ASTM D120-95

(Specification)Standard Specification for Rubber Insulating Gloves

Standard Specification for Rubber Insulating Gloves

SCOPE

1.1 This specification covers manufacturing and testing of rubber insulating gloves for protection of workers from electrical shock.

1.2 Two types of gloves are provided and are designated as Type I, non-resistant to ozone, and Type II, resistant to ozone.

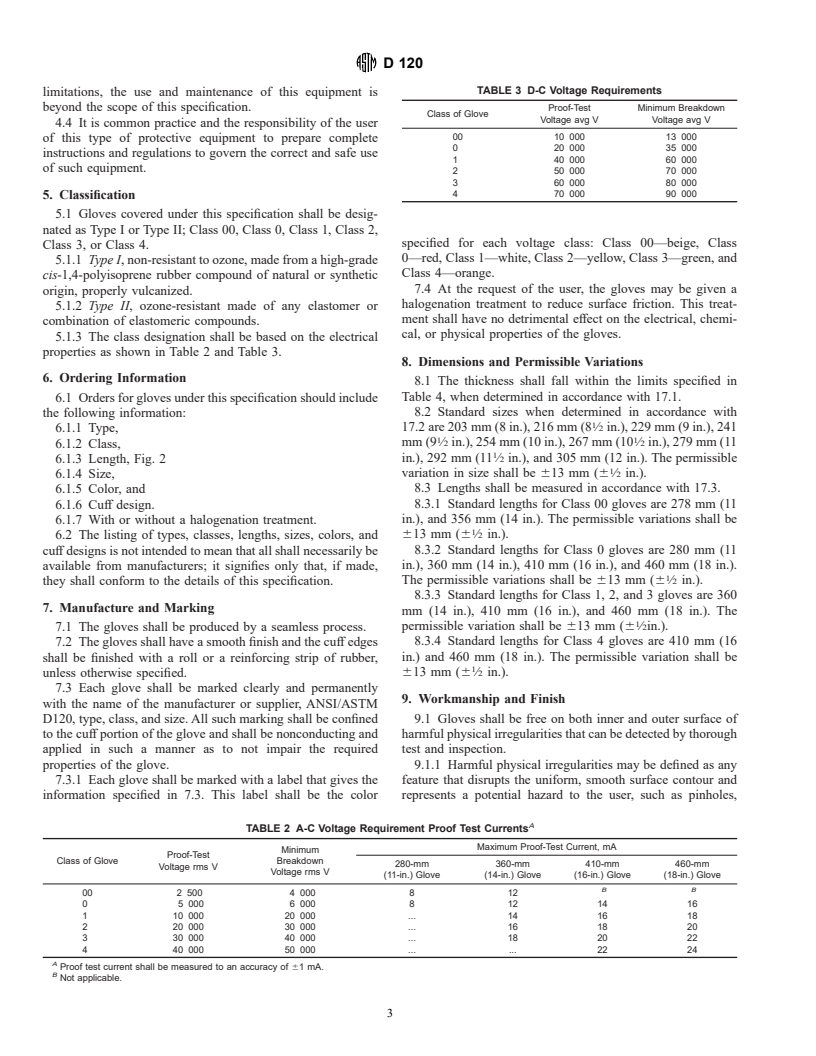

1.3 Six classes of gloves, differing in electrical characteristics, are provided and are designated as Class 00, Class 0, Class 1, Class 2, Class 3, and Class 4.

1.4 The values stated in SI units are to be regarded as the standard. See ASTM SI 10.

1.5 The following safety hazards caveat pertains only to the test method portion, Sections 16, 17, 18, and 19, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.For specific precaution statements, see 18.2.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 120 – 95

Standard Specification for

1

Rubber Insulating Gloves

This standard is issued under the fixed designation D 120; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D 1415 Test Method for Rubber Property—International

2

Hardness

1.1 This specification covers acceptance testing of rubber

D 2240 Test Method for Rubber Property—Durometer

insulating gloves for protection of workers from electrical

2

Hardness

shock.

