ASTM D5344-22

(Test Method)Standard Test Method for Extension Force of Partially Oriented Yarn

Standard Test Method for Extension Force of Partially Oriented Yarn

SIGNIFICANCE AND USE

5.1 This test method is considered satisfactory for acceptance testing of commercial shipments because current estimates of between-laboratory precision are acceptable and the method is used extensively in the trade for acceptance testing.

5.1.1 If there are differences or practical significance between reported test results for two laboratories (or more), comparative tests should be performed to determine if there is a statistical bias between them, using competent statistical assistance. As a minimum, the test samples to be used are as homogeneous as possible, are drawn from the material from which the disparate test results are obtained, and are assigned randomly in equal numbers to each laboratory for testing. Other materials with established test values may be used for this purpose. The test results from the two laboratories should be compared using a statistical test for unpaired data, at a probability level chosen prior to the testing series. If a bias is found, either its cause must be found and corrected, or future test results must be adjusted in consideration of the known bias.

5.2 Elapsed time between spinning and testing has a marked effect on the results of the draw tension test, especially during the first 24 h. Therefore, if tested within 24 h of spinning, specimens should be compared only if tested after the same elapsed time. No specimen should be tested within 4 h of spinning because the aging process is at its most rapid rate during this period, and the differences in rate due to fiber structure are most pronounced.

5.3 The extension force of manufactured filament yarns is related to the alignment of the molecules in the yarn filaments, which influences the yarn processing behavior. Knowledge of this property of partially oriented yarn is useful to determine processing conditions.

SCOPE

1.1 This test method covers the measurement of extension force developed while drawing a partially oriented filament yarn between pairs of draw rolls of different surface speeds.

1.2 Extension force provides an estimate of the yarn orientation.

1.3 This test method applies to partially oriented filament yarns less than 33.3 tex (300 denier), but it can be used for higher deniers by applying the test conditions as directed in Appendix X1.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses are provided for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5344 − 22

Standard Test Method for

1

Extension Force of Partially Oriented Yarn

This standard is issued under the fixed designation D5344; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D2904 Practice for Interlaboratory Testing of a Textile Test

Method that Produces Normally Distributed Data (With-

1.1 This test method covers the measurement of extension

3

drawn 2008)

force developed while drawing a partially oriented filament

D2906 Practice for Statements on Precision and Bias for

yarn between pairs of draw rolls of different surface speeds. 3

Textiles (Withdrawn 2008)

D4849 Terminology Related to Yarns and Fibers

1.2 Extension force provides an estimate of the yarn orien-

tation.

3. Terminology

1.3 This test method applies to partially oriented filament

3.1 For terminology related to yarn test methods refer to

yarns less than 33.3 tex (300 denier), but it can be used for

Terminology D4849.

higher deniers by applying the test conditions as directed in

3.2 The following terms are relevant to this standard:

Appendix X1.

drawing;drawratio(DR);drawtexturing;extension;extension

force; partially oriented yarn.

1.4 The values stated in SI units are to be regarded as

standard. The values given in parentheses are provided for

3.3 For definitions of other textile terms used in this test

information only.

method refer to Terminology D123.

