ASTM D5235-18

(Test Method)Standard Test Method for Microscopic Measurement of Dry Film Thickness of Coatings on Wood Products

Standard Test Method for Microscopic Measurement of Dry Film Thickness of Coatings on Wood Products

SIGNIFICANCE AND USE

5.1 As a base for calibration adjustment or accuracy verification of dry film coating thickness measuring instruments.

5.2 The dry film thickness of coatings on wood or wood-based products is specified in written product warranties for proper decorative and protective performance of coatings on wood or wood-based products.

5.3 The minimum and maximum dry film thickness of coatings is recommended by coating companies for satisfactory decorative and protective performance on wood or wood-based products.

5.4 The average dry film thickness of coatings on wood or wood-based material may be used by manufacturing companies to estimate the theoretical cost of applied coatings.

5.5 The ratio of minimum to maximum dry film thickness on textured products is used as an indication of coating uniformity.

5.6 Specific coated product requirements may dictate certain film thickness determinations to be made. Agreement between buyer and seller may be advisable to accommodate product needs relative to dry film thickness.

SCOPE

1.1 This test method covers the measurement of dry film thickness of coatings applied to a smooth, textured or curved rigid substrate of wood or a wood-based product.

1.2 This test method covers the preparation of wood or wood-based specimens for the purpose of microscopic measurement of dry film thickness.

1.3 This test method suggests an analysis of dry film thickness of coatings on wood or wood-based products using a microscopic measurement.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5235 − 18

Standard Test Method for

Microscopic Measurement of Dry Film Thickness of

1

Coatings on Wood Products

This standard is issued under the fixed designation D5235; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E691Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 This test method covers the measurement of dry film

thickness of coatings applied to a smooth, textured or curved

3. Terminology

rigid substrate of wood or a wood-based product.

3.1 Definitions of Terms Specific to This Standard:

1.2 This test method covers the preparation of wood or

3.1.1 dry film thickness or DFT, n—the thickness of dried,

wood-based specimens for the purpose of microscopic mea-

cured coating film on the substrate surface which may include

surement of dry film thickness.

attached fibers but excludes free fibers that are encapsulated in

1.3 This test method suggests an analysis of dry film

the layer itself.

thickness of coatings on wood or wood-based products using a

3.1.2 edge face, n—that part of the specimen that is a plane

microscopic measurement.

perpendicular to the surface showing a cross section of the

1.4 The values stated in either SI units or inch-pound units

coating and substrate.

are to be regarded separately as standard. The values stated in

3.1.3 soak in, n—refers to a coating on a porous (wood)

each system may not be exact equivalents; therefore, each

where the coating does not lie essentially on the surface of the

system shall be used independently of the other. Combining

wood or wood-based product, but has penetrated into the fiber

values from the two systems may result in non-conformance

structure of the wood or wood-based material.

with the standard.

3.1.3.1 Discussion—Woodorwood-basedproductsaregen-

1.5 This standard does not purport to address all of the

erally of a porous nature; sometimes exhibiting uniform

safety concerns, if any, associated with its use. It is the

absorption of coatings. Frequently absorption of coatings is of

responsibility of the user of this standard to establish appro-

a non-uniform nature and influenced by localized surface

priate safety, health, and environmental practices and deter-

density differences or wood pore size. These conditions of

mine the applicability of regulatory limitations prior to use.

coating absorption are commonly referred to as soak in.

