28 radian (90, 180 and 360°), but other wrap angles may be used, again with a possible change in precision and level. The angle of wrap should not be so great, especially for yarns having high coefficients of friction, that it causes the output tension to exceed the yield value for the yarn being tested. Also, in every case the angle of wrap should not be less than 1.57 rad (90°).

1.5 This test method has been applied to yarns having linear densities ranging between 1.5 and 400 tex [14 and 3600 denier] and having coefficients of friction ranging between 0.1 and 1.0 but may also be used with yarns outside these ranges of linear densities and coefficients of friction.

1.6 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D3108/D3108M − 13 (Reapproved 2020)

Standard Test Method for

Coefficient of Friction, Yarn to Solid Material

This standard is issued under the fixed designation D3108/D3108M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.7 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method covers the measurement of the kinetic

responsibility of the user of this standard to establish appro-

frictional properties of a moving yarn in contact with a solid

priate safety, health, and environmental practices and deter-

material.

mine the applicability of regulatory limitations prior to us-

NOTE 1—For determining yarn-to-yarn friction, refer to Test Method

e.Specific precautionary statements are given in Section 7.

D3412.

1.8 This international standard was developed in accor-

1.2 Thistestmethodspecifiesarelativespeedof100m/min.

dance with internationally recognized principles on standard-

The test method may be used at other speeds, although with a

ization established in the Decision on Principles for the

possible change in precision and coefficient of friction.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

1.3 This test method covers the measurement of the coeffi-

Barriers to Trade (TBT) Committee.

cient of kinetic friction between yarn and solid surface or

surfaces of constant radius in the contact area. If a yarn of

2. Referenced Documents

uniform value is used, comparisons of frictional properties of

different solid materials can be made with relation to that yarn. 2.1 ASTM Standards:

If a given solid material is used, comparisons of frictional D123 Terminology Relating to Textiles

properties of different yarns, or yarns with different finishes, D1776 Practice for Conditioning and Testing Textiles

can be made with relation to that particular solid material. D1907 Test Method for Linear Density of Yarn (Yarn Num-

ber) by the Skein Method

1.4 This test method specifically recommends wrap angles

D2258 Practice for Sampling Yarn for Testing

of 1.57, 3.14 and 6.28 radian (90, 180 and 360°), but other

D3412 Test Method for Coefficient of Friction, Yarn to Yarn

wrap angles may be used, again with a possible change in

D4849 Terminology Related to Yarns and Fibers

precision and level. The angle of wrap should not be so great,

especially for yarns having high coefficients of friction, that it

3. Terminology

causes the output tension to exceed the yield value for the yarn

3.1 For all terminology relating to D13.58, Yarns and

being tested. Also, in every case the angle of wrap should not

Fibers, refer to Terminology D4849.

be less than 1.57 rad (90°).

3.1.1 The following terms are relevant to this standard:

1.5 This test method has been applied to yarns having linear

coefficient of friction, friction, kinetic friction, radian, static

densitiesrangingbetween1.5and400tex[14and3600denier]

fraction, wrap angle.

and having coefficients of friction ranging between 0.1 and 1.0

3.2 For all other terminology related to textiles, refer to

but may also be used with yarns outside these ranges of linear

Terminology D123.

densities and coefficients of friction.

1.6 The values stated in either SI units or inch-pound units

4. Summary of Test Method

are to be regarded separately as standard. The values stated in

4.1 A length of yarn is run at known speeds and in contact

each system are not necessarily exact equivalents; therefore, to

with either single or multiple friction surfaces using a specified

ensure conformance with the standard, each system shall be

wrapangle.(SeeFig.1.)Theyarninputandoutputtensionsare

used independently of the other, and values from the two

measured, and the coefficient of friction is calculated by means

systems shall not be combined.

ofAmontons’law(see11.4).Alternatively,apparatusisusedin

This test method is under the jurisdiction ofASTM Committee D13 on Textiles

and is the direct responsibility of Subcommittee D13.58 on Yarns and Fibers. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Feb. 1, 2020. Published March 2020. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1972. Last previous edition approved in 2013 as D3108/D3108M – 13. Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D3108_D3108M-13R20. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3108/D3108M − 13 (2020)

FIG. 1 Schematic Diagram of Angle of Wrap

which the ratio of output tension to input tension is measured measures the interaction between two bodies or elements such

allowing the coefficient of friction to be indicated directly. as a yarn running over a surface.

