ASTM C1332-01(2007)

(Test Method)Standard Test Method for Measurement of Ultrasonic Attenuation Coefficients of Advanced Ceramics by Pulse-Echo Contact Technique

Standard Test Method for Measurement of Ultrasonic Attenuation Coefficients of Advanced Ceramics by Pulse-Echo Contact Technique

SCOPE

1.1 This test method describes a procedure for measurement of ultrasonic attenuation coefficients for advanced structural ceramic materials. The procedure is based on a broadband buffered piezoelectric probe used in the pulse-echo contact mode and emitting either longitudinal or shear waves. The primary objective of this test method is materials characterization.

1.2 The procedure requires coupling an ultrasonic probe to the surface of a plate-like sample and the recovery of successive front surface and back surface echoes. Power spectra of the echoes are used to calculate the attenuation spectrum (attenuation coefficient as a function of ultrasonic frequency) for the sample material. The transducer bandwidth and spectral response are selected to cover a range of frequencies and corresponding wavelengths that interact with microstructural features of interest in solid test samples.

1.3 The purpose of this test method is to establish fundamental procedures for measurement of ultrasonic attenuation coefficients. These measurements should distinguish and quantify microstructural differences among solid samples and therefore help establish a reference database for comparing materials and calibrating ultrasonic attenuation measurement equipment.

1.4 This test method applies to monolithic ceramics and also polycrystalline metals. This test method may be applied to whisker reinforced ceramics, particulate toughened ceramics, and ceramic composites provided that similar constraints on sample size, shape, and finish are met as described herein for monolithic ceramics.

1.5 This test method sets forth the constraints on sample size, shape, and finish that will assure valid attenuation coefficient measurements. This test method also describes the instrumentation, methods, and data processing procedures for accomplishing the measurements.

1.6 This test method is not recommended for highly attenuating materials such as very thick, very porous, rough-surfaced monolithics or composites. This test method is not recommended for highly nonuniform, heterogeneous, cracked, defective, or otherwise flaw-ridden samples that are unrepresentative of the nature or inherent characteristics of the material under examination.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1332 − 01(Reapproved 2007)

Standard Test Method for

Measurement of Ultrasonic Attenuation Coefficients of

Advanced Ceramics by Pulse-Echo Contact Technique

This standard is issued under the fixed designation C1332; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.6 This test method is not recommended for highly attenu-

atingmaterialssuchasverythick,veryporous,rough-surfaced

1.1 Thistestmethoddescribesaprocedureformeasurement

monolithics or composites. This test method is not recom-

of ultrasonic attenuation coefficients for advanced structural

mended for highly nonuniform, heterogeneous, cracked,

ceramic materials. The procedure is based on a broadband

defective, or otherwise flaw-ridden samples that are unrepre-

buffered piezoelectric probe used in the pulse-echo contact

sentative of the nature or inherent characteristics of the

mode and emitting either longitudinal or shear waves. The

material under examination.

primary objective of this test method is materials characteriza-

1.7 This standard does not purport to address all of the

tion.

safety concerns, if any, associated with its use. It is the

1.2 The procedure requires coupling an ultrasonic probe to

responsibility of the user of this standard to establish appro-

the surface of a plate-like sample and the recovery of succes-

priate safety and health practices and determine the applica-

sive front surface and back surface echoes. Power spectra of

bility of regulatory limitations prior to use.

the echoes are used to calculate the attenuation spectrum

(attenuation coefficient as a function of ultrasonic frequency)

2. Referenced Documents

forthesamplematerial.Thetransducerbandwidthandspectral

2.1 ASTM Standards:

response are selected to cover a range of frequencies and

C1331Test Method for Measuring Ultrasonic Velocity in

corresponding wavelengths that interact with microstructural

Advanced Ceramics with Broadband Pulse-Echo Cross-

features of interest in solid test samples.

Correlation Method

1.3 The purpose of this test method is to establish funda-

E664Practice for the Measurement of theApparentAttenu-

mental procedures for measurement of ultrasonic attenuation

ation of Longitudinal Ultrasonic Waves by Immersion

coefficients.Thesemeasurementsshoulddistinguishandquan-

Method

tify microstructural differences among solid samples and

E1316Terminology for Nondestructive Examinations

therefore help establish a reference database for comparing

E1495 Guide for Acousto-Ultrasonic Assessment of

materials and calibrating ultrasonic attenuation measurement

Composites, Laminates, and Bonded Joints

equipment.