1.6 This international standard was developed in accor-

dance with internationally recognized principles on standard-

4. Summary of Test Method

ization established in the Decision on Principles for the

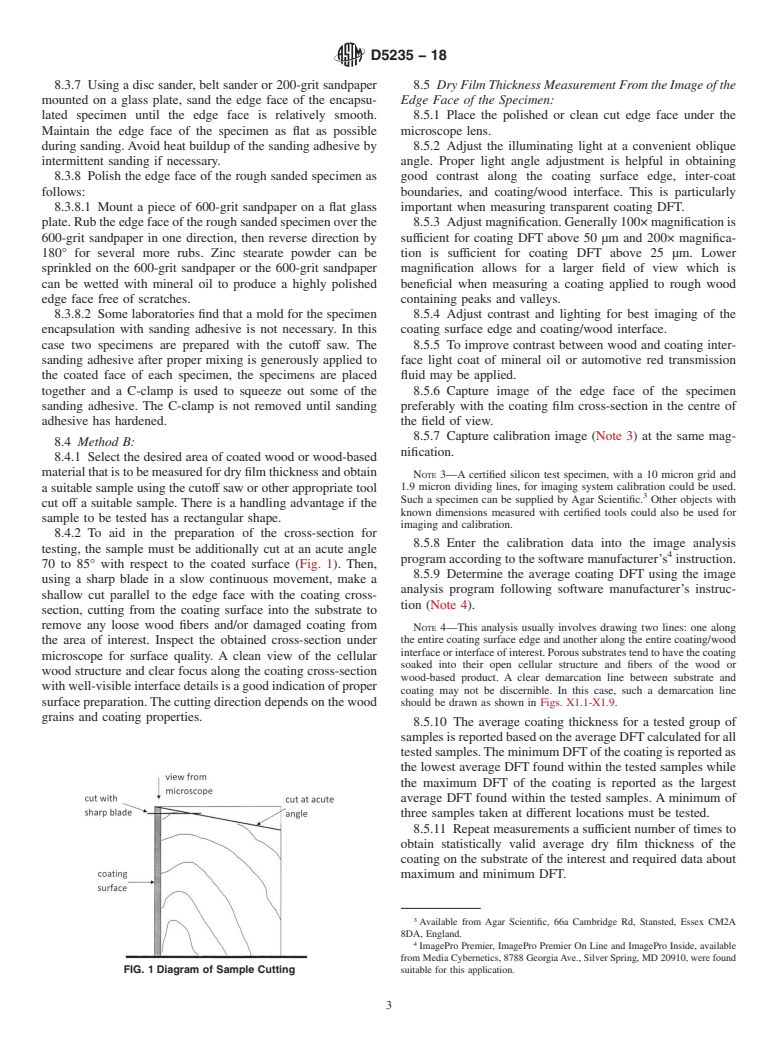

4.1 A specimen of coated wood or wood-based product is

Development of International Standards, Guides and Recom-

cut to convenient size and edge face with the coating film

mendations issued by the World Trade Organization Technical

cross-section is prepared by polishing or cutting with a sharp

Barriers to Trade (TBT) Committee.

blade.

2. Referenced Documents

4.2 The prepared edge of the specimen is imaged by a

2

2.1 ASTM Standards:

calibrated imaging system with known magnification in order

E177Practice for Use of the Terms Precision and Bias in

to measure the dry film thickness using an image analysis

ASTM Test Methods

computer program.

4.3 Suggestions regarding interpretation of dry film thick-

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint

ness on porous wood or wood-based material are offered.

and Related Coatings, Materials, andApplications and is the direct responsibility of

Subcommittee D01.52 on Factory Coated Wood Products.

Current edition approved Jan. 15, 2018. Published June 2018. Originally 5. Significance and Use

approved in 1992. Last previous edition approved in 2014 as D5235–14. DOI:

5.1 As a base for calibration adjustment or accuracy verifi-

10.1520/D5235-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or cation of dry film coating thickness measuring instruments.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.2 The dry film thickness of coatings on wood or wood-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. based products is specified in written product warranties for

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5235 − 18

proper

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5235 − 14 D5235 − 18

Standard Test Method for

Microscopic Measurement of Dry Film Thickness of

1

Coatings on Wood Products

This standard is issued under the fixed designation D5235; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the measurement of dry film thickness of coatings applied to a smooth, textured or curved rigid

substrate of wood or a wood-based productproduct.

1.2 This test method covers the preparation of wood or wood-based specimens for the purpose of microscopic measurement of

dry film thickness.

1.3 This test method suggests an analysis of dry film thickness of coatings on wood or wood-based products using a microscopic

measurement.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 dry film thickness or DFT, n—the thickness of dried, cured coating film on the substrate surface which may include

attached fibers but excludes free fibers that are encapsulated in the layer itself.

3.1.2 edge face, n—that part of the specimen that is a plane perpendicular to the surface showing a cross section of the coating

and substrate.

3.1.3 soak in, n—refers to a coating on a porous (wood) where the coating does not lie essentially on the surface of the wood

or wood-based product, but has penetrated into the fiber structure of the wood or wood-based material.

3.1.3.1 Discussion—

Wood or wood-based products are generally of a porous nature; sometimes exhibiting uniform absorption of coatings. Frequently

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.52 on Factory Coated Wood Products.