5.4 Although this method lays down standardized condi-

5. Significance and Use

tions of test, nonstandard conditions may be used for research

5.1 Test Method D3108 for the determination of kinetic

or diagnosis but should be reported as such.

friction between yarn and solid materials may be used for the

5.5 This method covers determination of the mean friction

acceptance testing of commercial shipments of yarn, but

over a specified length of yarn.

caution is advised since between laboratory precision is known

5.6 Additional information has been reported in the

to be poor. Comparative tests as directed in 5.1.1 may be

3,4,5

literature.

advisable.

5.1.1 If there are differences or practical significance be-

6. Apparatus

tween reported test results for two laboratories (or more),

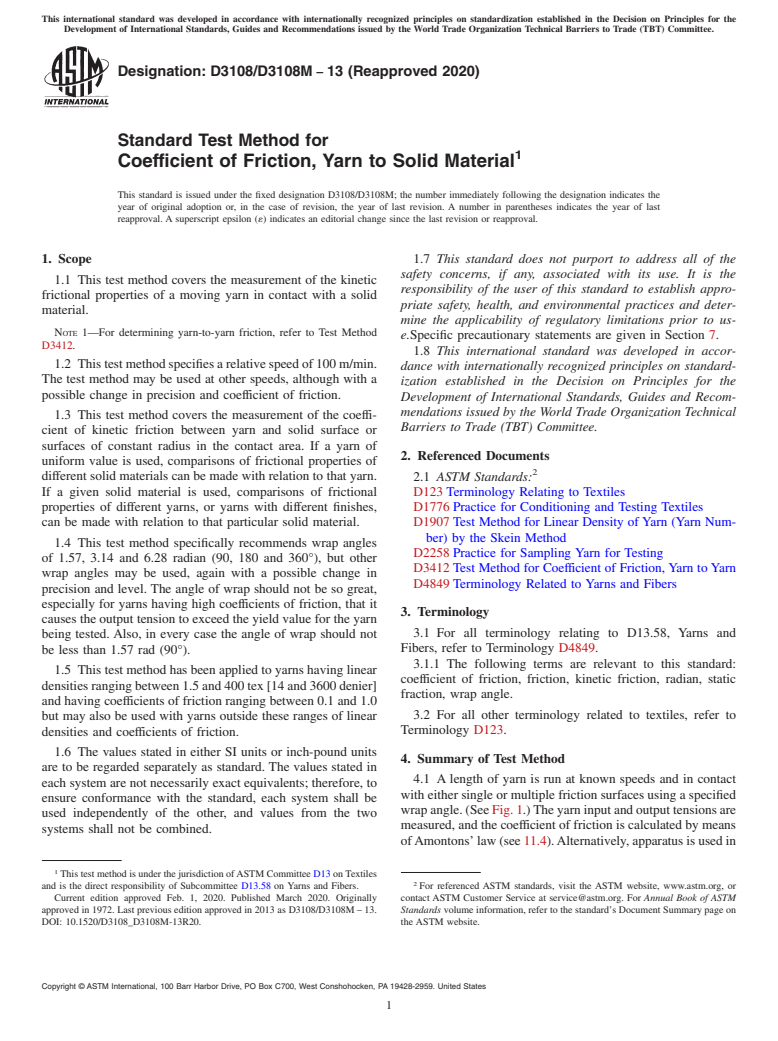

6.1 Friction Testing Apparatus (Indirect) (Fig. 2)—

comparative tests should be performed to determine if there is

Apparatus in which the input tension is measured or controlled

a statistical bias between them, using competent statistical

to a set value, the output tension is measured, and the

assistance.Asaminimum,testsamplesthatareashomogenous

coefficient of friction is calculated within or outside the

as possible, drawn from the material from which the disparate

apparatus.

test results were obtained, and randomly assigned in equal

6.1.1 Yarn Tension Input Control—A means of controlling

numberstoeachlaboratoryfortesting.Thetestresultsfromthe

the yarn input tension to the nearest 61mN[60.1 gf]. A

two laboratories should be compared using a statistical test for

demand-fed apparatus with a fixed weight is suitable.

unpaired data, at a probability level chosen prior to the testing

6.1.2 Yarn Input Tension Measurement—The yarn input

series. If a bias is found, either its cause must be found and

tension is measured to within 61mN[60.1 gf] using a

corrected, or future test results for that material must be

suitable tension gage producing an electrical signal. The signal

adjusted in consideration of the known bias.

is recorded as mN [gf], or is used in combination with the yarn

5.2 The frictional properties of textile yarns and of machin-

output tension measurement to calculate the coefficient of

ery components such as yarn guides are of general interest and

friction.