2.2 ASNT Document:

1.4 Thistestmethodappliestomonolithicceramicsandalso

Recommended Practice SNT-TC-1A for Nondestructive

polycrystalline metals. This test method may be applied to

Testing Personnel Qualification and Certification

whisker reinforced ceramics, particulate toughened ceramics,

2.3 Military Standard:

and ceramic composites provided that similar constraints on

MIL-STD-410 Nondestructive Testing Personnel Qualifica-

sample size, shape, and finish are met as described herein for 4

tion and Certification

monolithic ceramics.

2.4 Additional references are cited in the text and at end of

1.5 This test method sets forth the constraints on sample

this test method.

size, shape, and finish that will assure valid attenuation

coefficient measurements. This test method also describes the

instrumentation, methods, and data processing procedures for

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

accomplishing the measurements.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

This test method is under the jurisdiction of ASTM Committee C28 on the ASTM website.

Advanced Ceramics and is the direct responsibility of Subcommittee C28.03 on AvailablefromAmericanSocietyforNondestructiveTesting(ASNT),P.O.Box

Physical Properties and Non-Destructive Evaluation. 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org.

Current edition approved Aug. 1, 2007. Published August 2007. Originally Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

approved in 1996. Last previous edition approved in 2001 as C1332–01. DOI: Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

10.1520/C1332-01R07. www.dodssp.daps.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1332 − 01 (2007)

3.1.9 free surface—the back surface of a solid test sample

interfacedwithaverylowdensitymedium,usuallyairorother

gas, to assure that the back surface reflection coefficient equals

1 to a high degree of precision.

3.1.10 frequency (f)—number of oscillations per second of

ultrasonic waves, measured in megahertz, MHz, herein.

3.1.11 front surface—the surface of a test sample to which

thebufferrodiscoupledatnormalincidence(designatedastest

surface in Terminology E1316).

FIG. 1 Cross Section of Buffered Broadband Ultrasonic Probe

3.1.12 inherent attenuation—ultrasound energy loss in a

solid as a result of scattering, diffusion, and absorption. This

standard assumes that the dominant inherent losses are due to

Rayleigh and stochastic scattering (2) by the material micro-

3. Terminology

structure, for example, by grains, grain boundaries, and mi-

3.1 Definitions of Terms Specific to This Standard:

cropores. Measured ultrasound energy loss which, if not

3.1.1 acoustic impedance (Z)—a property (1) defined by a

corrected, may include losses due to diffraction, individual

material’s density, p, and the velocity of sound within it, v,

macroflaws, surface roughness, couplant variations, and trans-

where Z = ρv.

ducer defects.

3.1.2 attenuation coeffıcient (α)—decrease in ultrasound

3.1.13 reflection coeffıcient (R)—measure of relative inten-

intensity with distance expressed in nepers (Np) per unit

sity of sound waves reflected back into a material at an

length, herein, α = [ln(I /I)]/d, where α is attenuation coeffi-

interface, defined in terms of the acoustic impedance of the

cient, d is path length or distance, I is original intensity and I

material in which the sound wave originates (Z ) and the

is attenuated intensity (2).

acoustic impedance of the material interfaced with it (Z),

i

3.1.3 attenuation spectrum—the attenuation coefficient, α,

where R=[(Z − Z )/(Z + Z )] .

i 0 i 0

expressed as a function of ultrasonic frequency, f, or plotted as

3.1.14 test sample— a solid coupon or material part that

α versus f, over a range of ultrasonic frequencies within the

meets the constraints needed to make the attenuation coeffi-

bandwidth of the transducer and associated pulser-receiver

cient measurements described herein, that is, a test sample or

instrumentation.

part having flat, parallel, smooth, preferably ground/polished

3.1.4 back surface—the surface of a test sample which is

opposing (front and back) surfaces and having no discrete

opposite to the front surface and from which back surface

flaws or anomalies that are unrepresentative of the inherent

echoes are returned at normal incidence directly to the trans-

properties of the material.

ducer.

