ASTM E2734/E2734M-10(2018)

(Specification)Standard Specification for Dimensions of Knife-Edge Flanges

Standard Specification for Dimensions of Knife-Edge Flanges

SCOPE

1.1 This standard specifies the dimensions of knife-edge style flanges and their associated gaskets used in vacuum systems for pressures ranging from 105 Pa to 10-11 Pa. Such flanges are widely used throughout vacuum technology applications in semiconductor processing tools, surface analysis systems, space simulation systems, and general research requiring vacuum.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2734/E2734M −10 (Reapproved 2018)

Standard Specification for

Dimensions of Knife-Edge Flanges

ThisstandardisissuedunderthefixeddesignationE2734/E2734M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 ISO Standard:

ISO 4288:1996 GeometricalProductSpecifications(GPS)—

1.1 This standard specifies the dimensions of knife-edge

Surface Texture: Profile Method—Rules and Procedures

style flanges and their associated gaskets used in vacuum

for the Assessment of Surface Texture

5 -11

systems for pressures ranging from 10 Pa to 10 Pa. Such

flanges are widely used throughout vacuum technology appli-

3. Terminology

cations in semiconductor processing tools, surface analysis

3.1 Definitions—For definitions used in this specification,

systems, space simulation systems, and general research re-

see Terminology E673.

quiring vacuum.

3.2 Definitions of Terms Specific to This Standard:

1.2 The values stated in either SI units or inch-pound units 3.2.1 knife-edge flange, n—vacuum flanges seal with a

are to be regarded separately as standard. The values stated in metal gasket; two mating surfaces with identical circular

each system may not be exact equivalents; therefore, each (triangular profile) knife-edges are bolted together; a deform-

system shall be used independently of the other. Combining able metal gasket, captured between the knife-edges provides a

values from the two systems may result in non-conformance leak-free seal.

with the standard. 3.2.1.1 Discussion—Vacuum flanges that seal with a metal

gasket were originally developed as Conflat flanges (trade-

1.3 This standard does not purport to address all of the

mark) by the Varian Corporation.

safety concerns, if any, associated with its use. It is the

3.2.2 type, n—knife-edge flanges come in a variety of sizes;

responsibility of the user of this standard to establish appro-

historically, the flange sizes were identified in North America

priate safety, health, and environmental practices and deter-

astheflange’soutsidediameter(ininches)andinEuropeasthe

mine the applicability of regulatory limitations prior to use.

maximum nominal bore of the tube (in millimetres) that might

1.4 This international standard was developed in accor-

be welded to the flange; for this specification, the flange

dance with internationally recognized principles on standard-

identification “type” is used where the type is approximately

ization established in the Decision on Principles for the

equal to the flange’s outside diameter in inches.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

4. Materials and Manufacture

Barriers to Trade (TBT) Committee.

4.1 Flange—Flanges must be manufactured from a suffi-

cientlyhardorhard-coatedmaterialtoresistdeformationofthe

2. Referenced Documents

knife-edge profile despite repeatedly forming a vacuum seal

2.1 ASTM Standard:

with metal gaskets.

E673 Terminology Relating to SurfaceAnalysis (Withdrawn

3 4.2 Gasket—Gasket must be manufactured from a soft,

2012)

annealed, or partially-tempered metal such that the mating

flanges’ knife-edges cause sufficient (initial) plastic deforma-

tion that a vacuum seal is accomplished.