have many applications. Because the frictional properties of

6.1.3 Yarn Output Tension Measurement—The yarn output

yarns will affect the performance and life of yarn guides,

tension is measured to within 61mN[60.1 gf] using a

sewing and knitting needles, and other contact surfaces, the

modifying effects of surface finishes and lubricants are of

Olsen, J. S., “Frictional Behaviour of Textile Yarns,” Textile Research Journal,

special interest. Frictional properties also affect the quality and

Vol 39, No 1, 1969, pp 31–37.

performance properties of yarns and subsequently of products

Lyne, D.G., “Dynamic Friction Between Cellulose Acetate Yarn and a Metal

made from them.As a consequence, frictional properties are of

Cylinder,” Journal of the Textile Institute, Vol 46, 1955, p 112.

interest in research, control, and product design. Rubenstein,C.,“ReviewoftheFactorsInfluencingtheFrictionofFibres,Yarns

and Fabrics,” Wear, Vol 2, 1958-59, p 296.

5.3 It is stressed that there is no coefficient of friction for a

Equipment meeting these requirements may be commercially obtained from

single body such as a yarn or a surface.Acoefficient of friction Lawson Hemphill (Sales) Inc., PO Drawer 6388, Spartanburg, SC 29304.

D3108/D3108M − 13 (2020)

FIG. 2 Schematic Diagram of Typical Yarn Friction Measuring Apparatus, Indirect Type

suitable tension gage producing an electrical signal. The signal because the absolute level of input tension can affect the

is recorded as mN [gf] or is used in combination with the yarn measured coefficient of friction for certain yarns, particularly

input tension measurement to calculate the coefficient of

low-twist yarns, the general level of input tension should be

friction. A suitable chart recorder may be used.

preset, for example with a dead weight disk tensioner.

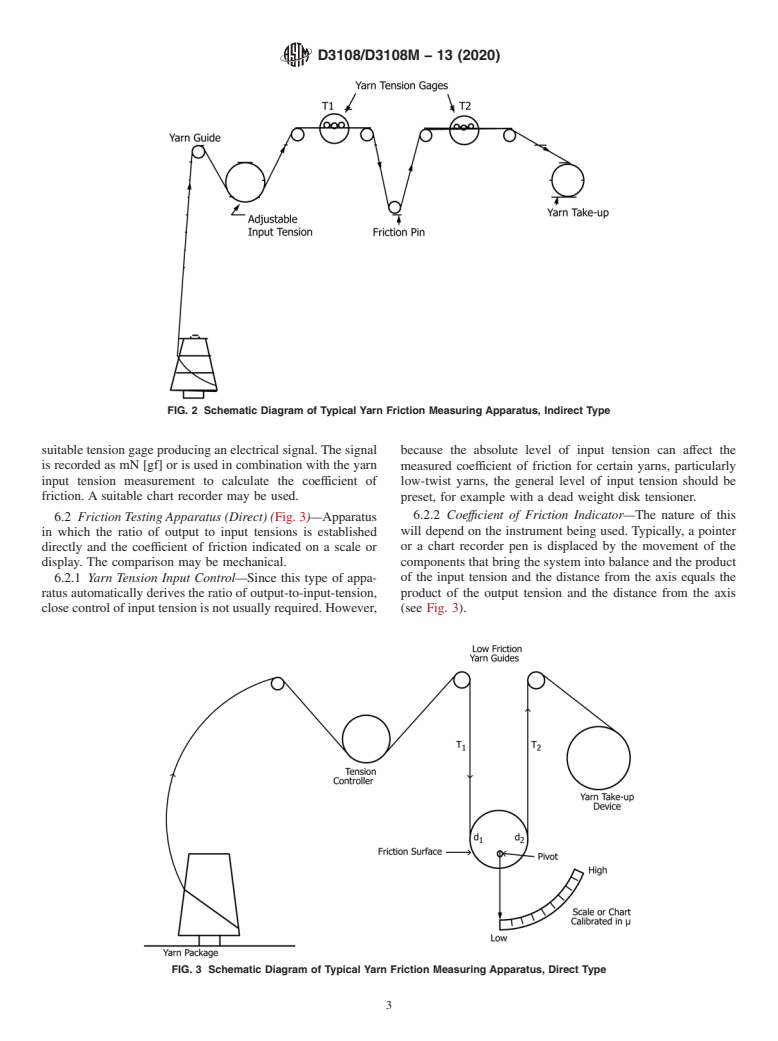

6.2.2 Coeffıcient of Friction Indicator—The nature of this

6.2 Friction Testing Apparatus (Direct) (Fig. 3)—Apparatus

will depend on the instrument being used. Typically, a pointer

in which the ratio of output to input tensions is established

directly and the coefficient of friction indicated on a scale or or a chart recorder pen is displaced by the movement of the

components that bring the system into balance and the product

display. The comparison may be mechanical.