3.1.15 transmission coeffıcient (T)—measure of relative in-

3.1.5 bandwidth—the frequency range of an ultrasonic

tensity of sound waves transmitted through an interface,

probe, defined by convention as the difference between the

defined in terms of the acoustic impedance of the material in

lower and upper frequencies at which the signal amplitude is 6

which the sound wave originates (Z ) and the acoustic imped-

dB down from the frequency at which maximum signal

anceofthematerialinterfacedwithit(Z),where T=(4Z Z )/(

i i 0

amplitude occurs. The frequency at which the maximum

Z + Z ) so that R + T=1.

i 0

occurs is termed the center frequency of the probe or trans-

3.1.16 wavelength (λ)—distance that sound (of a particular

ducer.

frequency)travelsduringoneperiod(duringoneoscillation), λ

3.1.6 broadband transducer—an ultrasonic transducer ca-

= v/f, where v is the velocity of sound in the material and

pableofsendingandreceivingundistortedsignalsoverabroad

where velocity is measured in cm/µs, and wavelength in cm,

bandwidth, consisting of thin damped piezoelectric crystal in a

herein.

buffered probe (search unit).

3.2 Other terms used in this test method are defined in

3.1.7 buffered probe—anultrasonicsearchunitasdefinedin

Terminology E1316.

TerminologyE1316butcontainingadelaylineorbufferrodto

which the piezoelement, that is, transducer consisting of a

4. Summary of Test Method

piezoelectric crystal, is affixed. The buffer rod separates the

4.1 This test method describes a procedure for determining

piezoelement from the test sample (see Fig. 1).

a material’s inherent attenuation coefficient and attenuation

3.1.8 buffer rod—an integral part of a buffered probe or

spectrumbymeansofabufferedbroadbandprobeoperatingin

search unit, usually a quartz or fused silica cylinder that

thepulse-echocontactmodeonasolidsamplethathassmooth,

provides a time delay between the excitation pulse from the

flat, parallel surfaces.

piezoelement and echoes returning from a sample coupled to

4.2 The procedure described in this test method involves

the free end of the buffer rod.

digital acquisition and computer processing of ultrasonic echo

waveforms returned by the test sample. Test sample con-

straints, probing methods, data validity criteria, and measure-

The boldface numbers in parentheses refer to a list of references at the end of

this standard. ment corrections are prescribed herein.

C1332 − 01 (2007)

5. Significance and Use accordance with a nationally recognized personnel qualifica-

tionpracticeorstandardsuchasASNTSNT-TC-1A,MILSTD

5.1 This test method is useful for characterizing material

410, or a similar document. The qualification practice or

microstructure or measuring variations in microstructure that

standardusedanditsapplicablerevision(s)shouldbespecified

occur because of material processing conditions and thermal,

in a contractual agreement.

mechanical, or chemical exposure (3) . When applied to

monolithicorcompositeceramics,theprocedureshouldreveal

6.2 Knowledge of the principles of ultrasonic testing is

microstructural gradients due to density, porosity, and grain required. Personnel applying this test method shall be experi-

variations. This test method may also be applied to polycrys-

enced practitioners of ultrasonic examinations and associated

talline metals to assess variations in grain size, porosity, and methods for signal acquisition, processing, and interpretation.

multiphase constituents.

6.3 Personnel shall have proficiency in computer program-

5.2 This test method is useful for measuring and comparing

ming and signal processing using digital methods for time and

microstructuralvariationsamongdifferentsamplesofthesame

frequency domain signal analysis. Familiarity with the Fourier

material or for sensing and measuring subtle microstructural

transform and associated spectrum analysis methods for ultra-

variations within a given sample.

sonic signals is required.

