ASTM E319-85(2003)

(Practice)Standard Practice for the Evaluation of Single-Pan Mechanical Balances

Standard Practice for the Evaluation of Single-Pan Mechanical Balances

SIGNIFICANCE AND USE

Monitoring Weighing Performance—This practice provides results in the form of control charts which measure the weighing capability at the time of the test. A series of tests at appropriate intervals will monitor balance performance over a period of time. A marked change from expected performance may result from a variety of causes including: maladjustment, damage, dirt, foreign material, and thermal disturbances. If the test results are to indicate future performance, any disturbances that occur exterior to the balance must be brought under control (2).

Acceptance Tests—This practice may also be used as acceptance tests for new balances. For this purpose, the tests should be conducted under favorable, but not necessarily ideal, conditions. Since systematic error in the course of the zero and the course of the sensitivity may be caused by disturbances external to the balance, limits on these errors are not ordinarily prescribed in acceptance requirements.

SCOPE

1.1 This practice covers testing procedures for evaluating the performance of single-arm balances required by ASTM standards.

1.2 This practice is intended for but not limited to sensitivity ratios of 10 or better and on-scale ranges of 1000 xd or more where d = readability either directly or by estimation.

1.3 This practice can also be applied to other single-pan balances with mechanical weight changing of different capacities or sensitivities with appropriate test loads and calibration weights.

Note 1—Mechanical balances of this type have largely been replaced by automatic electronic balances incorporating a variety of operational principles. Nevertheless, some single-pan mechanical balances are still manufactured and many older balances will remain in service for years to come. One type of automatic electronic balance, the so-called "hybrid," bears considerable similarity to single-pan mechanical balances of the null type. (1)

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E319–85 (Reapproved 2003)

Standard Practice for the

Evaluation of Single-Pan Mechanical Balances

This standard is issued under the fixed designation E319; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

The balance performs two basic functions: (1) it compares an unknown load with one or more

weights, and (2) it indicates the difference between the two loads for differences smaller than the

smallestweightsnormallyusedonthebalance.Thetestproceduregivenhereinmeasurestheprecision

withwhichthebalancecancomparethetwoloads,andtheratesatwhichsystematicerrorsmayaffect

the observed difference.

1. Scope 2.1.1 accuracy—the degree of agreement of the measure-

ments with the true value of the magnitude of the quantity

1.1 This practice covers testing procedures for evaluating

measured (2).

the performance of single-arm balances required by ASTM

2.1.2 correction for a weight—thecorrectionfortheerrorin

standards.

adjustment is:

1.2 Thispracticeisintendedforbutnotlimitedtosensitivity

ratios of 10 or better and on-scale ranges of 1000xd or more Cr.W 5 A 2 N (1)

where d = reability either directly or by estimation.

1.3 This practice can also be applied to other single-pan

where:

balances with mechanical weight changing of different capaci-

Cr.W = correction for the error in adjustment to nominal

ties or sensitivities with appropriate test loads and calibration

value,

weights.

A = actual value of the weight, and

N = nominal value.

NOTE 1—Mechanical balances of this type have largely been replaced

by automatic electronic balances incorporating a variety of operational

NOTE 2—In practice it is not possible to adjust weights exactly to their

principles. Nevertheless, some single-pan mechanical balances are still

nominal values.

manufactured and many older balances will remain in service for years to

come. One type of automatic electronic balance, the so-called “hybrid,”

2.1.3 correction for error in scale indication—the correc-

bearsconsiderablesimilaritytosingle-panmechanicalbalancesofthenull

tion for the scale indication, I, is:

type. (1)

Cr.I 5 A 2 I (2)

1.4 This standard does not purport to address all of the

safety problems, if any, associated with its use. It is the

NOTE 3—The correction for the scale is taken with reference to the

responsibility of the user of this standard to establish appro-

measured value of a weight used as a test load during calibration of the

priate safety and health practices and determine the applica-

on-scale range.

bility of regulatory limitations prior to use.

2.1.4 index of precision—the standard deviation, computed

in any acceptable manner, for a collection of measurements

2. Terminology

involving a given pair of mass standards (3).

2.1 Definitions (1):

NOTE 4—Thestandarddeviationiscomputedfromthedataprovidedby

the instrument precision test (see Section 7) index of precision.