6.2.1 Yarn Tension Input Control—Since this type of appa- of the input tension and the distance from the axis equals the

ratus automatically derives the ratio of output-to-input-tension, product of the output tension and the distance from the axis

close control of input tension is not usually required. However, (see Fig. 3).

FIG. 3 Schematic Diagram of Typical Yarn Friction Measuring Apparatus, Direct Type

D3108/D3108M − 13 (2020)

6.3 Friction Surface, may be changeable on some equip- 9. Conditioning

ment.

9.1 Preparation of Test Packages—Remove sufficient yarn

6.3.1 Standard Friction Surface—Friction surfaces having a

from the test packages to avoid testing nonrepresentative

diameter of 0.5 in. [12.7 mm] for yarns having linear densities

layers. If in doubt, remove about 10 % of the length of yarn on

ranging from 1.5 to 80 tex, or 0.79 in. [20.0 mm] for yarns

the package.

having linear densities ranging from 80 to 400 tex, and a

9.2 The strand to be tested must have a uniform moisture

chromesurfaceof0.03to6µmroughness.Theuseofone,two,

content along its length. Atmospheric conditions must there-

or three pins in sequence has been found satisfactory although

fore be stable and the strand must be in equilibrium with the

there may be a difference in the results (theoretically only the

prevailing atmosphere. To satisfy this condition, testing should

totalangleofwrapandnotthenumberofpinsshouldaffectthe

be carried out after thorough conditioning in the standard

results). (See 12.3.4).

atmosphere for testing textiles.

6.3.2 Other Friction Surfaces—Unless the apparatus has a

friction surface that cannot be altered, friction surfaces of

9.3 Precondition and condition the specimens as directed in

different materials, sizes, and surface finish may be used but

Practice D1776.

must be specified in the report (see 12.3.4).

10. Procedure

6.4 Drive System, consisting of a controlled speed yarn

transporting device with appropriate controls to record and

10.1 Test all specimens in the standard atmosphere for

adjustthelinearorthroughputspeed.Generally,aspeedofless

testing as directed in Practice D1776.

than 400 m/min has been found preferable. The yarn transport-

10.2 Prior to each test, thoroughly clean the friction

ing device should be constructed to eliminate yarn slippage by

elements, input rolls, and any other surfaces with which the

the use of high-friction surface.

yarn comes in contact up to and including the friction element,

6.5 Cotton Yarn For Cleaning—A thoroughly scoured cot-

using one of the following:

ton yarn that is highly absorbent (see section 10.2.2 and Annex

10.2.1 A solvent which contains no trace oils, or

A1).

10.2.1.1 Warning—If solvent is used, appropriate health

andsafetyprecautionsmustbetaken.(SeeSectiononHazards)

6.6 Solvent—See 10.2.

10.2.2 A thoroughly scoured cotton yarn that is highly

absorbent used as a cleaning yarn. See Annex A1 for details.

7. Hazard

10.3 Check the surface properties of the friction elements

7.1 Refer to the manufacturer’s material safety data sheet

for wear, gouging, or channeling. Some textile yarns, specifi-

for information on storage, handling, use, and disposal of

cally glass, stainless steel, delustered yarns, and other high-

chemicals used in this test method.

modulus yarns, are known to create excessive wear on most

guide surface materials, including chromium. Check for evi-

8. Sampling

dence of surface wear periodically by the use of control yarns,

8.1 Lot Sample—Asalotsampleforacceptancetesting,take

microscopic examination, or other forms of examining or

at random the number of shipping units directed in an

measuring surface uniformity. Replace or refurbish friction

applicable material specification or other agreement between

elements which show signs of wear, gouging, or channeling.

the purchaser and the supplier, such as an agreement to use

10.4 Take care not to contaminate the yarn test specimen or

Practice D2258. Consider shipping cases or other shipping

the cleaned yarn-contacting surfaces of the apparatus.

units to be the primary sampling units.

10.5 Feed the yarn through the apparatus. Use identical pin

NOTE 2—An adequate specification or other agreement between the

locations, friction surfaces, and input tensions for all tests to be

purchaser and the supplier requires taking into account the variability

compared directly.

between shipping units, between packages or ends within a shipping unit,

and between specimens from a single package so as to provide a sampling

10.5.1 If the apparatus requires the input tension to be

plan with a meaningful producer’s risk, consumer’s risk, acceptable

standardized, adjust it to 9.8 6 1 mN/tex [0.1 gf/den] for yarns

quality level, and limiting quality level.

having linear densities ranging from 1.5 to 80 tex,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.