2.2 ANSI Standard:

1.2 Two types of gloves are provided and are designated as

ANSI C84.1 Voltage Ratings for Electric Power Systems

Type I, non-resistant to ozone, and Type II, resistant to ozone.

3

and Equipment

1.3 Six classes of gloves, differing in electrical characteris-

tics, are provided and are designated as Class 00, Class 0, Class

3. Terminology

1, Class 2, Class 3, and Class 4.

3.1 Definitions of Terms Specific to This Standard:

1.4 The values stated in SI units are to be regarded as the

3.1.1 breakdown—the electrical discharge or arc occurring

standard.

between the electrodes and through the equipment being tested.

1.5 The following safety hazards caveat pertains only to the

3.1.2 color splash—a smear or streak of contrasting color

test method portion, Sections 16, 17, 18, and 19, of this

evident on the inside or outside surface of the gloves that was

specification: This standard does not purport to address all of

deposited during the dipping operation and is vulcanized into

the safety concerns, if any, associated with its use. It is the

the glove as part of the homogenous compound.

responsibility of the user of this standard to establish appro-

3.1.3 flashover—the electrical discharge or arc occurring

priate safety and health practices and determine the applica-

between electrodes and over or around, but not through, the

bility of regulatory limitations prior to use. For specific

equipment being tested.

precaution statements, see 18.2.

3.1.4 gauntlet—the area of the glove between the wrist and

2. Referenced Documents the reinforced edge of the opening.

3.1.5 glove cuff roll—the roll or reinforced edge of an

2.1 ASTM Standards:

insulating glove at the cuff.

D 297 Test Methods for Rubber Products—Chemical

2

3.1.6 halogenation—exposure of the entire glove surface

Analysis

area to a halogen for the purpose of reducing surface friction.

D 412 Test Methods for Vulcanized Rubber and Thermo-

2

3.1.7 insulated—separated from other conducting surfaces

plastic Rubbers and Thermoplastic Elastomers—Tension

by a dielectric substance (including air space) offering a high

D 518 Test Method for Rubber Deterioration—Surface

2 resistance to the passage of current.

Cracking

3.1.7.1 Discussion—When any object is said to be insu-

D 573 Test Method for Rubber—Deterioration in an Air

2 lated, it is understood to be insulated in a suitable manner for

Oven

the conditions to which it is subjected. Otherwise, it is, within

D 624 Test Method for Tear Strength of Conventional

2 the purpose of this definition, uninsulated. Insulating covering

Vulcanized Rubber and Thermoplastic Elastomers

of conductors is one means of making the conductor insulated.

D 1149 Test Method for Rubber Deterioration—Surface

2 3.1.8 isolated—an object that is not readily accessible to

Ozone Cracking in a Chamber

persons unless special means of access are used.

3.1.9 ozone—a very active form of oxygen that may be

produced by corona, arcing, or ultraviolet rays.

1

This specification is under the jurisdiction of ASTM Committee F-18 on

Electrical Protective Equipment for Workers and is the direct responsibility of

Subcommittee F18.15 on Worker Personal Equipment. This standard replaces ANSI

Standard J 6.6, which is no longer available.

Current edition approved Dec. 10, 1995. Published February 1996. Originally

3

published as D 120 – 21 T. Last previous edition D 120 – 94a. Available from American National Standards Institute, Inc., 11 West 42nd

2

Annual Book of ASTM Standards, Vol 09.01. Street, 13th Floor, New York, NY 10036.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 120

TABLE 1 Proof-Test/Use Voltage Relationship

3.1.10 ozone cutting and checking—the cutting action pro-

duced by ozone on rubber under mechanical stress into a series A-C Proof-Test D-C Proof-Test Maximum Use

Class of Glove

A

Voltage rms V Voltage avg V Voltage a-c rms, V

of interlacing cracks.

00 2 500 10 000 500

3.1.11 rubber—a generic term that includes ela

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.