ASTM C919-12(2017)

(Practice)Standard Practice for Use of Sealants in Acoustical Applications

Standard Practice for Use of Sealants in Acoustical Applications

SIGNIFICANCE AND USE

4.1 Walls, ceilings, and floors in building construction, especially those that are of lightweight construction, and that are designed to reduce or limit sound transmission, can have undesirable sound transmission characteristics if care is not taken to seal joints, voids, and penetrations that typically occur. Unsealed joints, voids, and penetrations will substantially increase the sound transmission characteristics of these types of construction. By sealing them the transmission of sound can be substantially diminished by eliminating “flanking paths.”

SCOPE

1.1 This practice provides information for the use of sealants to reduce sound transmission characteristics of interior walls, ceilings, and floors by proper application of sealants to joints, voids, and penetrations normally found in building construction, which are commonly referred to as “flanking paths.”

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.3 The committee with jurisdiction over this standard is not aware of any comparable standards published by other organizations.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C919 − 12 (Reapproved 2017)

Standard Practice for

Use of Sealants in Acoustical Applications

This standard is issued under the fixed designation C919; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C1642 Practice for DeterminingAir Leakage Rates ofAero-

sol Foam Sealants and Other Construction Joint Fill and

1.1 This practice provides information for the use of seal-

Insulation Materials

ants to reduce sound transmission characteristics of interior

E90 Test Method for Laboratory Measurement of Airborne

walls, ceilings, and floors by proper application of sealants to

Sound Transmission Loss of Building Partitions and

joints, voids, and penetrations normally found in building

Elements

construction, which are commonly referred to as “flanking

E336 Test Method for Measurement of Airborne Sound

paths.”

Attenuation between Rooms in Buildings

1.2 This standard does not purport to address all of the

E413 Classification for Rating Sound Insulation

safety concerns, if any, associated with its use. It is the 3

2.2 HUD Standard:

responsibility of the user of this standard to establish appro-

HUD Minimum Property Standards for Housing, Section

priate safety and health practices and determine the applica-

4910.1

bility of regulatory limitations prior to use.

2.3 IBC Standard:

1.3 Thecommitteewithjurisdictionoverthisstandardisnot

International Building Code (IBC), Section 1207

aware of any comparable standards published by other orga-

nizations.

3. Terminology

1.4 This international standard was developed in accor-

3.1 Definitions—For definitions of terms used in this rec-

dance with internationally recognized principles on standard-

ommended practice, see Terminologies C717 and C634.

ization established in the Decision on Principles for the

4. Significance and Use

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

4.1 Walls, ceilings, and floors in building construction,

Barriers to Trade (TBT) Committee.

especially those that are of lightweight construction, and that

are designed to reduce or limit sound transmission, can have

2. Referenced Documents

undesirable sound transmission characteristics if care is not

2.1 ASTM Standards: takentosealjoints,voids,andpenetrationsthattypicallyoccur.

C634 Terminology Relating to Building and Environmental Unsealed joints, voids, and penetrations will substantially

Acoustics increase the sound transmission characteristics of these types

C717 Terminology of Building Seals and Sealants of construction. By sealing them the transmission of sound can

C834 Specification for Latex Sealants be substantially diminished by eliminating “flanking paths.”

C920 Specification for Elastomeric Joint Sealants

5. Sound Transmission Requirements

C1193 Guide for Use of Joint Sealants

C1520 Guide for Paintability of Latex Sealants 5.1 The construction industry has adopted Sound Transmis-

C1620 Specification for Aerosol Polyurethane and Aerosol

sionClass(STC)units,asdefinedinTerminologyC634,torate

Latex Foam Sealants the sound transmission properties of walls, ceilings, and floors.

TheSTCisdeterminedinaccordancewithClassificationE413.

The test data are obtained in accordance with Test Methods

This practice is under the jurisdiction of ASTM Committee C24 on Building E90 and E336.

Seals and Sealants and is the direct responsibility of Subcommittee C24.10 on

5.2 Various building and other governmental adopted codes

Specifications, Guides and Practices.