ThisspecificationisunderthejurisdictionofASTMCommitteeE42onSurface

Analysis and is the direct responsibility of Subcommittee E42.13 on Vacuum

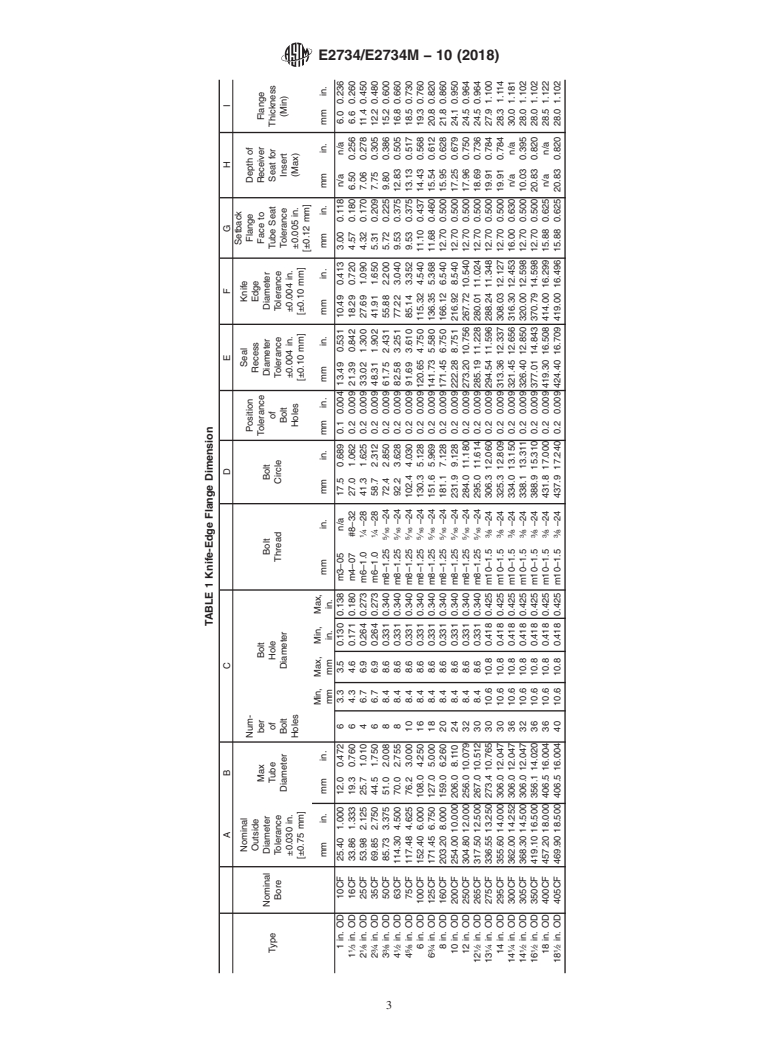

5. Dimensions, Mass, and Permissible Variations

Technology.

Current edition approved June 1, 2018. Published June 2018. Originally 5.1 Figs. 1-3 and Tables 1 and 2 contain the required

approved in 2010. Last previous edition approved in 2010 as E2734/E2734M–10.

dimensions and tolerances for rotatable and non-rotatable

DOI: 10.1520/E2734_E2734M-10R18.

knife-edge vacuum flanges.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Available from International Organization for Standardization (ISO), ISO

The last approved version of this historical standard is referenced on Central Secretariat, BIBC II, Chemin de Blandonnet 8, CP 401, 1214 Vernier,

www.astm.org. Geneva, Switzerland, http://www.iso.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2734/E2734M − 10 (2018)

FIG. 1 Flange Dimensions: (a) Non-Rotatable Flange (b) Rotatable Flange

FIG. 2 Knife-Edge Detail

FIG. 3 Knife-Edge Gasket Dimensions

E2734/E2734M − 10 (2018)

TABLE 1 Knife-Edge Flange Dimension

AB C D E F G H I

Setback

Nominal Seal Knife

Num- Position Flange Depth of

Outside Recess Edge

Max ber Bolt Tolerance Face to Receiver Flange

Nominal Diameter Bolt Bolt Diameter Diameter

Type Tube of Hole of Tube Seat Seat for Thickness

Bore Tolerance Thread Circle Tolerance Tolerance

Diameter Bolt Diameter Bolt Tolerance Insert (Min)

±0.030 in. ±0.004 in. ±0.004 in.

Holes Holes ±0.005 in. (Max)

[±0.75 mm] [±0.10 mm] [±0.10 mm]

[±0.12 mm]

Min, Max, Min, Max,

mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm in.

mm mm in. in.

1 in. OD 10CF 25.40 1.000 12.0 0.472 6 3.3 3.5 0.130 0.138 m3–05 n/a 17.5 0.689 0.1 0.004 13.49 0.531 10.49 0.413 3.00 0.118 n/a n/a 6.0 0.236

1 ⁄3 in. OD 16CF 33.86 1.333 19.3 0.760 6 4.3 4.6 0.171 0.180 m4–07 #8–32 27.0 1.062 0.2 0.009 21.39 0.842 18.29 0.720 4.57 0.180 6.50 0.256 6.6 0.260

1 1

2 ⁄8 in. OD 25CF 53.98 2.125 25.7 1.010 4 6.7 6.9 0.264 0.273 m6–1.0 ⁄4 –28 41.3 1.625 0.2 0.009 33.02 1.300 27.69 1.090 4.32 0.170 7.06 0.278 11.4 0.450

3 1

2 ⁄4 in.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.