1.5 This standard does not purport to address all of the

4. Summary of Test Method

safety concerns, if any, associated with its use. It is the

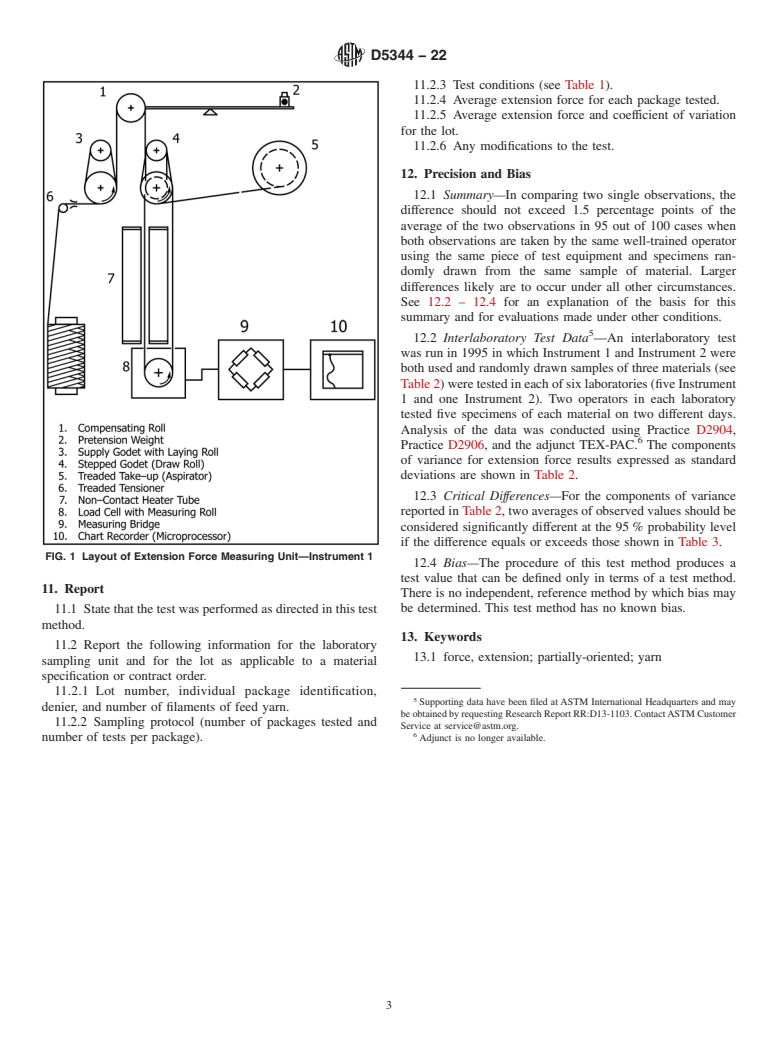

4.1 Partially oriented filament yarn withdrawn from a pack-

responsibility of the user of this standard to establish appro-

age is pretensioned, heated, and drawn on an instrument under

priate safety, health, and environmental practices and deter-

conditions similar to those used in the draw-texturing process.

mine the applicability of regulatory limitations prior to use.

Atension measuring head senses the force required to draw the

1.6 This international standard was developed in accor-

running yarn a specified amount of its original length under

dance with internationally recognized principles on standard-

given conditions.

ization established in the Decision on Principles for the

5. Significance and Use

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

5.1 This test method is considered satisfactory for accep-

Barriers to Trade (TBT) Committee.

tance testing of commercial shipments because current esti-

mates of between-laboratory precision are acceptable and the

2. Referenced Documents method is used extensively in the trade for acceptance testing.

5.1.1 If there are differences or practical significance be-

2

2.1 ASTM Standards:

tween reported test results for two laboratories (or more),

D123 Terminology Relating to Textiles

comparative tests should be performed to determine if there is

D1776 Practice for Conditioning and Testing Textiles

a statistical bias between them, using competent statistical

D2258 Practice for Sampling Yarn for Testing

assistance. As a minimum, the test samples to be used are as

homogeneous as possible, are drawn from the material from

which the disparate test results are obtained, and are assigned

1

This test method is under the jurisdiction ofASTM Committee D13 on Textiles randomly in equal numbers to each laboratory for testing.

and is the direct responsibility of Subcommittee D13.58 on Yarns and Fibers.

Other materials with established test values may be used for

Current edition approved Nov. 1, 2022. Published December 2022. Originally

this purpose. The test results from the two laboratories should

approved in 1993. Last previous edition approved in 2017 as D5344–99 (2017).

be compared using a statistical test for unpaired data, at a

DOI: 10.1520/D5344-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5344 − 22

NOTE 1—Preconditioning is generally not advisable because it prolongs

probability level chosen pr

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5344 − 99 (Reapproved 2017) D5344 − 22

Standard Test Method for

1

Extension Force of Partially Oriented Yarn

This standard is issued under the fixed designation D5344; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the measurement of extension force developed while drawing a partially oriented filament yarn

between pairs of draw rolls of different surface speeds.

1.2 Extension force provides an estimate of the yarn orientation.

1.3 This test method applies to partially oriented filament yarns less than 33.3 tex (300 denier), but it can be used for higher deniers

by applying the test conditions as directed in Appendix X1.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses are provided for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D123 Terminology Relating to Textiles

D1776 Practice for Conditioning and Testing Textiles

D2258 Practice for Sampling Yarn for Testing

3

D2904 Practice for Interlaboratory Testing of a Textile Test Method that Produces Normally Distributed Data (Withdrawn 2008)

3

D2906 Practice for Statements on Precision and Bias for Textiles (Withdrawn 2008)

D4849 Terminology Related to Yarns and Fibers

3. Terminology

3.1 For terminology related to yarn test methods refer to Terminology D4849.

1

This test method is under the jurisdiction of ASTM Committee D13 on Textiles and is the direct responsibility of Subcommittee D13.58 on Yarns and Fibers.