Current edition approved June 1, 2017. Published June 2017. Originally include requirements for sound transmission.

approved in 1979. Last previous edition approved in 2012 as C919 – 12. DOI:

10.1520/C0919-12R17.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from Superintendent of Documents, U.S. Government Printing

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Office, Washington, DC 20402.

Standards volume information, refer to the standard’s Document Summary page on Available from International Code Council (ICC), 500 New Jersey Ave., NW,

the ASTM website. 6th Floor, Washington, DC 20001, http://www.iccsafe.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C919 − 12 (2017)

5.2.1 For example, the International Building Code (IBC),

Section 1207, has requirements for the amount of sound that is

allowed to be transmitted through the interior walls, partitions,

and floor and ceiling assemblies between adjacent dwelling

units and between them and public spaces of a building.

5.2.2 Additionally, the department of Housing and Urban

Development (HUD) has the following standard for STC

limitations for various housing units: HUD Minimum Property

Standards for Housing, Section 4910.1.

6. Why Seal Openings?

6.1 The sound transmission of a wall, ceiling, or floor, no

matter how well built, can be substantially defeated by the

presence of unsealed joints, voids, and penetrations. Fig. 1

illustrates examples of how sound travels through unsealed

joints, voids, and penetrations in walls and how sealing them

will minimize sound transmission.

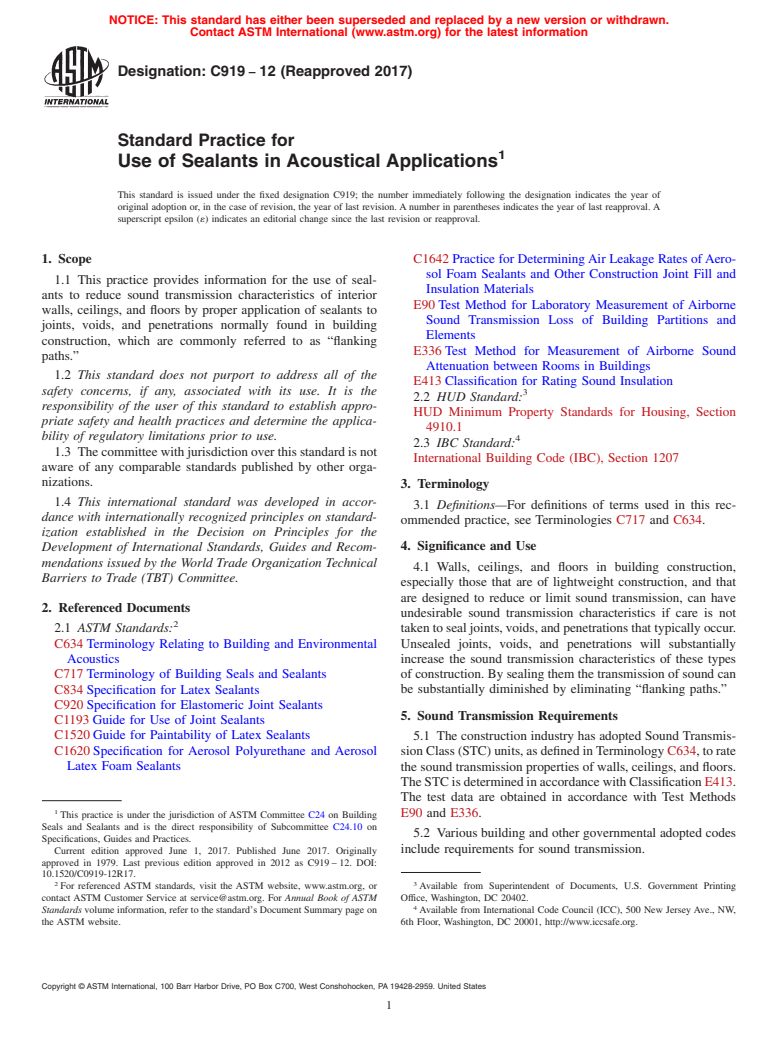

6.2 The effect of unsealed joints, voids, and penetrations on

the STC rating of partition walls is illustrated in Fig. 2. For the

sample wall example, with an STC rating of 40 that has

2 2

openings that total 9 cm (1.4 in. ) will have its STC reduced

FIG. 2 Effect of Unsealed Hole Openings on STC-Rated Test

to 36 a 10 % difference. However, that small difference results

Wall, 3.8by2.4m(12 ft6in. by8ft)

in a change to the apparent loudness of sound transmission to

that which is twice as loud.