Current edition approved Dec. 1, 2014Jan. 15, 2018. Published February 2015June 2018. Originally approved in 1992. Last previous edition approved in 20132014 as

D5235 – 13.D5235 – 14. DOI: 10.1520/D5235-14.10.1520/D5235-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5235 − 18

absorption of coatings is of a non-uniform nature and influenced by localized surface density differences or wood pore size. These

conditions of coating absorption are commonly referred to as soak in.

4. Summary of Test Method

4.1 A specimen of coated wood or wood-based product is cut to convenient size and edge face with the coating film

cross-section is prepared by polishing or cutting with a sharp blade.

4.2 The prepared edge of the specimen is imaged by a calibrated imaging system with known magnification in order to measure

the dry film thickness using an image analysis computer program.

4.3 Suggestions regarding interpretation of dry film thickness on porous wood or wood-based material are offered.

5. Significance and Use

5.1 As a base for calibration adju

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5235 − 18

Standard Test Method for

Microscopic Measurement of Dry Film Thickness of

1

Coatings on Wood Products

This standard is issued under the fixed designation D5235; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 This test method covers the measurement of dry film

thickness of coatings applied to a smooth, textured or curved

3. Terminology

rigid substrate of wood or a wood-based product.

3.1 Definitions of Terms Specific to This Standard:

1.2 This test method covers the preparation of wood or

3.1.1 dry film thickness or DFT, n—the thickness of dried,

wood-based specimens for the purpose of microscopic mea-

cured coating film on the substrate surface which may include

surement of dry film thickness.

attached fibers but excludes free fibers that are encapsulated in

1.3 This test method suggests an analysis of dry film

the layer itself.

thickness of coatings on wood or wood-based products using a

3.1.2 edge face, n—that part of the specimen that is a plane

microscopic measurement.

perpendicular to the surface showing a cross section of the

1.4 The values stated in either SI units or inch-pound units

coating and substrate.

are to be regarded separately as standard. The values stated in

3.1.3 soak in, n—refers to a coating on a porous (wood)

each system may not be exact equivalents; therefore, each

where the coating does not lie essentially on the surface of the

system shall be used independently of the other. Combining

wood or wood-based product, but has penetrated into the fiber

values from the two systems may result in non-conformance

structure of the wood or wood-based material.

with the standard.

3.1.3.1 Discussion—Wood or wood-based products are gen-

1.5 This standard does not purport to address all of the

erally of a porous nature; sometimes exhibiting uniform

safety concerns, if any, associated with its use. It is the

absorption of coatings. Frequently absorption of coatings is of

responsibility of the user of this standard to establish appro-

a non-uniform nature and influenced by localized surface

priate safety, health, and environmental practices and deter-

density differences or wood pore size. These conditions of

mine the applicability of regulatory limitations prior to use.

coating absorption are commonly referred to as soak in.

1.6 This international standard was developed in accor-

dance with internationally recognized principles on standard-

4. Summary of Test Method

ization established in the Decision on Principles for the

4.1 A specimen of coated wood or wood-based product is

Development of International Standards, Guides and Recom-

cut to convenient size and edge face with the coating film

mendations issued by the World Trade Organization Technical

cross-section is prepared by polishing or cutting with a sharp

Barriers to Trade (TBT) Committee.

blade.

2. Referenced Documents

4.2 The prepared edge of the specimen is imaged by a

2

2.1 ASTM Standards:

calibrated imaging system with known magnification in order

E177 Practice for Use of the Terms Precision and Bias in

to measure the dry film thickness using an image analysis

ASTM Test Methods

computer program.

4.3 Suggestions regarding interpretation of dry film thick-

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint

ness on porous wood or wood-based material are offered.

and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.52 on Factory Coated Wood Products.

5. Significance and Use

Current edition approved Jan. 15, 2018. Published June 2018. Originally

approved in 1992. Last previous edition approved in 2014 as D5235 – 14. DOI:

5.1 As a base for calibration adjustment or accuracy verifi-

10.1520/D5235-18.

2

cation of dry film coating thickness measuring instruments.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.2 The dry film thickness of coatings on wood or wood-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. based products is specified in written product warranties for

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5235 − 18

proper decorative and protective performance of coatings on 8. Procedure

wood or wood-based products.

8.1 Specimen Preparation—Sel

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.