ASTM D2050-04

(Terminology)Standard Terminology Relating to Subassemblies

Standard Terminology Relating to Subassemblies

SCOPE

1.1 This terminology covers all terminology pertaining to items that are considered subassemblies in the manufacture of textile products (not including seams and stitches). Textile joining structures (seams and stitches) are discussed in detail in

1.2 The principle parts of zippers defined in this terminology are illustrated in Figs. 1-9. These figures are descriptive only and are not intended to be restrictive as to design.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D2050–04

Standard Terminology Relating to

1

Subassemblies

This standard is issued under the fixed designation D 2050; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope bridge top stop, n—a part affixed immediately above the

chain, holding the tops of two stringers together and pre-

1.1 This terminology covers all terminology pertaining to

venting the slider from leaving the chain. (See Fig. 2.)

items that are considered subasseblies in the manufacture of

cam lock slider, n—a slider that incorporates a curled projec-

textile products (not including seams and stitches). Textile

tion or projections on the pull that extends through a window

joining structures (seams and stitches) are discussed in detail in

or windows to effect a locking action by pressing against the

1.2 The principle parts of zippers defined in this terminol-

interlocking elements when the cam lock slider is in the

ogy are illustrated in Figs. 1-9. These figures are descriptive

locked position.

only and are not intended to be restrictive as to design.

chain, n—the assemblage formed by interlocking several

2. Referenced Documents elements of two stringers.

2

chain thickness, n—themeasurementfromfronttobackofthe

2.1 ASTM Standards:

chain.

D 6193 Practice for Stitches and Seams

chain width, n—the measurement between the shoulders of

3. Terminology

the interlocked elements or between the outermost edges of

the bead if the bead extends beyond the elements.

automatic lock slider, n—a slider that provides involuntary,

connecting ring, n—adeviceshapedliketheletter“D”usedto

positive locking action on the chain when the pull is

secure a pull, having more than one component in its design,

released.

to the bail of the slider.

bail, n—a portion or portions of the slider to which the pull or

continuous element, n—aconfiguredelementformedcontinu-

pulls are attached. (Syn. lug.)

ously along a length of monofilament. (Compare separate

bead, n—in a separate element zipper, an enlarged section on

element.)

the inner edge of each tape to which interlockable elements

continuous element zipper, n—a zipper consisting of two

are affixed.

continuously formed elements, each attached to one of the

bead, n—in continuous element zippers, an optional enlarged

opposing edges of two tapes, which are engaged and

sectionofthetapelocatedattheouteredgeofthecontinuous

disengaged by the movement of a slider. (See Fig. 3.)

interlockable elements and against which the slider flanges

(Compare separate element zipper.)

bear.

cord, n—a strand of multiple yarns for use in forming a bead.

bottom assembly, n—the components of the lowermost part of

crimp, n—as applied to a continuous element zipper, the

a slide fastener which determine whether the slide fastener

predetermined formation of the monofilament cross-section

will be non-separable or separable. (See also non-separable

at the point where the continuous element is interlocked.

zipper and separable zipper.)

cut-off, n—the measurement of a separate element from the

bottom stop, n—a part affixed to both stringers immediately

head side to the pocket side of the legs.

below, or over the chain, holding the two stringers together

diamond, n—thewedge-shapedportionofasliderbetweenthe

at the bottom and preventing the slider from leaving the

throats.

chain. (See Fig. 1.)

element, n—a device designed for interlocking, capable of

being affixed along the edge of a tape. (Compare continuous

1

ThisterminologyisunderthejurisdictionofASTMCommitteeD13onTextiles element and separate element.) (See Fig. 4.)

and is the direct responsibility of Subcommittee D13.54 on Subassemblies. These

exposed tape width, n—the part of the tape extending beyond

definitions were developed in cooperation with the American Fastener and Closure

the shoulders of the interlocking elements to the outer tape

Assn. Inc.

edge.