7. Positioning of Sealants

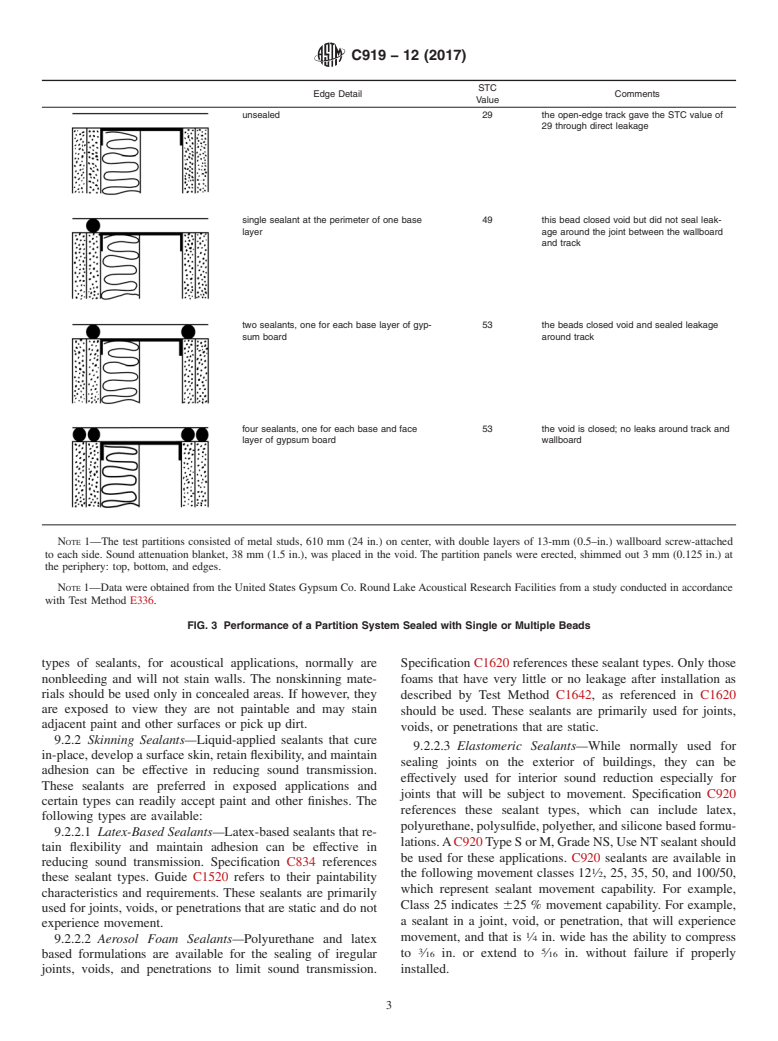

7.1 Fig. 3 illustrates placement of liquid-applied sealants to

improve the STC rating from a value of 29 to a value of 53.

Note that two properly placed sealants are sufficient and

sealing beyond that is unnecessary.

8. Application of Sealants

8.1 Fig. 4 illustrates typical liquid-applied sealant applica-

tions. Additional sealant application information can be ob-

tained from Guide C1193 and manufacturers literature for

specific products and applications.