This practice is under the jurisdiction ofASTM Committee E41 on Laboratory

2.1.5 null-type balance—a balance which requires, as the

Apparatus and is the direct responsibility of Subcommittee E41.06 on Weighing

Devices.

final step in its operation, that the observer restore the angle of

Current edition approved Aug. 30, 1985. Published October 1985. Originally

the balance beam to its original (or null) position. The least

e1

published as E319–68. Last previous edition E319–68(1976) .

2 significant figures of the balance indication are obtained from

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

this practice. this operation.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E319–85 (2003)

2.1.6 optical-type balance—in this type the least significant period of time. A marked change from expected performance

figures of the balance indication are related to the deflection may result from a variety of causes including: maladjustment,

angle of the beam from its original (or null) position. A scale damage, dirt, foreign material, and thermal disturbances. If the

placed on the moving beam is optically projected onto the testresultsaretoindicatefutureperformance,anydisturbances

(stationary) balance case to provide this indication. thatoccurexteriortothebalancemustbebroughtundercontrol

2.1.7 precision—the repeatability of the balance indication (2).

with the same load under essentially the same conditions.

4.2 Acceptance Tests—This practice may also be used as

acceptance tests for new balances. For this purpose, the tests

NOTE 5—The more closely the measurements are grouped, the smaller

shouldbeconductedunderfavorable,butnotnecessarilyideal,

the index of precision will be. The precision must be measured under

conditions. Since systematic error in the course of the zero and

environmental conditions that represent the conditions under which the

the course of the sensitivity may be caused by disturbances

balance is normally used.

external to the balance, limits on these errors are not ordinarily

2.1.8 readability—the value of the smallest decimal subdi-

prescribed in acceptance requirements.

vision of a scale division in terms of mass units, that can be

read, when the balance is read in the intended manner.

5. Preparation of Apparatus

NOTE 6—The readability of a particular instrument is not a measure of

5.1 Balance (In all cases, the balance should be used in

its performance as a weighing device. The relationship between the

accordance with the manufacturer’s instructions):

numericalvalueobtainedbyreadingdevicesandtheabilityoftheoperator

to estimate the location of the reference device or index is important. It is 5.1.1 The results obtained will depend on the environment.

possible to introduce a large number of readable subdivisions of the main

Select an area which is free of excessive vibration and air

scale divisions that would increase the “readability” as defined but if the

currents, where rapid changes in temperature and relative

readingdevicecannotberesettothesamenumericalvaluewhenthebeam

humidity will not be encountered, and where the floor is rigid

is in an immovable condition, or when the load on the beam is a constant

enough to be free of a tilting effect on the balance indication.

value, the readability becomes meaningless. Readability substantially less

Place the balance on a sturdy bench. If the balance has been

than 1 standard deviation as determined by repeated measurement with a

moved to a new location, permit it to come to thermal

given test weight is usually superfluous.

equilibrium for at least 1 h before performing the test,

2.1.9 scale division—the smallest graduated interval subdi-

preferably several hours.

vided either by estimation or with the aid of a vernier.

5.1.2 Inspect and test the balance to make sure that it is in

Subdivisions which appear as divisions on the vernier are not

proper mechanical order.Arrest and release the beam to make

considered to be scale divisions, but rather parts of scale

sure that readings are approximately repetitive. Observe the

divisions.

indication during arrest and release to ensure that there is no

2.1.10 sensitivity weight—a small weight used to measure

“kick” that would indicate that arrestment points might be out

the “on-scale” deflection of the balance indicator.

of adjustment. If necessary, have the balance adjusted by a

NOTE 7—With single-pan balances the sensitivity weight should be

competent balance technician.

equal to the value of the smallest built-in weight represented by the first

5.1.3 Make a few trial measurements of the interval from

step on the dial for the smallest weights.

zero to the full-scale indication.

2.1.11 test load—aloadchosentorepresentthesampleload

5.2 Reading the Balance—The balance should be read in

in the test procedure.

accordance with the instructions supplied by the manufacturer.

2.1.12 value of the division—the change in load required to

Optical types should include the reading of verniers or mi-

change the balance indication by one scale division. The

crometres. Null types should include the indication of the

reciprocal of the sensitivity is its most useful function.

device for restoring to null including verniers or micrometres.