Current edition approved July 1, 2017Nov. 1, 2022. Published July 2017December 2022. Originally approved in 1993. Last previous edition approved in 20112017 as

D5344–99(2011).D5344–99 (2017). DOI: 10.1520/D5344-99R17.10.1520/D5344-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5344 − 22

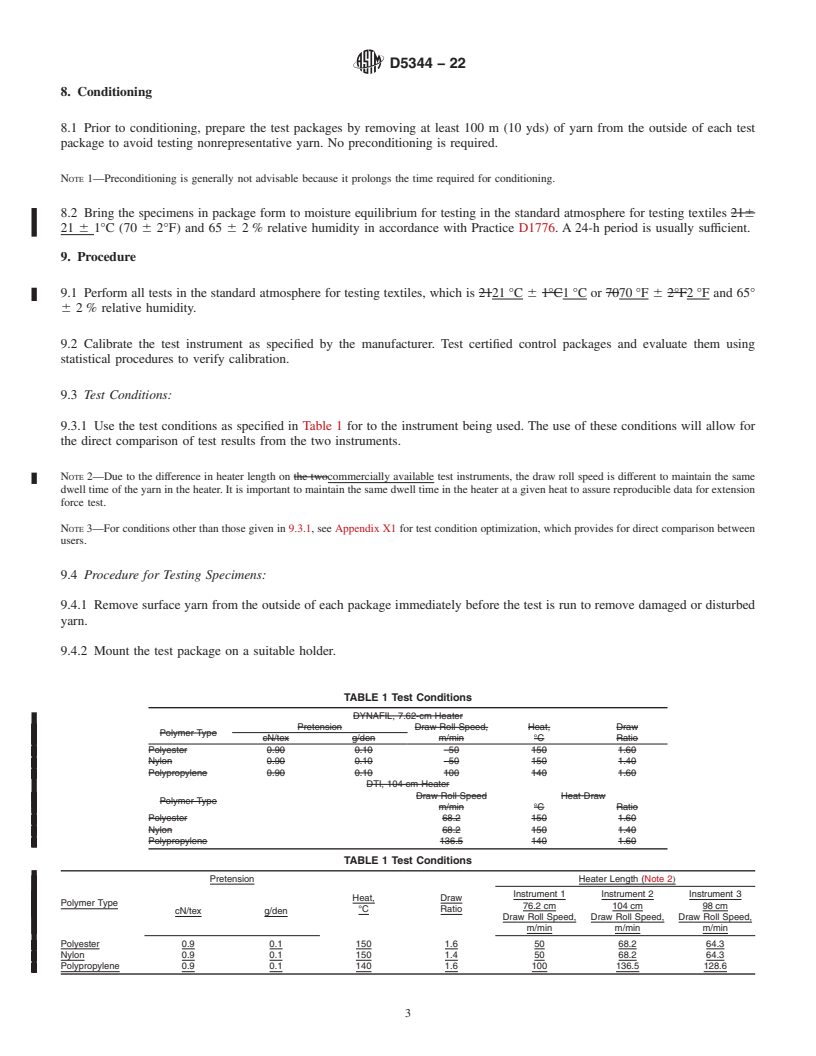

3.2 The following terms are relevant to this standard: drawing; draw ratio (DR); draw texturing; extension; extension force;

partially oriented yarn.

3.3 For definitions of other textile terms used in this test method refer to Terminology D123.

4. Summary of Test Method

4.1 Partially oriented filament yarn withdrawn from a package is pretensioned, heated, and drawn on an instrument under

conditions similar to those used in the draw-texturing process. A tension measuring head senses the force required to draw the

running yarn a specified amount of its original length under given conditions.

5. Significance and Use

5.1 This test method is considered satisfactory for acceptance testing of commercial shipments because current estimates of

between-laboratory precision are acceptable and the method is used extensively in the trade for acceptance testing.

5.1.1 If there are differences or practical significance between reported test results for two laboratories (or more), comparative tests

should be performed to determine if there is a statistical bias between them, using competent statistical assistance. As a minimum,

the test samples to be used are as homogeneous as possible, are drawn from the material from which the disparate test results are

obtained, and are assigned randomly in equal numbers to each laboratory for testing. Other materials with established test values

may be used for this purpos

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.