Current edition approved Oct. 1, 2004. Published October 2004. Originally

approved in 1961. Last previous edition approved in 1997 as D 2050 – 03

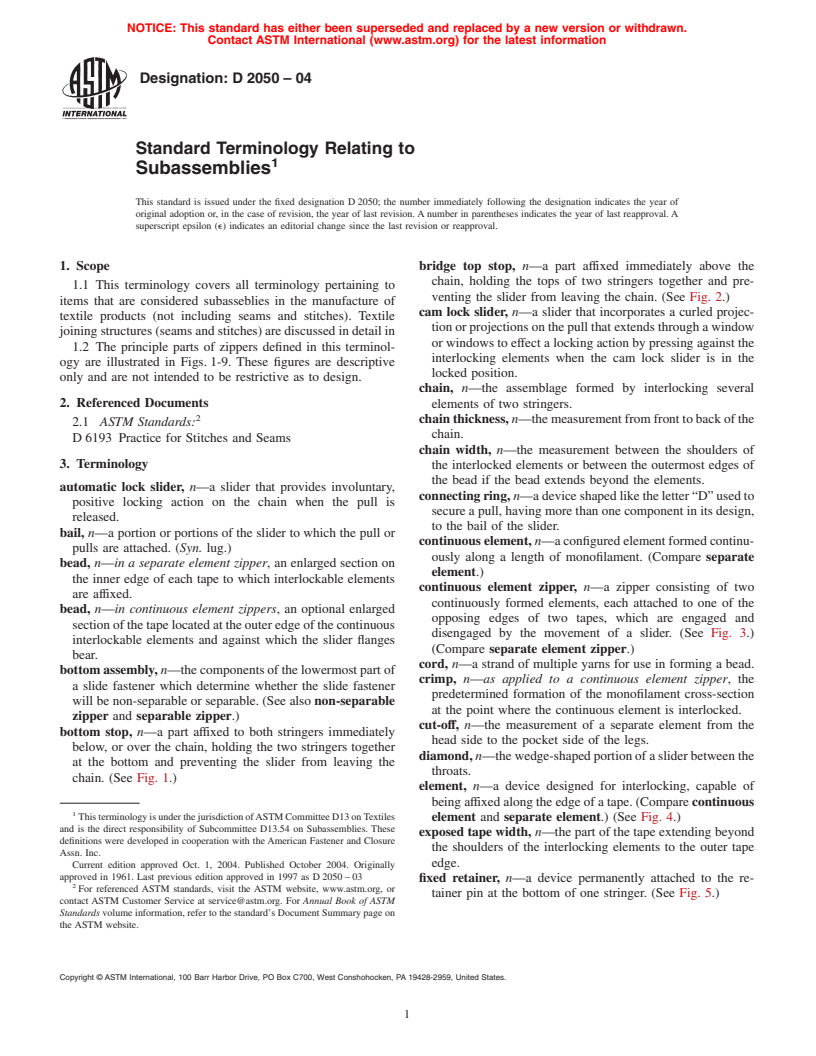

fixed retainer, n—a device permanently attached to the re-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

tainer pin at the bottom of one stringer. (See Fig. 5.)

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

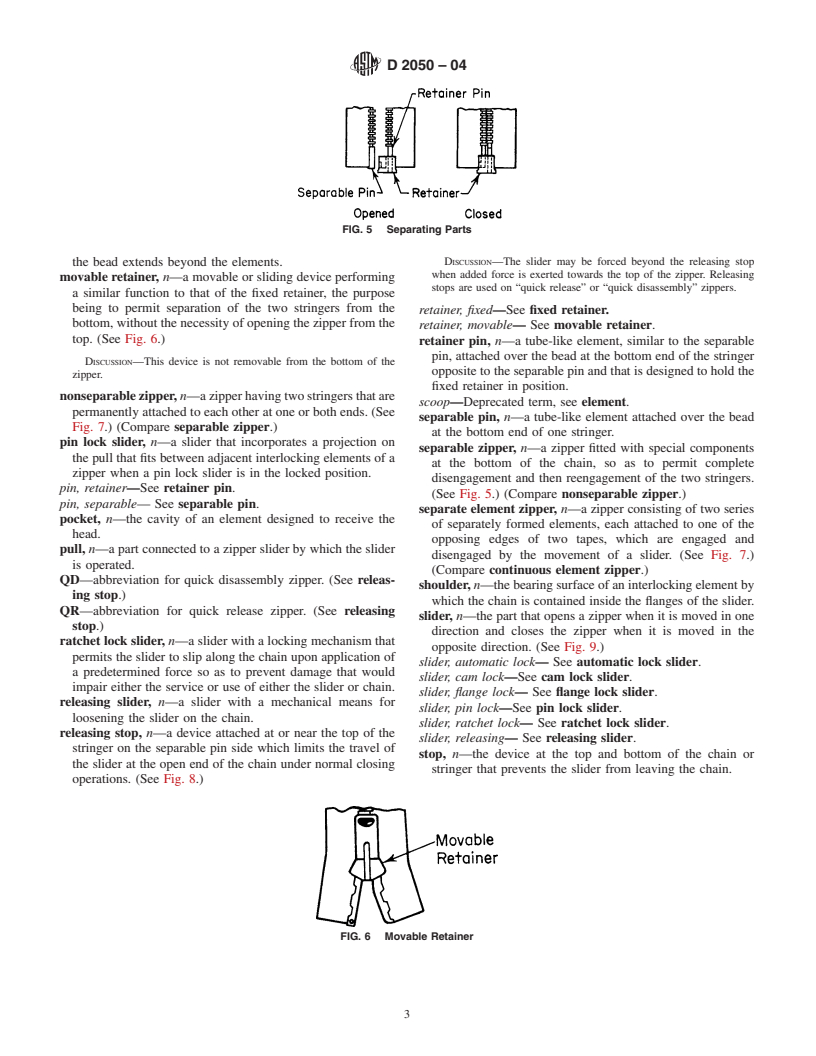

1

---------------------- Page: 1 ----------------------

D2050–04

FIG. 1 Bottom Stop

FIG. 2 Bridge Stop

FIG. 3 Principl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.