3. Summary of Practice

6. Preliminary Testing of Single-Arm Balances

3.1 The accuracy of the direct-reading scale, the smallest

6.1 Summary of Method—With single-pan balances the

weight of the set of built-in weights, and uniformity of

smallest built-in weight, indicated by the first step on the dial,

sensitivity between the upper and lower halves of full-scale

is compared with a calibrated weight. The direct-reading scale

deflections are verified by preliminary tests.

istestedforagreementwiththesmallestbuilt-inweightandthe

3.2 Estimatesofrateofchangeofthezerowithtime,rateof

sensitivity is adjusted, if necessary, so that the indications of

change in the value of the scale division with time, and a

the scale are precise in terms of the calibrated weight. A

quantitative measure of the variability or random error are

“fifty-fifty” test verifies the accuracy of the midpoint at

provided by short tests for precision and bias.

half-full scale. This test should be performed before proceed-

3.3 An overall test of the direct-reading capability is pro-

ing to other tests. After the accuracy of adjustment of the

vided by tests of the built-in weights.

smallest built-in weight is verified, this weight is used to test

full-scale deflections.Tests are also made for the uniformity of

4. Significance and Use

deflection over the lower and upper halves of the full-scale

4.1 Monitoring Weighing Performance—This practice pro- deflection.Thepreliminarytestsshoweitherthatthebalanceis

vides results in the form of control charts which measure the operating properly, or that discrepancies indicate the presence

weighing capability at the time of the test. A series of tests at of sources of error. Uncertainties of perhaps one millionth of

appropriate intervals will monitor balance performance over a the balance capacity may be caused by dirt or foreign material

E319–85 (2003)

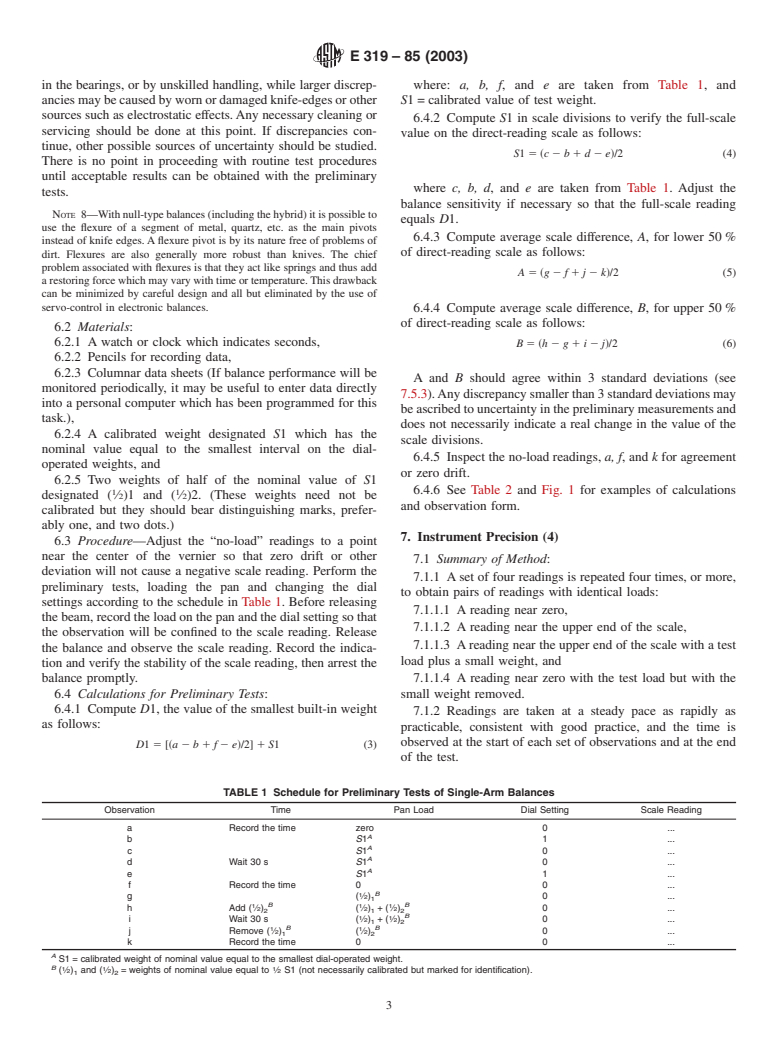

in the bearings, or by unskilled handling, while larger discrep- where: a, b, f, and e are taken from Table 1, and

anciesmaybecausedbywornordamagedknife-edgesorother S1=calibrated value of test weight.

sources such as electrostatic effects.Any necessary cleaning or

6.4.2 Compute S1 in scale divisions to verify the full-scale

servicing should be done at this point. If discrepancies con-

value on the direct-reading scale as follows:

tinue, other possible sources of uncertainty should be studied.