9. Types of Sealants

9.1 Precured Sealants—Precured sealants include a wide

variety of gaskets and tapes, and foamed shapes that have

constant dimensions. These materials are effective sound seals

when the tolerances for joint, void, or penetration opening can

be accurately predicted and installed within those tolerances.A

varying opening width along its length, which exceeds those

tolerances, will cause the gasket, tape or foamed shape to have

difficulty in maintaining a proper seal at all points with the

constant compression that is necessary

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C919 − 12 C919 − 12 (Reapproved 2017)

Standard Practice for

Use of Sealants in Acoustical Applications

This standard is issued under the fixed designation C919; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice provides information for the use of sealants to reduce sound transmission characteristics of interior walls,

ceilings, and floors by proper application of sealants to joints, voids, and penetrations normally found in building construction,

which are commonly referred to as “flanking paths.”

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.3 The committee with jurisdiction over this standard is not aware of any comparable standards published by other

organizations.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

C634 Terminology Relating to Building and Environmental Acoustics

C717 Terminology of Building Seals and Sealants

C834 Specification for Latex Sealants

C920 Specification for Elastomeric Joint Sealants

C1193 Guide for Use of Joint Sealants

C1520 Guide for Paintability of Latex Sealants

C1620 Specification for Aerosol Polyurethane and Aerosol Latex Foam Sealants

C1642 Practice for Determining Air Leakage Rates of Aerosol Foam Sealants and Other Construction Joint Fill and Insulation

Materials

E90 Test Method for Laboratory Measurement of Airborne Sound Transmission Loss of Building Partitions and Elements

E336 Test Method for Measurement of Airborne Sound Attenuation between Rooms in Buildings

E413 Classification for Rating Sound Insulation

2.2 HUD Standard:

HUD Minimum Property Standards for Housing, Section 4910.1

2.3 IBC Standard:

International Building Code (IBC), Section 1207

3. Terminology

3.1 Definitions—For definitions of terms used in this recommended practice, see Terminologies C717 and C634.

This practice is under the jurisdiction of ASTM Committee C24 on Building Seals and Sealants and is the direct responsibility of Subcommittee C24.10 on Specifications,

Guides and Practices.

Current edition approved June 1, 2012June 1, 2017. Published July 2012June 2017. Originally approved in 1979. Last previous edition approved in 20082012 as

C919 – 08.C919 – 12. DOI: 10.1520/C0919-12.10.1520/C0919-17.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from Superintendent of Documents, U.S. Government Printing Office, Washington, DC 20402.

Available from International Code Council (ICC), 500 New Jersey Ave., NW, 6th Floor, Washington, DC 20001, http://www.iccsafe.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C919 − 12 (2017)

4. Significance and Use

4.1 Walls, ceilings, and floors in building construction, especially those that are of lightweight construction, and that are

designed to reduce or limit sound transmission, can have undesirable sound transmission characteristics if care is not taken to seal

joints, voids, and penetrations that typically occur. Unsealed joints, voids, and penetrations will substantially increase the sound

transmission characteristics of these types of construction. By sealing them the transmission of sound can be substantially

diminished by eliminating “flanking paths.”

5. Sound Transmission Requirements

5.1 The construction industry has adopted Sound Transmission Class (STC) units, as defined in Terminology C634, to rate the

sound transmission properties of walls, ceilings, and floors. The STC is determined in accordance with Classification E413. The

test data are obtained in accordance with Test Methods E90 and E336.

5.2 Various building and other governmental adopted codes include requirements for sound transmission.

5.2.1 For example, the International Building Code (IBC), Section 1207, has requirements for the amount of sound that is

allowed to be transmitted through the interior walls, partitions, and floor and ceiling assemblies between adjacent dwelling units

and between them and public spaces of a building.

5.2.2 Additionally, the department of Housing and Urban Development (HUD) has the following standard for STC limitations

for various housing units: HUD Minimum Property Standards for Housing, Section 4910.1.