5.3 This test method is useful for mapping variations in the

7. Apparatus

attenuation coefficient and the attenuation spectrum as they

pertain to variations in the microstructure and associated

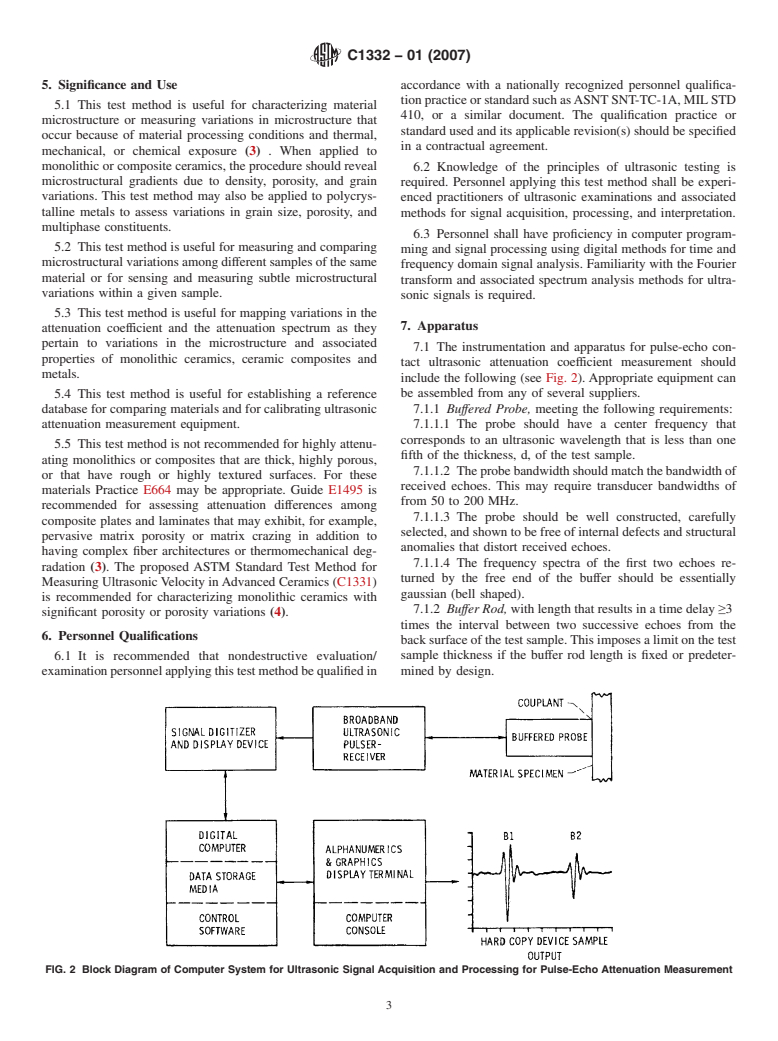

7.1 The instrumentation and apparatus for pulse-echo con-

properties of monolithic ceramics, ceramic composites and

tact ultrasonic attenuation coefficient measurement should

metals.

include the following (see Fig. 2).Appropriate equipment can

5.4 This test method is useful for establishing a reference be assembled from any of several suppliers.

7.1.1 Buffered Probe, meeting the following requirements:

databaseforcomparingmaterialsandforcalibratingultrasonic

attenuation measurement equipment. 7.1.1.1 The probe should have a center frequency that

corresponds to an ultrasonic wavelength that is less than one

5.5 This test method is not recommended for highly attenu-

fifth of the thickness, d, of the test sample.

ating monolithics or composites that are thick, highly porous,

7.1.1.2 Theprobebandwidthshouldmatchthebandwidthof

or that have rough or highly textured surfaces. For these

received echoes. This may require transducer bandwidths of

materials Practice E664 may be appropriate. Guide E1495 is

from 50 to 200 MHz.

recommended for assessing attenuation differences among

7.1.1.3 The probe should be well constructed, carefully

composite plates and laminates that may exhibit, for example,

selected,andshowntobefreeofinternaldefectsandstructural

pervasive matrix porosity or matrix crazing in addition to

anomalies that distort received echoes.

having complex fiber architectures or thermomechanical deg-

7.1.1.4 The frequency spectra of the first two echoes re-

radation (3). The proposed ASTM Standard Test Method for

turned by the free end of the buffer should be essentially

MeasuringUltrasonicVelocityinAdvancedCeramics(C1331)

gaussian (bell shaped).

is recommended for characterizing monolithic ceramics with

7.1.2 Buffer Rod,withlengththatresultsinatimedelay ≥3

significant porosity or porosity variations (4).

times the interval between two successive echoes from the

6. Personnel Qualifications

backsurfaceofthetestsample.Thisimposesalimitonthetest

6.1 It is recommended that nondestructive evaluation/ sample thickness if the buffer rod length is fixed or predeter-

examinationpersonnelapplyingthistestmethodbequalifiedin mined by design.

FIG. 2 Block Diagram of Computer System for Ultrasonic Signal Acquisition and Processing for Pulse-Echo Attenuation Measurement

C1332 − 01 (2007)

7.1.3 Couplant, meeting the following requirements: 7.1.10 Video Monitors,oneanalog,onedigital(optional)for

real-time visual inspection of echo waveforms and for making

7.1.3.1 The couplant should be a fluid such as glycerine or

interactivemanualadjustmentstothedataacquisitioncontrols.

an ultrasonic gel that will not corrode, damage, or be absorbed

by the test sample or part being examined. These control adjustments may include probe realignment/

repositioning, couplant thickness optimization, and other ad-

7.1.3.2 Thecouplantfilmorcouplantlayerthicknessshould

justments to obtain echo waveforms that meet acceptance

bemuchlessthantheultrasoundwavelengthinthecouplantat

criteria given herein.

the probe’s center frequency.

7.1.11 XYZ-Ax

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.