S1 5 ~c 2 b 1 d 2 e!/2 (4)

There is no point in proceeding with routine test procedures

until acceptable results can be obtained with the preliminary

where c, b, d, and e are taken from Table 1. Adjust the

tests.

balance sensitivity if necessary so that the full-scale reading

NOTE 8—Withnull-typebalances(includingthehybrid)itispossibleto

equals D1.

use the flexure of a segment of metal, quartz, etc. as the main pivots

6.4.3 Compute average scale difference, A, for lower 50%

instead of knife edges.Aflexure pivot is by its nature free of problems of

of direct-reading scale as follows:

dirt. Flexures are also generally more robust than knives. The chief

problem associated with flexures is that they act like springs and thus add

A 5 ~g 2 f 1 j 2 k!/2 (5)

arestoringforcewhichmayvarywithtimeortemperature.Thisdrawback

can be minimized by careful design and all but eliminated by the use of

servo-control in electronic balances.

6.4.4 Compute average scale difference, B, for upper 50%

of direct-reading scale as follows:

6.2 Materials:

6.2.1 A watch or clock which indicates seconds,

B 5 ~h 2 g 1 i 2 j!/2 (6)

6.2.2 Pencils for recording data,

6.2.3 Columnar data sheets (If balance performance will be

A and B should agree within 3 standard deviations (see

monitored periodically, it may be useful to enter data directly

7.5.3).Anydiscrepancysmallerthan3standarddeviationsmay

into a personal computer which has been programmed for this

beascribedtouncertaintyinthepreliminarymeasurementsand

task.),

does not necessarily indicate a real change in the value of the

6.2.4 A calibrated weight designated S1 which has the

scale divisions.

nominal value equal to the smallest interval on the dial-

6.4.5 Inspect the no-load readings, a, f, and k for agreement

operated weights, and

or zero drift.

6.2.5 Two weights of half of the nominal value of S1

1 1 6.4.6 See Table 2 and Fig. 1 for examples of calculations

designated ( ⁄2)1 and ( ⁄2)2. (These weights need not be

and observation form.

calibrated but they should bear distinguishing marks, prefer-

ably one, and two dots.)

7. Instrument Precision (4)

6.3 Procedure—Adjust the “no-load” readings to a point

near the center of the vernier so that zero drift or other

7.1 Summary of Method:

deviation will not cause a negative scale reading. Perform the

7.1.1 Aset of four readings is repeated four times, or more,

preliminary tests, loading the pan and changing the dial

to obtain pairs of readings with identical loads:

settings according to the schedule in Table 1. Before releasing

7.1.1.1 A reading near zero,

thebeam,recordtheloadonthepanandthedialsettingsothat

7.1.1.2 A reading near the upper end of the scale,

the observation will be confined to the scale reading. Release

7.1.1.3 Areading near the upper end of the scale with a test

the balance and observe the scale reading. Record the indica-

load plus a small weight, and

tion and verify the stability of the scale reading, then arrest the

balance promptly. 7.1.1.4 A reading near zero with the test load but with the

6.4 Calculations for Preliminary Tests: small weight removed.

6.4.1 Compute D1, the value of the smallest built-in weight

7.1.2 Readings are taken at a steady pace as rapidly as

as follows:

practicable, consistent with good practice, and the time is

observed at the start of each set of observations and at the end

D1 5[~a 2 b 1 f 2 e!/2] 1 S1 (3)

of the test.

TABLE 1 Schedule for Preliminary Tests of Single-Arm Balances

Observation Time Pan Load Dial Setting Scale Reading

a Record the time zero 0 .

A

b S1 1 .

A

c S1 0 .

A

dWait30s S1 0 .

A

e S1 1 .

f Record the time 0 0 .

B

g( ⁄2) 0 .

B B

1 1 1

h Add ( ⁄2) ( ⁄2) +( ⁄2) 0 .

2 1 2

B

1 1

iWait30s ( ⁄2) +( ⁄2) 0 .

1 2

1 B 1 B

j Remove ( ⁄2) ( ⁄2) 0 .

1 2

k Record the time 0 0 .

A

S1 = calibrated weight of nominal value equal to the smallest dial-operated weight.

B

1 1 1

( ⁄2) and ( ⁄2) = weights of nominal value equal to ⁄

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.