6. Why Seal Openings?

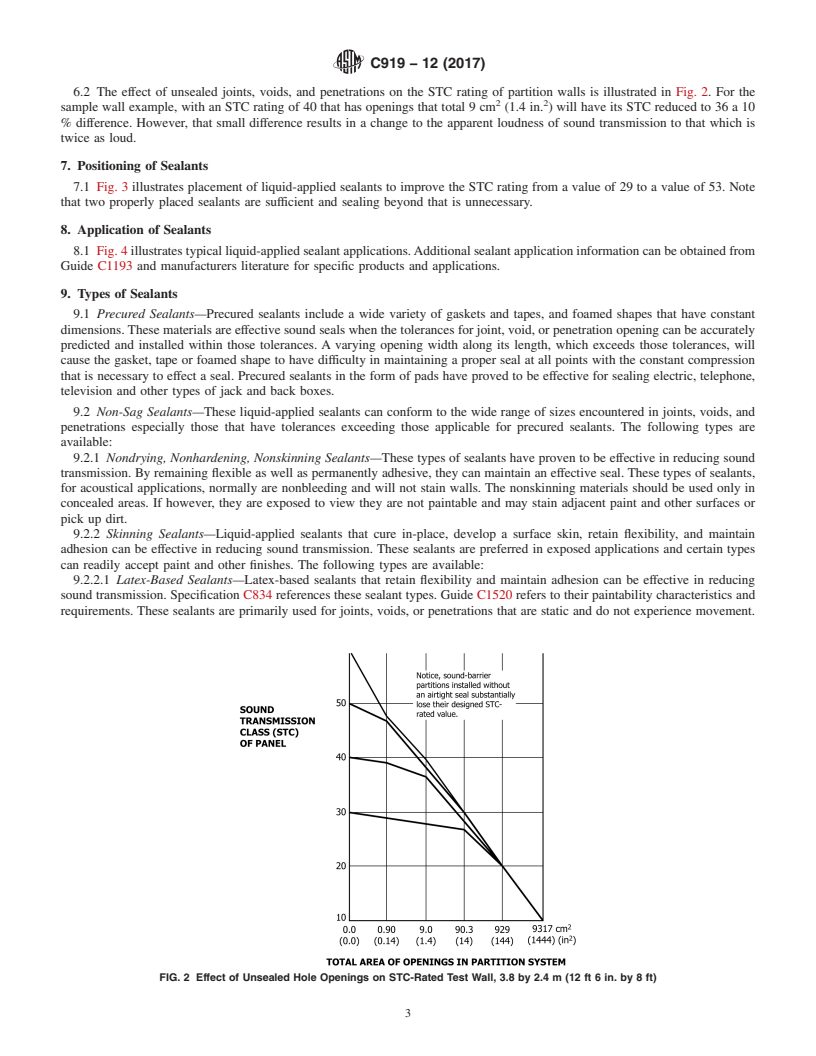

6.1 The sound transmission of a wall, ceiling, or floor, no matter how well built, can be substantially defeated by the presence

of unsealed joints, voids, and penetrations. Fig. 1 illustrates examples of how sound travels through unsealed joints, voids, and

penetrations in walls and how sealing them will minimize sound transmission.

FIG. 1 Examples of Achieving an Effective Sound Barrier and Maintaining the Designed STC Value of Partition Systems

C919 − 12 (2017)

6.2 The effect of unsealed joints, voids, and penetrations on the STC rating of partition walls is illustrated in Fig. 2. For the

2 2

sample wall example, with an STC rating of 40 that has openings that total 9 cm (1.4 in. ) will have its STC reduced to 36 a 10

% difference. However, that small difference results in a change to the apparent loudness of sound transmission to that which is

twice as loud.

7. Positioning of Sealants

7.1 Fig. 3 illustrates placement of liquid-applied sealants to improve the STC rating from a value of 29 to a value of 53. Note

that two properly placed sealants are sufficient and sealing beyond that is unnecessary.

8. Application of Sealants

8.1 Fig. 4 illustrates typical liquid-applied sealant applications. Additional sealant application information can be obtained from

Guide C1193 and manufacturers literature for specific products and applications.

9. Types of Sealants

9.1 Precured Sealants—Precured sealants include a wide variety of gaskets and tapes, and foamed shapes that have constant

dimensions. These materials are effective sound seals when the tolerances for joint, void, or penetration opening can be accurately

predicted and installed within those tolerances. A varying o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.